Topens MultiRuta CASAR 800 User manual

GARAGE DOOR OPENER

User’s Manual

Model:

CASAR 800

www.topens.com

Email: s[email protected]

★

Please read and follow all warnings, precautions and instructions before

installation and use.

★Save this manual.

C030554

VER 21a

TOPENS Website

CONTACT US:

Visit: www.topens.com

Please record the product model, your email address etc.

in the spaces provided below. Refer to this list when contacting TOPENS

for technical service or assistance with your automatic gate opener.

Where did you purchase? (Amazon.com; Amazon.ca: Amazon.co.uk, Amazon.de; Other, Please

Specify)

Order# Product Model Purchase Date

Full Name Phone# Email Address (VERY

IMPORTANT)

Street Address, Apartment /Unit, City, State /Province, Zip Code Country/Region

Did you purchase any

accessories? (Please list

below)

Issue Details

Email Us: support@topens.com

Call: +1 (888) 750 9899 (Toll Free USA & Canada)

Table of Contents

1. Before You Begin ....................................................................................................................................... 4

1.1 Door Types ......................................................................................................................................................4

1.2 Tools Required for Installation...................................................................................................................5

1.3 Accessories Connection .............................................................................................................................5

1.4 Completed Installation.................................................................................................................................6

2. ASSEMBLY SECTION................................................................................................................................. 7

2.1 Open the Chain Package.............................................................................................................................7

2.2 Assemble the Driving Assembly ...............................................................................................................7

2.3 Assemble the Rail..........................................................................................................................................7

2.4 Fasten Rail to Opener and Install Chain..................................................................................................8

2.5 Attach Sprocket Cover.................................................................................................................................9

2.6 Install Header Sleeve and Tighten Chain ................................................................................................9

3. INSTALLATION SECTION ........................................................................................................................ 10

3.1 Position the Header Bracket.....................................................................................................................10

3.2 Install the Header Bracket.........................................................................................................................11

3.3 Attach Rail to Header Bracket..................................................................................................................12

3.4 Position the Opener....................................................................................................................................12

3.5 Hang Opener.................................................................................................................................................13

3.6 Fasten Door Bracket...................................................................................................................................13

3.7Assemble Door Arm (NOT Bow Arm) ......................................................................................................14

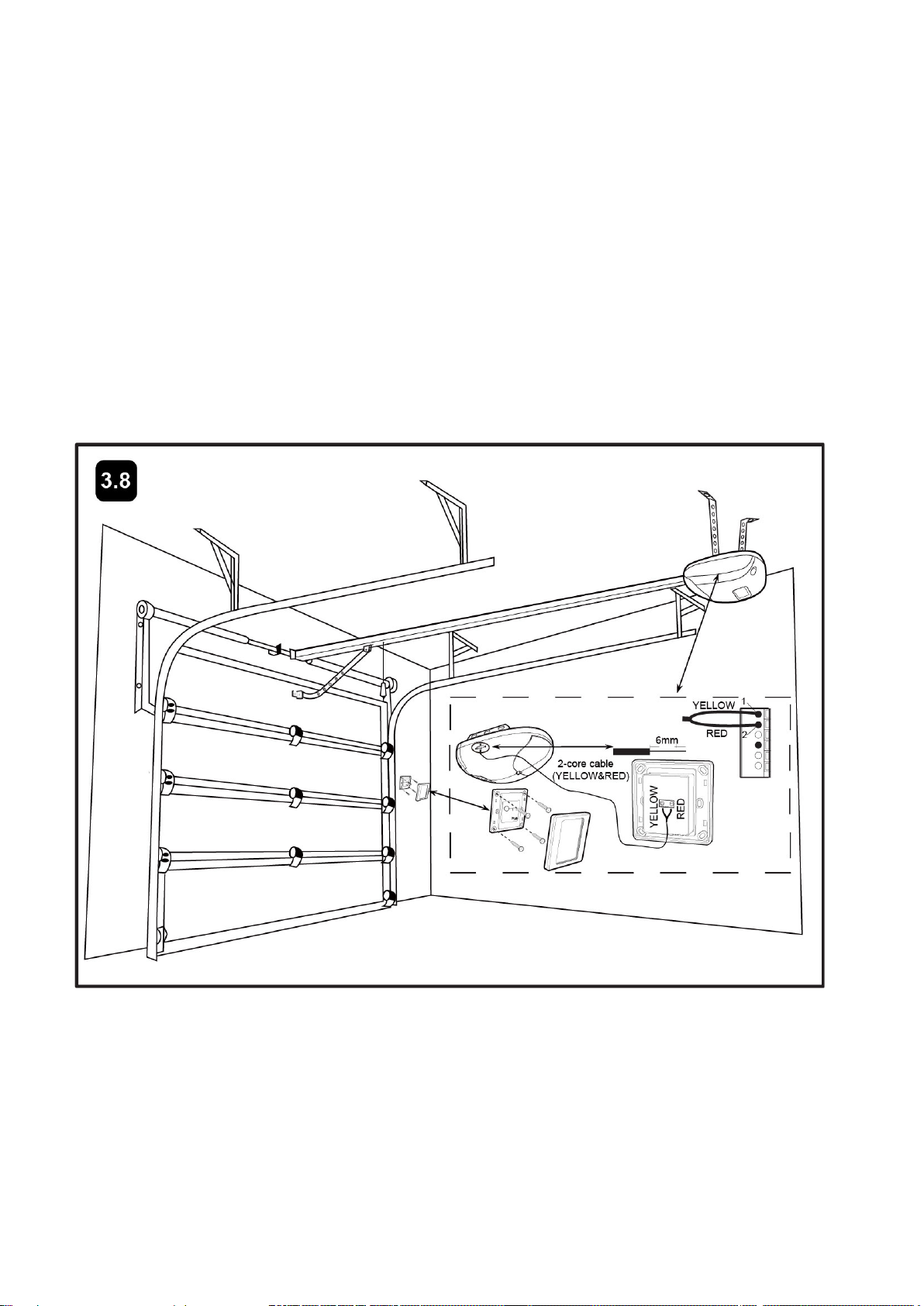

3.8 Install Door Control (Optional).................................................................................................................15

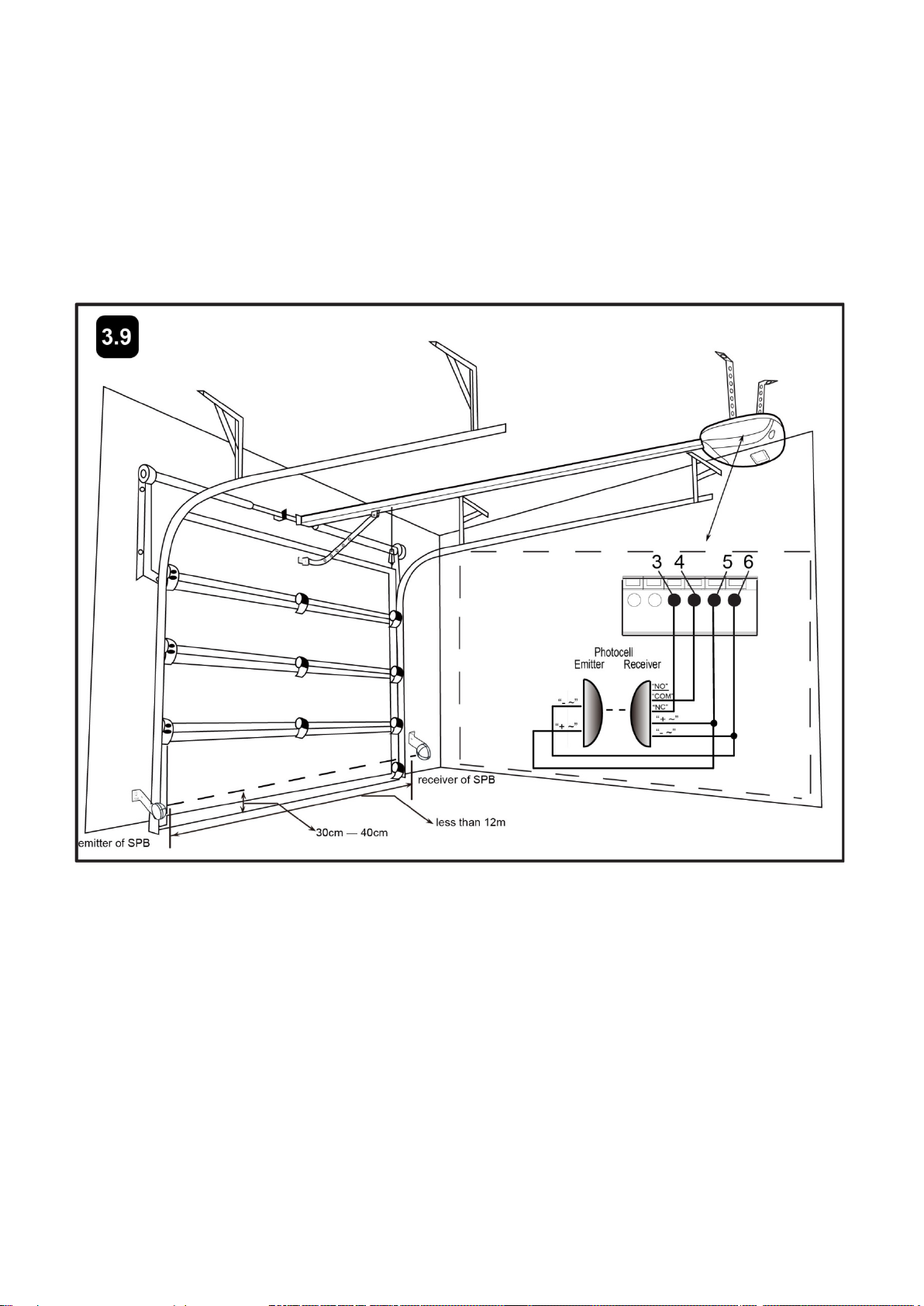

3.9 Install the Safety Photocell Beam (SPB) System (Optional) ............................................................16

4. ADJUSTMENT SECTION.......................................................................................................................... 17

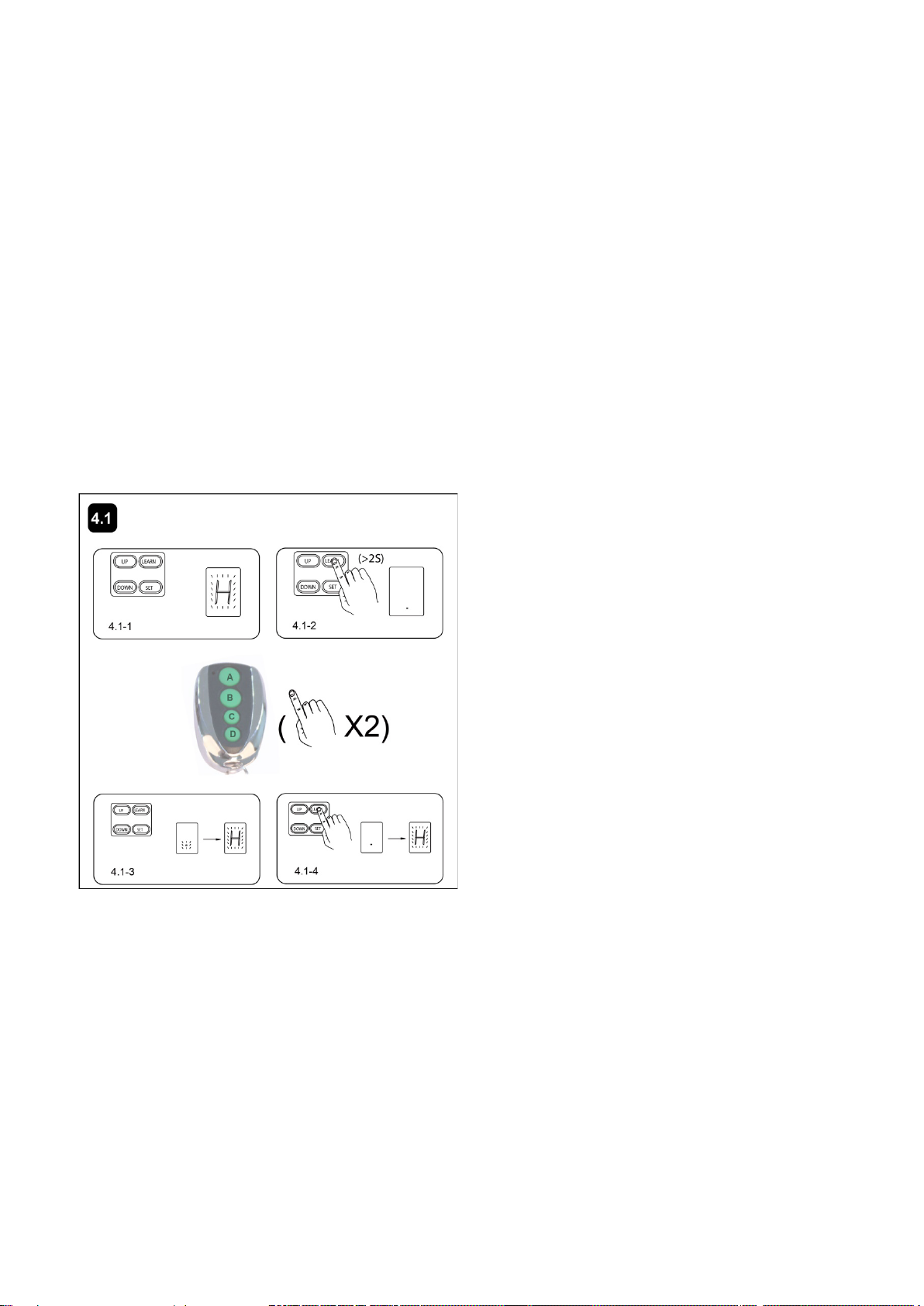

4.1 Learning the code. ......................................................................................................................................17

4.2 Setting the Limits ........................................................................................................................................18

4.3 Setting the Open Force..............................................................................................................................19

4.4 Setting the Close Force .............................................................................................................................19

4.5 Setting the Automatic Closing Time.......................................................................................................20

4.6 Set the Safety Photocell Beam (SPB) System (Optional) .................................................................20

4.7 Test the Safety Reverse System

(

Very Important

)

..........................................................................21

4.8 Wireless Keypad Programming (Optional)...........................................................................................21

4.9 Install HLR01 HomeLink Remote Control Kit (Optional)...................................................................22

4.10 Light Features............................................................................................................................................22

4.11 Trouble Shooting.......................................................................................................................................22

4.12 Care of Your Opener.................................................................................................................................24

4.13 Maintenance of Your Opener..................................................................................................................24

5. Quick-Setting Guide................................................................................................................................. 25

5.1 Program your Opener & Remote.............................................................................................................25

5.2 To Erase all remote Control codes .........................................................................................................25

5.3 Unit Setting ...................................................................................................................................................26

1

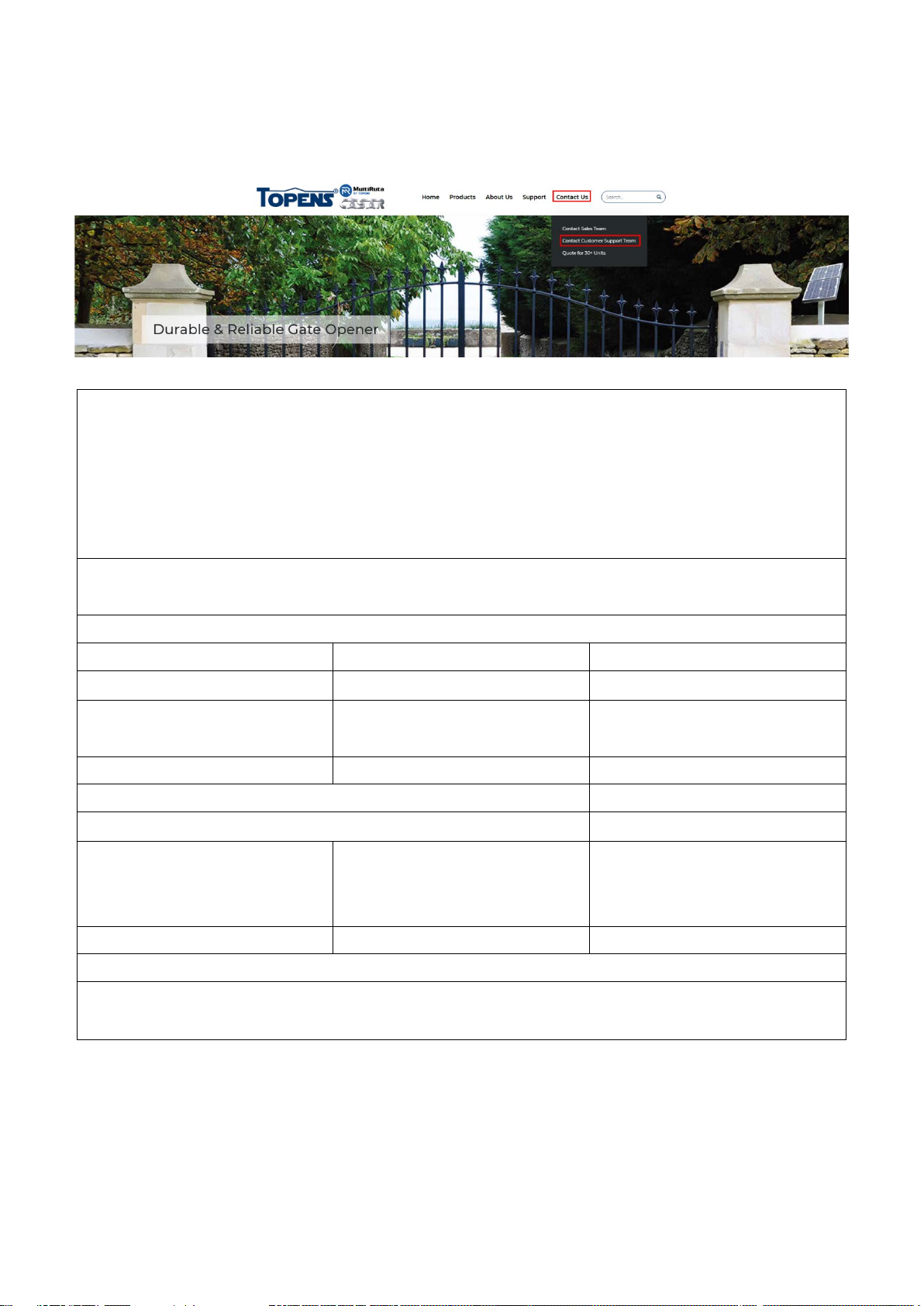

Technical Specifications & Features

Specifications

Input Voltage: 110 - 120V/60Hz or 220 - 240V/50Hz

Motor Voltage: 24VDC

Light Power: 120V or 230V, 10-15W (subject to consumer area)

Operation Speed: 120mm/s(4.7 in/s)

Frequency: 433.92MHz

Standby Power: <8W

Rated Force:

300N

Max. Force:

800N

Headroom Required:

30mm (1.2 in)

Features:

·

Stop in case of obstruction during gate opening

·

Reverse in case of obstruction during gate closing

·

Soft start and soft stop (each soft period can Not be adjusted).

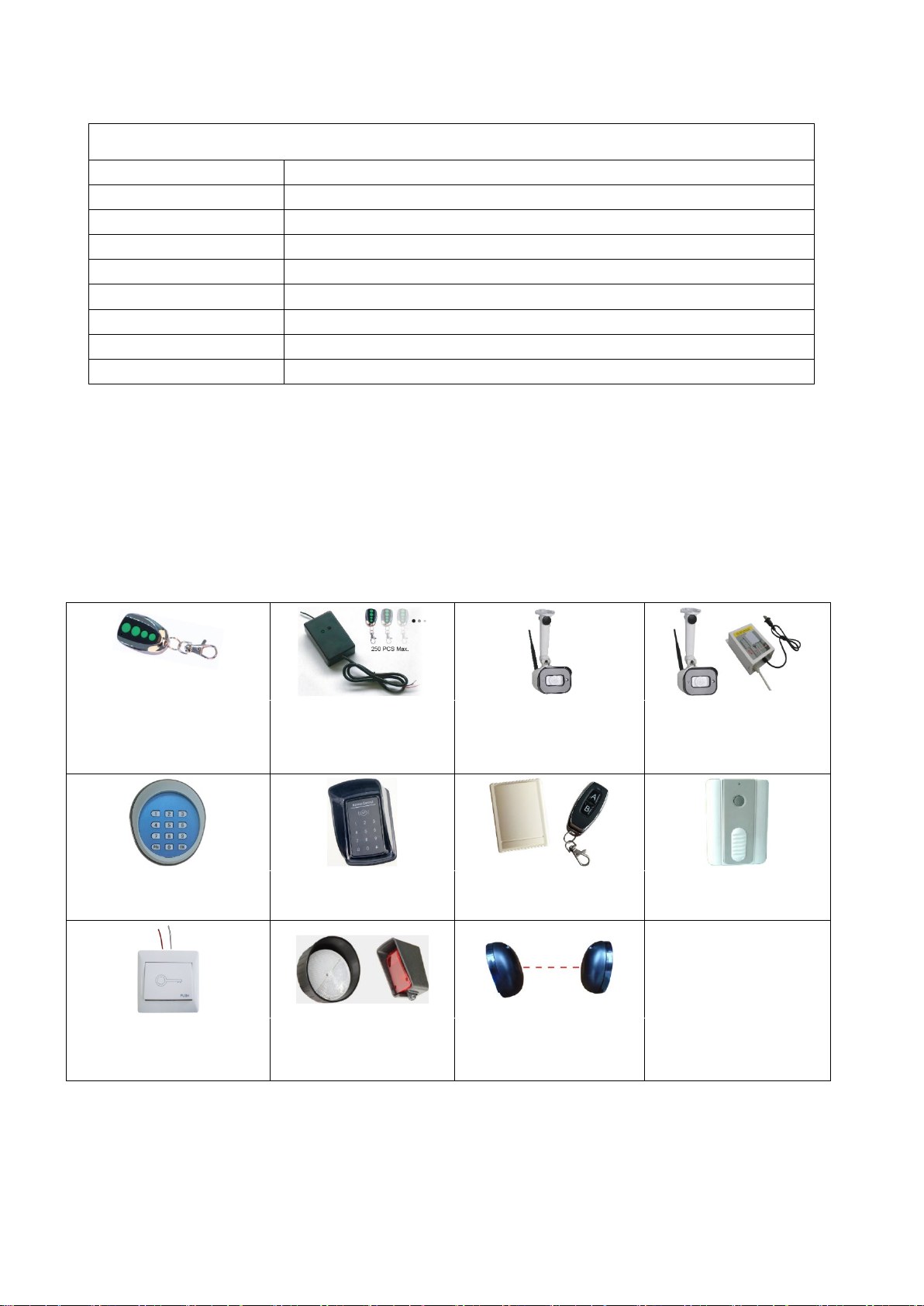

Optional Accessories Parts List (Available at TOPENS

Store)

M12 Remote Control ERM12 External

Receiver

TC186-R WiFi

Smartphone Remote

Control with Camera

TC186 WiFi

Smartphone Remote

Control with Camera

TKP3 Wireless Keypad TC175P Wired Keypad HLR01 HomeLink

Remote Control Kit

TC173 Wireless Push

Button

TC147 Wired Push

Button

TRF3 Reflection

Photocell Sensor

TC102 Photo Eye

Beam Sensor

2

Replacement Parts

CKMJ2A Control Board

WARNING: Changes or modifications not expressly specified by this user manual, TOPENS could void

the warranty of this equipment.

3

Start by Reading These Important Safety Rules

These safety alert symbols mean WARNING-a personal safety or property damage instruction.

Read these instructions carefully.

This garage door opener is designed and tested to offer reasonable safe service provided it is installed and

operated in strict accordance with the following safety rules.

Failure to comply with the following instructions may result in serious personal injury or property damage.

The garage door opener is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of

the appliance by a person responsible for this safety.

WARNING: If your garage has no service entrance door, an Outside Quick Release must be installed. This accessory allows

manual operation of the garage door from outside in case of power failure.

Keep garage door balanced. Sticking or binding

doors must be repaired. Garage doors, door springs,

cables, pulleys, brackets and their hardware are under

extreme tension and can cause serious personal injury. Do

not attempt to loosen, move or adjust them. Call for garage

door service.

Do not wear rings, watches, or loose clothing while

installing or servicing a garage door opener.

Before installing the garage door opener, remove all

unnecessary ropes or chains and disable any equipment,

such as locks, not needed for powered operation. Check

that the door is in good mechanical condition, correctly

balanced and opens and closes properly. Installation and

wiring must be in compliance with your local building and

electrical codes. Connect the power supply cord only to

properly earthed mains.

Lightweight doors of fiberglass, aluminum or steel

must be substantially reinforced to avoid door damage.

The best solution is to check with your garage door

manufacturer for an opener installation reinforcement kit.

Important safety instructions. Follow all instructions

since incorrect installation can lead to severe injury.

This unit should not be installed in a damp or wet

space.

After installation,

ensure that the mechanism is

properly adjusted and that the

opener reverses when the

door contacts a 100mm(4”

) high object placed on the floor.

Failure to properly adjust the opener may resu

lt in serious

personal injury from a closing garage door.

Each month

check that the opener reverses when the door contacts a

100mm (4”)

high object placed on the floor for opener

incorporating an entrapment protection system depending

on contact with the bottom edge of the door. Adjust if

necessary and recheck since an incorrect adjustment may

present a hazard.

After installation, ensure that parts of the door do

not extend over public footpaths or roads.

The opener must not be used with a door

incorporating a wicket door (unless the opener can not be

operated with the wicket door open.)

Frequently examine the installation, in particular check

cable, springs and mountings for signs of wear, damage or

imbalance. Do not use if repair of adjustment is needed since

a fault in the installation or an incorrectly balanced door may

cause injury.

Fasten the child warning label adjacent to the lighted

door control button as a reminder of safe operating

procedures.

Disengage all existing garage door locks to

avoid damage to garage door.

Install any fixed control at a height of at least 1.5m and

within sight of the door but away from moving parts and out

of the reach of children. Permanently fix the labels warning

against entrapment in a prominent place or near any fixed

controls. Children should be supervised to ensure that they

do not play with the appliance. Do not allow children to play

with door controls. Keep remote controls away from children.

Serious personal injury from a closing garage door may

result from misuse of the opener.

Activate opener ONLY when the door is in full view,

free of obstructions and opener is properly adjusted. No one

should enter or leave the garage while the door is in motion.

Do not allow children to play near the door.

Watch the

moving door and keep people away until the door is

completely opened or closed.

Install the actuating member for the manual release at

a height less than 1.8m.

Use manual release only to

disengage the trolley and, if possible, ONLY when the door is

closed. Do not use the red handle to pull the door open or

closed.

Take care when operating the manual release since

an open door may fall rapidly due to weak or broken springs

or being out of balance.

The opener

must not be used with a door having

opening exceeding 10 mm (0.4”) in diameter or having edges

or protruding parts a person could grip or stand on.

Disconnect the supply when cleaning or carrying out

other maintenance.

This product is provided with a transformer and power

supply cord of special design which, if damaged, MUST be

replaced by a transformer from your local distributor and

fitted by a specialist.

SAVE THESE INSTRUCTIONS

4

1. Before You Begin

Look at the wall or ceiling above the garage door. The header bracket MUST be securely fastened

to structural supports. It is easier to fit this door opener while the garage door is in the colsed

position and before you set the control board.

Do you have a finished ceiling in your garage? If so, a support bracket and additional fastening

hardware (not supplied) may be required..

Do you have an access door in addition to the garage door? If not, an Outside Quick Release

Accessory is required.

1.1 Door Types

Max. Door Height: 7.5 feet (2.3 m)

Max. Door Area: 129.2 ft² (12 m²)

5

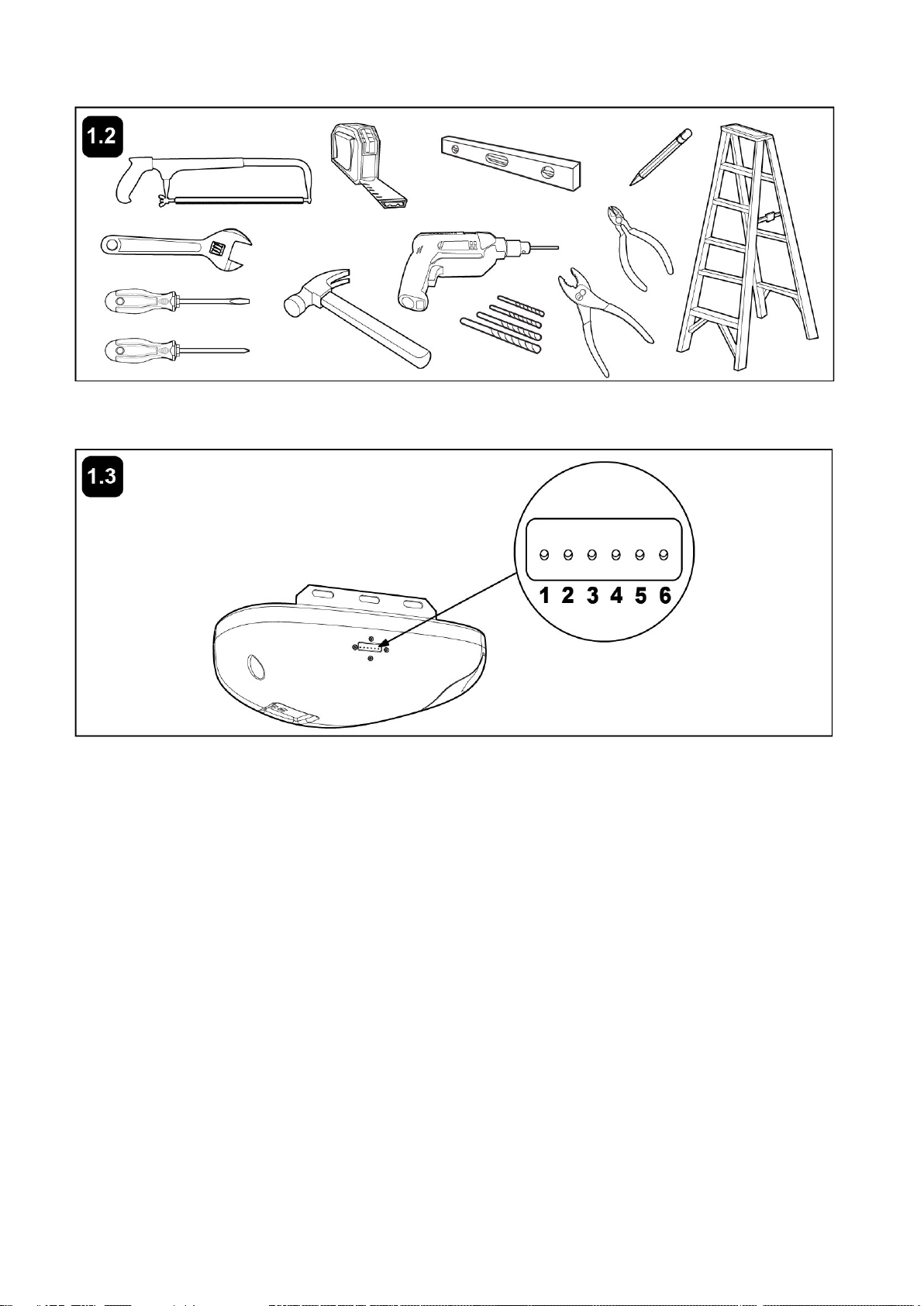

1.2 Tools Required for Installation

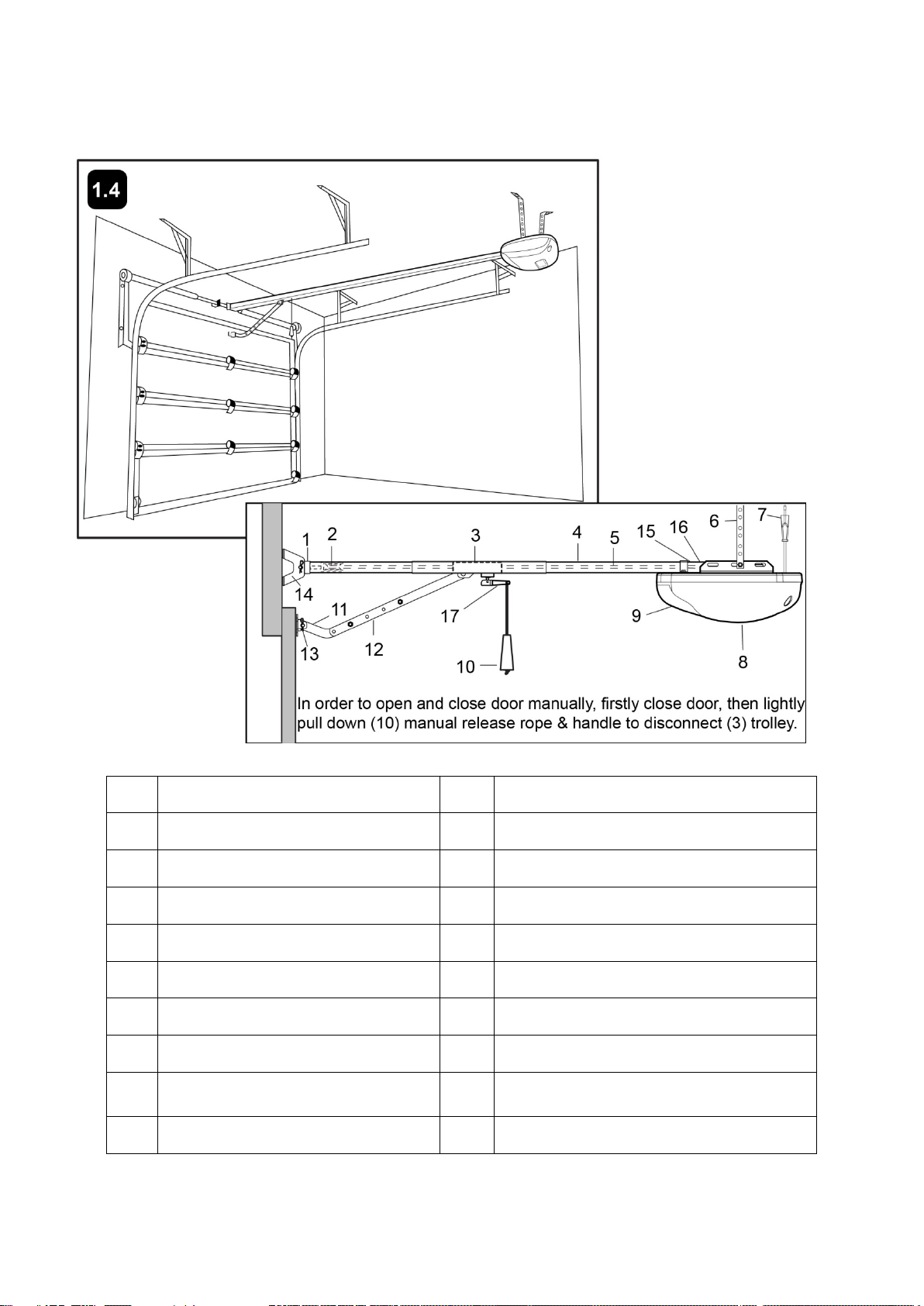

1.3 Accessories Connection

There is Connecting Wire Terminal in the unit’s side as picture 3, the function is as follows:

Terminal 1 for DOOR CONTROL BUTTON

Terminal 2 for DOOR CONTROL BUTTON

Terminal 3 for SAFETY PHOTOCELL BEAM (SPB)

Terminal 4 for SAFETY PHOTOCELL BEAM (SPB)

Terminal 5 for positive of Additional 24VDC Power Source

Terminal 6 for negative of Additional 24VDC Power Source

NOTE: The output current of port 5 and 6 is less than 100mA.

6

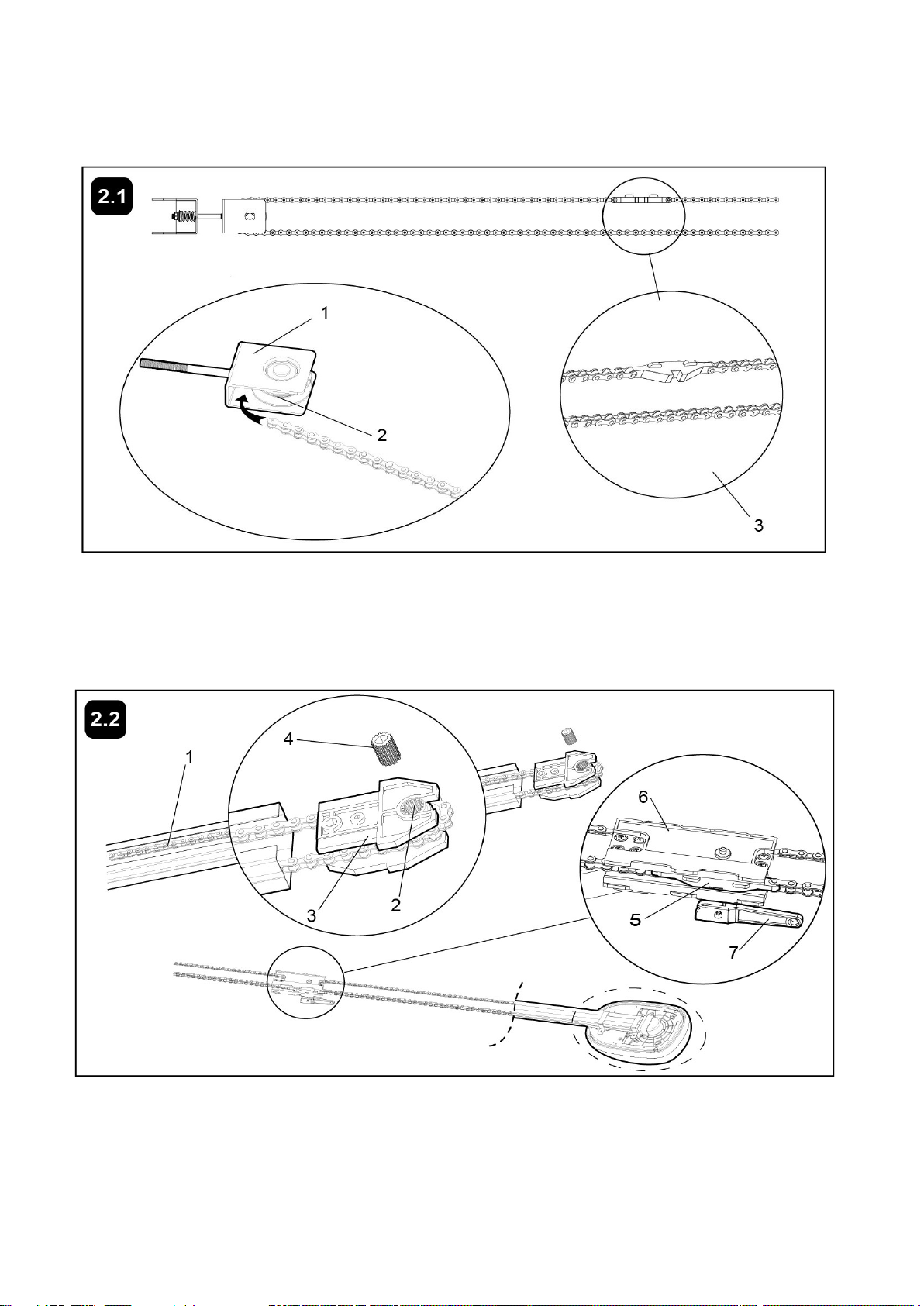

1.4 Completed Installation

As you proceed with the assembly, installation and adjustment procedures in this manual, you may find it

helpful to refer back to this illustration of a completed installation.

NO. Name NO. Name

1 Header Sleeve 10 Manual Release Rope & Handle

2 Idler Pulley Bracket 11 Curved Door Arm

3

Trolley

12 Straight Door Arm

4 Rail 13 Door Bracket & Plate

5 Chain 14 Header Bracket

6 Hanging Bracket 15 Driving Wheel

7 Power Cord 16 Wheel Base

8 Opener 17 Rope’s Lever

9 Light Lens

7

2. ASSEMBLY SECTION

2.1 Open the Chain Package

Drill the one end of chain through the space between the pulley bracket (1) and Idler pulley (2), wrapping it

round the idler pulley (2). Then connect live knots in both ends of the Chain to both ends of the chain

connector (3). Finally push Idler pulley bracket (1) into the rail section which is with holes.

2.2 Assemble the Driving Assembly

The driving assembly (consisting of driving wheel (2), wheel base (3) and splined sleeve (4)) has been well

assembled in the factory. Assemble the Chain in each end of the trolley (6), and then put them in the rail.

Trolley (6) and chain connector (5) should lock together.

NOTE: Rope’s lever (7) should be toward the door opener unit.

Wrap the chain round the driving wheel (2), and push the driving assembly into the rail.

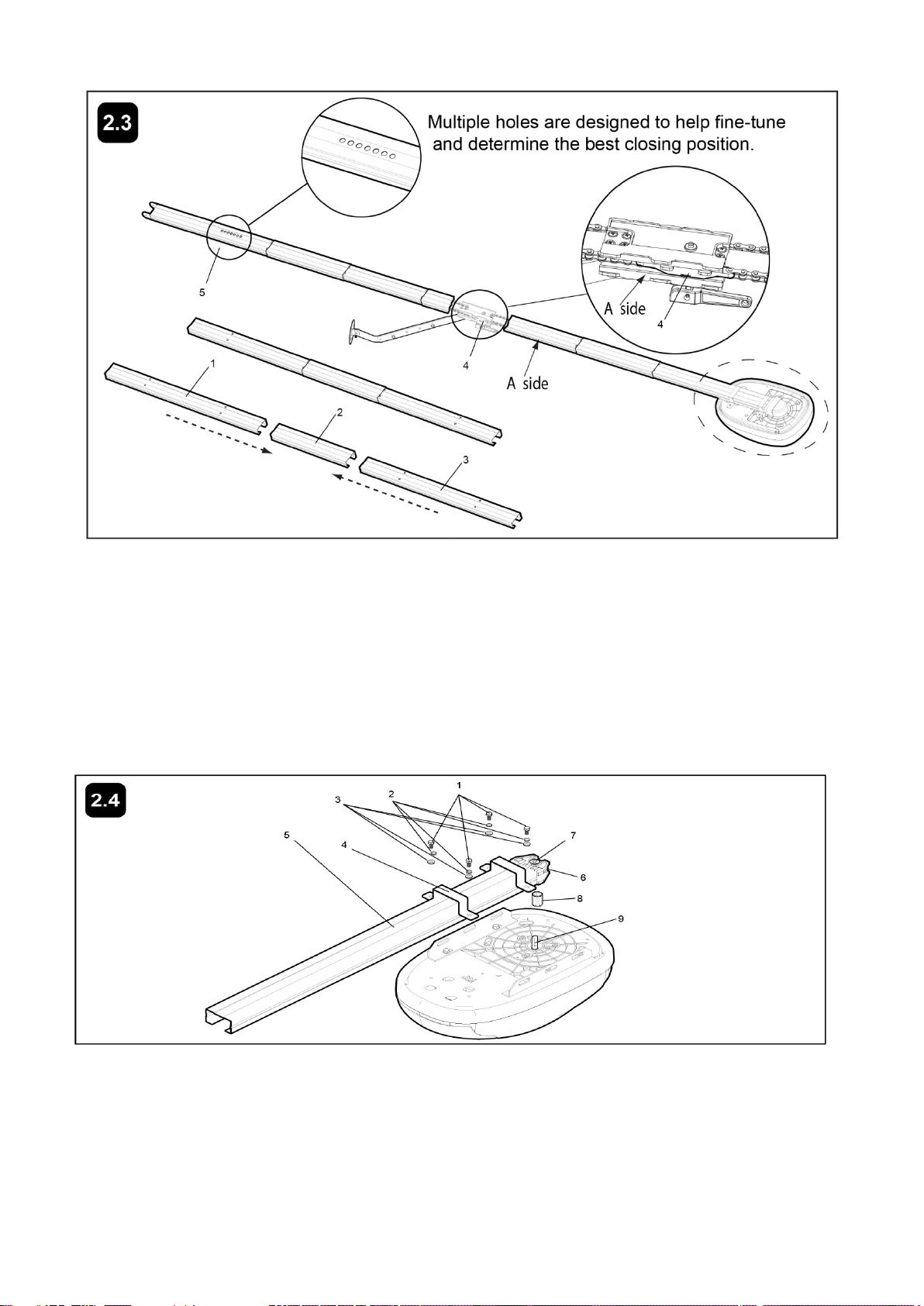

2.3 Assemble the Rail

8

Wear protective gloves when assemble the rail to protect your hands from possible injury from the edge of

the rail.

Place rail pieces (1) on flat surface for assembly. All four rail sections are interchangeable. Slide rail brace (2)

onto rail section. Connect rail by sliding rail brace onto next rail section. Tap rail assembly on piece of wood

until rail sections are flush. Repeat with remaining rail sections. Please check whether the chain connector

(4) is on the A side as picture shows.

NOTE: Check if the rail section with holes (5) is in the farthest end from the opener.

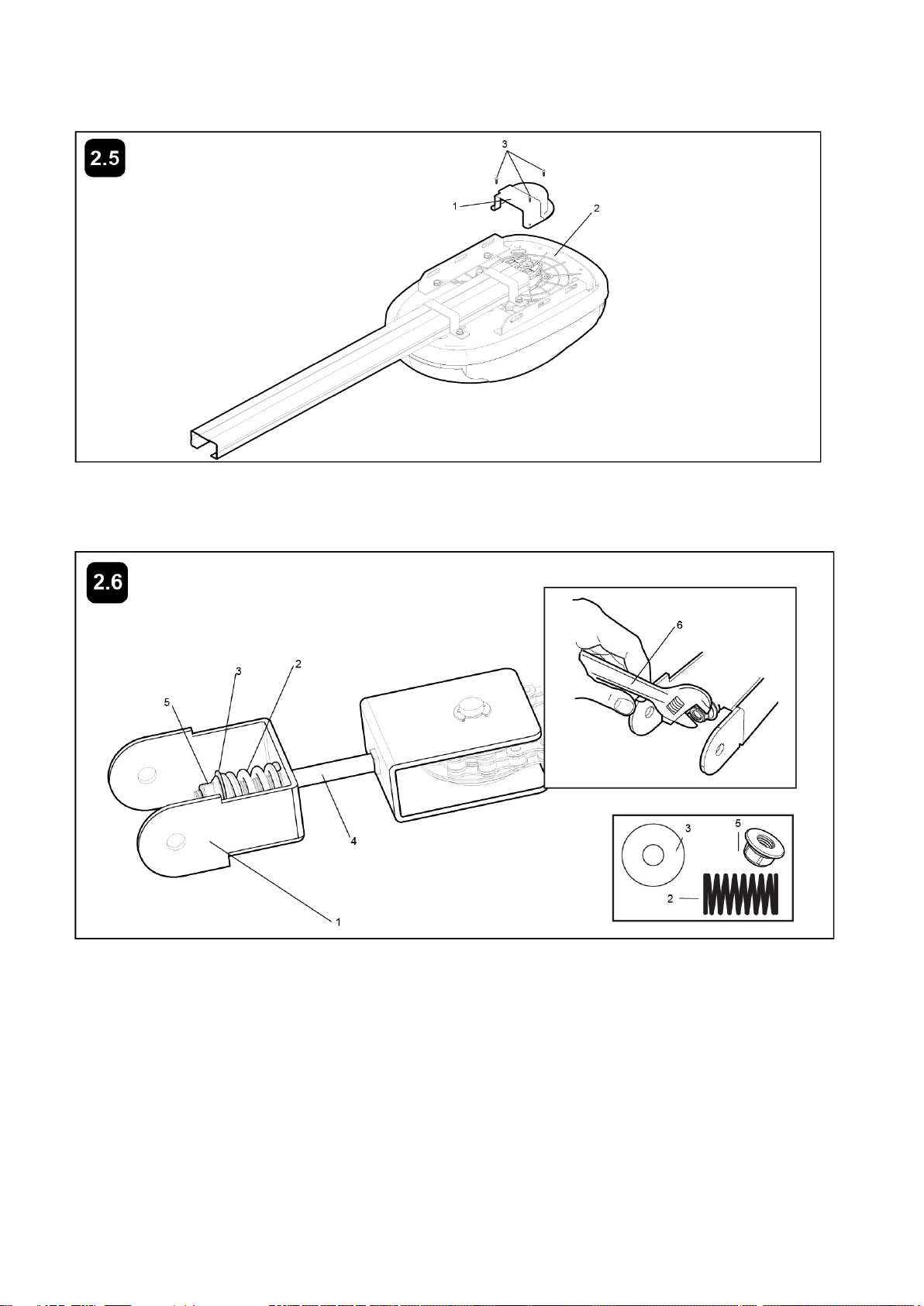

2.4 Fasten Rail to Opener and Install Chain

Insert four bolts (1) into the holes of brackets (4), secure with elastic washer (2) and washer (3). Place rail (5)

on opener. Wrap chain (6) over sprocket (7). Push idler pulley bracket assembly toward front of the rail to

eliminate excess slack in chain. Insert the splined sleeve (8) into sprocket (7). Put the splined sleeve (8)

onto the output shaft (9). Align bolt holes on brackets (4) with bolt holes on opener. Secure brackets to

opener with previously removed bolts. Tighten bolts securely. The opener sprocket teeth must engage the

chain.

CAUTION: Use only those bolts mounted in the top of opener. Use of any other bolts will cause serious

9

damage to opener.

2.5 Attach Sprocket Cover

Place sprocket cover (1) on top of the opener (2), secure with screws (3).

2.6 Install Header Sleeve and Tighten Chain

Slide header sleeve (1) onto rail. Slide flat washer (3), spring (2) and washer (3) onto carriage bolt (4).

Thread nut (5) onto carriage bolt until finger tight. Use an open end wrench (6) to tighten nut until the chain is

not against the inside surface of the rail.

ASSEMBLY

OF

YOUR

OPENER

IS

NOW

COMPLETE.

10

3. INSTALLATION SECTION

Wear protective goggles when working overhead to protect your eyes from injury.

Disengage all existing garage door locks to avoid damage to garage door. To avoid serious

personal injury from entanglement, remove all ropes connected to garage door before installing

opener.

Installation of this product shall comply with ZH1/494, VDE 0700 Part 238, and VDE 0700 Part 1. It

is recommended that the opener be installed 2.1m (7 feet) or more above the floor where space

permits.

3.1 Position the Header Bracket

The

header

bracket

must

be

rigidly

fastened

to

a

structural

support

of

the

garage.

Reinforce

the

wall

or

ceiling

with

a

40

mm

(1-1/2")

board

if

necessary

.

Failure

to

comply

may

result

in

improper

operation

of

safety

reverse

system.

You can attach the header bracket either to the header wall (1) or to the ceiling (3). Follow the instructions

which will work best for your particular requirements.

With the door closed, mark the vertical centerline (2) of the garage door. Extend line onto header wall above

the door.

Open door to highest point of travel. Draw an intersecting horizontal line (4) on header wall 5 cm (2") above

high point to provide travel clearance for top edge of door.

11

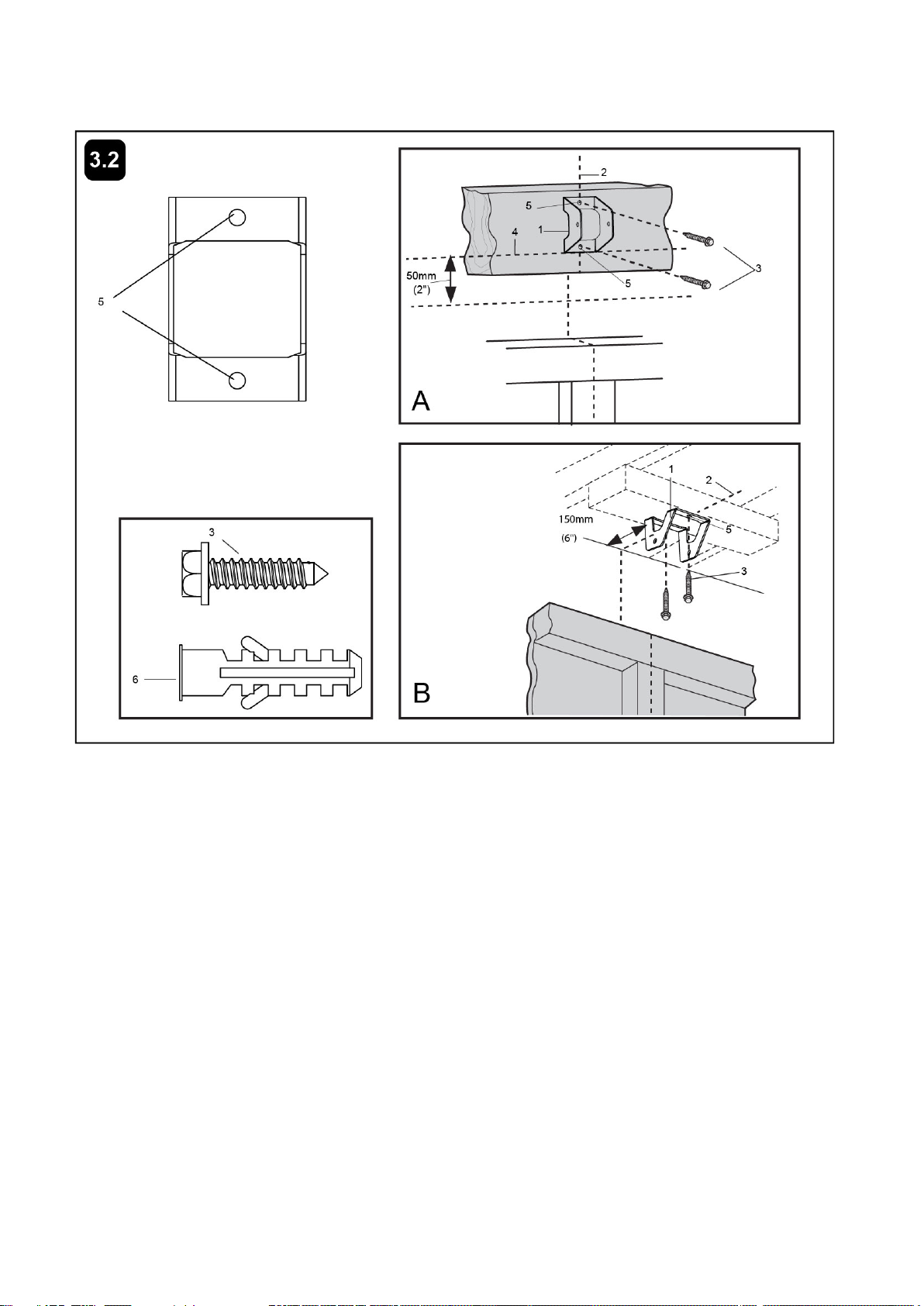

3.2 Install the Header Bracket

NOTE:

Refer

to

vertical

center

and

horizontal

lines

created

in

step

10

for

proper

placement

of

header

bracket.

A. Wall Mount: Center the header bracket (1) on the vertical center line (2) with the bottom edge of the

header bracket on the horizontal line (4) (with the arrow pointing toward the ceiling). Mark all of the header

bracket holes (5). Drill 4.5 mm (3/16") pilot holes and fasten the header bracket with wood screws (3).

B. Ceiling Mount: Extend vertical center line (2) onto the ceiling. Center the header bracket (1) on the

vertical mark no more than 150 mm (6") from the wall. Make sure the arrow is pointing toward the opener.

Mark all of the header bracket holes (5). Drill 4.5 mm (3/16") pilot holes and fasten the header bracket with

wood screws (3). For concrete ceiling mount, use concrete anchors (6) provided.

12

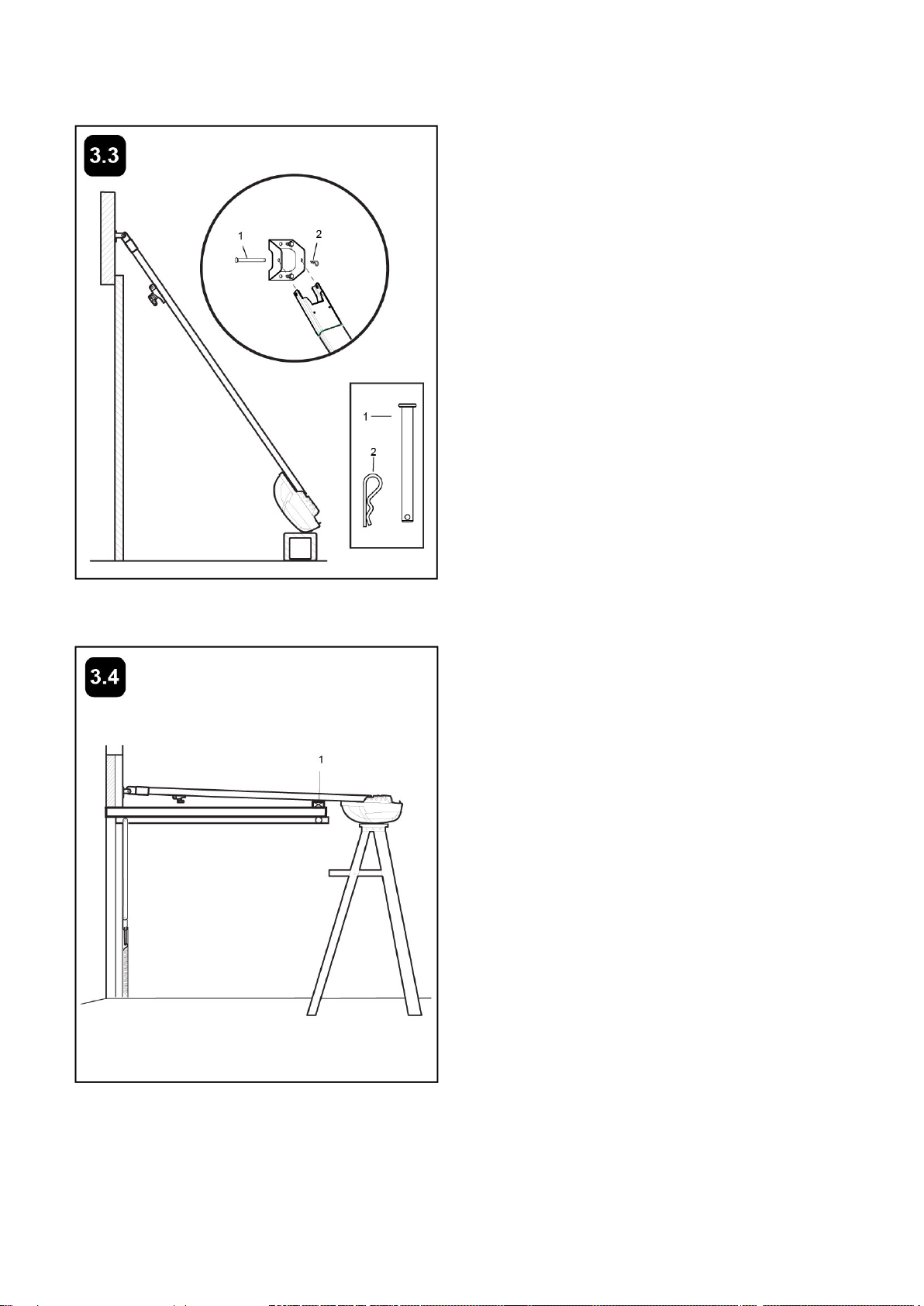

3.3 Attach Rail to Header Bracket

3.4 Position the Opener

Position opener on garage floor below the

header bracket. Use packing material to

protect the cover. Raise rail until holes in the

header sleeve and holes in the header

bracket align. Join with clevis pin (1). Insert

“R” pin (2) to secure.

NOTE:

T

o

enable

the

rail

to

clear

sectional

door

springs,

it

may

be

necessary

to

lif

t

opener

onto

a

temporary

support.

The

opener

must

either

be

secured

to

a

support

or

held

firmly

in

place

by

another

person.

Raise the opener onto a stepladder. Open

garage door. Place a 25mm (1") board (1)

laid flat on the top section of door near the

centerline as shown. Rest the rail on the

board.

If the raised door hits the trolley, pull down on

the trolley release arm to disconnect the

inner and outer trolley sections. The trolley

can remain disconnected until connecting

door arm to trolley is completed.

NOTE:

A

25mm

(1")

board

(1)

is

convenient

for

setting

an

ideal

door

-to-rail

dist

ance

(unless

headroom

is

not

sufficient).

13

3.5 Hang Opener

Bend Hanging Brackets (1) so they are flat against ceiling. Measure distance from Header Bracket to Ceiling

Mounting Bracket Bolts (4). Mark length on ceiling starting at the Header Wall, along this point is where the

unit will be mounted. Lift door to full open position, rest opener on door. Slide Hanging Brackets on to Ceiling

Mounting Bracket Bolts (4) on the opener. Secure Brackets with Nut (5). For concrete ceilings, drill 8mm(0.3”)

pilot holes into ceiling and insert Concrete Anchors (2). Secure Hanging Brackets to ceiling with Lag Screws

(3). For wood ceilings, drill 4mm(0.16”) pilot holes and secure with Lag Screws (3).

3.6 Fasten Door Bracket

If you have a canopy garage door, a door arm conversion kit is required. Follow the installation instructions

included with the replacement door arm. Exercise care in removing and assembling arm conversion kit.

Keep fingers away from the sliding parts.

NOTE:

Horizont

al

and

vertical

reinforcement

is

needed

for

lightweight

garage

doors.

14

Sectional

and

One-Piece

Door

Installation

Procedure:

Door bracket has left and right side fastening holes. If your installation requires top and bottom fastening

holes use both the door bracket and door bracket plate as shown.

Center door bracket (with or without door bracket plate, as required) at the top inside face of door as shown.

Mark holes.

3.7Assemble Door Arm (NOT Bow Arm)

A.

ONE-PIECE

DOOR

INST

ALLA

TION:

Fasten the straight (1) and curved (2) door arm sections together to the longest possible length (with a 2 or 3

hole overlap) using hardware (3, 4 and 5). With the door closed connect the straight door arm section (1) to

the door bracket with clevis pin (6). Secure with “R” pin (7). Disconnect the inner and outer trolley. Slide the

outer trolley back toward the opener and join the curved arm (2) to the connector hole in the trolley (8) with

clevis pin (6). It may be necessary to lift the door slightly to make the connection. Secure with “R” pin (7).

NOTE:

When

setting

the

up

limit,

the

door

should

not

have

a

“backward”

slant

when

fully

open.

A

slight

backward

slant

(9)

will

cause

unnecessary

bucking

and/or

jerking

operation

as

the

door

is

being

opened

or

closed

from

the

fully

open

position.

B.

SECTIONAL

DOOR

INST

ALLA

TION:

Connect according to Figure B, and then proceed to Step A.

15

3.8 Install Door Control (Optional)

Locate door control where the garage door is visible, away from door and door hardware and out of the

reach of children. Mount at least 5 feet (1.5 meters) above the floor.

Serious personal injury from a moving garage door may result from misuse of opener. Do not allow children

to operate the door control or remote control transmitter.

Permanently fasten the caution label permanently to the wall near the door control as a reminder of safe

operating procedures.

Fasten the door control to an inside garage wall with sheet metal screws (not provided). A convenient place

is beside the service door and out of reach of children.

Use a 2-core cable 2C x 22 AWG (2 x 0.3 mm² shielded wire) to connect the push button to the garage door

opener regardless of the polarity of terminal 1 & terminal 2.

Run the wire up the wall and across the ceiling to the garage door opener. The receiver quick connect

terminals are located on the side of the opener. Connect the wire to the terminals.

Press to open or close the door. Press again to stop the door while moving.

16

3.9 Install the Safety Photocell Beam (SPB) System (Optional)

1. Position the transmitter and receiver at a height of 30-40cm (11.8”-15.7”) from the ground. For the best

protection, please DON’T exceed the height of 40cm (15.7”).

2.If the TC102 photo eye beam sensor is connected,use a 2-core cable to connect the “+ ~”terminal of the

photocell’s emitter to the terminal 5, the “- ~” terminal to the terminal 6. Also the “+ ~”and “- ~” terminals of

the photocell’s receiver should be connected to the terminals 5 and 6 in parallel.

Use another 2-core cable to connect the “NC”terminal of the receiver to the terminal 3, the “COM”terminal

to the terminal 4.

NOTE: The distance between transmitter and receiver should be less than 12m. Or the SPB will fail in

function and the door opener wouldn’t work normally.

IMPORTANT:

If the photocell is not equipped, you must adjust the “0” in LED to ensure the Photocell set is OFF. Otherwise

the unit can’t work to close at all.

If the photocell is connected, you must adjust the “1”in LED to ensure the photocell set is ON,referring

to step 4.6.

17

4. ADJUSTMENT SECTION

Program Your Opener & Remote

Activate the opener only when door is in full view, free of obstruction and properly adjusted. No

one should enter or leave garage while door is in motion. Do not allow children to operate push

button(s) or remote(s). Do not allow children to play near the door.

Max. 8 remotes can be programmed for the opener. An External Receiver (optional) allows up to

250pcs remotes to be programmed for the opener. TOPENS ERM12 Universal External Receiver

is available at TOPENS Store.

TOPENS ERM12 Universal External Receiver is also compatible with other brand swing gate

opener, sliding gate opener and garage door opener.

Your garage door opener receiver and remote control transmitter are set to a matching code. If you

purchase additional remote controls, the garage door opener must be programmed to accept the new

remote code.

NOTE: Check again for completed and correct assembly of your Opener and Door.

4.1 Learning the code.

To Erase all Remote Control Codes

Press and hold LEARN button on the Opener, the Digital Display indicates “ ·” before it comes to “H”.

The codes are now erased when the Digital Display flashes with “H”(Pic. 4.1-4).

How to use the remote to control the opener

Each of the 4 keys in the remote can be programmed to operate the gate opener. The other 3 keys are

optional for program to operate another garage door opener, swing/sliding gate opener in our brand. But for

sliding gate opener, the Key B is used to achieve the Pedestrian Mode function. When the key has been

programmed, you can press it to operate the corresponding opener to work alternately

(open-stop-close-stop-open).

1. Connect the Cord Plug to power supply. The Digital

Display flashes with “H”, and the Light is ON. The unit

is into standby (Pic.4.1-1).

2.Press and hold LEARN button on the Opener for

more than 2 seconds, the Digital Display indicates “ ·”

(Pic.4.1-2). Press the key (button) two times on the

remote control, between the two times HOLD ON

FOR A MOMENT, and “ ·” flashes several times

before it comes to “H”(Pic. 4.1-3). Now the opener

has learned the code.

NOTE:

If you want the Opener to learn

additional remote codes, perform the above

steps. The Opener can learn 6 remotes at

most.

This manual suits for next models

1

Table of contents

Popular Garage Door Opener manuals by other brands

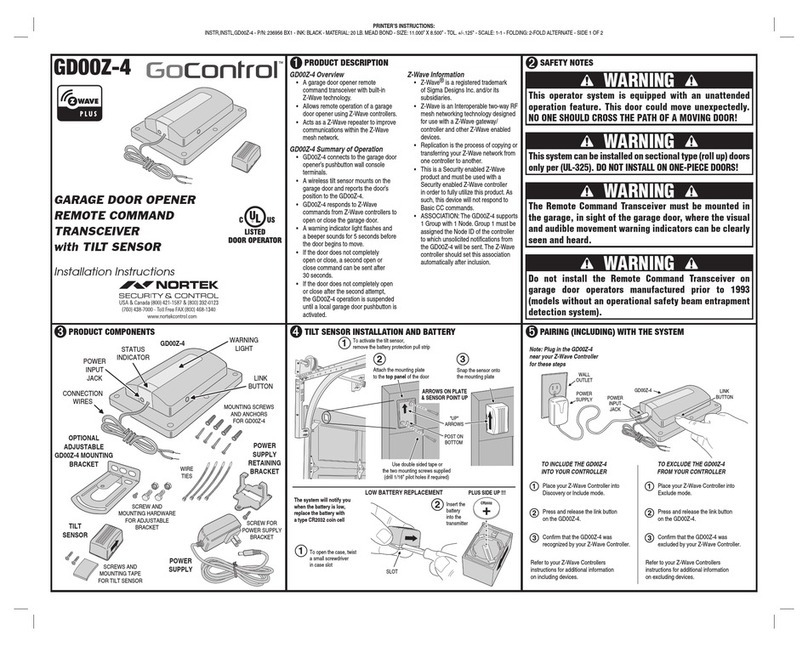

Nortek

Nortek GoControl GD00Z-4 Installation instructions manual

Chamberlain

Chamberlain 5100-2K owner's manual

Chamberlain

Chamberlain LiftMaster Security+ 2500C owner's manual

Roger Technology

Roger Technology F70/IPU36 Instruction and warnings for the installer

Autoglide

Autoglide CASA-M Series product manual

Zap

Zap Series 3 Technician's installation and service training manual

Erreka

Erreka ARES Quick installation and programming guide

V2

V2 Gold Series manual

Primere

Primere K2R E Installation instruction

GFA

GFA ELEKTROMAT SI 8.20-25,00 10003369 10011 installation instructions

Craftsman

Craftsman 139.18054 owner's manual

moore o matic

moore o matic XX325 Assembly and installation instructions