Toky T52L Series User manual

Temperature Acquisition Module

User Manual

(T52L Series)

(For T52L A Version)

广东东崎电气有限公司

TOKY electrical co.,ltd. http://www.toky.com.cn

⊙PT100 input, temperature unit Fahrenheit or Celsius can be selected

⊙With many functions, measured display, disconnection detection, RS485 communication, etc

⊙Communication address can be set by toggle switch

⊙This product is used in lithium battery high vacuum baking equipment

2

T52L-PF-12P8 A

P: No shell board

T52L: Temperature acquisition module

F: DC 24V power supply

12: 12 channel 08: 8 channel

P: PT100 input

RS485

communication

port

Power

: Functional insulation DC 500V

PT100 CH1-CH12 input

66.0mm

91.0mm

10.0mm

4.0mm

24V+

POWER ADD RUN 4*φ4

COMM

PT100 INPUT 1-12

GND

B-

A+

99.0mm

48.0mm

ISO9001

国家高新技 术企业

1

National High-tech Enterprise/ National Standard Drafting Unit

Version code:KKT52L-A01E-A/0-20221202

Hotline:400-0760-168

Caution

1)When the failure or abnormality of this product may lead to serious system accidents, please

set proper protection circuits in the external.

2)The product may occur radio interference when it used at home.You should take adequate

countermeasures.

3)The product get an electric shock protection through reinforced Insulation. When the product

is embedded in the devices and wiring,please subject to the specification of embedded

devices.

4)In order to prevent surge occurs,when using this product in the place of over 30m indoor

wiring and wiring in outdoor, you need to set the proper surge suppression circuitry.

5)The product is produced based on mounting on the disk.In order to avoid to touch the wire

connectors,please take the necessary measures on the product.

6)Be sure to observe the precautions in this manual, otherwise there is a risk of a major injury

or accident.

7)When wiring, please observe the local regulation.

8)To prevent to damage the machine and prevent to machine failure, the product is connected

with power lines or large capacity input and output lines and other methods please install

proper capacity fuse or other methods of protection circuit.

9)Please don't put metal and wire clastic mixed with this product,otherwise it may lead to

electric shock, fire, fault.

10)Please tighten screw torque according to the rules.If not,it may lead to electric shock and

fire.

11)In order not to interfere with this products to dissipate heat, please don't plug casing around

the cooling vent hole and equipment.

12)Please don’ t connect any unused terminal.

13)Please do the cleaning after power off, and use the dry cleaning cloth to wipe away the dirt.

Please don’ t use desiccant, otherwise, it may casue the deformation or discoloration of the

product.

14)Please don`t knock or rub the panel with rigid thing.

15)The readers of this manual should have basic knowledge of electrical,control, computer and

communications.

16)The illustrations, data examples and picture examples used in this manual are recorded for

the convenience of understanding the manual, and are not guaranteed to be the results of

the operation.

17)In order to use this product with safety for long-term,regular maintenance is necessary. The

life of some parts of the equipments are by some restrictions, but the performance of some

will change for using many years.

18)Without prior notice, the contents of this manual may will be change. We hope these is no

any loopholes, if you have questions or objections, please contact us.

19) Our company will not liable for any indirect losses suffered by users or third parties, such

as the results impact of using this product, unpredictable product defects, imitations of this

product and other indirect losses.

I. Safe Caution

The instruction explain T52L series instrument settings, connections,name and etc, please

read carefully before you use the temperature controller. Please keep it properly for necessary

reference.

1) Please don`t plug in before completing all the wire.Otherwise it may lead to electric shock,

fire, fault.

2) Don’ t touch power terminal and other high voltage part when the power on, otherwise you

may get an electric-shock.

3)Don’ t remove,repair and modify this product,otherwise it may lead to electric shock, fire,

fault and electrical Danger.

1) Not allow to use outside the scope of product specification,otherwise it may lead to fire,fault.

2) Not allow to use in the place where is inflammable and explosive gas.

3) The product should not be used in a nuclear facility and human life associated medical

equipment.

Warning:

Electric-shock

Warning:

Forbiddance

1. Installation

1) This product is used in the following environmental standards.

(IEC61010-1)[Overvoltage categoryⅡ、class of pollution 2]

2)This product is used in the following environment:Temperature range:-20 ~125℃;humidity:

45~85%RH; environment condition:Indoor use. The altitude is less than 5000m.

Caution of Installation & Wiring

Features:

3) Please avoid using in the following places:

The place will be dew for changing temperature;with corrosive gases and flammable

gas; with vibration and impact;with water, oil, chemicals, smoke and steam facilities with

dust, salt, metal powder;and with clutter interference, static electric and magnetic fields,

noise;where the air from air conditioning or heating is blowing directly; where will be

illuminated directly by sunlight; where accumulation of heat will happen caused by radiation.

4) On the occasion of the installation, please consider the following before installation.

In order to prevent heat saturated, please open enough ventilation space.

Please consider connections and maintenance environment,and ensure that there is more

than 50mm space above and below the product.

Please avoid to install the product above the machines with high the calorific value (Such as

heaters, transformer, semiconductor operations, the bulk resistance).

The surrounding environment shall not exceed the limit of using conditions.

In order to improve the anti - interference performance and security, please try to stay away

from high pressure machines, power machines to install.

Don`t install on the same plate with high pressure machine and the product.

The distance should be more than 200mm between the product and power line.

The power machine shall be installed at a distance as far as possible.

2. Cable caution:

1)Please use specified compensation wire in the place of TC input; Please use insulated TC

if the measured device is heated metal.The influence of external resistance is about 0.3 μ

V/Ω。

2)Please use the cable with small wire resistance in the place of RTD input,and the cable

(3 wire) must be no resistance difference, The wire should be run in parallel and the cable

length should less than 5m.

3)In order to avoid the effect of noise,please wire the input signal away from meter

cable,power cable,load cable.

4)In order to reduce the power cables and the load power cables on the effect of this product,

please use noise filter in the place where easy to effect. You must install it on the grounding

of the disk if you use the noise filter,and make the wiring to be shortest between noise filter

output side and power connectors. Don`t install fuse and switch on the wiring of noice filter

output side,otherwise it will reduce the effect of noise filter.

5)It takes 5s from input power to output.If there is a place with interlocking actions circuit

signal,please use timer relay.

6)Please use twisted pair with a shield for analog output line, can also connect the

common-mode coil to the front-end of the signal receiving device to suppress line

interference if necessary, to ensure the reliabilty of signal.

7) Please use twisted pair with a shield for remote RS485 communication cable, and deal with

the shield on the host side earth, to ensure the reliabilty of signal.

8)This product don’ t have the fuse; please set according to rated voltage 250V, rated current

1A if you need; fuse type:delay fuse.

9)Please use suitable screw force and suitable crimping terminal

Terminal screw size: see real object

Recommended terminal tightening torque: 0.4N.m.

Proper cables: 0.25 ~1.65mm single cable/multiple core cable

10)Please don’ t put the Crimp terminal or bare wire part contact with adjacent connector.

II. Model Illustration A: Version

8: With RS485 communication

III. Specifications

1. Electrical parameters:

Sampling rate 2 times per second

Power supply

Power consumption 10 ~30V DC

< 1VA

Communication port RS485 port Modbus-RTU protocol

Voltage drop & short

interruption immunity

Isolation voltage

Pulse traip

anti-interference

ESD IEC/EN61000-4-2 Contact ±4KV /Air ±8KV perf.Criteria B

IEC/EN61000-4-4 ±2KV perf.Criteria B

IEC/EN61000-4-29 0% ~70% perf.Criteria B

Signal input and commnucation port DC500V,1min

Power failure memory 5 years, times of writing: 1 million times

2. Non-electrical parameters:

Ambient

conditions Indoor use only, temperature: -20-125℃no condensation,

humidity<85%RH, altitude<5000m

Total weight About 150g

Shell and panel base frame PC / ABS (flame retardant UL94V-0)Shell material

-40 ~140℃,no condensation

Storage

environment

3、Measured signal specifications :

PT1

PT2

0~150.0

0~150

0.1℃

1℃

0.5%F.S±0.3℃

0.5%F.S±3digits 0

1

Input type Measuring range Resolution Accuracy

Communication

code

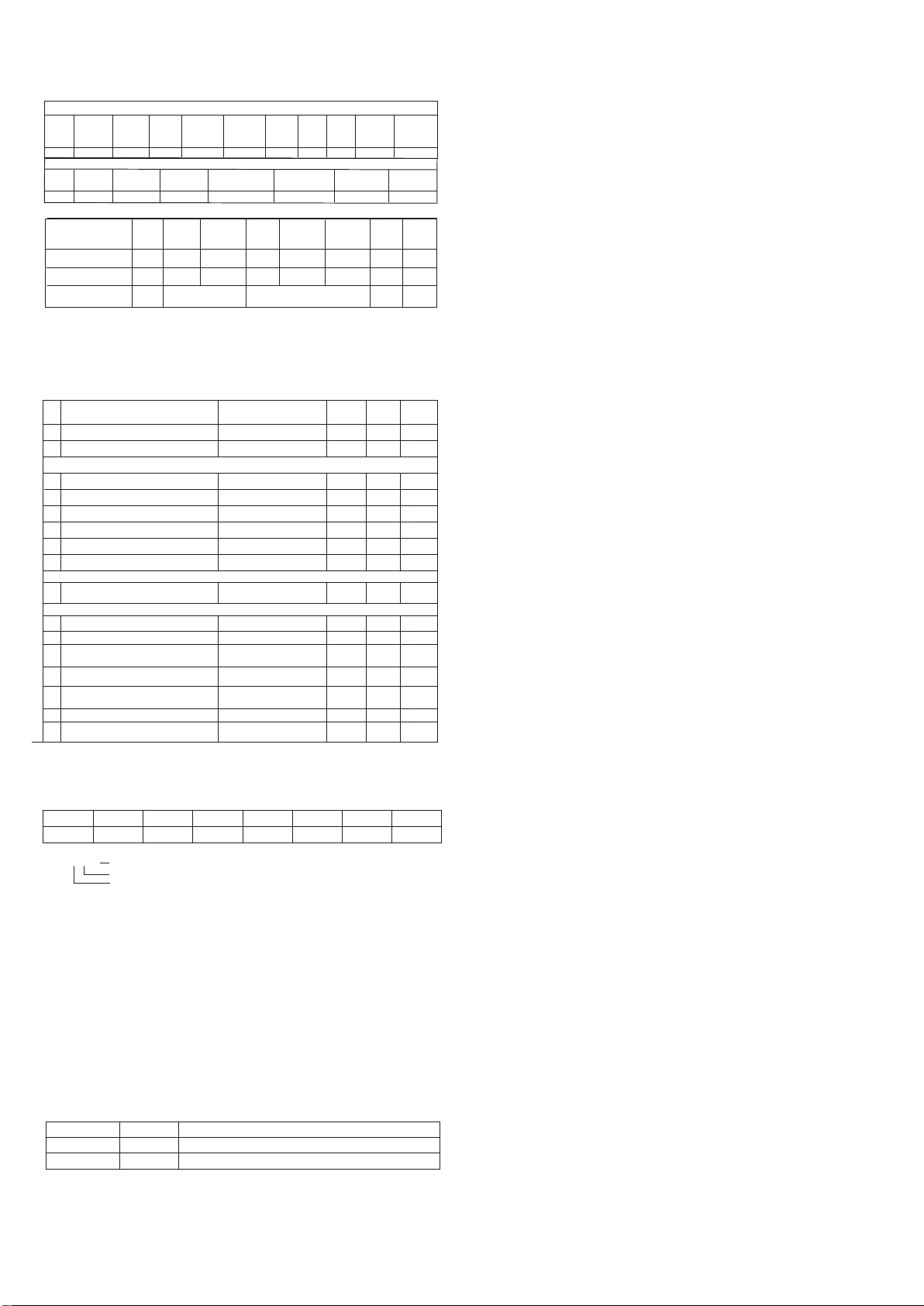

4. Isolation diagram:

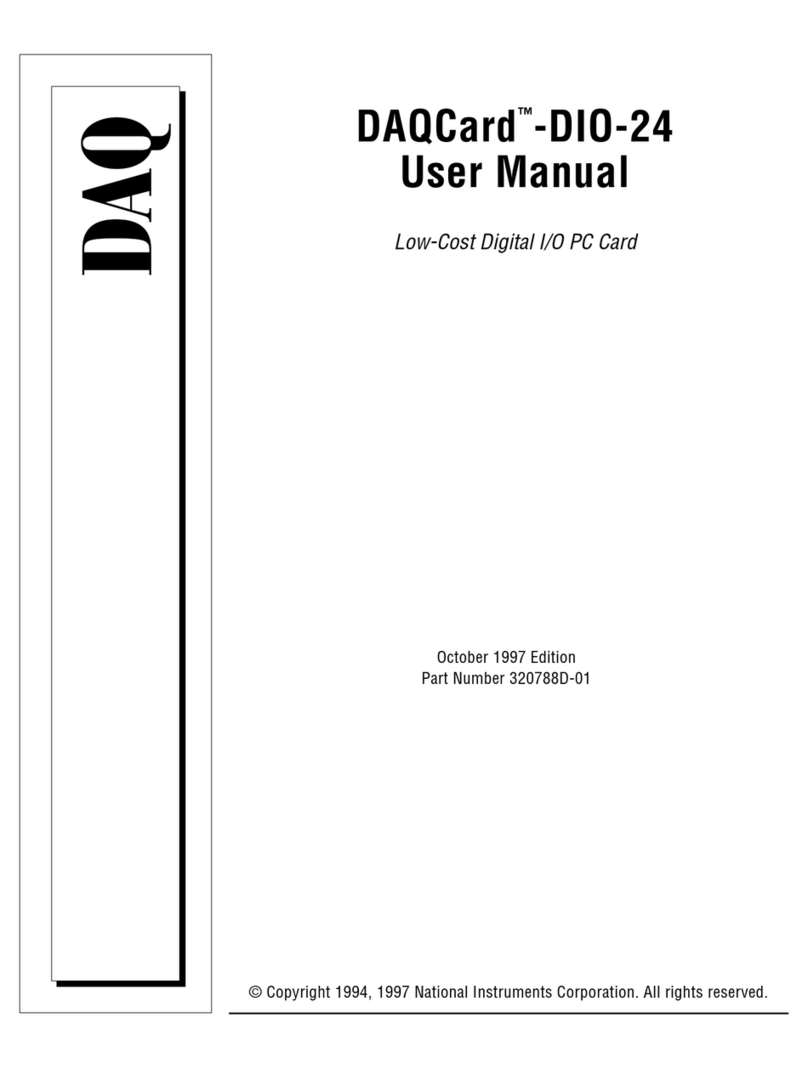

IV. Dimension and Installation Method

3 4

VI.Networking application

1

013

14

15

RCVF 0~9999

--

--

ADD Communication

address (can be set

by toggle switch) 1~4 1

5

6

7

8

10

11

9

INP

PV Measured value

Input signal type selection: see the corresponding

table of measuring signal parameters for details

--

0~1

PS Amend value, display value= actual measured value

+ amend value -1000~1000 0

0

FL 0

FH 1500

FT 0~255 10

UNIT ℃/℉25(℃)

12 PRS 0~10

2

DTC

See

communication

protocol

4

BAD RS485 Baud rate 0:4800;1:9600 2:19200 3:38400

4:57600 5:115200 0~5 3

PRTY Parity bit setting, 0:NONE, 1:ODD parity,

2:EVEN parity 0~2

0

03

Communication data transmission sequence setting;

When it is set to 10, data bytes are exchanged

sequentially, and the default value is 0.

Write 123 can restore factory settings

RTC Ambient temperature, 1 decimal place --

VER

16 Total channels quantity , query total quantity of

channels in different application schemes

LOOPSUM --

1 2 3 4

1:1 control is applied for 1 patrol inspection,

acquisition 1 is connected to controller,

acquisition 2 is connected to PLC (patrol inspection)

One collection

board + controller

combination to

realize temperature

acquisition and control A acquisition board communicates

with PLC to realize temperature acquisition

RS485 RS485

(Need to be purchased separately)

Note: 1. Different network application schemes can be customized through communication

with our company technician

2. This manual only introduces the application of the acquisition board.

The products used in the scheme other than the acquisition board need to be equipped

separately,Our company provides PID controller and Modbus communication gateway.

Please contact our relevant personnel for details.

(PLC/HMI is not

equipped )

Acquisition board 1

PLC/HMI/Gateway

Two acquisition boards

communicate with the

controller to realize

temperature acquisition

and heating control

Application 2: The acquisition board is connected with the temperature controller.

No. Name Description Remark

01

02

03

04

01-A/B/C/D: fixed screw holes of four acquisition boards( φ= 4)

Power supply:10~30VDC (+24V=positive, GND=negative)

Communication: A+/B - connect the upper computer PLC or our

temperature controller

Select different communication addresses of the acquisition board

0x01 ~0x04

02: Single/double connecting terminal,used for connecting with

PT100 temperature sensor.Note: PT100 sensor is a 3-wire sensor

Sensor channel

Fixed screw hole

Power input interface

RS485 interface

05 used for device firmware upgradeInterface upgrade

485 address selection

A

B

C

D

Positive input terminal of power supply

RS485 "-" terminal, connected to PLC or our temperature controller

Negative input terminal of power supply

RS485 "+" terminal, connected to PLC or our temperature controller

GND

+24V

A+

B-

channel 1

channel 2

B1B1A1B3B3A3

B2B2A2B4B4A4

24V+

GND

B-

A+

A

B

C

D

24V+

01-A

03

01-B

01-C

04 05

02

01-D

POWER ADD RUN

COMM

PT100 INPUT 1-12

GND

B-

A+

V.Interface function introduction

2. Wiring description for power supply and RS485

1. Interface description of temperature acquisition module

3. Sensor wiring description

RS485 -RS485

No. Name Description

VIII . Methods of simple fault

Display info

LLLL/HHHH

Method

Check the input whether is disconnected; check the FH value and FL value;

check the working environment temperature whether is normal; check the

input signal selection whether is correct.

Meter adopts RS485 Modbus RTU communication protocol, Read function code 0x03 of the

holding register in zone 04, write function code 0x10/0x06. Adopt 16 digit CRC check, the

meter does not return for error check. The data type is a 16 bit signed or unsigned integer.

Data frame format:

Start bit

Data bit

1 8 1 None/odd parity/even parity

Stop bit Check bit

IX. Communication procotol

1. Read register

For example:Host reads SV(PV1 = 200)

The address code of SV is 0x2000 ("0x" represents for hexadecimal), because SV data type

is a 16-bit integer (2 bytes),seizes 1 data register. The memory code of decimal integer 200

convert to hexadecimal code is 0x00C8.. Note: When reading data, should determine the

decimal point position firstly and then convert the reading data to obtain the actual value.

CRC

Code CRC

Code

0x01

0x01

0x01 0x03

0x83

0x03 0x02

0x20

0x02

0x00

0x00 0xC8 0xC0

0xB9 0xD2

0xCA0x8F0x01

0xF1

0x00

error code

bits

For example:Host request address is 0x2011

Read multi-register

Host request

Slave normal answer

Slave abnormal answer

Meter

ADD

Function

code

Start

ADD

High bit

Start

ADD

Low bit

Data byte

Length

high bit

Data byte

Length

low bit

Acquisition board 2

(Need to be purchased separately)

VII. Menu Illustration

1. Regular Menu

No.

Name

Illustration Setting

range Factory

setting

Measure range low limit, the set value must be less

than measure range high limit

Measure range high limit,the setting value must be

more than measure range low limit.

Filter coefficient, the higher of value, the stronger

of filter function

Temperature unit setting:25: Celsius degrees ℃.

26:Fahrenheit degrees ℉

Software version

Setting parameter saving address:

0 (EEP): EEPROM has power failure protection;

1 (RAM): RAM no power failure protection

Refer to

measured signal

parameter table

Refer to

measured signal

parameter table

5 6

unsigned int Get_CRC(uchar *pBuf, uchar num)

{

unsigned i,j;

unsigned int wCrc = 0xFFFF;

for(i=0; i<num; i++)

{

wCrc ^= (unsigned int)(pBuf[i]);

for(j=0; j<8; j++)

{

if(wCrc & 1){wCrc >>= 1; wCrc ^= 0xA001; }

else

wCrc >>= 1;

}

}

return wCrc;

}

X. Version and Revision History

2022.12.02

NO

1

2R

1

Status value R1②

0x200C~0x2017(48205~48216)

0x2000~0x200B(48193~48204)

3

4

5

6

7

8

R/W

1

R/W1

1R/W

R/W

1R/W1

R/W1

0x210C~0x2117(48461~48472)

0x2100~0x210B(48449~48460)

0x2124~0x212F(48485~48496)

0x2118~0x2123(48473~48484)

0x213C~0x2147(48509~48520)

0x2130~0x213B(48497~48508)

9 R/W10x2400~0x240B(49217~49228)

③

12

10

11

13

14

15

16

R/W1

R/W1R/W1

R/W1

R1

R1

Restore factory settings

RCVF

Total channels quantity

Software version VER

R1

Ambient temperature of

acquisition board RTC

0x2503(49476)

0x2502(49475)

0x2501(49474)

0x2500(49473)

0x2505(49478)

0x2504(49477)

0x2506(49479)

Host write SV with 06 function(SV= 150)

0x01 0x10 0x21 0x10 0x00 0x01 0x02 0x00 0x96

Meter

ADD Function

code Start ADD

High bit Start ADD

Low bit Data byte

length high bit Data byte

length low bit ※CRC code

low bit

※CRC code

high bit

Slave normal answer (write multi-register)

0x300x0A0x010x000x100x210x100x01

Meter

ADD Function

code Start

ADD

High bit

Start

ADD

Low bit

Data byte

Length

high bit

Data

high

bit

Data

low

bit

Data byte

Length

low bit

Data

byte

Length

Host request (write multi-register)

0x15 0xAC

CRC

code CRC

code

0x00

0x10

0x21

0x060x01

0x5d0x020x96

0x5d

0x020x96

0x000x100x210x060x01

0xA10x01 0x86 Error Code0x02 0xC3

Write single

register Meter

ADD

Function

code

Start

ADD

Low bit

Start

ADD

High bit

CRC

Code CRC

Code

Data byte

Length

low bit

Data byte

Length

high bit

Host request

Slave normal answer

Slave abnormal

answer

Function

code

Handling of abnormal communication:

When abnormal response,put 1 on the highest bit of function code. For example: Host request

function code 0x03,and slave response function code should be 0x83.

Error code:

0x01---Illegal function: the function code sent from host is not supported by meter.

0x02---Illegal address:the register address designated by host beyond the address range of meter.

0x03---Illegal data: Date value sent from host exceeds the corresponding data range of meter.

2. Write multi-register

For example:Host use 10 function code write SV(SV=150)

ADD code of SV1 is 0x2110,because

SV1 data type is a 16-bit integer (2 bytes),seizes 1 data

register.

The decimal integer 150 convert to hexadecimal code is 0x0096. Before writing the data,

you should convert the data to the corresponding magnification and then writing the data into the

instrument.

Meter parameters address mapping table

Address (Register No①) Register R/W RemarkVariable name

Measured value PV

Reserve

Input signal selection INP

Display low limit FL

Display high limit FH

Amend value PS

Filter constants FT

Measuring Unit UNIT

Reserve

Reserve

Paramters saving

address PRS

baud rate BAD

Parity Check PRTY

Communication data

transfer sequence DATC

1st edition

A/0 Version

Date Version Revision content

---- HHHH LLLL

℃

℉----

D7 D6 D5 D4 D3 D1 D0

----

D2 ----

Note①: The register number is the address converted to decimal plus 1 and then the register

identification code 4 is added in front; for example: the register number of the data address

0x2000 is 8192 + 1 = 8193 and then 4 is added in front, that is, the register number 48193;

Related applications can be seen, such as Siemens S7-200 PLC.

Note ②: Measurement status indication. When the data bit is 1, it means execution, and when it

is 0, it means no execution.

□ □ □

DATC:

Note③: DATC communication data transmission sequence description

Reserve

Byte transfer order: when it is 0, 1, 2, and when it is 1, 2, 1

Reserve

Manufacturer contact information:Toky Electrical Co., Ltd

Add: No.8 Minke West Rd, Shiqi District, Zhongshan, Guangdong, CN 528400

Contact:0760-23371800

Technical consultation contact:400-0760-168

Web:http://www.toky.com.cn

※16-bit CRC check code to get C program

Popular Control Unit manuals by other brands

MAZATROL

MAZATROL M PLUS Series Maintenance manual

CAME

CAME PXC2-32 Installer manual

Siemens

Siemens Flowrite 599 Series Technical instructions

Kohler

Kohler K-10668 Homeowner's guide

Redi Controls

Redi Controls RuptureSeal RS-2 operation & maintenance

extronics

extronics ISOLATE 100: ISOLATE 100M operating manual

EOS

EOS Compact D18 Installation and operating instructions

SEA

SEA SWING 2 manual

Honeywell

Honeywell D06FN-1B Installation instruction

Beehive International

Beehive International DM3270 Technical user's manual

CAMBRIONIX

CAMBRIONIX ModIT-Boss user manual

Burkert

Burkert AirLINE 8652 Series operating instructions