Tokyo Sokki Kenkyujo TC-32K User manual

Operation Manual

TC-32K

HANDHELD

DATA LOGGER

NOTICE

This manual describes how to operate Handheld Data Logger TC-32K and its operation

procedures. Please read this operation manual thoroughly to familiarize yourself with the

functions and operating procedures of this product. It will enable you to make maximum use

of all its functions and take precise measurements effectively.

Please keep this manual always ready to use.

When you read this manual

This manual uses following symbols to describe important items. Please read carefully.

Reproduction or reprinting of this instruction manual, either partially or totally, without

permission from Tokyo Sokki Kenkyujo Co., Ltd. is strictly prohibited.

The contents of this instruction manual are subject to change without notice for the purpose of

product improvement.

If you have any questions or comments regarding contents of this manual such as

misdescription, inaccuracy and missing items, please feel free to contact us.

The company and product names referred to in this manual represent trade names or

registered trademarks.

This operation manual applies to the software version 1.2.

This indication shows any matters to understand this content deeply and the

useful information.

This indication shows any attention or supplement to avoid erroneous operation

etc.

✍

If you ignore this indication and use this system in an improper way, it may

cause danger which will result in injury.

If you ignore this indication and use this system in an improper way, it may

cause danger which will result in death or serious injury.

If you ignore this indication and use this system in an improper way, it may

cause the occurrence of physical obstacles.

Danger

Warning

Caution

Note

Safety Precautions

Powder or dust inside the system may cause poor contact or a lowered

insulation effect in the connector. Pay special attention, during use and

storage, not to allow dust to enter the system.

Do not operate the system in a place where there is flammable gas or

flammable steam. This may cause fire.

Danger

Operate the system at a specified temperature. If the operating site is

exposed to direct sunlight or an extremely low temperature, arrange for shade

or a thermal insulating material.

It is not recommended for the user to disassemble or remodel the system.

Such a do-it-yourself action may cause an electric shock or a malfunction.

Never connect the grounding cable to a gas pipe. In addition, make it a rule

to disconnect the power supply cable before connecting or disconnecting the

grounding cable. There is danger of a fire and the electric shock.

Operate the system at a relative humidity less than 85%. Do not expose it to

rain or extreme humidity. When water flowed into the system or system is

flooded, dry enough before turning on the power supply. If the system does

not start normally, some trouble might be caused. Please contact us.

Warning

The system may malfunction if either the unit or its wiring is placed near such

machines as a large motor, crane, transformer, or welding machine. When

extending the sensor to a place subject to a strong electric field, such as near

a power substation or radio transmission station, use a special cable such as

a shielded cable.

The system is vulnerable to the dielectric effect of thunderbolts. Take

preventive measures against thunderbolts where applicable. Contact your

dealer or Tokyo Sokki Kenkyujo for details.

Danger

Danger

Caution

Caution

Caution

Caution

Do not forcibly drag the system with connection cables connected. The

cables may be damaged and/or the connectors may be disconnected. In

addition, do not apply impact to the connector of the cable. Keep the

connectors away from soil, mud, water and oil.

Caution

The range of power supply voltage for this system is DC 9~18 V.

Malfunction may be caused if larger voltage is supplied. If the system is

used in a positive grounded vehicle, do not contact the housing of this system

with the body of the vehicle.

Caution

Table of Contents

NOTICE

Safety Precautions

Table of Contents

Chapter 1 Overview

1.1 Overview ································································································ 1 - 2

1.2 Features ································································································· 1 - 2

1.3 Details about each part ············································································· 1 - 3

Front and side ·················································································· 1 - 3

Top, bottom, and back ········································································ 1 - 4

Chapter 2 Preparation

2.1 Instructions for use ··················································································· 2 - 2

2.2 Power Source ·························································································· 2 - 3

How to set batteries ··········································································· 2 - 3

Operating time by batteries ································································· 2 - 4

Connection for AC adapter ·································································· 2 - 5

Power ON/OFF ················································································· 2 - 5

2.3 Instructions for field measurement ······························································· 2 - 6

Grounding ······················································································· 2 - 6

Lightning protection ··········································································· 2 - 6

2.4 Screen outline ························································································· 2 - 7

Startup screen ·················································································· 2 - 7

Screen configuration ·········································································· 2 - 7

2.5 Operation outline ······················································································ 2 - 8

Operation system ·············································································· 2 - 8

Key switch ······················································································· 2 - 9

Key lock ·························································································· 2 - 9

Chapte 3 Sensor Connection

3.1 Sensor connection ··················································································· 3 - 2

How to use input terminal block ···························································· 3 - 2

Wire connection by sensor type ··························································· 3 - 3

Chapter 4 Monitor Display and Measurement

4.1 Monitor screen outline ··············································································· 4 - 2

4.2 Monitor display ························································································ 4 - 2

Value monitor ··················································································· 4 - 2

Waveform monitor ··········································································· 4 - 3

Meaning of displayed value ······························································· 4 - 3

Monitor type selection ······································································ 4 - 4

Waveform monitor setting ································································· 4 - 4

4.3 Initial value processing ············································································ 4 - 5

Initial-in ························································································· 4 - 5

Initial-in of monitor channel ······························································· 4 - 6

Rewrite of initial value ······································································ 4 - 7

4.4 Channel setting ······················································································ 4 - 8

Measurement mode ········································································· 4 - 8

Switching of measurement mode ························································ 4 - 8

Channel setting in single channel mode ················································· 4 - 9

4.5 Record of measurement value ··································································· 4 -10

Manual measurement ······································································· 4 -10

Auto measurement ··········································································· 4 -11

4.6 Sub LCD ······························································································· 4 -11

Chapter 5 Measurement Setting

5.1 Measurement setting outline ······································································· 5 - 2

5.2 Sensor mode ··························································································· 5 - 3

Sensor mode ···················································································· 5 - 3

Sensor mode setting ·········································································· 5 - 4

Group setting ··················································································· 5 - 5

5.3 Coefficient, indication digits, and unit ···························································· 5 - 6

Parameters ······················································································ 5 - 6

Parameter setting example ································································· 5 - 6

Coefficient, indication digits, and unit setting ··········································· 5 - 7

Coefficient setting by Cap/RO ······························································ 5 - 9

Check of coefficient ·········································································· 5 -10

5.4 Thermocouple RJC setting ········································································ 5 -11

5.5 TEDS sensor ·························································································· 5 -12

Reading of sensor setting ·································································· 5 -12

Applying the read setting ··································································· 5 -13

5.6 Switching of measurement mode ································································ 5 -13

5.7 Switching between Measure and Direct ······················································· 5 -14

5.8 Automatic measurement ··········································································· 5 -15

Interval measurement ······································································· 5 -15

Interval timer setting ········································································· 5 -15

Real-time start setting ······································································· 5 -17

Goto Step ······················································································· 5 -18

Goto Step setting ············································································· 5 -19

Start and stop of interval measurement ················································· 5 -20

Sleep function ················································································· 5 -21

5.9 Various checks ······················································································· 5 -22

Insulation check ··············································································· 5 -22

Resistance check ············································································· 5 -22

Dispersion check ·············································································· 5 -23

Lead wire resistance check ································································ 5 -23

Bridge output check ·········································································· 5 -23

Coefficient setting check ···································································· 5 -24

5.10 Measurement auxiliary setting ·································································· 5 -24

Simple measure setting ····································································· 5 -24

Comet setting ·················································································· 5 -26

Power source frequency of measurement environment ···························· 5 -26

Initial-in permission ··········································································· 5 -27

Burnout check setting ········································································ 5 -27

Chapter 6 Record Setting

6.1 Record setting outline ··············································································· 6 - 2

6.2 Data memory ·························································································· 6 - 3

Data memory structure ······································································· 6 - 3

Readout of data ················································································ 6 - 4

Data memory setting ·········································································· 6 - 4

Deletion of data in data memory ··························································· 6 - 5

Printout of data memory ····································································· 6 - 5

6.3 CF card ·································································································· 6 - 6

Readout of data ················································································ 6 - 6

File name and file format setting ··························································· 6 - 7

File deletion ····················································································· 6 - 9

Saving data file ················································································· 6 - 9

Reading of setting file ········································································ 6 -10

CF card formatting ············································································ 6 -10

6.4 File copy ······························································································· 6 -11

6.5 Recording in data memory and CF card ······················································· 6 -12

Chapter 7 Interface Setting

7.1 Interface setting outline ············································································· 7 - 2

7.2 RS-232C setting ······················································································ 7 - 3

Communication conditions ·································································· 7 - 3

7.3 Data output ····························································································· 7 - 4

Connection with device ······································································ 7 - 4

Data output destination and output procedure ········································· 7 - 4

7.4 Data output format setting ·········································································· 7 - 5

7.5 External indicator setting ··········································································· 7 - 6

7.6 Cautions for printer setting ········································································· 7 - 6

7.7 Remote measurement ··············································································· 7 - 7

Configuration ···················································································· 7 - 7

Function ·························································································· 7 - 7

Chapter 8 Other Settings

8.1 Other setting outline ················································································· 8 - 2

8.2 Auto power-off setting ··············································································· 8 - 3

8.3 Version information ·················································································· 8 - 4

8.4 Date and time setting ················································································ 8 - 4

8.5 Switching between Japanese and English ····················································· 8 - 5

8.6 Maintenance ··························································································· 8 - 6

LCD backlight setting ········································································· 8 - 6

LCD backlight brightness ···································································· 8 - 7

Contrast setting ················································································ 8 - 7

Buzzer volume setting ········································································ 8 - 8

Upgrading ························································································ 8 - 8

8.7 Factory setting ························································································ 8 -10

Execution of factory setting ································································ 8 -10

List of factory setting ········································································· 8 -11

Chapter 9 Increase of the Number of Measurement Points

9.1 Outline of increase of the number of measurement points ································ 9 - 2

Options to increase the number of measurement points ···························· 9 - 2

9.2 Switching box ·························································································· 9 - 3

CSW-5B connection ·········································································· 9 - 3

Data memory ··················································································· 9 - 3

Measurement mode setting ································································· 9 - 4

Channel setting ················································································· 9 - 4

Box number setting ············································································ 9 - 4

Monitor display ················································································· 9 - 5

Monitor type selection ········································································ 9 - 5

Initial value processing ······································································· 9 - 6

Program setting ················································································ 9 - 6

Record of measurement value ····························································· 9 - 7

Various checks ················································································· 9 - 7

9.3 Inclinometer adapter ················································································· 9 - 8

IA-32 connection ··············································································· 9 - 8

Data memory ··················································································· 9 - 8

Measurement mode setting ································································· 9 - 9

Channel setting ················································································· 9 - 9

Monitor display ················································································· 9 - 9

Program setting ··············································································· 9 -10

Record of measurement value ···························································· 9 -10

Unavailable function in inclinometer mode ············································· 9 -11

Chapter 10 Strain Compensation

10.1 Wire connection of strain gauge ······························································· 10 - 2

1-gauge 4-wire method ····································································· 10 - 2

Quarter bridge 2-wire method ····························································· 10 - 2

Quarter bridge 3-wire method ····························································· 10 - 2

Half bridge method ··········································································· 10 - 2

Full bridge method ············································································ 10 - 2

10.2 Sensitivity drop due to sensor cable extension ············································ 10 - 3

Measurement by constant voltage method ············································ 10 - 3

Measurement by constant current method ············································· 10 - 5

10.3 Complete Compensation Method of Strain (Comet) ······································ 10 - 7

Compensation method in quarter bridge 3-wire method ··························· 10 - 7

Comet NON ···················································································· 10 - 8

Comet A ························································································· 10 - 8

Comet B (Quarter bridge 3-wire method only) ········································ 10 - 8

10.4 How to find the lead wire resistance ·························································· 10 - 9

10.5 Compensation method in 1-gauge 4-wire method ······································· 10 -10

Chapter 11 Specifications

11.1 Specifications ······················································································· 11 - 2

11.2 Standard accessories ············································································· 11 - 6

11.3 Option ·································································································11 - 7

11.4 Outside drawing ···················································································· 11 - 8

Chapter 12 Error Message

12.1 Explanations and countermeasures for error messages ································ 12 - 2

Chapter 1

Overview

1.1 Overview ···················································· 1 - 2

1.2 Features ···················································· 1 - 2

1.3 Details about each part ·································· 1 - 3

1.1 Overview

1-2

1.1 Overview

TC-32K is a compact hand held instrument that you can hold with one hand. Its splash proof construction

allows safety use outside. The terminals connecting the sensors are one-touch type, and provide easy

connection with the lead wires and banana plugs, and speedy measurement. You can set the sensor mode,

coefficient, and initial values of up to 20 channels and record their data, so it is easy to organize the data

even when you are moving around multiple fields to collect data. Also, by using a dedicated switching

box CSW-5B/CSW-5B-05, auto measurement of 5 points becomes available. In addition, TC-32K has

various functions including the interval timer, data memory, data storage by Compact Flash TM memory

card, and connection with PC for control and data transfer. With the resistance check and insulation

resistance check functions, you can check strain gauges and strain gauge type transducers.

1.2 Features

▪Good for measuring strain, DC voltage, thermocouple, Pt-RTD (platinum resistance temperature

detector), resistance, and insulation resistance

▪Provides insulation resistance measurement to enable sensor check

▪Supports 1-gauge 4-wire strain measurement method

▪TEDS compatible

▪Quick connection of a cable without connector

▪Auto measurement by interval timer

▪Low power consumption

▪Simple replaceable power source, four size AA batteries

▪Combination with the switching box CSW-5B/CSW-5B-05 provides multiple points measurement

▪Combination available with adaptor for 2-directional inclinometer

1.3 Details about each part

1-3

1.3 Details about each part

■Front and side

1: Input terminal Connects strain gauges and various sensors.

2: Main LCD Displays monitored measurement values and provides various settings.

3: Sub LCD Displays the timer operation and memory status.

4: POWER key Main power switch

5: Function key Switches the functions.

6: Cursor key Moves the cursor.

7: Ten keys Used for input of values and selection of menu items.

8: ENT key Used to fix the setting values, and to start of the timer.

9: ESC key Used for cancellation of settings, and escape from each menu.

10: I/F connector cap Protection cap for interface connector

11: DC connector cap Protection cap for DC input connector

12: USB connector Connector for USB

13: RS-232C connector Connector for RS-232C

14: DC input connector Connector for AC adapter

1

2

3

4

5

6

8

9

12

7

13

14

10

11

1.3 Details about each part

1-4

■Top, bottom, and back

1: Wire connection label Shows how to connect wires of strain gauges.

2: Input connector NDIS connector receptacle for connecting strain gauge type transducer

3: CF card*slot Slot for memory card based on CF card TYPE I

4: Eject button Double-push button to remove a CF card

5: CF cover Protection cover for CF card slot

6: NDIS connector cap Protection cap for NDIS connector receptacle

7: Fixing thread Used for fixing of the main body (effective screw depth: 5mm)

8: Nonslip rubber Rubber sheet for anti slip

9: Serial Number This is the serial number of the instrument.

10: Battery hatch Removed when batteries are replaced.

* CF card: CompactFlashTM memory card (hereafter abbreviated as CF card)

1

2

3

7

8

10

9

4

6

5

Chapter 2

Preparation

2.1 Instructions for use ······································· 2 - 2

2.2 Power source ·············································· 2 - 3

2.3 Instructions for field measurement ··················· 2 - 6

2.4 Screen outline ············································· 2 - 7

2.5 Operation outline ·········································· 2 - 8

2.1 Instructions for use

2-2

Note

2.1 Instructions for use

Please pay attention to the following information when using this instrument.

Do not use the instrument in places affected by strong or continuous vibrations. Do

not drop the instrument during transportation. Do not give strong impact to the

instrument. Otherwise, the instrument may be damaged.

Warning

Before transportation, pack the instrument with packing materials for delivery or other

materials as needed to protect the instrument from vibration and crash.

Do not put a heavy thing on the instrument.

When the body of the instrument gets dirty, wipe away lightly with soft cloth

moistened with diluted mild detergent and then wipe off the moisture with a dry cloth.

Do not use a strong solvent like thinner, which may damage or change the color of

the body of the instrument.

With the connector capped, this instrument is equivalent to IP-54 (not affected by

water splash from any direction). Do not let the instrument soak directly in water.

For waterproof, the connector cap and the CF cover must be attached correctly.

The eject button used for removing a CF card may be broken easily by external force

when the button is in projected position. Always keep the button depressed inside.

Do not insert anything other than CF cards in the CF card slot.

The liquid crystal display consists of the number of pixels. In some cases, there are

some pixels that always light up or always black out. Such pixels are called stuck

pixels. Please note that they are not a failure but a characteristic of liquid crystal

display, and that stuck pixels are not initial failure, and not covered by our repair or

exchange services.

Please wait 5 or more seconds after you pull out or insert a CF card. Otherwise, the

instrument cannot recognize the CF card. Also, do not remove the CF card or turn

off the power when data are being written into the CF card.

Warning

Warning

Warning

Warning

Warning

Note

2.2 Power source

2-3

2.2 Power source

This instrument is driven by four AA size batteries or an optional AC adapter.

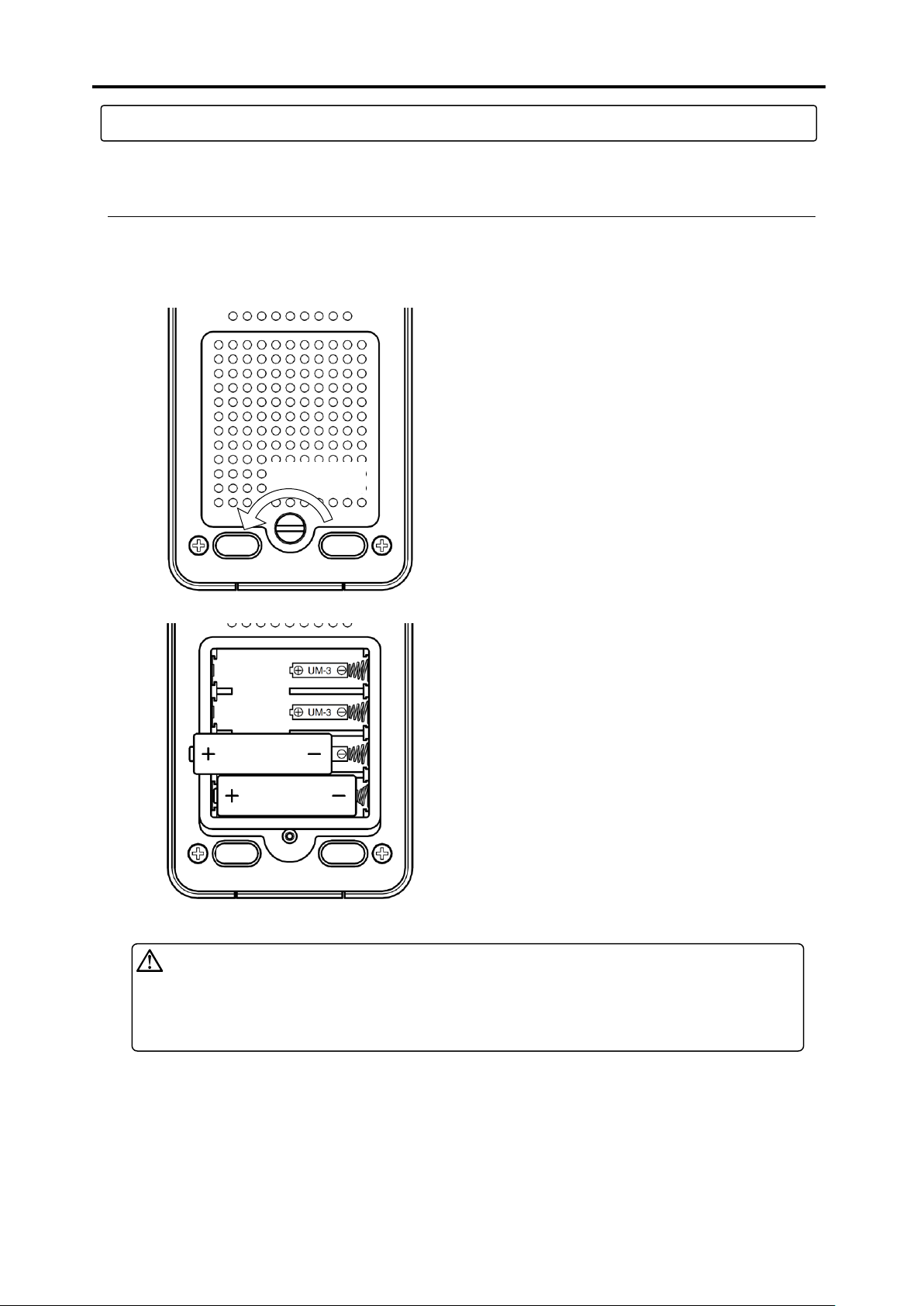

■How to set batteries

You can use size AA alkaline batteries or rechargeable batteries for this instrument. This instrument does

not have function to charge the batteries set inside. When using rechargeable batteries, charge them in

advance.

1) Rotate the screw anticlockwise with a coin or

something and remove the battery hatch.

Loosened

2) Set four batteries in correct positions.

3) Return the battery hatch and rotate the screw

clockwise to lock the hatch.

In order to prevent blowout or leakage of batteries:

▪Check the + indication and the –indication, and set them in the right positions.

▪Do not mix different battery models or new and old batteries.

▪When you do not use the instrument for a long time, remove batteries from the

main body.

Warning

2-4

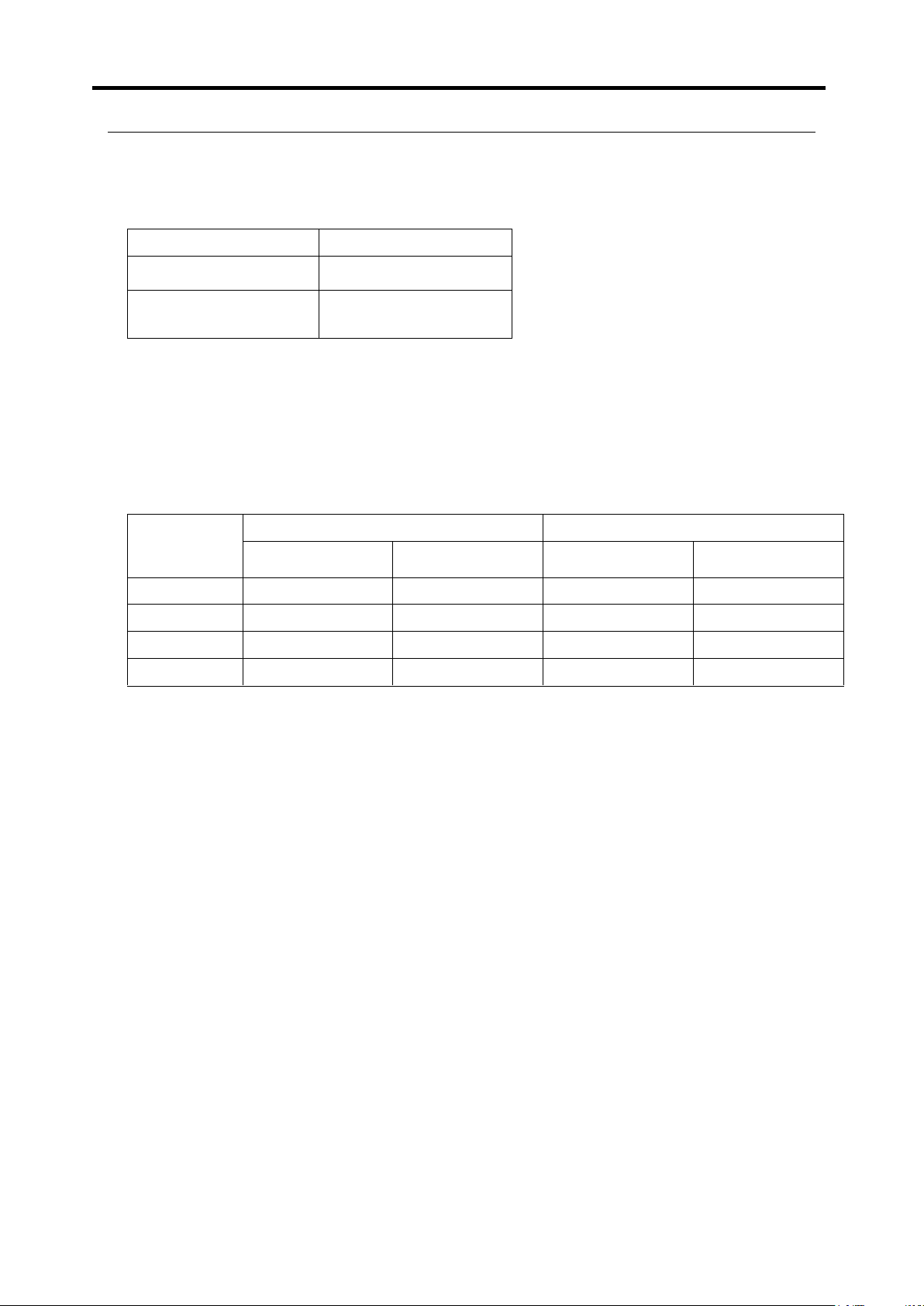

■Operating time by batteries

Operating time by batteries varies depending on ambient temperature and other factors. The list below

shows standard operating time when using new alkaline batteries.

Operating time in continuous use

Condition

Alkaline battery

Single unit of TC-32K

10 hours

TC-32K

+

CSW-5A or

CSW-5B

6 hours

The operating time above is on the following conditions.

* The auto power-off function is not used.

* The LCD backlight is OFF.

* The monitor display is ON.

* The CF card is in the slot.

* Ambient temperature is 23°C.

Operating time using sleep-interval

Interval time

Ambient temperature: 23°C

Ambient temperature: 0°C

Single unit of

TC-32K

+ CSW-5A or

CSW-5B

Single unit of

TC-32K

+ CSW-5A or

CSW-5B

1 minute

60 hours (2.5 days)

43 hours (1.8 days)

42 hours (1.75 days)

30 hours (1.2 days)

10 minutes

580 hours (24 days)

428 hours (17 days)

400 hours (16 days)

300 hours (12 days)

1 hour

2800 hours (116 days)

2400 hours (100 days)

1960 hours (81 days)

1680 hours (70 days)

3 hours or more

7200 hours (300 days)

6000 hours (250 days)

5000 hours (208 days)

3500 hours (145 days)

* The operating time above is by using alkaline batteries.

2-5

■Connection of AC adapter

The AC adapter “CR-1869”is an optional product.

■Power ON/OFF

Remove the connector cap and connect the

AC adapter “CR-1869”to the DC input

connector on the main body. Then, connect

the AC adapter unit to the 100~240 V AC

wall socket. Even if batteries are set in the

TC-32K, power supply from the AC adapter

is prioritized.

Power ON

Press the [POWER] key for 2 seconds or

more. The startup screen appears on the

main LCD and then, the monitor screen is

displayed.

Power OFF

Press the [POWER] key for 2 seconds or

more.

To repeat turning ON/OFF power excessively fast imposes a burden on the

instrument. Wait for more than 5 seconds before power-on after shut-down, or

shut-down after power-on.

Note

▪Do not use any AC adapter other than “CR-1869.”.

▪Connect the AC adapter to the main body first and then, connect it to the 100~240 V

AC wall socket.

Warning

CR-1869

To AC100~240V

wall socket

2.3 Instructions for field measurement

2-6

2.3 Instructions for field measurement

When installing the TC-32K together with the switching box CSW-5A or CSW-5B for long-term

measurement, be sure to arrange grounding correctly. Also, if there is a risk of lightning stroke, be sure to

ground correctly.

■Grounding

■Lightning protection

In fields where cables between switching boxes and sensors are extended, pulse generated by induction of

lightning stroke may cause serious damage on sensors, switching boxes and instrument, and even break

them even if they are not hit by lightning stroke directly. Therefore, proper countermeasures against

lightning are essential.

Cable layout

For sensor cables, use dedicated cables for transducers such as rubber sheathed shielded cable. In

order to minimize the difference of induction voltage against the ground, avoid wiring in midair, and

lay wires down on the ground. If it is impossible to lay them down on the ground (for example if

cables are installed around steel towers), use the arrester for sensors mentioned in the next article.

Arrester for sensor

NZ-6B is the 6-wire system arrester for strain gauge type transducers and also applied to strain gauges.

Insert the arrester near the sensor as much as possible. Although the input terminals of TC-32K have

simple built-in arresters for sensor, it is recommended to install another arrester for sensor together to

make assurance double sure.

Connect the earth wire to the input terminal E. Use a thick

earth wire as much as possible and ground with the

shortest length. Grounding is also effective for

prevention of noise from lightning or heavy equipments.

If peal of thunder is near, or there is a

risk of lightning stroke, stop the

wiring works for grounding and

power source, operation of the

instruments, and keep away from the

instruments. If being hit by a stroke

of lightning during these works, you

may get an electric shock, get

burned, or even die.

Danger

2.4 Screen outline

2-7

2.4 Screen outline

■Startup screen

■Screen configuration

You can move to the setting screen for functions and measurement operations from the monitor screen that

appears after startup. The illustration below shows the outline of the screen configuration:

The basic operations are: to check values or status on the monitor screen; to select “To Menu”to go to

other setting screens; and to change settings.

Soon after you turn on power, the startup screen

shown in the left appears. Then, the monitor

screen shown below appears.

Monitor screen

▪Display measurement

values

▪Main screen

Process of Initial value

▪Initial-in

▪Initial-in of monitor channel

▪Rewriting of initial value

Channel setting

▪Select measurement

channel

▪Select measurement

mode

Menu

▪Set program

▪Change between Measure/Direct

▪Set auto measurement

▪Various checking

▪Set measurement related items

▪Memory, etc.

2.5 Operation outline

2-8

2.5 Operation outline

From the monitor screen, you can move to various modes with three function keys. This section explains

these function keys and systems, and the keys used for operation and their functions.

■Operation system

The operation system of TC-32K is shown below:

Monitor screen

Process of Initial value

Initial-in

Initial-in of monitor channel

Rewriting of initial value

Channel setting

Measurement mode switching

CSW-5B setting

(only in multi-channel mode)

Monitor type selection

Menu

Program setting

Sensor mode

Coefficient , Display digit, Unit

Coefficient

Display digit

Unit

Cap/R.O. setting

Coefficient setting check

RJC for thermocouple

Reading of TEDS sensor

Measurement mode switching

Measure/Direct switching

Auto measurement setting

Interval measurement setting

Interval measurement Start/Stop

Various checks

Insulation check

Resistance check

Dispersion check

Lead wire resistance check

Bridge output check

Coefficient setting check

Settings for measurement

Simple measure

Comet

Power frequency

Initial-in permission

Burn out check

Menu

Memory

Data memory

File dump

Data memory setting

Data number setting

Ring buffer setting

Deletion of data memory

Printout of data memory

CF card

File dump

File name and format setting

Deletion of files

Saving data files

Reading the saved files

CF card formatting

Copying the file

Record on data memory, CF card

Interface setting

RS-232C setting

Baud rate

Data bit

Parity

Stop bit

Flow control

Timeout

Data output destination setting

Data output format setting

Data format

Presence of header

Presence of time data

Settings for external display

Baud rate

Parity

Other settings

Auto power off

Version information

Date and clock

Display language

Maintenance

LCD backlight

LCD brightness

Contrast

Alarm sound volume

Upgrading

Factory setting

Table of contents