5.4-

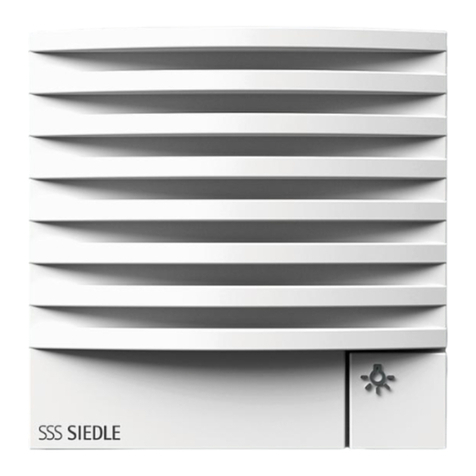

TRIPPING OF THE SENSORS

• In order to let the rain sensor trip, it is sufficient to touch with a finger for some second

the sensitive part (there is not hazard of electric shock since the device is protected

and works at low voltage).

• In order to let the wind sensor trip, let the fan rotate for at least 5 seconds.

• In order to let the brightness (sun) sensor trip, it is sufficient to cover it with a cloth

and then to uncover it. The cloth shall preferably have a dark colour. Perform the

tripping adjustment according to the prescriptions of the following paragraph.

5.5- TECHNICAL INFORMATION ON OPERATION

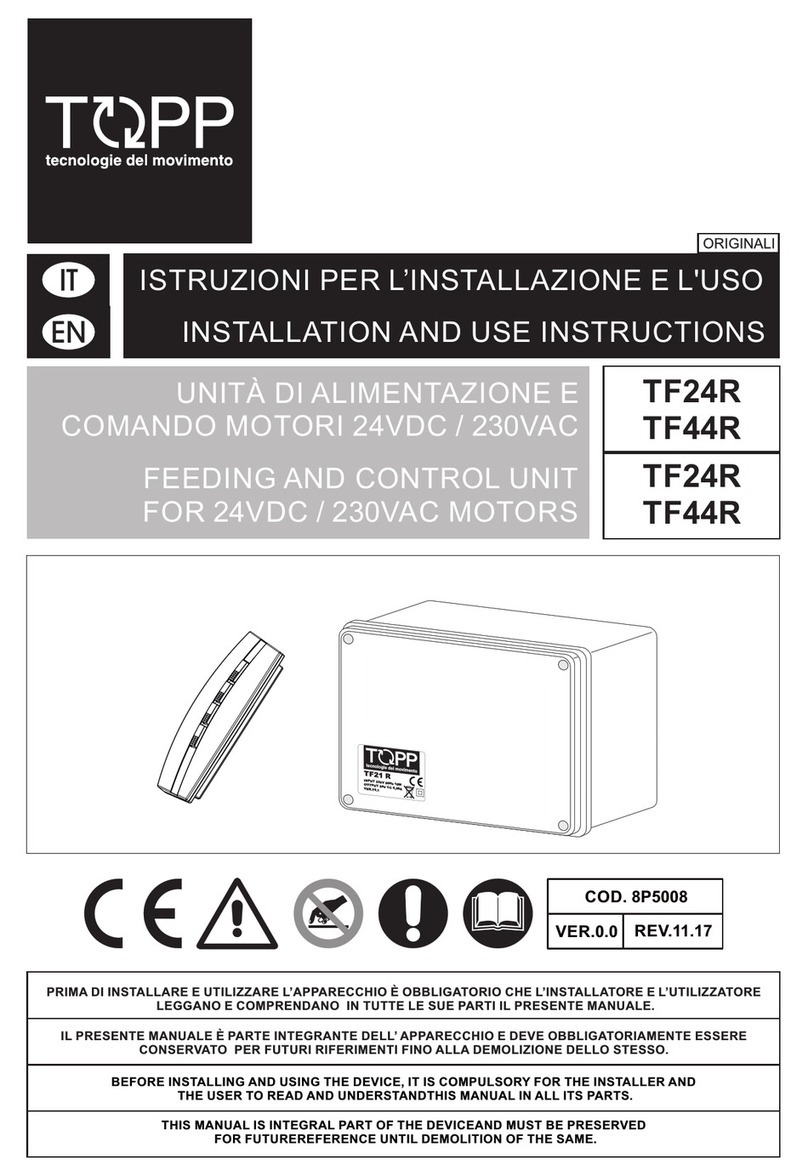

The control unit TF2 can operate the connected motors (actuators) manually or

automatically by means of the sensors connected to it.

For the manual operation, it is necessary to connect temporarily the feeding unit to a

manual push-button (also called "with man present") of approved bipolar type, or in the

mod. …R or in the mod. …T, the control occurs by means of 433MHz radio control or by

infrared remote control.

5.6- AUTOMATIC OPERATION WITH PREDEFINED LOGIC

The automatic operation follows a predefined logic.

1) When an atmospheric event of rain or wind beyond the pre-set limits occurs, the

feeding unit closes automatically the connected windows independently from the

control status. In other words, the automatic command takes priority on any other

command given.

2) The automatic closing command due to wind or rain is enabled for 1 minute.

After the closing command due to wind, all manual commands are inhibited for 6

minutes.

3) The forced manual re-opening is allowed also with enabled rain sensor.

After 10 minutes from the opening command, if the sensor is still wet, the windows

close; while if it is dry, they remain open.

4) The value referred to the wind speed can be calibrated by acting on the DIP-Switch

housed on the electronic card. The feeding unit starts to work when the wind speed

exceeds the value set in the programmed “DIP-Switch”;

The programming codes are given in Tab.2:

13

TF21/44R/T

INSTALLATION AND USE INSTRUCTIONS

INSTALLATION -5

VER.1.0

REV.07.04