Toolshop 240-2003 User manual

SAVE THIS MANUAL

You will need this manual for safety instructions, operating procedures and warranty.

Put it and the original sales receipt in a safe dry place for future reference.

For questions about this product, please call 1-866-915-8626.

Operator’s Manual

240-2003

8IN. DRILL PRESS

WARNING:

1

When using electric tools, machines or equipment, basic safety

precautions should always be followed to reduce the risk of fire,

electric shock, and personal injury.

IMPORTANT SAFETY INSTRUCTION

READALL INSTRUCTIONS BEFORE USING THIS TOOL

1. KEEP WORKAREA CLEAN. Cluttered areas invite injuries.

2. CONSIDERWORKAREA ENVIRONMENT. Don’t use power tools in damp,

wet, or poorly lit locations. Don’t expose your tool to rain. Keep the work area

well lit. Don’t use tools in the presence of ammable gases or liquids.

3. KEEP CHILDREN ANDBYSTANDERSAWAY.All children should be kept

away from the work area. Don’t let them handle machines, tools or extension

cords. Visitors can be a distraction and are difcult to protect from injury.

4. GROUNDEDTOOLS must be plugged into an outlet that itself is properly

installed and grounded. Grounding provides a low-resistance path to carry

electricity to ground away from the operator, should the tool malfunction elec-

trically. Do not remove the grounding prong from the plug or alter the plug in

any way. If in doubt as to whether the outlet is properly grounded according

to code, check with a qualied electrician.

5. OBSERVE PROPERPRECAUTIONS REGARDING GROUNDEDPLUG.

Plug power cord into a 110-120V properly grounded type outlet protected by a

12 amp time delay, a circuit saver fuse or circuit breaker.

6. GUARD AGAINST ELECTRIC SHOCK. Prevent body contact with grounded

surfaces: pipes, radiators, ranges, and refrigerator enclosures. When your

body is grounded the risk of electric shock increases. When working wherever

“live” electrical wires may be encountered, try to ascertain whether there is

a danger of shock. Even so, DO NOT TOUCH ANY METAL PARTS OF THE

TOOL while using it.

7. HANDLE THE CORD CAREFULLY. Never pull on the cord to unplug this tool.

Protect the cord from potential sources of damage:heat, oil & solvents, sharp

edges, or moving parts. Replace damaged cords immediately.

8. WHEN WORKING OUTDOORS, USE AN OUTDOOR-RATEDEXTENSION

CORD.An extension cord rated for outdoor use must be marked “W-A” or

“W”.

9. DO NOT EXPOSE ELECTRICAL POWERTOOLS TO MOISTURE. Rain or

wet conditions can cause water to enter the tool and lead to electric shock.

10. ENSURE THE EXTENSION CORD YOU USE IS OF SUFFICIENT GAUGE

FORITS LENGTH.

Recommended Minimum Wire Gauge for Extension Cords

Amps

from

Tool Nameplate

25’(7 m) length 50’(15 m)length 75’(23 m)length 100’(30 m) length 150’ (46 m)length 200’(61 m)length

0-5 amps 16 ga. 16 ga. 16 ga. 14 ga. 12 ga. 12 ga.

5.1-8 amps 16 ga. 16 ga. 14 ga. 12 ga. 10 ga. Do Not Use

8.1-12 amps 14 ga. 14 ga. 16 ga. 10 ga. Do Not Use Do Not Use

12.1-15 amps 12 ga. 12 ga. 10 ga. 10 ga. Do Not Use Do Not Use

15.1-20 amps 10 ga. 10 ga. 10 ga. Do Not Use Do Not Use Do Not Use

11. STORE IDLE EQUIPMENT. Store equipment in a dry area to inhibit rust.

Equipment also should be in a high location or locked up to keep out of reach

of children.

12. DON’T FORCE THE TOOL. It will do the job better and more safely at the

rate for which it was intended.

13. USE THE RIGHT TOOL. Don’t force a small tool or attachment to do the work

of a larger industrial tool. Don’t use a tool for a purpose for which it was not intended.

2

IMPORTANT SAFETY INSTRUCTION

contain long hair and keep it from harm.

15. USE EYE PROTECTION. Use a full-face mask if the work you’re doing produces

Goggles are acceptable in other situations.

Wear a clean dust mask if the work involves creating a lot of ne or coarse

dust.

16. SECURE WORK. Use clamps or a vise to hold the work. It’s safer than using

your hands and it frees both hands to operate the tool.

17. DON’T OVERREACH. Keep proper footing and balance at all times. Do not

reach over or across tools that are running.

18. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for better and

safer performance. Follow instructions for lubricating and safe performance.

Follow instructions for lubricating and changing accessories. Keep handles dry,

clean and free from oil and grease.

19. AVOIDUNINTENTIONAL STARTING. Be sure the switch is in the OFF position

before plugging in.

20. ALWAYS CHECK ANDMAKE SURE TO REMOVE ANY ADJUSTING KEYS

ORWRENCHES before turning the tool on. Left attached, these parts can y

off a rotating part and result in personal injury.

21. DO NOT USE THE TOOL IF IT CANNOT BE SWITCHEDON OROFF. Have

your tool repaired before using it.

22. DISCONNECT THE PLUG FROM POWERBEFORE MAKING ANY AD-

JUSTMENTS. Changing attachments or accessories can be dangerous if the

tool could accidentally start.

23. STAY ALERT. Watch what you are doing & use common sense. Don’t operate

any tool when you are tired.

24. CHECK FORDAMAGEDPARTS. Before using this tool, any part that is dam-

aged should be carefully checked to determine that it will operate properly and

perform its intended function. Check for alignment of moving parts, binding

of moving parts, breakage of parts, mountings, and other conditions that may

affect its operation. Inspect screws and tighten any ones that are loose. Any

part that is damaged should be properly repaired or replaced by an authorized

service center unless otherwise indicated elsewhere in the instruction manual.

Have defective switches replaced by an authorized service center. Don’t use

the tool if switch does not turn it on and off properly.

25. REPLACEMENT PARTS. When servicing, use only identical replacement parts.

26. SERVICE ANDREPAIRSshould be made by qualied repair technicians at an

authorized repair center. Improperly repaired tools could cause serious shock

or injury.

14. DRESS PROPERLY. Don’t wear loose clothing or jewelry; they can be caught

in moving parts. Protective, non-electrically conductive gloves and non-skid

footwear are recommended when working. Wear protective hair covering to

SAFETY PRECAUTIONS FORDRILL PRESS

WARNING: Do not operate your drill press until it is completely

assembled and installed according to the instructions.

1. Never turn on the drill press before clearing the table of all objects (tools,

scraps, etc.).

2. Always keep hands and fingers away from the drill bit.

3. Do not drill material that does not have a flat surface, unless a suitable

support is used.

4. Never start the drill press with the drill bit pressed against the workpiece.

5. Make sure the table lock is tightened before starting the machine.

!

SAFETY PRECAUTIONS FORDRILL PRESS

3

!

!

WARNING - ngers touch the terminals of the plug when installing

or removing the plug to or away from the outlet.

WARNING - If not properly grounded, this tool can incur the potential hazard

of electrical shock particularly when used in damp locations or in proximity to

plumbing. If an electrical shock occurs, there is the potential of a secondary hazard

like your hands contacting the tool.

Electricity Requirements

CONNECTING THE TOOL TO A POWERSOURCE OUTLET

This machine source must be grounded while in use to protect the operator from

electric shock. In case of malfunction or breakdown, grounding provides a path

of least resistance for electrical current to reduce the risk of electrical shock. This

tool is equipped with an electric cord having an equipment grounding conductor

outlet that is properly installed and grounded in accordance with all local codes

and ordinances.

Improper connections of the equipment-grounding conductor can result in a risk of

electrical shock. The conductor with insulation having an outer surface that is green

(with or without yellow strips) is the equipment-grounding conductor. If repair or

replacement of the electric cord or plug is necessary, do not connect the equipment-

grounding conductor to a live terminal.

Plug power cord into a 120V properly grounded type outlet protected by a 3.0A

time delay, a circuit saver fuse or circuit breaker.

Protect Your Eyes

The operation of any power tool can result in foreign objects being thrown into the

eyes, which can result in severe eye damage. Always wear eye protection during

operation of the tool.

FIGURE 1

GROUNDING PRONG

PROPERLY GROUNDEDTHREE

PRONG OUTLET

THREE PRONG PLUG

This tool is intended for use on a circuit that has an outlet that looks like the one in

Figure 1.

6. Never perform layout, assembly, or set-up work on the table while the drill

is in use.

7. Make sure drill bit is securely locked in the chuck.

8. Make sure chuck key is removed from the chuck before turning power on.

9. Adjust the table or depth stop to avoid drilling into the table.

10. Always stop the drill before removing scrap pieces from the table.

11. Use clamps or a vise to secure workpiece to the table. This will prevent

workpiece from rotating with the drill bit.

12. Do not wear gloves when operating a drill press.

13. Shut the power off, remove the drill bit, and clean the table before leaving

the drill press.

14. Set the drill press to the speed appropriate for the job.

15. Should any part of your drill press be missing, damaged, or any electrical

component fail to perform properly, shut power off and unplug the drill press.

Replace missing, damaged, or failed parts before resuming operation.

Do not modify the plug provided. If the plug does not t the proper

outlet, have a proper outlet installed by a qualied electrician.

4

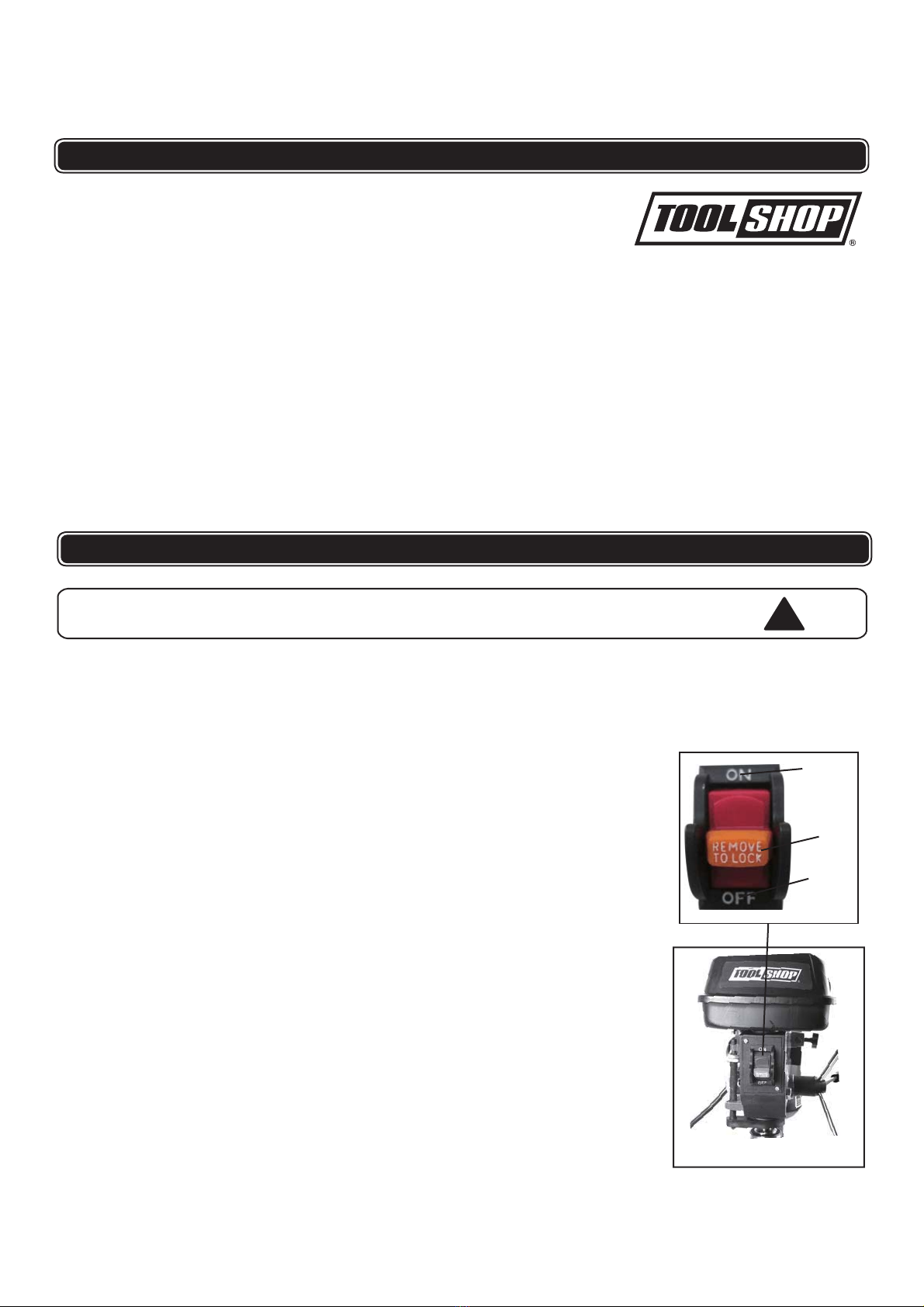

FUNCTION DESCRIPTION

1

2

3

4

5

10

9

8

7

6

Voltage: 120V ~ 60Hz,

Current Rating: 3.0 Amps

Spindle Speed: 740, 1100, 1530, 2100, 3140 RPM (No Load)

Chuck Capacity: 1/2"

Spindle travel: 2"

Spindle Attachment: JT33

Table Height Adjustment: 8-1/2"

Swing: 8"

Contents:(1) Chuck Key

(2) 1/8" & 5/32" hex wrench, Product Manual

SPECIFICATIONS

1. Belt cover

6. Lock handle

2. On/Off Switch

7. Column assembly

3.

8. Motor

4. Work table

Chuck

9. Handle

5. Base

10. Belt tension lock knob

5

ASSEMBLY ANDADJUSTMENTS

WARNING: To reduce the risk of injury, never connect plug to power source

outlet until all assembly steps are completed.

Base to column

1. Place Colum

(See Fig. 2)

(See Fig. 1)

(See Fig. 3)

n (1) on the Base (3) and align holes

in the Column with holes in the Base.

2. Attach using Bolt, Spring Washer,and Washer

(2) in each hole through the Column and into the

Base.

Table to column

1. Loosen the Lock handle (3) on the table. (2).

2. Slide the Table(2) over the Column (1).

3. Tighten the Lock handle (3) to secure the Table (2)

in place.

Drill press head to column

1. Lift the drill press head assembly (1) carefully and

place the mounting hole of the drill press head onto

the top of the column (3). Make sure the head is

seated properly on.

2. Align the direction of the drill press head to the

direction of the base and the table.

3. Tighten the set screws (2) using the 5/32" hex wrench.

4. Thread the handle rods (4) into the holes on the hub.

5. Hand tighten.

Note:One or two of the handles may be removed

unusually

if an

-shaped workpiece interferes with handle

rotation.

1

2

3

1

2

3

Fig. 1

Fig. 2

1

Fig

1

1

F

i

Fig. 3

1

2

3

4

ASSEMBLY ANDADJUSTMENTS

Install the chuck (see Fig. 4 ).

1. Inspect and clean the taper hole in the chuck and the spindle.

Remove all grease, coatings, and particles from the chuck and

spindle surfaces with a clean cloth.

2. Open the chuck jaws by turning the chuck barrel clockwise by

hand. Make sure the jaws are completely recessed inside the

chuck.

3. Seat the chuck on the spindle by placing a block of wood

under the chuck and tapping the wood with a hammer or

tap the chuck with a rubber mallet.

Removethe chuck at alater time

1. Turn the feed handles to lower the chuck (1) to the lowest position.

2. Place a ball joint separator tool (4) above the chuck (2) and tap it

lightly with a hammer (3) to cause the chuck to drop from the

spindle.

Note:This ball joint separator tool not included and sold separately.

Note: To avoid possible damage, be prepared to catch the chuck

as it falls.

CAUTION: To avoid damaging the chuck, make sure the jaws are

completely recessed into the chuck. Do not use a metal

hammer directly to drive the chuck into the spindle.

Install the belt

1. Open the pulley and belt cover (1).

2. Loosen the belt tension lock knob (2).

3. Slide the motor (3) as close to the drill press head as possible.

4. Place a belt (4) on the motor pulley (5) and the spindle pulley

(6) in the proper position for the desired speed.

5. Pull the motor away from the drill press head until the belt is

properly tensioned. Tighten the belt tension lock knobs.

Note:The belt (4) should be tight enough to prevent slippage.

Correct tension is set if the belt flexes about 1/2" (13 mm) when

thumb pressure is applied at the midpoint of the belt

pulleys.

between the

1

23

4

5

6

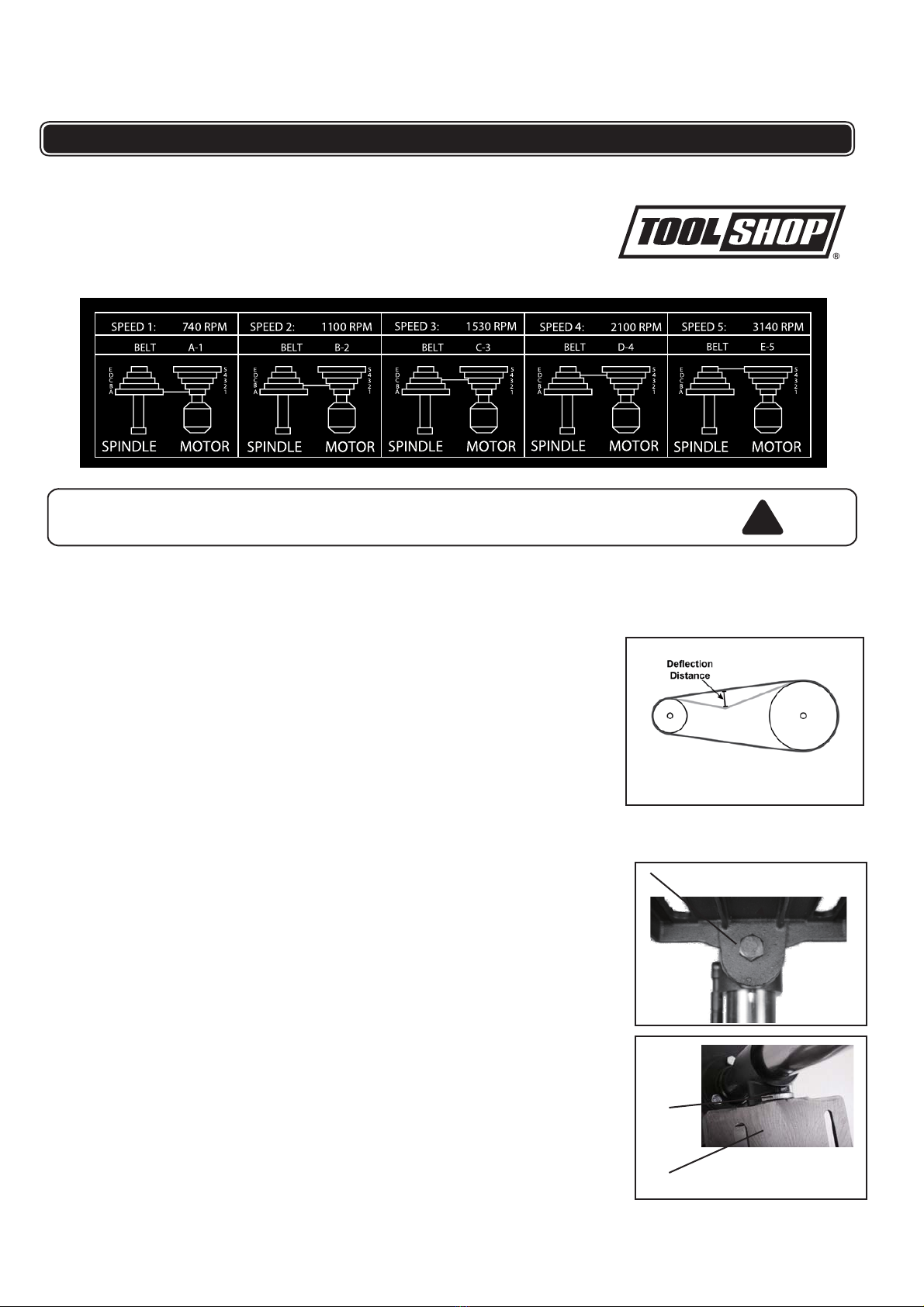

Spindle speeds

This drill press offers 5 spindle speeds from 740 to 3140 RPM.

The highest speed is obtained when the belt is positioned on

the largest motor pulley step and the smallest spindle pulley step.

(see Fig. 6 and Fig. 7).

(The belt is included).

(see Fig. 5 ).

6

Fig. 4

Fig. 6

Fig. 7

!

Fig. 5

1

2

4

13

2

ASSEMBLY ANDADJUSTMENTS

WARNING: Disconnect the drill press from the power source before

making any speed adjustments.

Adjust speeds and tension the belt

1. Open the drill press pulley cover.

2. Loosen the belt tension knob (2) (see Fig 7).

3. Pull the motor (3) (see Fig. 7) toward the drill press head.

4. Set the belt on the desired steps of the motor and spindle

pulleys

chart

according to the belt positions on the spindle speed

. (See above chart)

5. Pull the motor away from the drill press head to increase

the belt tension.Tighten the tension knobs (2) (see Fig. 7).

(see Fig. 9 and Fig. 10).

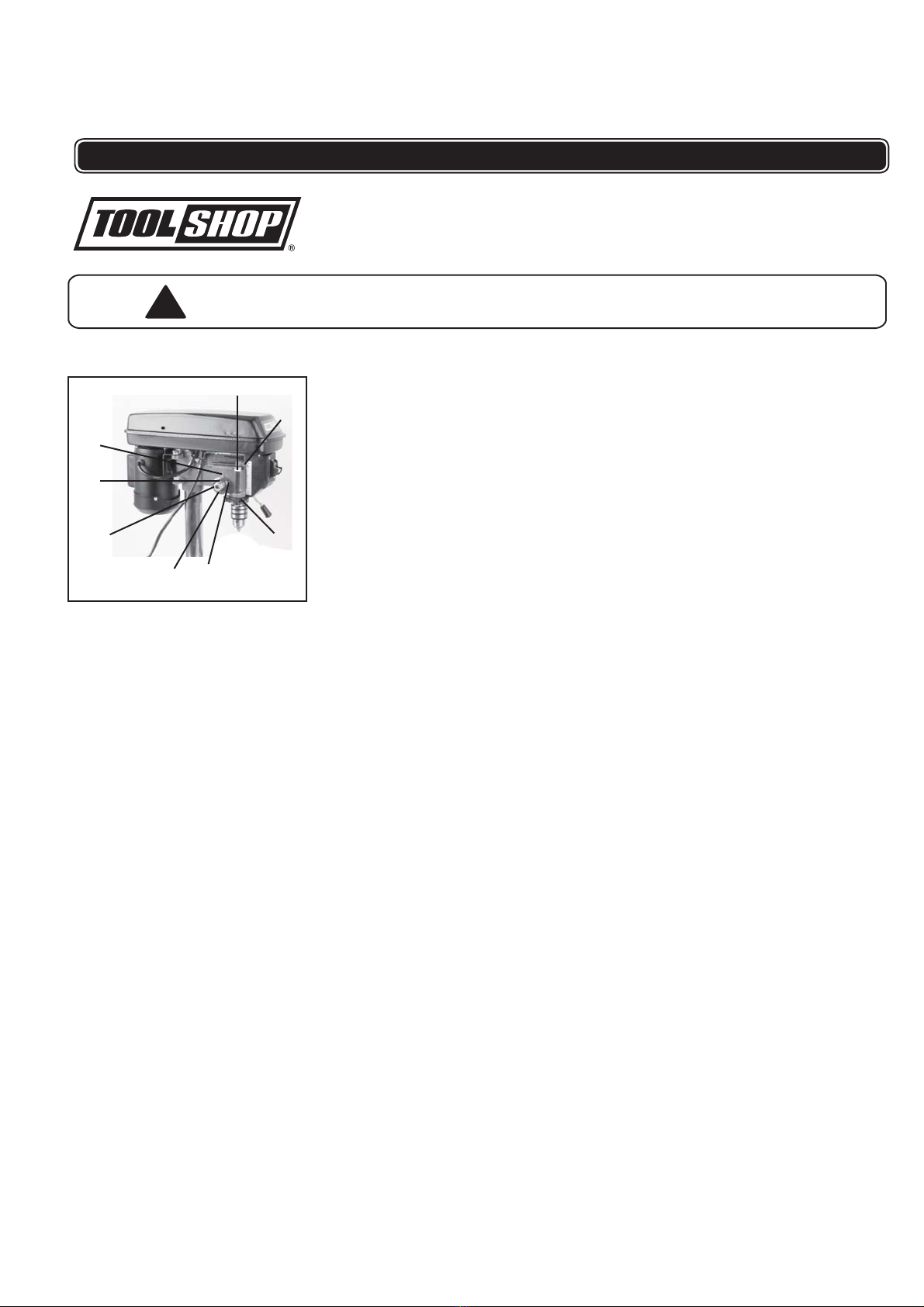

6. The belt should be tight enough to prevent slippage. Correct

tension is set if the deflection distance is about 1/2" (13 mm)

when thumb pressure is applied at the midpoint of the belt

between the pulleys.

Tilt the table

The table can be tilted from 0 to 45° to the left and right.

1. Loosen the bevel lock bolt (1) with a 3/4" hex wrench.

2. Tilt the table (2) to the desired angle, using the bevel scale (3)

as a basic guide.

3. Re- tighten the bevel lock bolt (1).

4. To return the table to its original position, loosen the bevel lock

bolt. Realign the bevel scale (3) to the 0° setting.

5. Tighten the bevel lock bolt (1) with the 3/4" hex wrench.

Note: This 3/4” hex wrench is not included and sold separately.

1

2

3

7

Fig. 8

Fig. 9

Fig. 10

!

(See Fig. 11)

ASSEMBLY ANDADJUSTMENTS

Coil spring adjustment

WARNING: Disconnect the drill press from the power source

before adjustment .

If the quill (8) returns too quickly or too slowly when the handles

are released, adjust the spring.

Note: This adjustment is set at the factory and should not need

changing. Re-adjustments may eventually be necessary due to

normal wear and tear.

1. Raise the spindle to the top position.

2. Move both depth scale nuts (1) to the lowest position and

tighten to prevent the quill from dropping down.

3. Place a screwdriver in the notch (2) of the spring housing.

4. Firmly hold the screwdriver in place to prevent the spring

and housing from moving.

5. Loosen and remove the outer jam nut (3).

6. Loosen, BUT DO NOT REMOVE, the inner nut (4).

7. Pull out, BUT DO NOT REMOVE, the housing (5) from the

raised lug (6) on the drill press head.

8. With the screwdriver in the notch, carefully turn the spring

housing(5) counter-clockwise until the next notch engages

with the raised lug.

9. Release the housing and tighten the inner nut (4). Do not

remove the screwdriver.

10. Check the quill (8) tension

Move the two stop nuts(1) on the depth scale rod to the

top position.

Turn the handles and release, raising the depth

pointer (7) to the top position. If there is not enough

tension, repeat steps 6- 9, moving the spring housing

one more notch. If there is too much tension, move

the housing one notch at a time in the opposite

direction.

8

Fig. 11

25

3

4

6

1

7

8

!

ASSEMBLY ANDADJUSTMENTS

11. If the quill (8) returns gently to top position (correct operation):

Tighten the inner nut (4). Do not overtighten.

Replace the jam nut (3). Tighten against the inner nut.

Remove the screwdriver.

Rotate the handles and check the quill (8) for unrestricted

movement.

12. If the quill (8) movement is too restricted or tight:

Loosen the jam nut (3).

Slightly loosen the housing inner nut (4).

Tighten the jamnut (3).

Check the quill (8) movement again and repeat steps 1-3

until the quill (8) moves freely.

Safety Switch: Insert the Safety Key (Fig 12) into the Switch. This

“Key” is a safety precaution and should remain in the Switch during

use and be removed after Switch is turned off and/or any time the

Drill Press is left unattended or in storage.

OPERATION

WARNING:

9

TURNING ON AND OFF

Note:The pulley cover must be closed to operate the drill press.

Risk of injury due to accidental starting. Do not use in an

area where children may be present.

(Fswitch.

clamps.

switch.

ig 12).

(Fig 12).

1. Switch the drill press on by pressing the “ON” button on the

2. Switch the drill press off by pressing the “OFF” button on

the

3. Secure your workpiece to the table if possible, using a vice or

!

OFF

Safety

Key

ON

Fig. 12

OPERATION

Check the belt tension after the first 3-5 hrs. of operation to ensure

that the belts have not become stretched and loose from their

'breaking in' use.

MAINTAINING YOURDRILL PRESS

WARNING:

Before each use:

1. Check the power cord and plug for any wear or damage.

2. Check for any loose screws or hardware.

3.

4.

5.

Check the area to make sure it is clear of any misplaced

lumber, cleaning supplies, etc. that could

tools,

hamper the

operation of the drill press.

safe

To avoid a build-up of wood dust, regularly clean all parts

of the machine using a soft cloth, brush or compressed air.

A general cleaning should be done after every use to avoid

future problems and ensure the machine is in ready condition

for the next time it is used.

WARNING: If blowing sawdust, wear proper eye protection to prevent

debris from blowing into eyes. The use of dust collection

is also advised.

Keep the table, column and base free of resin and rust. Clean them

regularly with a non -flammable

of dry lubricant spray, or wax, to keep their surfaces clean. Do not

use

solvent, then coat with a light film of

ordinary dustoil which will collect and hamper the operation of

the machine.

All of the ball bearings are lifetime lubricated, sealed, and do not

need any further care. Keep the drive belts free of oil and grease.

10

4. Select your drilling depth and secure the depth stop lock knob in

position.

5. Adjust the table to your desired position.

6. Slowly rotate the wheel handles to bring the drill bit down towards

the table and into your workpiece. After drilling a hole, release the

wheel handles slowly to return the chuck to its original position.

7. Continue the operation until the task is completed. When

completed, switch the drill press off by pressing the “OFF button

on the switch.

Turn the power switch “OFF” and disconnect the plug from

the outlet prior to adjusting or maintaining the machine.

DO NOT attempt to repair or maintain the electrical

components of the motor. Contact a qualified service

technician for this type of maintenance.

!

!

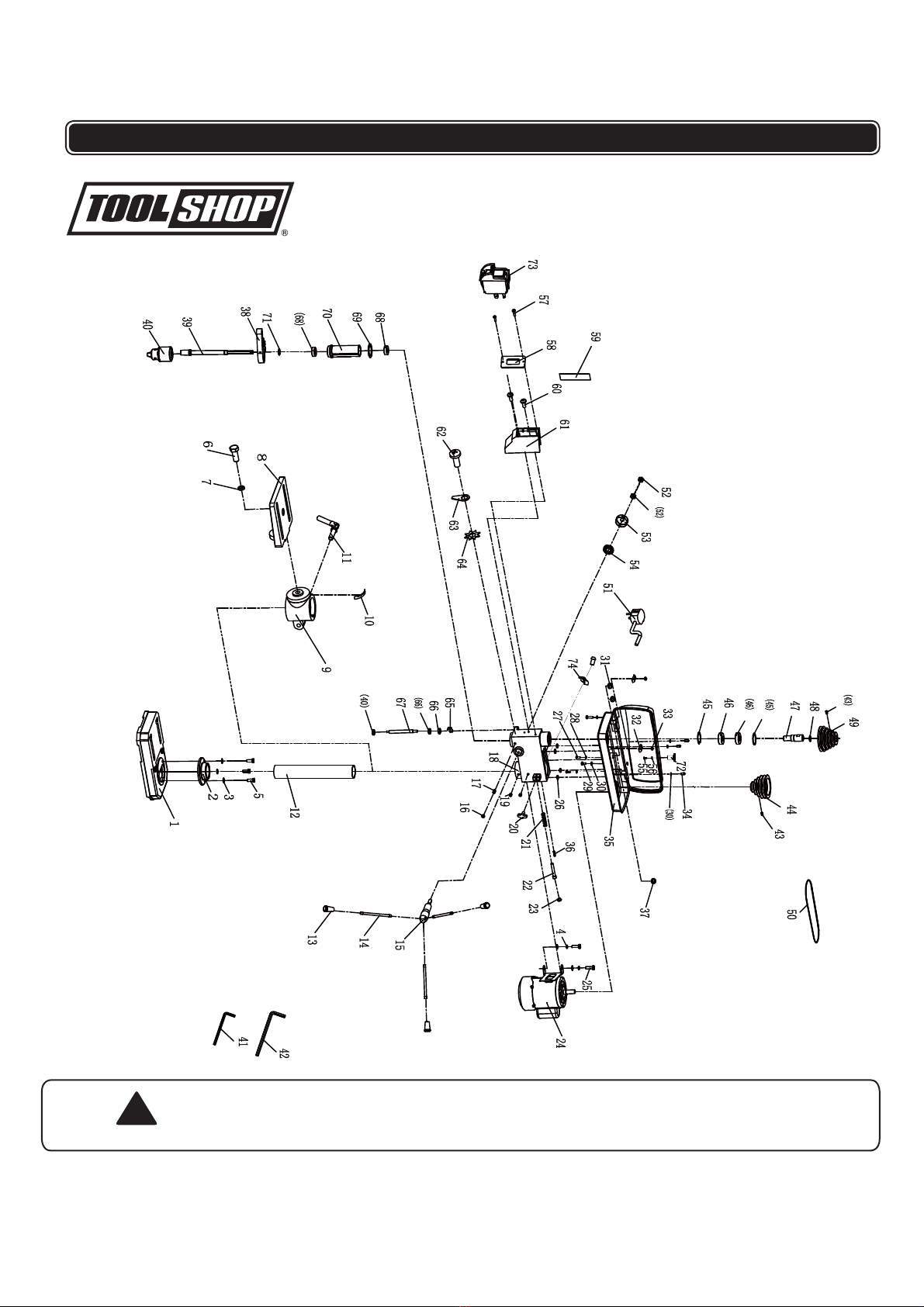

PARTS LIST ANDSCHEMATIC DRAWING

11

12 '(6&5,37,2 21

1 BASE

2 COLUMN FLANGE

3FLATWASHER

4 SPRING WASHER

5 OUTSIDE HEX. BOLT

6 OUTSIDE HEX. BOLT

7 SPRING WASHER

8WORKINGTABLE

9 TABLE SUPPORT

10 ANGLE LABEL

11 LOCKING HANDLE

12 COLUMN

13 HANDLE TIP

14 HANDLE

15 GEAR SHAFT

16 NUT

17 HEAD SCREW

18 HOUSING

19 HEX. SOC SET SCREW

20 WING KNOB

21 MOTOR SPRING

22 MOTOR BOLT

23 WASHER

24 MOTOR

25 OUTSIDE HEX. BOLT

26 DAMPING WASHER

27 CROSS RECESS PAN HD SCREW

28 FLAT WASHER

29 CROSS RECESS PAN HD SCREW

30 FLAT WASHER

31 PROTECTOR RING

32 CORD CLAMP

33 NUT

34 CROSS RECESSED PAN HEAD SCREW

35 PULLEY COVER ASSEMBLY

36 ROLL PIN

37 PROTECTOR RING

38 RULER HOLDER

39 MAIN SPINDLE

40 CHUCK

41 HEXAGON BAR WRENCH

42 HEXAGON BAR WRENCH

43 HEX. SOC SET SCREW

44 MOTOR PULLEY

45 CIRCLIP FOR HOLE

12 '(6&5,37, 1

46 BEARING

47 KEYWAY SPINDLE

48 CIRCLIP FOR BEARING

49 SPINDLE PULLEY

50 BELT

51 PLUG WITH CABLE

52 NUT

53 SPRING COVER

54 SPRING

55 CROSS RECESSED PAN HEAD SCREW

56 BIG FLAT WASHER

57 CROSS RECESS HEAD TAPPING SCREW

58 SWITCH PANEL

59 CALIBRATION LABEL

60 CROSS RECESSED PAN HEAD SCREW

61 SWITCH BOX

62 CROSS RECESSED PAN HEAD SCREW

63 GROUNDED PARTS

64 TOOTH LOCK WASHER

65 INDICATOR

66 NUT

67 LIMITED BOLT

68 BEARING

69 WASHER

70 SPINDLE SOCKET

71 CIRCLIP FOR BEARING

72 PULLEY COVER TIP

73 FRONT AMERICAN TYPE SWITCH

74 CORD CLAMP

Repairs should be made by an authorized repair center.

Do not open or disassemble this power tool.Contact at

1-866-915-8626 for questions regarding this power tool.

PARTS LIST ANDSCHEMATIC DRAWING

!WARNING:

12

TOOL SHOP®

1-YEARLIMITEDWARRANTY:

This

TOOL SHOP®

brand power tool carries a 1-Year Limited Warranty to the

original purchaser. If the tool fails within one (1) year from the date of

purchase, simply bring this tool with your original sales receipt back to your

nearest

MENARDS

® retail store. At its discretion,

TOOL SHOP®

agrees to

have the tool replaced with the same or similar

TOOL SHOP®

product free of

charge, within the stated warranty period, when returned by the original

purchaser with original sales receipt. Notwithstanding the foregoing, this

limited warranty does not cover any damage that has resulted from abuse or

misuse of the Merchandise. This warranty: (1) excludes expendable parts

including but not limited to blades, belts, bits, light bulbs, and/or batteries; (2)

shall be void if this tool is used for commercial and/or rental purposes; and (3)

does not cover any losses, injuries to persons/property or costs. This

warranty does give you specific legal rights and you may have other rights,

which vary from state to state. Be careful, tools are dangerous if improperly

used or maintained. Seller’s employees are not qualified to advise you on the

use of this Merchandise. Any oral representation(s) made will not be binding

on seller or its employees. The rights under this limited warranty are to the

original purchaser of the Merchandise and may not be transferred to any

subsequent owner. This limited warranty is in lieu of all warranties,

expressed or implied including warranties or merchantability and fitness for a

particular purpose. Seller shall not be liable for any special, incidental, or

consequential damages. The sole exclusive remedy against the seller will be

for the replacement of any defects as provided herein, as long as the seller is

willing or able to replace this product or is willing to refund the purchase price

as provided above. For insurance purposes, seller is not allowed to

demonstrate any of these power tools for you.

For questions / comments, technical assistance or repair parts –

Please call toll free at: 1-866-915-8626

(M-F 8am – 5pm EST)

SAVE YOURRECEIPTS. THIS WARRANTY IS VOIDWITHOUT THEM.

8 IN. DRILL PRESS

13

Table of contents

Other Toolshop Power Tools manuals

Toolshop

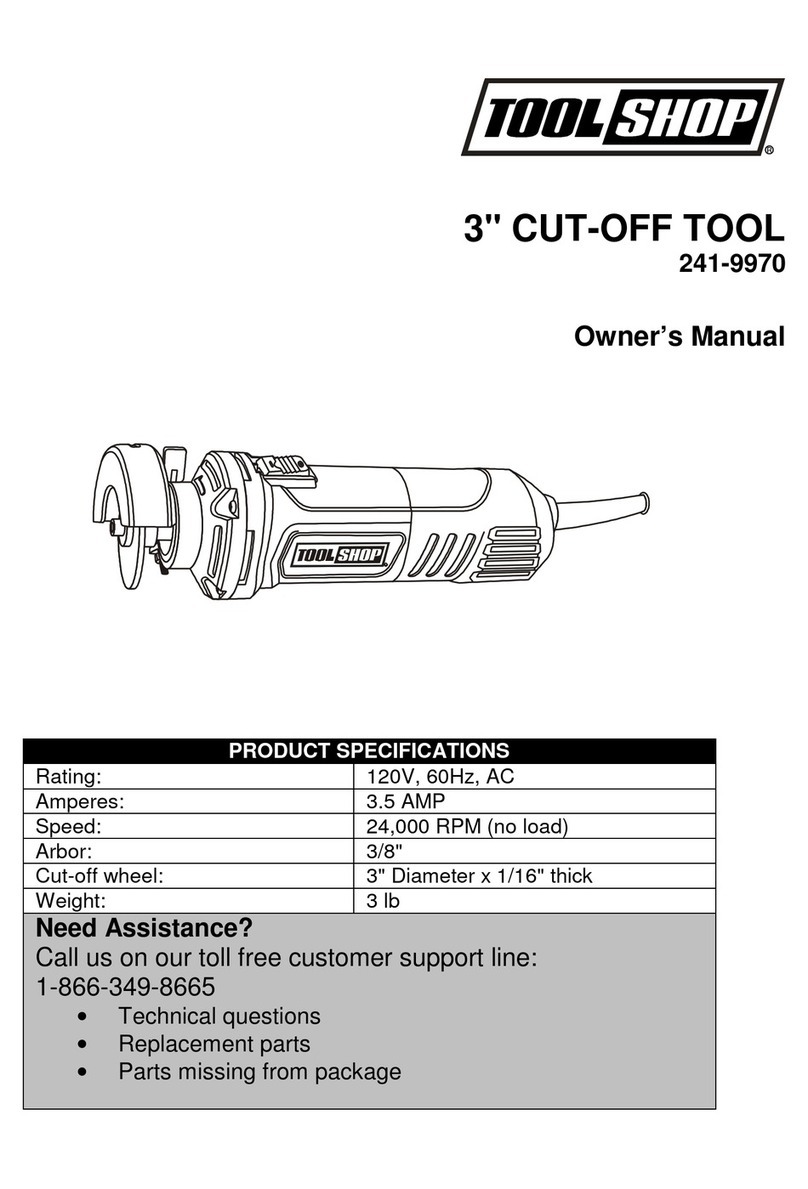

Toolshop 241-9970 User manual

Toolshop

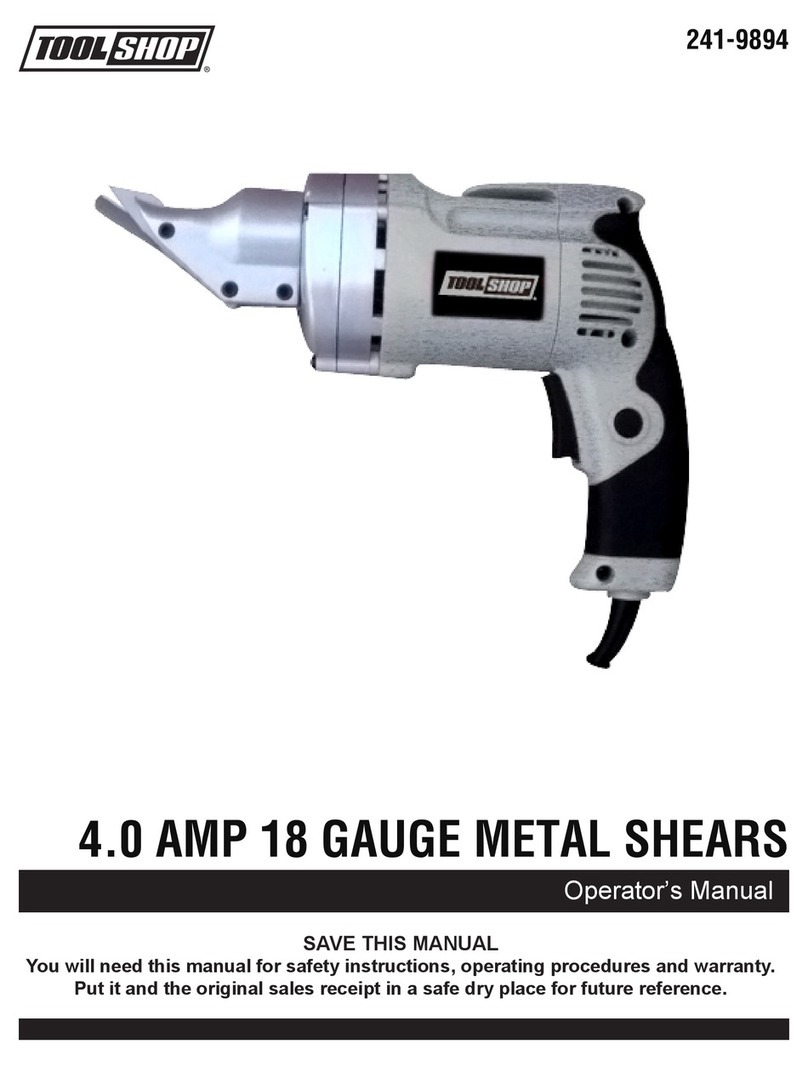

Toolshop 241-9894 User manual

Toolshop

Toolshop 241-9023 User manual

Toolshop

Toolshop 241-9*780 User manual

Toolshop

Toolshop 241-9778 User manual

Toolshop

Toolshop 241-9895 User manual

Toolshop

Toolshop 241-8502 User manual

Toolshop

Toolshop 207-4825 User manual

Toolshop

Toolshop 241-9834 User manual