Installation an Maintenance Manual

SI unit-CANopen compatible

Type EX260-SCA1-X176

EX260-TFQ01

How to Or er

EX260-SCA1-X176

176 34-pin connector

Output connector type

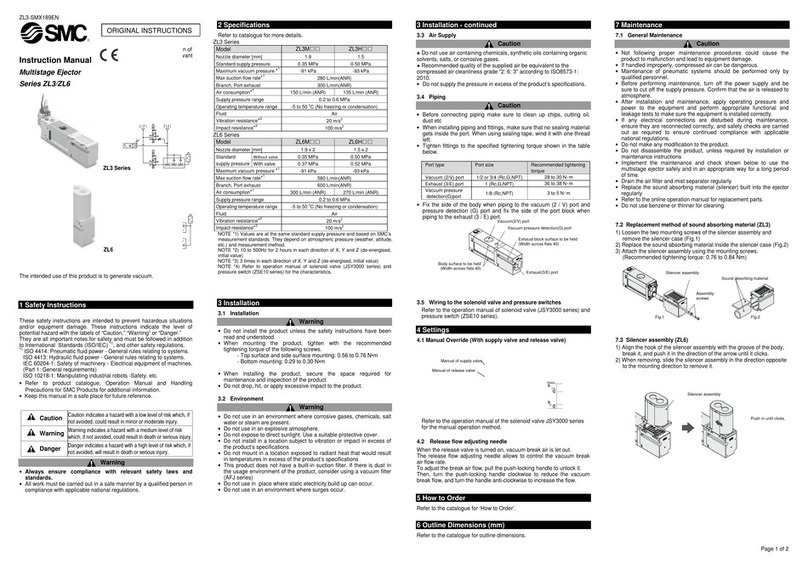

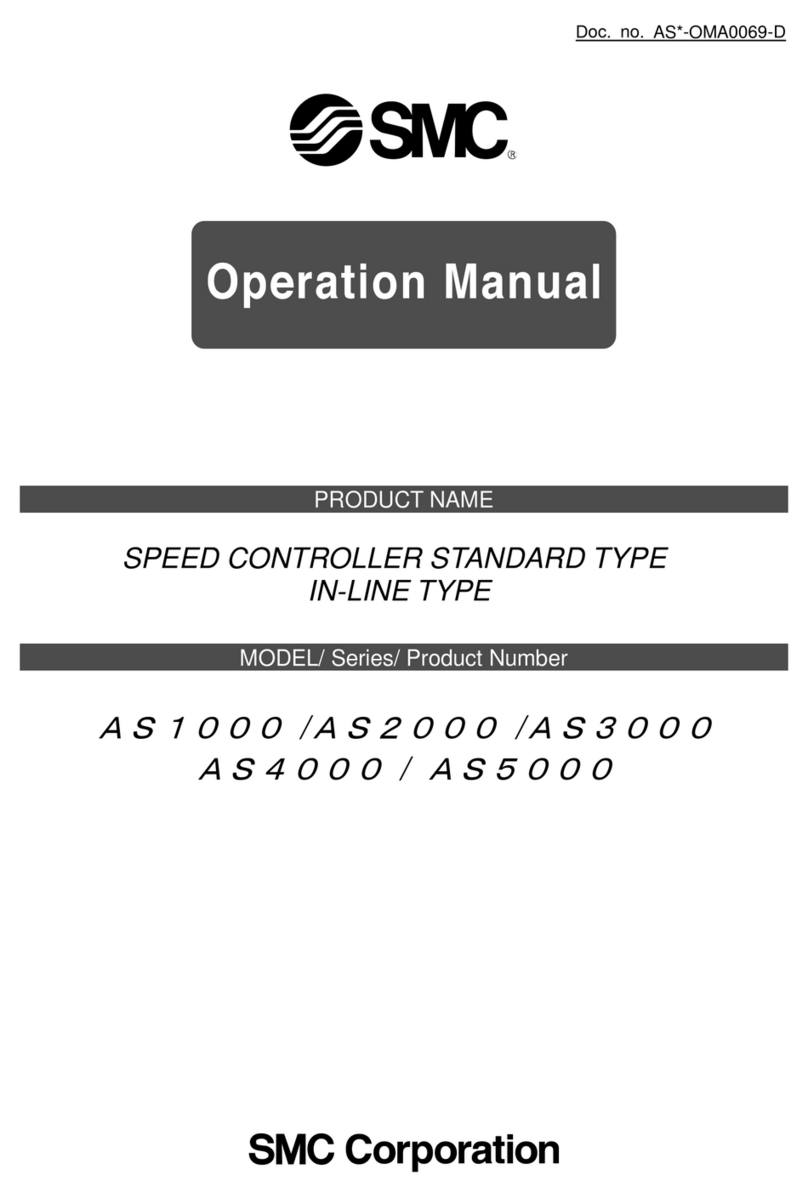

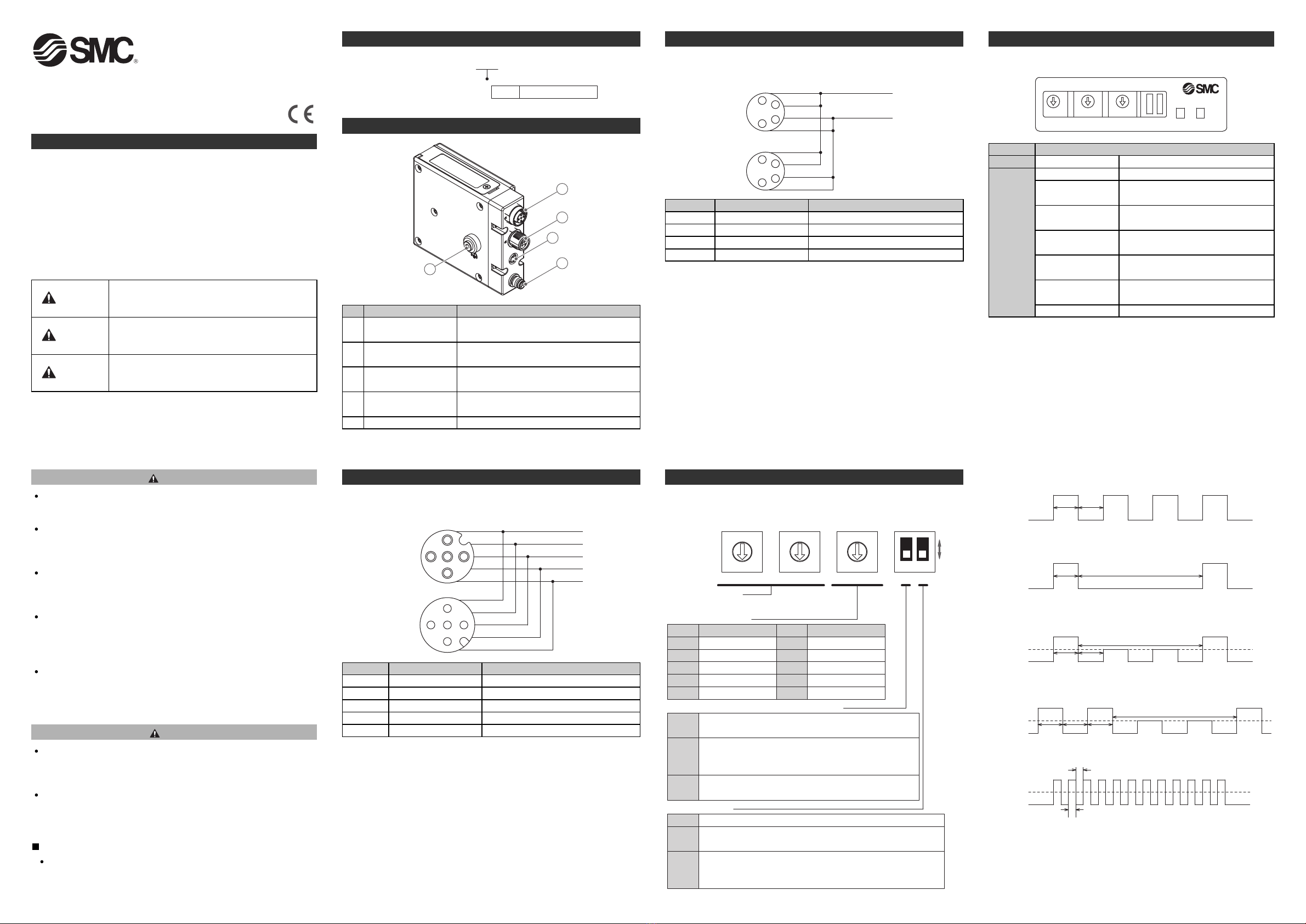

Summary of Pro uct elements

o. Element Description

1Communication

connector BUS OUT

Connect to CA open communication line

and power supply for communication (OUT).

2Communication

connector BUS I

Connect to CA open communication line

and power supply for communication (I ).

3Power supply

connector PWR OUT

Connect to the power supply for solenoid

valve (OUT).

4Power supply

connector PWR I

Connect to the power supply for solenoid

valve (I ).

5 FG terminal Used for functional ground.

1

2

3

4

5

1

2

3

4

5

CAN_SHLD

CAN_V+

CAN_GND

CAN_H

CAN_L

BUS OUT

(Socket (female))

BUS IN

(Plug (male)) 1

2

3

45

1

2

3

45

Pin o.

1

2

3

4

5

Description

CA _SHLD

CA _V+

CA _G D

CA _H

CA _L

Function

Shield

Power supply + for CA open

Power supply - for CA open

CA _H bus line (dominant high)

CA _L bus line (dominant low)

Wiring

•Internal wiring of communication connectors

Communication connector (M12 plug (male)/socket (female) 5 pins)

BUS connector cable: M12 5 pins cable with shield

(according to ISO11898))

The permissible current of the internal wiring (CA _V + and CA _G D)

between communication connectors is 2 Amps maximum.

Safety Instructions

This manual contains essential information for the protection of users

and others from possible injury and/or equipment damage.

•Read this manual before using the product, to ensure correct handling,

and read the manuals of related apparatus before use.

•Keep this manual in a safe place for future reference.

•These instructions indicate the level of potential hazard by label of

"Caution", "Warning" or "Danger", followed by important safety

information which must be carefully followed.

•To ensure safety of personnel and equipment the safety instructions in

this manual and the product catalogue must be observed, along with

other relevant safety practices.

CAUTIO indicates a hazard with a low level of risk

which, if not avoided, could result in minor or

moderate injury.

Caution

Warning

Danger

WAR I G indicates a hazard with a medium level

of risk which, if not avoided, could result in death or

serious injury.

DA GER indicates a hazard with a high level of risk

which, if not avoided, will result in death or serious

injury.

This product is class A equipment that is intended for use in an industrial

environment.

There may be potential difficulties in ensuring electromagnetic

compatibility in other environments due to conducted as well as radiated

disturbances.

Do not isassemble, mo ify (inclu ing changing the printe

circuit boar ) or repair.

An injury or failure can result.

Do not operate the pro uct outsi e of the specifications.

Do not use for flammable or harmful fluids.

Fire, malfunction, or damage to the product can result.

Verify the specifications before use.

Do not operate in an atmosphere containing flammable or

explosive gases.

Fire or an explosion can result.

This product is not designed to be explosion proof.

If using the pro uct in an interlocking circuit:

•Provide a double interlocking system, for example a mechanical

system.

•Check the product regularly for proper operation.

Otherwise malfunction can result, causing an accident.

The following instructions must be followe uring maintenance:

•Turn off the power supply.

•Stop the air supply, exhaust the residual pressure and verify that the

air is released before performing maintenance.

Otherwise an injury can result.

Warning

NOTE

When conformity to UL is required, the SI unit should be used with a

UL1310 Class 2 power supply.

Caution

After maintenance is complete, perform appropriate functional

inspections.

Stop operation if the equipment does not function properly.

Safety cannot be assured in the case of unexpected malfunction.

Provi e groun ing to assure the safety an noise resistance of

the Fiel bus system.

Individual grounding should be provided close to the product with a

short cable.

2

3

4

1

2

3

4

1

+24 V for

solenoid valve

0 V for

solenoid valve

PWR OUT

(Socket (female))

PWR IN

(Plug (male))

4

2

3

1

4

2

3

1

Pin o.

1

2

3

4

Description

SV 24 V

SV 24 V

SV 0 V

SV 0 V

Function

+24 V for solenoid valve

+24 V for solenoid valve

0 V for solenoid valve

0 V for solenoid valve

Wiring (continue )

•Internal wiring of communication connectors

Power supply connector (M8 plug (male)/socket (female) 4 pins)

(Connector caable: M8 4 pins cable)

The permissible current of the internal wiring (SV24 V-SV0 V) between

power supply connectors is 4 Amps maximum.

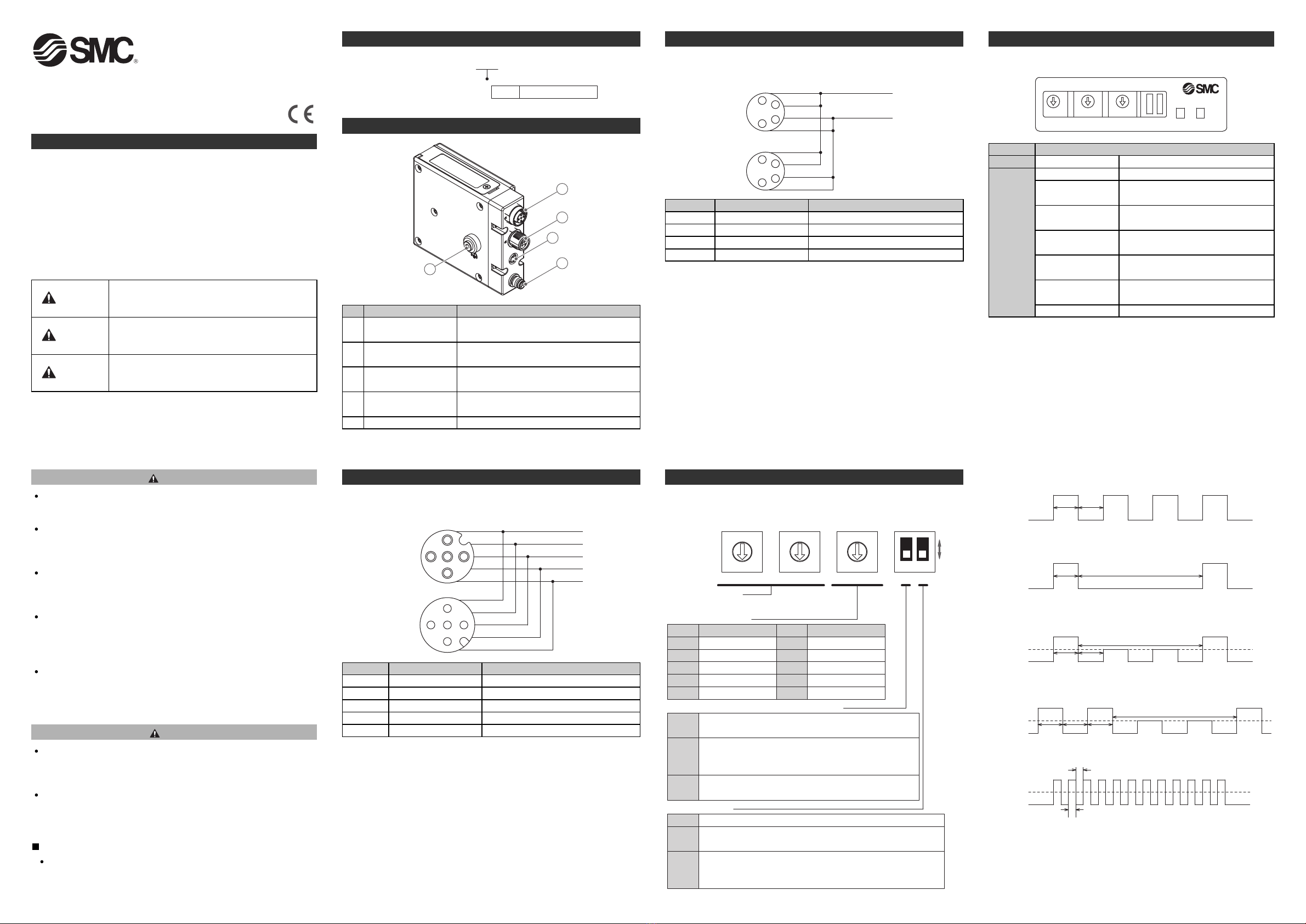

Setting of output when communication stops

Setting of Node-ID

The setting range is 1-99. (0 is invalid)

Setting of mode

SW1

x10 x1

SW2

BAUD SETTINGS

SW3 SW4

Setting of Baud Rate

SW3

The output shall use the pre-defined condition specified

in the Error Value Output Object (6207h, 6307h, 6327h).

Default: All outputs are cleared (OFF).

All outputs are held in the state immediately before the

communication stopped.

State of solenoid valve output when error (Error Control,

Emergency Object) occurs or fault message is received.

SW4-1

0

1

SW mode. Setting of Node-ID is achieved via network. SW1 and

SW2 become unavailable. Node-ID can be set up to 127.

Default is 127 (7Fh).

HW mode. Setting of Node-ID is achieved using SW1 and SW2.

Setting of

Baud Rate

is achieved using SW3.

Mode

SW4-2

0

1

0

1

2

3

4

Baud Rate [kbps]

1000

800

500

250

125

6

5

7

8

9

50

Reserved

20

10

Reserved

SW3 Baud Rate [kbps]

0

5

2

7

8

3

9

4

1

6

0

5

2

7

8

3

9

4

1

6

0

5

2

7

8

3

9

4

1

6

ON

OFF

12

Setting

•Internal wiring of communication connectors

Communication connector (M12 plug (male)/socket (female) 5 pins)

Indication

PWR(V)

CA

Content

Green Light

Green Light

Green Light

(flashing)

Green Light

(single flash)

Red Light

(single flash)

Red Light

(double flash)

Green/Red Light

(flashing)

Red Light

Power for solenoid valves is supplied

SI unit is in the Operational state

SI unit is in the Pre-Operational state

SI unit is in Stopped state

CA controller error occured

Error Control Event occured

SI unit is in Configuration mode

(LSS services)

SI unit is in "Bus OFF" state

Setting (continue )

•LED indication

Green (flashing): Pre-Operational State

NODE-ID

X10 X1 BAUD

SETTINGS CAN PWR(V)

Green

LED ON

Green

LED OFF

200 ms 200 ms

Green (Single Flash): Stopped State

Green

LED ON

Green

LED OFF

200 ms

1000 ms

Red (Single Flash): CA controller error

Red

LED ON

Green

LED ON

200 ms 200 ms

1000 ms

OFF

Red (Double Flash): Error Control Event

Red

LED ON

Green

LED ON

200 ms 200 ms 200 ms

1000 ms

OFF

Green/Red (flashing): LSS Configuration Mode

Red

LED ON

Green

LED ON 50 ms

50 ms

OFF

∗: LED Indication of SI unit is based on CA open specification

(CA open spec. DR-303-3).

Refer to DR-303-3 indicator specification for details.