3. Warning

FCC Warning:

This device complies with part 15 of the FCC Rules. Operation is subject to the following

two conditions.

(1) This device may not cause harmful interference;

(2) This device must accept any interference received, including interference that may

cause undesired operation.

Any Changes or modifications not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment.

INTEGRATION INSTRUCTIONS

1. This module has been tested and found to comply with the FCC Part15.247 for

Modular Approval.

2. This Modular Approval is limited to OEM installation for mobile and fixed applications

only. The antenna installation and operating configurations of this transmitter, including

any applicable source-based time- averaging duty factor, antenna gain and cable loss

must satisfy MPE categorical Exclusion Requirements of 2.1091. This modular should be

installed and operated with minimum distance 20 cm between the radiator& your body.

3. The U.FL connector antenna has been approved for the modular. The maximum

antenna gain is 3dBi. For situations where the host manufacturer is responsible for an

external connector, the integration instructions shall inform the installer that a unique

antenna connector must be used on the Part 15 authorized transmitters used in the host

product.

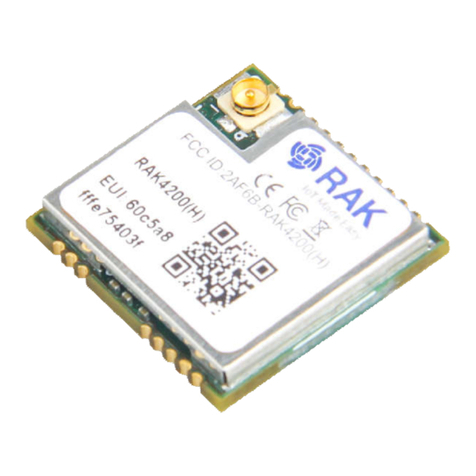

4. When the module is installed in the host device, the FCC ID label must be visible

through a window on the final device or it must be visible when an access panel, door or

cover is easily removed. If not, a second label must be placed on the outside of the final

device that contains the following text: ―Contains FCC ID: 2AF6B-RAK4200H.

5. The Shenzhen Rakwireless Technology Co., Ltd. uses various test mode programs for

test set up which operate separate from production firmware. Host integrators should

contact Shenzhen Rakwireless Technology Co., Ltd. for assistance with test modes

needed for module/host compliance test requirements.

6. The Shenzhen Rakwireless Technology Co., Ltd. modular transmitter is only FCC

authorized for the FCC Part15.247 listed on the grant, and that the host product

manufacturer is responsible for compliance to any other FCC rules that apply to the host

not covered by the modular transmitter grant of certification. If the grantee markets their

product as being Part 15 Subpart B compliant (when it also contains

unintentional-radiator digital circuity), then the grantee shall provide a notice stating that

the final host product still requires Part 15 Subpart B compliance testing with the modular

transmitter installed.