The TAURUS is classified as a class 3R Laser Product according to IEC Standard Publication

60825-1 Ed.2.0: 2007 and United States Government Code of Federal Regulation FDA CDRH

21CFR Part1040.10 and 1040.11 (Complies with FDA performance standards for laser products

except for deviations pursuant to Laser Notice No.50, dated June 24, 2007.)

CWARNING

• Use of controls or adjustments or performance of procedures other than those specified herein may

result in hazardous radiation exposure.

• Follow the safety instructions on the labels attached to the instrument as well as in this manual to

ensure safe use of this laser product.

• Never intentionally point the laser beam at another person. The laser beam is injurious to the eyes

and skin.

• The laser beam is emitted when the power is turned ON. Before turning the power on, make sure

that persons are not located in the path of the laser beam.

• Secure the instrument in a fixed position before it is used. If it is necessary to hold the instrument by

hand, make sure that persons are not located in the area before the laser is emitted.

• Do not look directly into the laser beam. Doing so could cause permanent eye damage.

• Do not stare at the laser beam. Doing so could cause permanent eye damage.

• Never look at the laser beam through a telescope, binoculars or other optical instruments. Doing so

could cause permanent eye damage.

CCAUTION

• Perform checks at start of work and periodic checks and adjustments with the laser beam emitted

under normal conditions.

• When the instrument is not being used, turn off the power.

• When disposing of the instrument, destroy the battery connector so that the laser beam cannot be

emitted.

• Operate the instrument with due caution to avoid injuries that may be caused by the laser beam

unintentionally striking a person in the eye. Avoid setting the instrument at heights at which the path

of the laser may strike pedestrians or drivers at head height.

• Never point the laser beam at mirrors, windows or surfaces that are highly reflective. The reflected

laser beam could cause serious injury.

• Only those who have received training as per the following items shall use this product.

- Read the Operator's manual for usage procedures for this product.

- Hazardous protection procedures (read this chapter)

- Requisite protective gear (read this chapter)

- Accident reporting procedures (stipulate procedures beforehand for transporting the injured and

contacting physicians in case there are laser-induced injuries). "

• Persons working within the range of the laser beam are advised to wear eye protection which

corresponds to the laser wavelength of the instrument being used.

• Areas in which the laser is used should be posted with a standard laser warning sign.

Laser beam emitted

from here

1

8

15

14

9

10

11

12

2

3

5

7

6

4

16

17

13

18

REPLACING THE BATTERIES

Rotating laser

1Turn the battery cover knob to OPEN and remove the battery cover.

2Pull out the slide board and remove the batteries.

3Insert new batteries as shown by the illustration on the battery cover.

4Replace the battery cover to its original position and turn the battery cover knob to LOCK.

G

• Always replace all 4 batteries at the same time. Do not use a combination of old and new batter-

ies.

• Alkaline batteries are recommended for use with the instrument. (Batteries included upon ship-

ment are for confirmation of operation by the user.) Commercially-available manganese, Ni-CD

and Ni-MH batteries may be used but the operating time will differ to that for alkaline batteries.

• Battery performance generally deteriorates temporarily at low temperatures.However, returning

to room temperature restores normal performance.

LS-1

1Open the battery cover at the back side of level sensor.

2Take out the batteries and replace with new ones (6F22 battery x 1).

3Insert cover tabs in grooves, press the cover down and click to close.

・Please read this operator's manual carefully before using this product.

・Verify that all equipment is included.

C"STANDARD EQUIPMENT"

・The specifications and general appearance of the instrument, and the content of this man-

ual are subject to change without notice.

・Some of the diagrams shown in this manual may be simplified for easier understanding.

Definition of Indication

Definition of Symbols

XGeneral

CWARNING Ignoring this indication and making an operation error could possibly result in

death or serious injury to the operator.

CCAUTION Ignoring this indication and making an operation error could possibly result in

minor injury or property damage.

JThis symbol indicates items for which caution (hazard warnings inclusive) is

urged. Specific details are printed in or near the symbol.

DThis symbol indicates items which are prohibited. Specific details are printed in

or near the symbol.

IThis symbol indicates items which must always be performed. Specific details

are printed in or near the symbol.

CWARNING

DDo not use the unit in areas exposed to high amounts of dust or ash, in areas where

there is inadequate ventilation, or near combustible materials. An explosion could oc-

cur.

GDo not perform disassembly or rebuilding. Fire, electric shock, burns or hazardous ra-

diation exposure could result.

EWhen securing the instrument in the carrying case make sure that all catches,

including the side catches, are closed. Failure to do so could result in the instrument

falling out while being carried, causing injury.

CCAUTION

DDo not use the carrying case as a footstool. The case is slippery and unstable so a

person could slip and fall off it.

DDo not place the instrument in a case with a damaged catch or handle. The case or

instrument could be dropped and cause injury.

XTripod

XPower Supply

PRECAUTIONS

Before starting work or during operation, check that the instrument is functioning correctly and per-

formance is normal.

TAURUS should be used with the level sensor (LS-1), a standard equipment. We do not guarantee

precision noted in this instruction manual when used with other level sensors.

STORAGE PRECAUTIONS

Always clean the instrument after use.

Use a clean cloth moistened with neutral detergent or water.

Never use an abrasive cleaner, ether, thinner, benzene, or other solvents.

Always make sure the instrument is completely dry before storing. Dry any moisture with a soft,

clean cloth.

PRECAUTIONS REGARDING LONG-TERM STORAGE

Remove batteries before storing when the instrument will not be used for periods on 1 month or

more.Batteries may leak fluid when left inside the insturment causing malfunction.

CCAUTION

EWhen mounting the instrument to the tripod, tighten the centering screw securely. Fail-

ure to tighten the screw properly could result in the instrument falling off the tripod,

causing injury.

ETighten securely the leg fixing screws of the tripod on which the instrument is mounted.

Failure to tighten the screws could result in the tripod collapsing, causing injury.

DDo not carry the tripod with the tripod shoes pointed at other persons. A person could

be injured if struck by the tripod shoes.

EKeep hands and feet away from the tripod shoes when fixing the tripod in the ground.

A hand or foot stab wound could result.

ETighten the leg fixing screws securely before carrying the tripod. Failure to tighten the

screws could lead to the tripod legs extending, causing injury.

CWARNING

DDo not use voltage other than the specified power supply voltage. Fire or electrical

shock could result.

DDo not use batteries if the contacts are wet. Resultant shorting could lead to fire or

burns.

DDo not heat or throw batteries into fire. An explosion could occur, resulting in injury.

CCAUTION

DDo not touch liquid leaking from batteries. Harmful chemicals could cause burns or

blisters.

PARTS AND FUNCTIONS OF THE INSTRUMENT 1. Rotary head

Laser beam emits from here.

2. Protective glass

3. Handle

4. Manual mode ON switch

ON: Push twice continuously.

OFF: Push once.

Manual mode

- Auto-leveling function is not active.

- Height alert function is not active.

5. Manual mode ON (Red LED)

Auto leveling does not function.

6. Height alert OFF switch

OFF:Push twice continuously.

ON:Push once.

7. Height alert OFF (Red LED)

Height alert does not function.

8. Battery power (Red LED)

Blinking:

The power is low, but laser is still usable. (Blinking continues for

one minute.)

On Solid:

Dead batteries. Replace the batteries with new ones. (The lamp is

solid for five minutes, then turned off automatically.)

9. Auto leveling (Green LED)

Blinking quickly:

Auto leveling is in process.

Blinking slowly:

Auto leveling is almost complete.

On Solid:

Auto leveling is complete.

10. Power switch

Turn the instrument ON or OFF.

11. Battery door knob

12. Battery door

Class 3R Laser Product

For the safe use of the product and prevention of injury to operators and other persons as well as

prevention of property damage, items which should be observed are indicated by an exclamation

point within a triangle used with WARNING and CAUTION statements in this operator's manual.

The definitions of the indications are listed below. Be sure you understand them before reading the

manual's main text.

Make sure all of the following are included.

13. Indicator

When moving the level sensor and detecting the datum position,

"====" (normal precision) or "-------" (high precision) is indicated.

Directional arrows and audio signals assist in locating the on-

grade position as the laser strikes the beam receiving window.

(Top of level sensor is 36mm (1 5/12") from on-grade index for

offset marking.)

The indicators are located on front and back sides of the instru-

ment.

14. Beam receiving window

Turn the beam receiving window side towards TAURUS to detect

the laser beam.

15. Power switch

Turns the detector ON/OFF.

Auto-cut off function

The power will be turned off automatically if no laser beam is

detected for approximately 20 minutes. (To turn on the level sen-

sor, press the power switch again.)

16. Precision Setting Shifting Switch

Two leveling precision options are available, normal precision

(±2mm) and high precision (±1mm). By pressing this switch, the

precision options are switched alternately. Confirm the selected

precision option by viewing the indicator. (Normal precision is

set when turning on the power switch.)

17. Audio tone switch

By pressing this switch, ON/OFF of buzzer sound is switched

alternately.

18. Buzzer speaker

Slide board

LASER SAFETY INFORMATION

PRECAUTIONS FOR SAFE OPERATION

STANDARD EQUIPMENT

Rotating laser LS-1

INSTRUCTION MANUAL

ROTATING LASER

After using the instrument, store it as shown below.

HOW TO STORE

• The user of this product is expected to follow all operating instructions and make periodic checks

of the product's performance.

• The manufacturer, or its representatives, assumes no responsibility for results of faulty or intentional

usage or misuse including any direct, indirect, consequential damage, or loss of profits.

• The manufacturer, or its representatives, assumes no responsibility for consequential damage, or

loss of profits due to any natural disaster, (earthquake, storms, floods etc.), fire, accident, or an act

of a third party and/or usage under unusual conditions.

• The manufacturer, or its representatives, assumes no responsibility for any damage (change of

data, loss of data, loss of profits, an interruption of business etc.) caused by use of the product or

an unusable product.

• The manufacturer, or its representatives, assumes no responsibility for any damage, and loss of

profits caused by usage different to that explained in the operator's manual.

• The manufacturer, or its representatives, assumes no responsibility for damage caused by incorrect

operation, or action resulting from connecting to other products.

EXCEPTIONS FROM RESPONSIBILITY

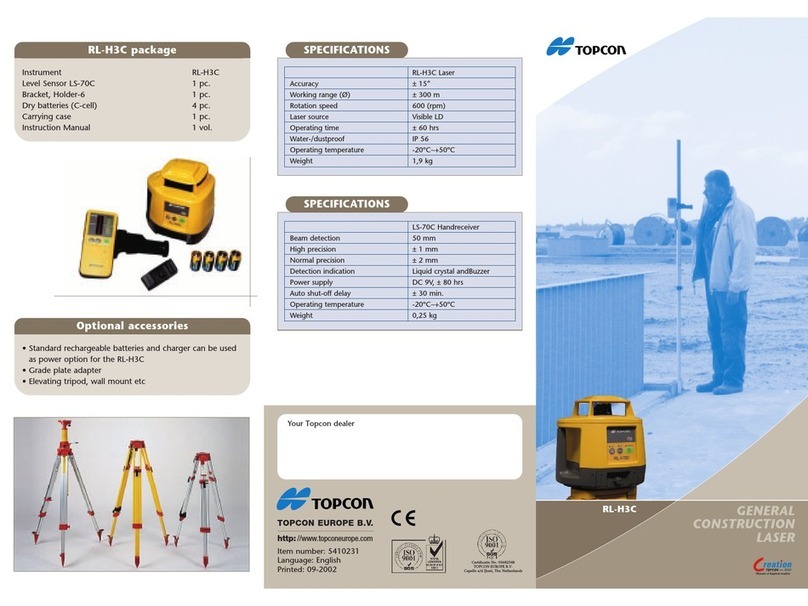

1 TAURUS Instrument . . . . . . . . . . . . . . . 1

2 Level Sensor (LS-1) . . . . . . . . . . . . . . . 1

3 Carrying case . . . . . . . . . . . . . . . . . . . . 1

4 Level Sensor Holder (Holder-7) . . . . . . 1

5 C-size dry cell batterys . . . . . . . . . . . . . 4

6 9V dry cell battery . . . . . . . . . . . . . . . . . 1

7 Operator's manual . . . . . . . . . . . . . . . . . 1