5

SETUP

INSPECTION

• Inspect the shipping carton for signs of damage. It is your responsibility to report damage to the

transport company. Uni-ram Corporation does not accept responsibility for shipping damage

once the machine has left our warehouse. Keep the packaging materials until you are sure the

machine has not been damaged during shipping.

• Remove the machine from the carton by opening the bottom flaps and sliding the carton up over

the machine.

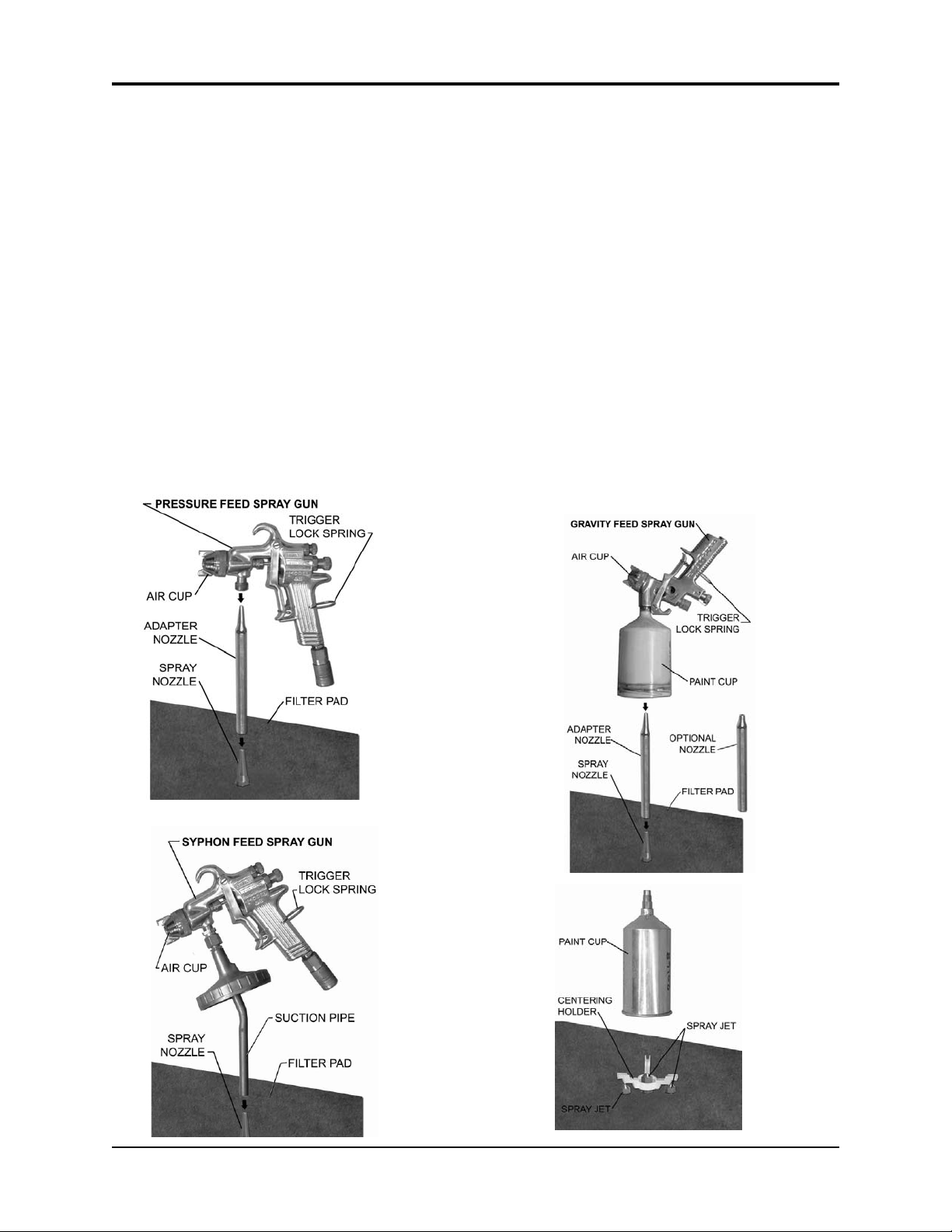

• Make sure the bag of accessories contains the following:

• Manual

• Trigger Lock Springs, 3 pieces (Part No. 120-350, Pkg of 3)

• Air Inlet Cap, 3 pieces (Part No. 100-611)

• Moisture Filter (Part No. 10-220)

• Nozzle Adapters, 1 each of 2 kinds (Part No. 110-430 and 110-430L1P)

(Part number for optional mini adapter is 110-430MJP)

If any item is missing, contact your supplier.

LOCATION

Position in a well-ventilated area away from sparks, heat and open flames.

LEVELING, VENT AND AIR SUPPLY

• Level the machine using the adjustable legs.

• Attach a vent hose (not supplied) to the vent outlet on top of the

machine. The duct system must not be under continuous vacuum.

• Remove the cover on the "Air Input" (right side of machine) and

screw in the Air Filter Assembly.

• Attach an air supply adapter (not supplied) to Air Filter.

The air supply pressure must be at least 85 PSI and

the air must be free from contaminants such as water, dust, rust, tar,

grease etc.

To prevent damage to the Diaphragm Pump an internal Air Pressure

Regulator has been installed to limit the air pressure to precisely 85 PSI. Do not install a sec-

ond air pressure regulator or use a pressure set below 85 PSI.

See the section, Daily Maintenance, for proper maintenance of the Air Filter Assembly.

MANUAL - SPRAY GUN CLEANERS - UG1000-3000 SERIES