Top Air TA1200 Installation and maintenance instructions

TA1200/1600

OPERATOR'S MANUAL

and

PARTS LIST

T-TANK SPRAYER

1200 & 1600 GALLON

1200 SPRAYER - 60'/80'/90' BOOMS

1600 SPRAYER - 80'/90'/110'/120'/132' BOOMS

401962

402061

2

Introduction

TABLE OF CONTENTS

SECTION II - OPERATION

PREPARING TRACTOR .............................. 2-2

PREPARING SPRAYER

Inspection ................................................ 2-2

Lubrication ............................................... 2-2

HITCHING TO TRACTOR

Drawbar Connection................................. 2-3

Transport Chain Connection .................... 2-4

Hydraulic Connections ............................ 2-4

Electrical Connections............................. 2-6

TRANSPORTING.......................................... 2-7

BOOM OPERATION

Unfolding Boom ....................................... 2-8

Folding Boom .......................................... 2-9

FILLING SPRAYER

Quick Fill ............................................... 2-10

Tank Mixing ........................................... 2-10

BASIC SPRAYER OPERATION

Initial Settings........................................ 2-11

Secondary Filter Monitoring .................. 2-11

SPRAY TANK RINSING

Rinsing - Complete System .................. 2-12

Rinsing - Boom Only ............................ 2-12

ELECTRICCOMMANDCENTER(Option) ..... 2-13

CHEMICAL INDUCTOR (Option)

Basic Operation..................................... 2-14

Chemical Container and Inductor

Tank Rinsing ........................................ 2-15

FOAM MARKER (Option)

Filling ..................................................... 2-16

Foam Collector Height........................... 2-16

Basic Operation..................................... 2-16

SECTION III - MAINTENANCE

LUBRICATION...............................................3-2

SPRAYER PUMP SET-UP

Load Sensing Closed-Center System ......3-3

Pressure-Compensating Closed-

Center System..........................................3-4

Open-Center System ................................3-4

Sprayer Pump Specifications ...................3-5

HYDRAULIC MANIFOLD SET-UP

Open-Center System ................................3-6

SECTION V - PARTS

Frame, Tongue, Hitch ................................. 5-2

Axle Mounting ............................................. 5-4

Axle Assembly ............................................ 5-5

Hub & Spindle............................................. 5-6

Wheels & Tires ........................................... 5-8

Mast .......................................................... 5-10

Lift Assembly, H-Frame ............................ 5-11

Frame Attachments................................... 5-12

Platform, Railings...................................... 5-14

Ladder, Railing .......................................... 5-16

Gauge Panel ............................................. 5-17

Main Tank ................................................. 5-18

Rinse Tank ................................................ 5-20

Sight Gauge .............................................. 5-22

Strainer...................................................... 5-23

Spray Pump .............................................. 5-24

1600 Spray System .................................. 5-26

1200 Spray System .................................. 5-27

Electric Controls (Option) ......................... 5-30

2-Point Hitch (Option) ............................... 5-32

Inductor Plumbing ..................................... 5-34

Inductor Mounting...................................... 5-36

Decals ....................................................... 5-38

Foam Marker............................................. 5-39

Spray Pump Breakdown ........................... 5-42

Load Sensing Closed-Center System ......3-6

AXLE ADJUSTMENT

Wheel Spacing Combinations ..................3-7

Adjustment Procedure ..............................3-8

WING ADJUSTMENTS

Inner Wing Adjustments ...........................3-9

Outer Wing Level Adjustment ............... 3-12

Wing Tilt Indicator Adjustment.............. 3-13

Wing Tip Breakaway Mechanism .......... 3-13

Twin Link Suspension Adjustment ........ 3-14

FILTERS

Self-Cleaning (Primary) Filter ................ 3-15

Secondary Filter .................................... 3-15

FOAM MARKER SYSTEM

Filter Maintenance ................................. 3-16

Power Box Plumbing Schematic........... 3-16

Foam Marker Winterization ................... 3-17

WINTERIZING SPRAYER.......................... 3-18

TROUBLESHOOTING ................................ 3-19

SCHEMATICS

Sprayer Chemical .................................. 3-20

Hydraulic................................................ 3-21

Electrical.................................................... 3-22

SPRAYER CALIBRATION

Calibrate tractor speed .......................... 3-25

Determine required nozzle size ............ 3-25

Verify nozzle flow .................................. 3-26

SECTION I - SAFETY

GENERAL HAZARD INFORMATION ............1-2

SAFETY DECALS ........................................1-3

GENERAL SAFETY INFORMATION ............1-4

CHEMICAL HAZARDS..................................1-4

SERVICE PLATFORM..................................1-5

ELECTRICAL SAFETY .................................1-5

CLEAN WATER TANK .................................1-5

BEFORE OPERATING OR SERVICING ......1-6

DURING OPERATION ..................................1-6

BEFORE TRANSPORTING ..........................1-7

DURING TRANSPORT..................................1-7

PRESSURIZED OIL ......................................1-8

SECTION IV - SET-UP

Boom Rest Initial Set-Up............................ 4-2

3

Introduction

INTRODUCTION

Product Identification

When ordering parts or when requesting further information or assistance, always give

the following information:

- Machine name

- Model number

- Serial number

Please fill out and retain this portion for your records. The serial number decal is located

at the left front corner of your grain cart.

Purchase date Model Serial no.'s

Dealer City

Dealer Contact Phone

NOTE: The information, specifications, and illustrations in the manual are on the

basis of information available at the time it was written. Due to continuing

improvements in the design and manufacture of Alliance/Top Air products, all

specificationsandinformationcontainedhereinaresubjectto changewithoutnotice.

Foreword

This symbol identifies important safety messages. When you see it, read the

message that follows and be alert to the possibility of personal injury.

Remember, safety instructions stated in this manual are for your protection. Read them

carefully and follow them closely when working around or using this machine.

Read andstudy thismanualcompletelybefore attemptingto operatethis implement. Take

this manual to the field for handy reference when operating, adjusting or servicing your

machine.

When referenced, "Right-Hand" (RH) and "Left-Hand" (LH) side of the machine are

determined by standing behind the machine and facing in the direction of travel.

4

Introduction

NOTES

1-1

Safety

SECTION I

SAFETY

GENERAL HAZARD INFORMATION ............... 1-2

SAFETY DECALS ............................................ 1-3

GENERAL SAFETY INFORMATION ................ 1-4

CHEMICAL HAZARDS..................................... 1-4

SERVICE PLATFORM ..................................... 1-5

ELECTRICAL SAFETY..................................... 1-5

CLEAN WATER TANK..................................... 1-5

BEFORE OPERATING OR SERVICING.......... 1-6

DURING OPERATION ...................................... 1-6

BEFORE TRANSPORTING .............................. 1-7

DURING TRANSPORT ..................................... 1-7

PRESSURIZED OIL.......................................... 1-8

1-2

Safety

Signal Words:

DANGER: Indicatesanimminentlyhazardoussituationthat,ifnot

avoided,willresultindeathorseriousinjury.

WARNING: Indicatesapotentiallyhazardoussituationthat,ifnot

avoided,couldresultindeathorseriousinjury.

CAUTION: Indicatesapotentiallyhazardoussituationthat,ifnot

avoided,mayresultinminorormoderateinjury.

GENERALHAZARD INFORMATION

Most accidents involving product operation, maintenance andrepair arecaused by failure to

observe basic safety rules or precautions. An accident can often be avoided by recognizing

potentiallyhazardous situations before an accident occurs. Aperson must be alert to poten-

tial hazards. This person should also have the necessary training,skills andtools to perform

thesefunctions properly.

REMEMBER:

THINK SAFETY

A CAREFUL OPERATOR IS THE

BEST INSURANCE AGAINST AN

ACCIDENT!

This symbol means

ATTENTION!

BECOMEALERT!

YOURSAFETYISINVOLVED!

Safety precautions and warnings are provided in this manual and on the product. If these

hazard warningsare notheeded, bodilyinjury or death couldoccurtoyou orother persons.

Thesehazardsare typicallyidentified bya "SAFETYALERTSYMBOL",followed bya "SIG-

NALWORD", such as "WARNING", as shown below:

Improper operation, maintenance or repair of this machine can be

dangerous and could result in injury or death. Do not operate or perform

any maintenance or repair on this machine until you have read and

understood all applicable safety, operation, maintenance, or repair

information.

1-3

Safety

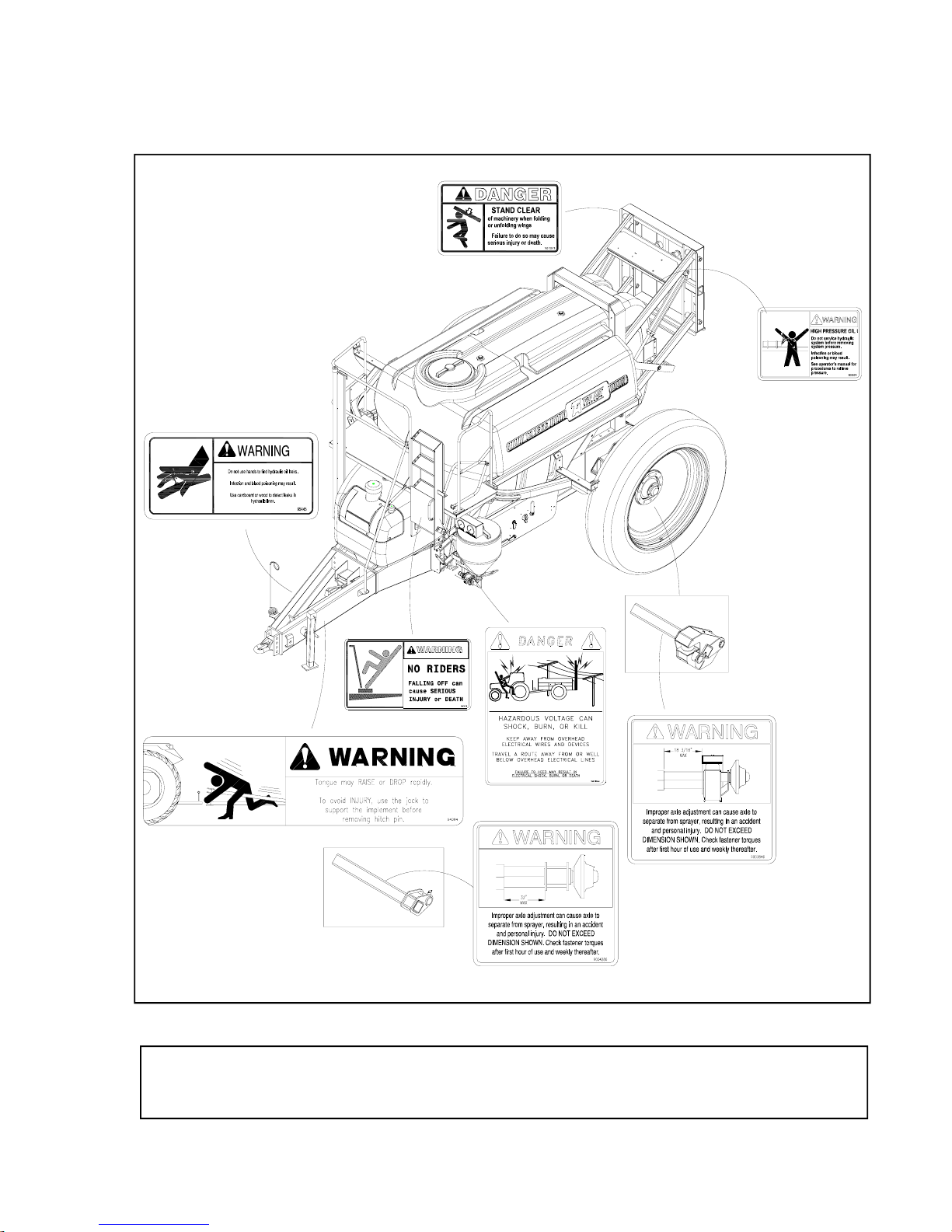

SAFETY DECALS

•401956

IMPORTANT

Replacelost,damaged, painted,orunreadabledecalsimmediately. If partsthathave decalsarereplaced,

also make sure to install new decals. These decals inform and remind the operator with operational

informationandsafetymessages.

•Revised011405

1-4

Safety

GENERALSAFETY

INFORMATION

•Donotallowchildrentoplayonor

near,andpreventinexperiencedor

unauthorizedpersonsfromoperating

thisequipment.

•Hitchsprayertoatractortostabilize

unitpriortofillingwithliquid,unfolding

boom orattachingand/orremoving

majorcomponents.

•Donotoperateequipmentuntilall

shields,coversandguardsare

installed.

•Keephands,feetandclothingaway

frommovingparts. Donotwear

loose-fittingclothes,astheymaycatch

onmovingparts.

•Inspectwhenfirstdeliveredand

regularlythereafterforanyloosebolts

and/orconnections.

•Donotstandbetweenthesprayerand

tractorwhenhitching. Alwaysengage

parkingbrakeandstopenginebefore

insertinghitchpin.

•Thissprayerisintendedtoonlyspray

agriculturalchemicals. Attemptingto

sprayotherliquidsmaycause

equipmentdamageandintroduce

unexpectedpersonalhazards.

CHEMICALHAZARDS

•Alwayswearpersonalprotective

equipmentwhenworkingwithornear

chemicals. Thisequipmentincludes,

butisnotlimitedto:protective

eyewear,gloves,shoes,socks,long-

sleevedshirtandlongpants.

Additionalprotectionmayberequired

formanytypesofchemicals.

•Spraytankmaycontainresidualtoxic

chemicals. DONOTENTERSPRAY

TANKFORANYREASONWITHOUT

WEARINGPROPERVENTILATING

EQUIPMENT. Failuretodo somay

resultinsuffocationanddeath.

•Seekandreceivechemicalproduct

trainingpriortousingagricultural

chemicals.

•Readandunderstandtheentirelabel

ofeverychemicalbeingappliedwith

thissprayer.

•Avoidbreathingspraymistorvapor.

•Washhandsbeforeeating,drinking,

chewinggum,orusingthetoilet.

•Removeclothingimmediatelyif

chemicalspenetrateclothingand

contactskin. Washthoroughlyandput

oncleanclothing.

•Disposeofunusedchemicalin

accordancewithchemicallabel

directionsandlocal/national

regulations.

1-5

Safety

SERVICEPLATFORM

•Mountanddismountthesprayeronly

wherestepsand/orhandholdsare

provided.

•Facethesprayerwhenmountingand

dismounting.

•Donotallowridersonsprayer.

•Inspect,andwhennecessary,clean

andhaverepairsmade tostepsand

handholdsbeforemountingand

dismounting.

•Maintainathree-pointcontact(two

feetand onehandoronefoot andtwo

hands)withthestepsandthe

handholds.

•Nevergetonoroffamovingsprayer.

•Neverjumpoffthesprayer.

•Donottrytoclimbonoroffthe

sprayerwhencarryingtoolsor

supplies.

ELECTRICALSAFETY

•Theelectricalsystemofthissprayer

is designed to operate on 12 volt DC

poweronly.

•Neveroperatethesprayerwitha

damagedelectricalcord. Disconnect

electrical power if a cord is damaged.

•Alwaysdisconnectpowerbefore

attemptinganyelectricalrepair.

•Disassemblyorattemptedrepairs, if

accomplishedincorrectly,cancreate

electricalshockand/orshorthazards.

Onlyqualifiedpersonnelshould

performrepairservice.

•Neverattempttobypass fuses. Do

notreplaceoriginalfuseswithhigher

amperagefuses. Ifafuserepeatedly

fails,ashorthazardmayexist.

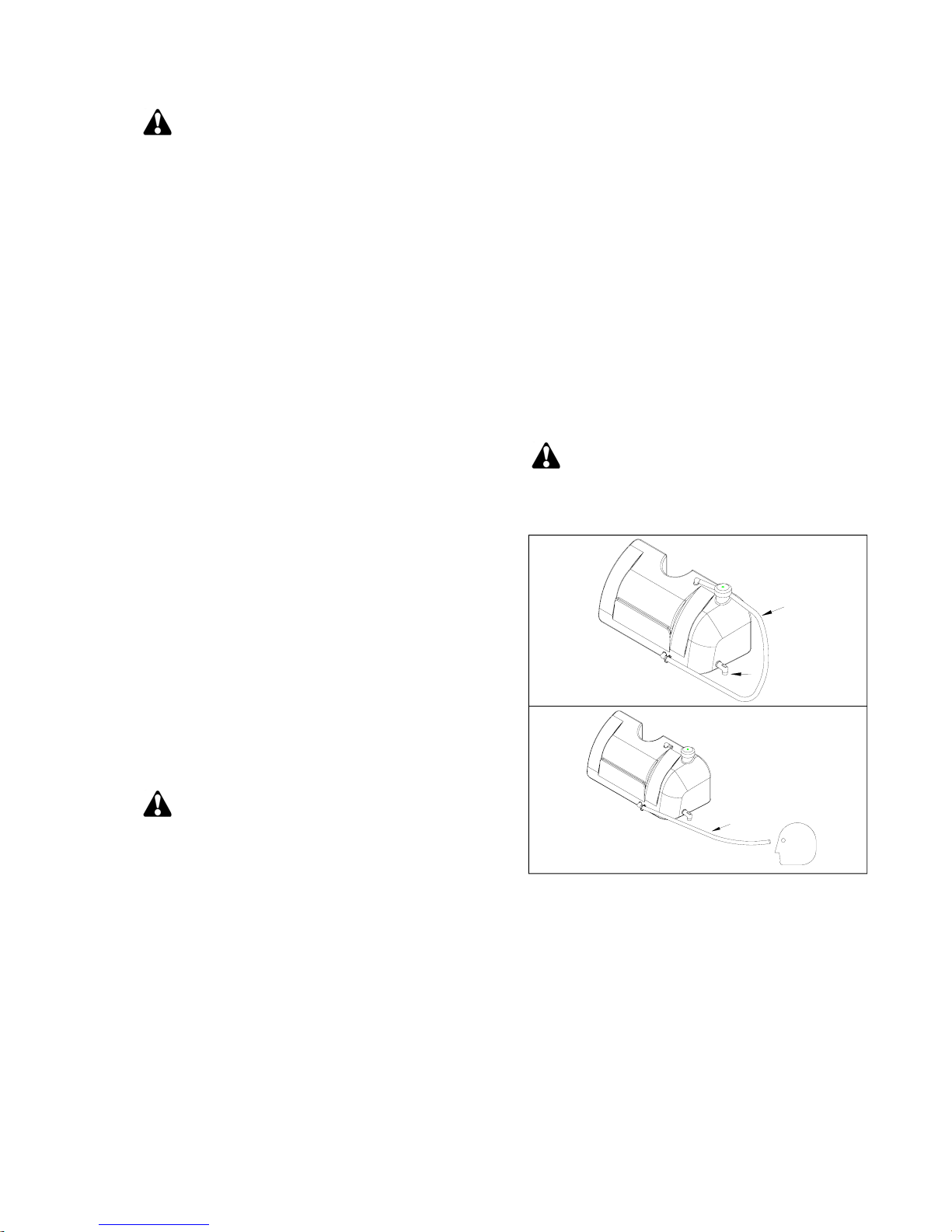

CLEAN WATER TANK

•Acleanwatertank isprovided as

standardequipment. Itisequipped

withaspigotforgeneralwashing,and

ahoseforemergencyeyewashing.

•Alwayskeepcleanwaterintank.

•Foremergencyeyewash,pullhoseoff

ofthetopfittingandflushaffected

area.

400935

HOSE

EYE WASH

EYE WASH

HOSE

SPIGOT

1-6

Safety

BEFOREOPERATING

OR SERVICING

•Securedrawbarpinwithalocking

deviceandlocktractordrawbarin

centeredposition. Ensurethatthe

tractordrawbarhassufficientstrength

tosupportboththedraftandvertical

tongueloadofafully-loadedsprayer.

•Lowerorsecurelyblockupelevated

componentsbeforeservicingorwhen

leavingtheequipment. Neverwork

underanimplementunlessitis

securelysupported.

•Turntractorpoweroffandremovekey

fromignitionbeforeservicingor

adjustingequipment.

•Whenoperatingsprayersonsidehill

conditions,itisrecommendedthatthe

wheel spacing be set as wide as

possibleforstability.

•Verifythatallguardsandshieldsare

inplace.

•Hitchsprayertotractorand clearall

personnelfromthesurroundingarea

beforefoldingandunfoldingwings.

•Become aware ofand avoid all

obstaclesandhazardsinthepathof

theequipment,suchaspowerlines,

ditches,etc.

•Residualpressuremayexistin

sprayerplumbingevenwhenunitis

notinuse. Removepressurebefore

servicinganyplumbing.

•Ensurethatallapplicablesafety

decalsareinstalledandlegible.

DURINGOPERATION

•Donotallowanyonetorideonthe

equipment. Neverdismountfroma

movingtractor. Severeinjuryordeath

canoccurfrombeingrunoverbythe

implement.

•Regulatespeedtofieldconditions.

Maintaincompletecontrolatalltimes.

•Neverlubricateequipmentwhenin

operation.

•Become awareoftheoperating width

ofthisimplement. Useextremecare

whenoperatingclosetoditches,

fences,powerlines,oronhillsides.

•Donotleaveequipmentunattended

withenginerunning.

1-7

Safety

BEFORE

TRANSPORTING

•Thissprayerisnotequippedwith

brakes. Ensurethatthetowingvehicle

hasadequateweightandbraking

capacitytotowthisimplement.

•Securetransportchaintotractorchain

supportbeforetransporting. Adjust

thechainlengthasnecessaryto

eliminateexcessiveslack,while

preventingbindingduringtightturns.

•Verifythatallappropriatelightingand

reflectorsareinstalledandcomply

withstateandlocallawsgoverning

highwaysafety.

DURINGTRANSPORT

•Usegoodjudgmentwhentransporting

equipmentonhighways. Regulate

speedtoroadconditionsand

maintaincompletecontrol.

•Maximumspeedofsprayershould

neverexceed25mph.

•Itisprobablethatthisimplementis

taller,widerandlongerthanthetowing

vehicle. Becomeawareof andavoid

allobstaclesandhazardsinthetravel

pathoftheequipment,suchaspower

lines,ditches,etc.

•Slowdownbeforemakingsharpturns

toavoidtipping. Driveslowlyover

roughgroundandsideslopes.

•Useexceptionalcarewhenoperating

sprayerequippedwithsingletiresand

setatnarrowwheelspacing. The

possibilityoftippingoverduringturns

ortravelonroughroadsisincreased

undertheseconditions

1-8

Safety

PRESSURIZEDOIL

•Alwaysuse a boardor cardboard

whencheckingforapressurizedoil

leak. Escapingfluidunderpressure,

evenapinhole-sizedleak,can

penetrateskin,causingseriousinjury,

andpossibledeath. Iffluidisinjected

intoyourskin,itmustbetreated

immediatelybyadoctorfamiliarwith

thistypeofinjury.

•Neverloosenorremoveanyhydraulic

fittingwithoutfirstverifyingthatallfluid

pressurehasbeenrelieved. Failure

todosomayresultinunintended

movementofalloraportionofthe

equipment,possiblycausingsevere

injuryordeathduetocrushingor

cutting. Injurymayalsooccurfrom

contactwithoilunderpressurethat

mayescapeduringfittingremoval.

• Accumulatorsusedinthis hydraulic

systemcanretainfluidunderpressure

evenaftertractorhydraulicvalveis

placedinFLOAT. Removeresidual

pressurefromwingtiltandmainlift

accumulatorsbyholdingwingtiltand

mainliftswitchesinDOWNposition

foratleast20secondsaftercylinders

havestoppedmoving.

•Safelyrelieveallfluidpressurefrom

hydraulichosesbeforedisconnecting

hydrauliccouplingsfromtractor.

•Donotbendorstrikehigh-pressure

lines. Donotinstall bentordamaged

tubesorhoses.

•Checkhydraulichosesandtubes

carefully. Replacecomponentsas

necessaryifanyofthefollowing

conditionsarefound:

-Endfittingsdamagedorleaking.

-Outercoveringchafedorcutand

wirereinforcingexposed.

-Outercoveringballooninglocally.

-Evidenceofkinkingorcrushingof

theflexiblepartofahose.

-Armoringembeddedintheouter

cover.

-Endfittingsdisplaced.

•Repair all oil leaks. Leaks can cause

fires,personalinjury,and

environmentaldamage.

•Routehosesandlinescarefullyto

preventprematurefailuredueto

kinkingandrubbingagainstother

parts. Makesurethatall clamps,

guardsandshieldsareinstalled

correctly.

•Revised011405

2-1

Operation

SECTION II

OPERATION

PREPARING TRACTOR.......................................... 2-2

PREPARING SPRAYER

Inspection............................................................ 2-2

Lubrication .......................................................... 2-2

HITCHING TO TRACTOR

Drawbar Connection........................................... 2-3

Transport Chain Connection............................... 2-4

Hydraulic Connections........................................ 2-4

Electrical Connections ........................................ 2-6

TRANSPORTING...................................................... 2-7

BOOM OPERATION ................................................ 2-8

Unfolding Boom.................................................. 2-8

Folding Boom ..................................................... 2-9

FILLING SPRAYER

Quick Fill........................................................... 2-10

Tank Mixing ...................................................... 2-10

BASIC SPRAYER OPERATION

Initial Settings ................................................... 2-11

Secondary Filter Monitoring ............................. 2-11

SPRAY TANK RINSING

Rinsing - Complete System ............................. 2-12

Rinsing - Boom Only ........................................ 2-12

ELECTRIC COMMAND CENTER (OPTION) ........ 2-13

CHEMICAL INDUCTOR (OPTION)

Basic Operation................................................ 2-14

Chemical Container & Tank Rinsing................ 2-15

FOAM MARKER (OPTION)

Filling ................................................................ 2-16

Foam Collector Height ..................................... 2-16

Basic Operation................................................ 2-16

2-2

Operation

Before operatingsprayer, readthe tractor

operator’smanual andgainan

understanding of its safe methods of

operation.

Check the tractor brakes and warning

lights. Make sure they are in proper

working order.

Check the tractor hydraulic oil reservoir

and add oil if needed.

Verify that the tractor is adequately

ballasted for drawbar operation at the

anticipateddraftand verticaltongue load.

Vertical tongue loadof aloaded sprayer

(with boomsfolded totransport position)

isapproximately 5000lbs. Ensure that

thetractor’sdrawbarhassufficient

strength to support thisload.

Ifpossible,adjustthetractordrawbar

verticallyso thetop sideof thedrawbar is

atleast 18inchesfromtheground.

Alternately, the sprayer hitch may be

adjusted vertically by choosing other

mounting holes provided.

Onsprayersequippedwithadrawbar-

stylehitch,raiseandsecurealltractor3-

point hitchlinkage to prevent interference

with the implement tongue and hydraulic

hosesduringturning.

Extratractorballast may berequired for

usewithsprayers equippedwith2-point

style hitch option. Shim or adjust tractor

3-point hitchto remove all sidesway prior

tooperation.

•Inspection

Performtheservicechecksasoutlined

below. Repair or replace any damaged

orworn parts before operating.

Boom Rest Set-up: Refer to page 4-2

for initialboomrestset-up procedures.

Hardware: Check for loose bolts and

nuts, and tighten as needed. Check

again after the first half-day of operation.

Pivot Pins: Check that all pins are in

place and in good condition. Replace

any worn, damaged, or missing pins.

Hydraulic System: Check all hoses and

cylinders for signs of leakage. Hoses

should not be kinked, twisted or rubbing

againstsharpedges. Rerouteor repair

hoses as necessary. Refer to SAFETY

section for additional information on

safe repair and inspection of hydraulic

components.

Tires/Wheels: Check tire pressures and

maintain at recommended values listed

in the MAINTENANCE section of this

manual. Maintain 500 lb-ft. torque for

the 7/8" wheel lug bolts.

CAUTION: Frequentlycheck the

torque ofall wheel lug nuts, particularly

during the initial transport and operation

ofthisimplement. Ifa lugboltorstud

becomes loose,this mayresult inthe loss

of a wheel and subsequent loss of control

ofthe tractor and/or sprayer.

PREPARING TRACTOR PREPARING SPRAYER

•Lubrication

Lubricate the sprayer as outlined in the

MAINTENANCE SECTION of this

manual.

•Revised011405

2-3

Operation

WARNING: Do not stand between

the implement and tractor when

hitching. Serious or fatal injury can

occur due to crushing hazard from

limited clearance between tractor and

implement. Always engage parking

brake and stop engine before inserting

hitch pin.

Connect the drawbar hitch only to the

tractordrawbar. Donotattemptto hitchto

any other location on the tractor.

Thesprayer isequipped standardwith a

clevishitch,whichrequiresa1 ¼”

drawbar pin. This hitch can be converted

to a single tang style by unbolting and

removingtheclevis. Whenusedasa

singletang style,a 1½” diameter

drawbarpin mustbe used.

NOTE: The useof a smaller diameter

hitchpin will result in additional clearance

between the implement hitch and pin.

Thisadditional clearancemay cause

acceleratedpin andhitch wear,alongwith

morepronouncedjoltingfromthesprayer

duringoperation.

Afterinserting drawbar pin, secure with a

locking device to helpprevent uncoupling

during use.

•2-Point Hitch (Optional)

Theoptional 2-pointhitchis compatible

with Cat III-N, CATIII andCATIV-N

hitches. Verifyhitchpinsize compatibility

priorto hitching.

After couplingto tractor,raisesprayer

tonguehigh enough to allowhitch stands

to beremoved. Reinsertstandsinto the

topof thereceiver tubesfor storage

duringsprayeruse. Maintainthetractor

hitch at aheight that allows the sprayer to

bereasonablylevel.

CAUTION: If a 3-point hitch quick-

couplerisused,alwaysverify thatthepin

retaining latches are fully engaged before

moving sprayer. Failureto dosocould

result inlossofsprayercontroldueto

hitchuncoupling.

401931

HITCHING TO TRACTOR

•Drawbar Connection

Verify and/or adjust the sprayer hitch

height before coupling to the tractor. The

sprayer hitch isadjusted by unbolting the

hitch and reinstalling in a different set of

holes provided.

NOTE: Thesprayermustbe relatively

level inorder forthetankvolume indicator

toreadaccurately.

•Revised011405

401931

Stands

Receiver Tubes

2-4

Operation

NOTE: The sprayer pumpis hydraulically

driven, and needs tobe configured

correctly to match the type of hydraulic

systemon thetractor(closedcenter, open

center,loadsensing,etc.). Failureto

configure the pumpcorrectly may

permanentlydamage the pump through

over-speeding. Refertothe

MAINTENANCE SECTION of this

manual for guidelines on configuring the

sprayer pump.

Connecthoses fromthe sprayerpump to

a tractorselective controlvalve (SCV)

circuit. The pump inlet (marked PUMP

PRESSURE) should be connected to

the RETRACT port and the pump outlet

(marked PUMP RETURN) to a low

pressure return port at the tractor

(recommended) orto theEXTENDport.

•Revised011405

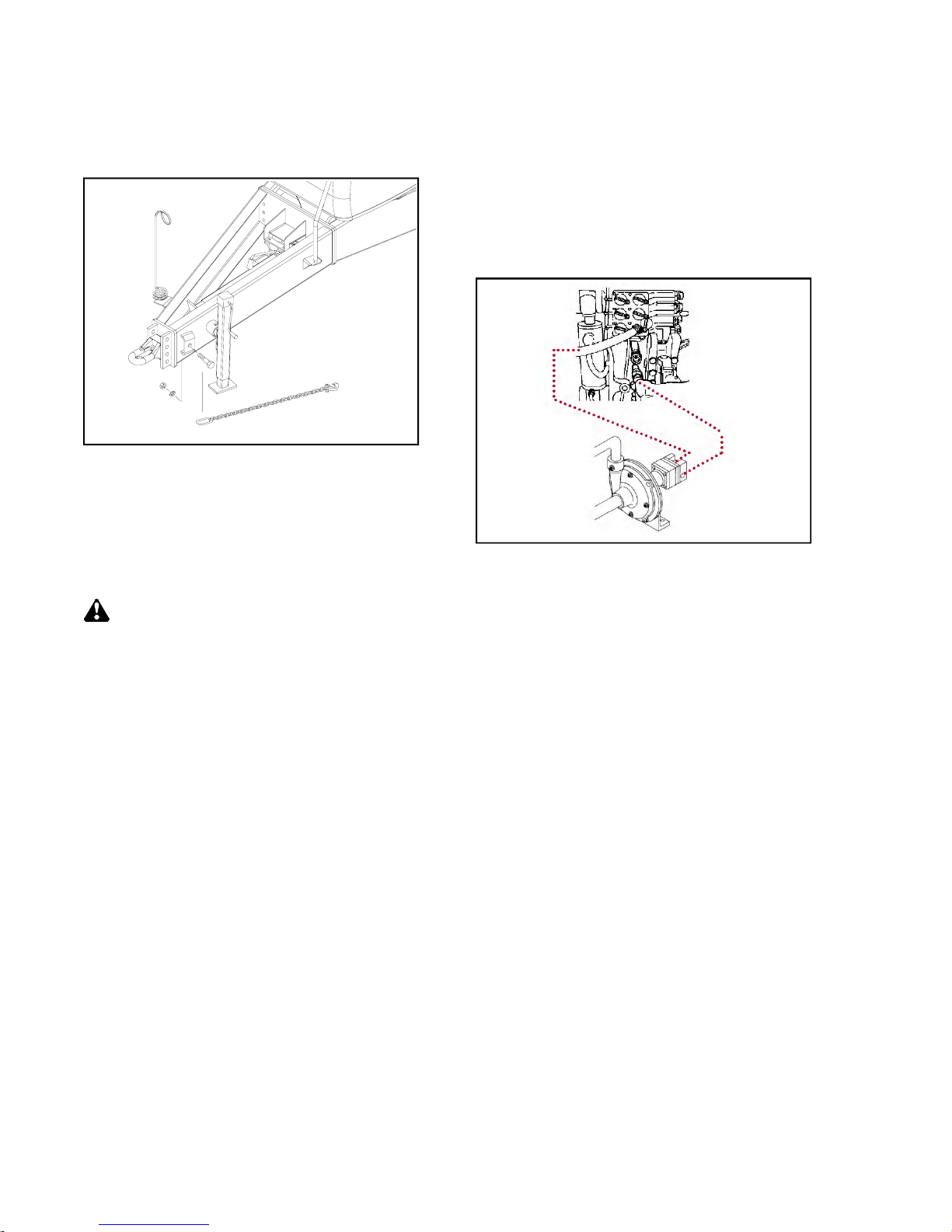

•Transport Chain Connection

(Drawbar Style Hitch Only)

Tractor must be equipped with a

transport chain support. Attach chain in

manner illustrated. Adjust the chain

length as necessary to eliminate

excessive slack, while preventing

binding during tight turns.

CAUTION: Always use a properly-

sizedtransportchain between sprayer

andtractor. Failuretousetransportchain

could result in personal injury or property

damage ifimplement andtractor become

disengagedduringoperation.

401930

•Hydraulic Connections

After cleaning hydraulic hose couplers,

connect to tractor hydraulic circuits as

follows:

Sprayer Pump Hydraulics

2-5

Operation

hydraulic circuit. When the circuit is

energized, oil will circulate constantly

through the sprayer hydraulic valve.

Because of this, it is important to

minimize the flow through this circuit.

Adjust the tractor SCV flow control to

the lowest setting that still allows the

boom functions to operate at an

acceptable speed. Doing so will keep

any oil heating to a minimum, and allow

other SCV circuits to operate normally.

Note: Ifthe SCVcontrol leverkicksout

prior to actuating any switch on the

boom control box, the most likely reason

is excessive hydraulic pressure. Try

reducing the tractor’s flow control

setting. Also, excessive pressure can

also occur if the hydraulic valve has

been modified for use with power

beyond systems. In thisinstance, attach

to the three power beyond couplers on the

tractor, or change thehydraulic valve

attachtothethreepowerbeyondcouplers

onthe tractor, or changethe hydraulic

valve setupfor usewithan SCV circuit.

Refer tothe MAINTENANCESECTION

for valvesetup information.

Toprotectthesprayerpumpfrom

damage due to excessive speed, adjust

circuit flow to minimum setting prior to

operating circuit for the first time. When

in operation, adjust flow per instructions

listed under the “Basic Sprayer Settings”

heading in this section.

IMPORTANT: Never operate sprayer

pump dry, or with PUMP INLET

SELECTOR valve closed. Pump

damage may result.

Boom Hydraulics

CAUTION: Do not unfold or fold

boom withouthitching tothe tractor.

Thewing-foldhydraulicsystemonthis

sprayeris configuredto connectto a

tractorSCV valve,but canalsobe

modified tooperate with power beyond

circuitsoftractorswitha load-sensing

hydraulic system(Referto the

MAINTENANCE SECTION for

information onconvertingtoa power

beyond circuit).

Connect the hose marked BOOM

PRESSURE to the EXTEND port of one

of thetractor SCVcircuits, andthe hose

marked BOOM RETURN to the

RETRACT portofthesamecircuit.

802967

Placethetractor SCVcontrol leverin the

EXTENDposition toenergize the

2-6

Operation

•Electrical connections

Thisimplement isequipped witha 7-pin

SAEconnectorplug,whichwill connect

withthereceptaclefoundonmostnew

tractors on the market today. If your

tractordoesnothavethistypeof

receptacle, an SAE J-S60A 7-pin socket

canbe purchasedfromyourTopAir

dealer (Partnumber 92824).

Thewiringschematicforthissprayer

complies withANSI/ASAE Standard

S279/SAE J137. Although most new

tractorsconformtothisstandard,many

older tractors (notably John Deere) can

have aslightlydifferentelectrical function

thanstandard. Becauseofthis,always

verify correct electrical function before

using this sprayer. Awiringschematic is

provided inthe MAINTENANCE

SECTION of this manual.

•Revised011405

Beforedisconnectinghosesfromthe

tractor,relievepressurefromthelinesby

placing the circuit in “float” while the

tractor engine is running. Shutoff engine

andapply parkingbrake before

disconnecting hoses.

NOTE: Accumulatorsusedinthishy-

draulic systemcan retain fluid under

pressure evenafter tractor hydraulic valve

is placed inFLOAT. Remove residual

pressure fromwing tiltandmainlift accu-

mulatorsbyholdingwingtiltandmainlift

switches inDOWN positionfor atleast 20

seconds after cylindershave stopped

moving.

NOTE: Afterinitial set-upor replacement

of any hydraulic component onthe

sprayer,air mustbe removedfromthe

wing-fold hydraulic systempriortoitsfirst

use. Failureto doso mayresultin

damage toboomcomponents due to

rapidmovement.

•Hydraulic Connections

(cont.)

2-7

Operation

WARNING: Use exceptional care

when operating sprayer equipped

with single tires and set at narrow

wheel spacing. The possibility of

tipping over during turns or travel on

rough roads is increased under these

conditions.

Usegoodjudgmentwhentransporting

equipmentonhighways. Regulatespeed

toroadconditionsandmaintain complete

control.

Itisprobablethatthisimplementistaller,

wider and longer than the towing tractor.

Become aware ofand avoid all obstacles

and hazards in thetravel path of the

equipment,suchas powerlines,ditches,

etc.

Slowdown beforemaking sharpturnsto

avoid tipping. Drive slowly over rough

ground and side slopes.

401962

TRANSPORTING

CAUTION: This implement is not

equipped with brakes. Ensure that the

towing vehicle has adequate weight and

brakingcapacityto towthis implement.

NOTE: It isstronglyrecommendedtouse

the 120”wheel spacing while running

single tires.

Asa guideline,thetowingvehicleshould

besizedsuchthat the loadedsprayer

does notweigh over1.5 times the towing

vehicle weight. Maximumspeedof

sprayershouldnotexceed25m.p.h..

Secure drawbar pin with a locking

device and lock tractor drawbar in

centered position.

Secure safety chain to tractor chain

support before transporting.

2-8

Operation

BOOM OPERATION

WARNING: Keep all personnel a

safe distance away from the sprayer

when unfolding or folding the boom.

Personal injury can result from

impact with boom.

WARNING: Perform boom

unfolding and folding operations only

in areas with adequate height, width

and length clearances. In particular,

be mindful of location of overhead

power lines. Failure to do so can

result in personal injury and property

damage.

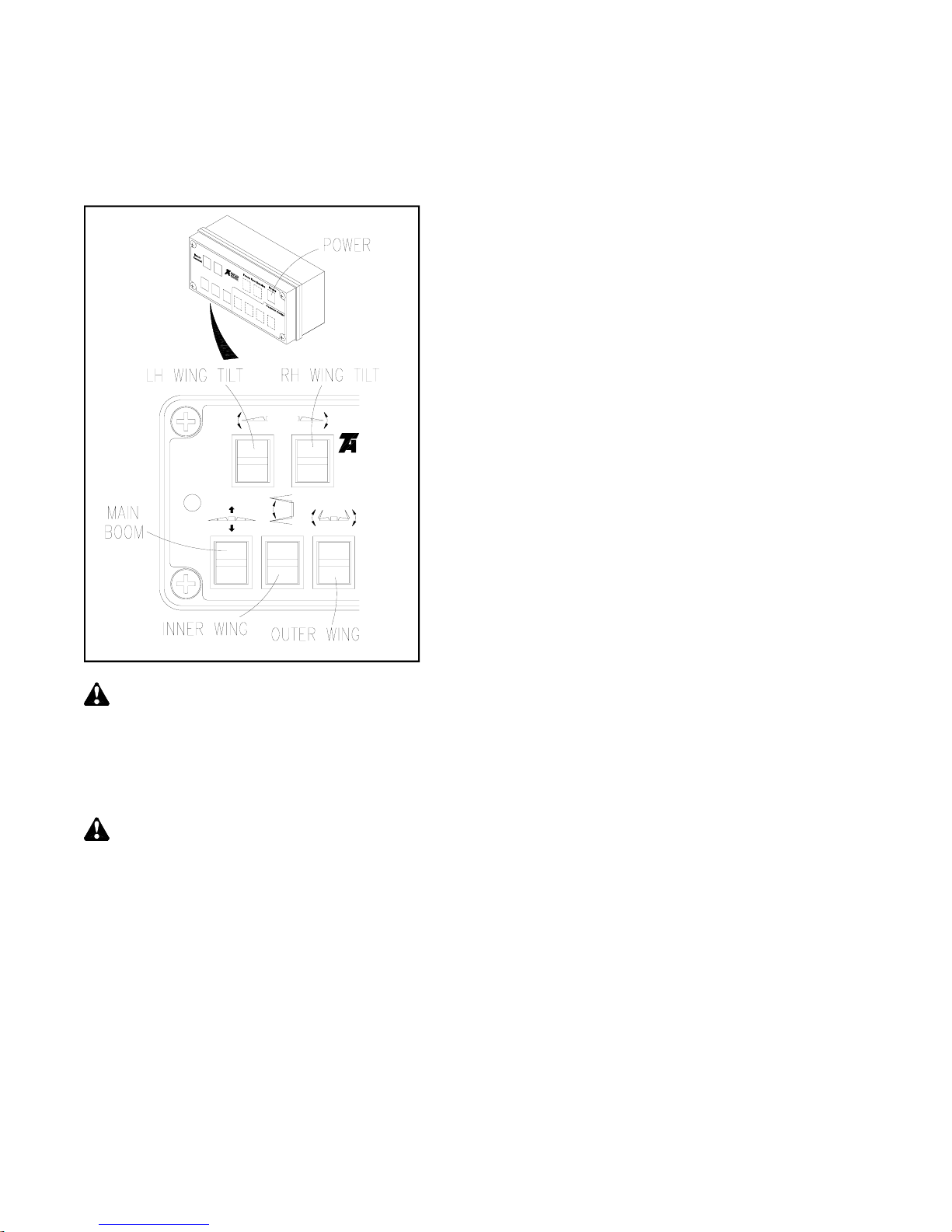

1. Press top of ON/OFF switch to turn

power on. (Red LED lamp on rocker

switch should illuminate. Green LED

lamp is provided to indicate circuit

continuity whenever any other switch

is pressed.)

2. Press and hold MAIN BOOM switch

in <RAISE> position until boom is

fully raised. This ensures that the

transport latch is not supporting the

weight of the boom.

3. Press and hold RH WING TILT and

LH WING TILT switches in <UP>

position until wings are fully tilted

upward. Note: Wing tilt function

may require several seconds of use

before wings begin to move.

4. Press and hold INNER WING switch

in <EXTEND> position until wings

are fully extended and wing locks are

engaged on lock pins.

5. Momentarily press WING TILT

switches either <UP> or <DOWN>

as required to approximately level

the wings horizontally.

6. Press and hold OUTER WING

switch in <EXTEND> position until

outer wings are fully extended.

7. Momentarily press WING TILT

switches either <UP> or <DOWN>

as required to level the wings

horizontally. (Observe the tilt

indicators located near the tilt

cylinders to assist with leveling the

wings.)

8. Press and hold MAIN BOOM switch

in <LOWER> position until boom is

at desired spray height.

IMPORTANT: Never unfold the unit

withoutattachingtotractorfirst. For

properboomsuspensionoperation,do

notoperateboomin thefullylowered

position. Theminimumsprayheightis

attained by lowering the boomfully, then

raisingit approximately 4 inches to permit

adequatesuspensiontravel.

401965

BOOM

CONTROL

RETRACT

EXTEND

RETRACT

EXTEND

•Unfolding Boom

•Revised011405

This manual suits for next models

1

Table of contents