Toptech TechPure TT-MAC-1625 User manual

1

218413-00 Rev. 1A 06/22

This manual covers the following models:

• TT-MAC-1625

• TT-MAC-2020

• TT-MAC-2025

• TT-MAC-1429

• TT-MAC-1729

• TT-MAC-2129

• TT-MAC-2429

• TT-MAC-1422

• TT-MAC-1722

• TT-MAC-2122

• TT-MAC-2522

INSTALLATION MANUAL

A trained, experienced technician

must install this product.

Carefully read these instructions. You

could damage this product or cause a

hazardous condition if you fail to follow

these instructions.

Need Help?

For assistance with this product please

visit http://www.toptechparts.com or call

customer care at 1-866-239-4440 during

normal business hours.

Table of Contents: Page

Features and Specications 2

Installation 3

Installation (continued) 4

Pressure Drop Data 5

Final Check and Contact Info 6

High performance media air cleaner. Air

cleaner cabinet is fully insulated.

IMPORTANT

Carefully read these instructions.

You could damage this product

or cause a hazardous condition

if you fail to follow these

instructions.

!

by

2

218413-00 Rev. 1A 06/22

FEATURES AND SPECIFICATIONS

Features

Easy to maintain, high efciency media

designed to capture small, medium, and

large airborne particles.

Applicable to forced warm air furnaces, heat

pumps, electric heat, and cooling systems

up to 5 tons (2000 CFM).

Designed to easily support weight of a

residential air handler, furnace, and a

residential evaporator coil.

No electricity is consumed.

Quick and easy lter media replacement.

Fully insulated cabinet

Positive seal gasket material included.

Two-stage lter seal on cabinet door.

Minimal air leakage design.

Specications

Unit Dimensions:

#TT-MAC-1625: 27.875"D x 17"H x 6.063"W

(Repl. Media: #TT-FM-1625)

#TT-MAC-2020: 22.875"D x 21"H x 6.063"W

(Repl. Media: #TT-FM-2020)

#TT-MAC-2025: 27.875"D x 21"H x 6.063"W

(Repl. Media: #TT-FM-2025)

#TT-MAC-1429: 28.5"D x 14.25"W x 6.063"H

(Repl. Media: #TT-FM-1425)

#TT-MAC-1729: 29.125"D x 17.25"W x 6.063"H

(Repl. Media: #TT-FM-1625)

#TT-MAC-2129: 29.125"D x 21.25"W x 6.063"H

(Repl. Media: #TT-FM-2025)

#TT-MAC-2429: 29.125"D x 24.25"W x 6.063"H

(Repl. Media: #TT-FM-2424)

#TT-MAC-1422: 22.875"D x 14.25"W x 6.063"H

(Repl. Media: #TT-FM-1420)

#TT-MAC-1722: 22.875"D x 17"W x 6.063"H

(Repl. Media: #TT-FM-1620)

#TT-MAC-2122: 22.875"D x 21"W x 6.063"H

(Repl. Media: #TT-FM-2020)

#TT-MAC-2522: 22.875"D x 25.25"W x 6.063"H

(Repl. Media: #TT-FM-2025)

Filter Media:

MERV 11. Our pleated design has greater

media capacity than non-pleated lters.

Temperature Rating:

-40° to 140° F (-40° to +60° C).

Replacement Media Dimensions:

#TT-FM-1420: 14"D x 20"H x 4"W

#TT-FM-1425: 14"D x 25"H x 4"W

#TT-FM-1620: 16"D x 20"H x 4"W

#TT-FM-1625: 16"D x 25"H x 4"W

#TT-FM-2020: 20"D x 20"H x 4"W

#TT-FM-2025: 20"D x 25"H x 4"W

#TT-FM1-2424: 24"D x 24"H x 4"W

3

218413-00 Rev. 1A 06/22

Application

The TechPure media air cleaner cabinet is designed

to capture a signicant amount of airborne particles.

The cabinets are sold with MERV 1 lter media.

TechPure media lter cabinets can be installed in all

forced warm air furnaces and cooling systems up to

5 tons (2000 CFM).

TechPure MAC Tip

Choose a mounting location that

is upstream of the furnace and/

or evaporator coil. This will keep

the furnace and/or evaporator coil

clean.

TechPure Install Tip

When installing the TechPure

media air cleaner with a humidier,

choose a mounting location that

will not allow the water mist to

come in contact with the lter

media.

Mounting Positions

The TechPure media air cleaner cabinet can be

mounted in any position.

Installation

1. Plan the installation:

The TechPure media air cleaner cabinet is designed

to support the weight of a residential furnace and

residential evaporator coil. This media air cleaner

can be mounted in any position in the return air duct.

Typically, the media air cleaner is mounted next to

the furnace blower compartment.

The media air cleaner cabinet is designed to be

installed in the return air duct. Do not mount the

media air cleaner cabinet in the supply duct.

Install the media air cleaner cabinet in a manner

that spreads airow evenly across the lter media.

Gradual transitions are required if the duct is a

different size than the media air cleaner cabinet.

To prevent turbulence, the maximum amount of

expansion on each side of the transition is 20

degrees.

Turning vanes are required if the duct turns sharply

just before attaching to the media air cleaner cabinet.

For example, turning vanes would be required if

there is an abrupt 90 degree elbow in the duct

directly next to the media air lter cabinet.

Install the media air cleaner cabinet in an area that

allows for at least 27" of clearance in front of the

cabinet door for easy replacement of the lter media.

INSTALLATION

Secure angled bracket

front to back with 8x1/2

self-tapping screws.

Secure flat bracket to

bottom or back with 8x1/2

self-tapping screws.

4

218413-00 Rev. 1A 06/22

INSTALLATION

Energy Star Home Certication

If installing the media air cleaner into an application

that is going to have the ducts leakage tested

for compliance with 2011 Energy Star Home

Certication, Energy Efcient Mortgage (EEM),

or Energy Improvement Mortgage (EMI) rating

requirements, then cut the provided roll of gasket

material to length and apply to the inner door anges

that meet up with the front access panel of the media

air cleaner to reduce the air leakage between the

door and the air cleaner.

More information about the Energy Star Home

Certication, EEM, and EMI requirements can be

found at http://www.texenergyaudit.org/facts.htm

Installing the Filter media

The arrow on the lter media must point in the

direction of the air ow. If the media cabinet is

installed in the return air side of the duct work,

the arrow will typically point toward the blower

compartment.

Installation (continued)

2. Fasten the media cabinet to the furnace

Carefully create or use opening in the furnace or air

handler to match the lter media cabinet opening.

Place enclosed gasket material on the side of the air

cleaner that joins up with furnace or air handler. You

can attach the media cleaner cabinet directly to the

furnace or air handler, or t a starting collar in the

furnace opening. Drill holes and secure the cabinet

to the furnace with sheet metal screws. (Rivets or

slip joints are also suitable.)

3. Fasten media cabinet to the return duct

Secure the cabinet in place by using locking pliers.

Drill holes and secure the cabinet to the furnace with

sheet metal screws. (Rivets or slip joints are also

suitable.)

4. Seal joints to prevent leaks

Ensure all joints are sealed.

Secure flat bracket front

to back with 8x1/2 self-

tapping screws.

Secure flat bracket front

to back with 8x1/2 self-

tapping screws.

Apply gasket material to

inner door flanges that

meet up with the front

access panel of the media

air cleaner.

5

218413-00 Rev. 1A 06/22

PRESSURE DROP DATA

MERV 11 Pressure Drop

Flow Rate

(CFM

Velocity

(FPM)

dP

(mm H2O)

Pressure Drop

(“H2O)

% of Rated

Airow Dust Fed Pressure Drop

0 0 0.00 0.000 0% 0.00 0.181

427 123 0.70 0.028 25% 21.50 0.221

854 246 1.65 0.065 50% 73.30 0.386

1281 369 2.80 0.110 75% 106.30 0.591

1708 492 4.60 0.181 100% 132.70 0.795

2135 615 6.95 0.274 125% 152.70 1.000

DP ("H2O) 0.181in. 0.221in. 0.386in. 0.591in. 0.795in. 1.000in. *CME

Size Range

(mm) Fractional Efciency (%)

0.3-0.4 15.7 15.1 21.2 26.3 34.2 38.5 15.1

0.4-0.55 19.9 19.5 25.9 36.3 42.9 51.2 19.5

0.55-0.7 28.0 30.6 39.8 52.3 57.6 65.8 28.6

0.7-1.0 42.0 45.3 52.6 65.9 71.2 79.3 43.0

1.0-1.3 53.4 57.8 63.7 74.8 81.4 86.6 53.4

1.3-1.6 61.5 65.9 72.0 81.5 85.9 91.3 61.5

1.6-2.2 69.1 74.8 80.3 86.9 90.9 95.0 69.1

2.2-3.0 77.0 82.9 88.2 93.2 95.0 97.2 77.0

3.0-4.0 81.7 88.0 92.2 95.7 96.8 98.2 81.7

4.0-5.5 85.1 90.8 95.1 97.0 97.8 99.0 85.1

5.5-7.0 86.5 92.6 96.5 98.0 98.3 99.5 86.5

7.0-10.0 87.2 93.5 97.2 98.6 99.0 99.8 87.2

*Test data performed on a 20x25x4 MERV 11 lter / 1708 CFM / 492 FPM, by LMS technologies

6

218413-00 Rev. 1A 06/22

FINAL CHECKS AND CONTACT INFO

Replacement Schedule

It is very important for optimal heating and cooling system efciency to replace the lter media

as recommended by your heating and cooling technician. The climate in which you live and

the particulate count in your indoor environment will be considered when your heating and

cooling technician personalizes a replacement schedule for your particular application. In many

climates, it is best to replace the lter at least before the heating season and before the cooling

season. The lter should always be replaced at least once a year in all circumstances.

Final Checks

Check installation:

1. TechPure air cleaner cabinet is installed securely on the return side of the system.

2. The arrow on the lter media points in the direction of the air ow.

3. If used, turning vanes and transitions are installed properly.

4. All joints in ductwork and between TechPure air cleaner and furnace/air handler are properly

sealed to prevent leaks.

5. Blower compartment is cleaned and the original lter has been removed.

6. Use enclosed cleaning cloth to wipe down access door.

Contact Info

TopTech

2000 Parks Oaks Ave

Orlando, FL 32808

Phone: 866-239-4440

Web: http://www.TopTechParts.com

Hours of operation: Mon-Fri (8am-5pm EST)

Disclaimer:

TechPure® products are exclusive products of Carrier Enterprise, LLC. and are manufactured by Dust Free, LP.

This manual suits for next models

10

Table of contents

Other Toptech Air Cleaner manuals

Popular Air Cleaner manuals by other brands

Tion

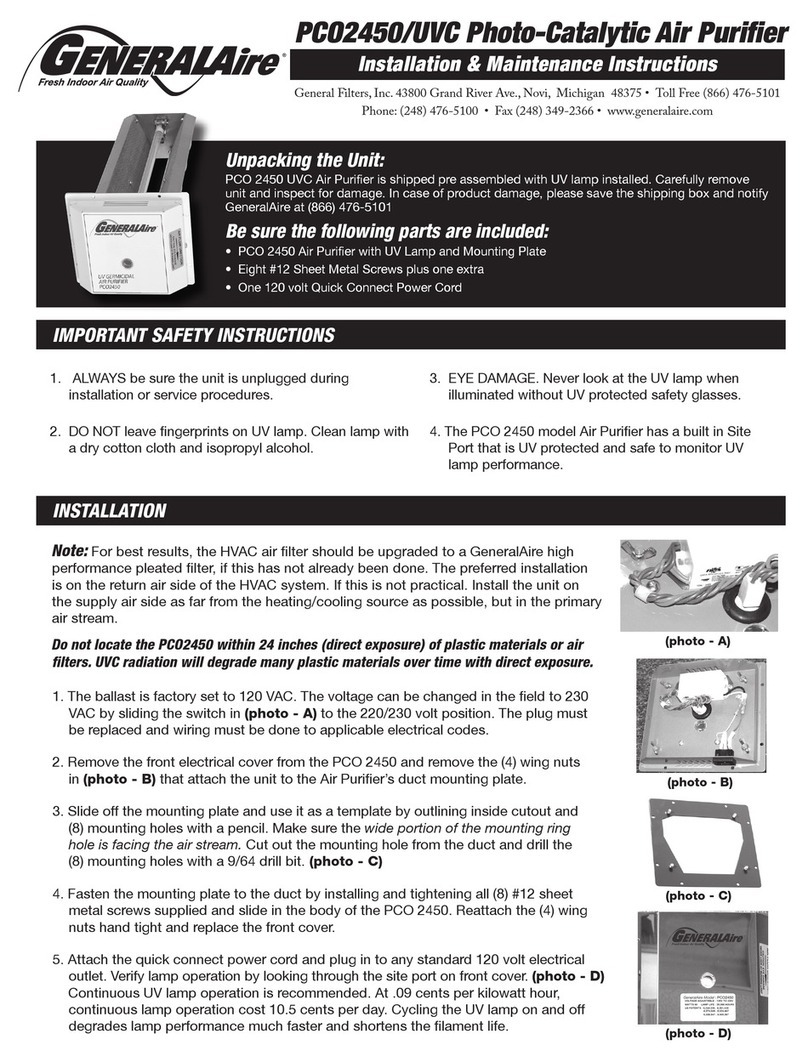

Tion Clever manual

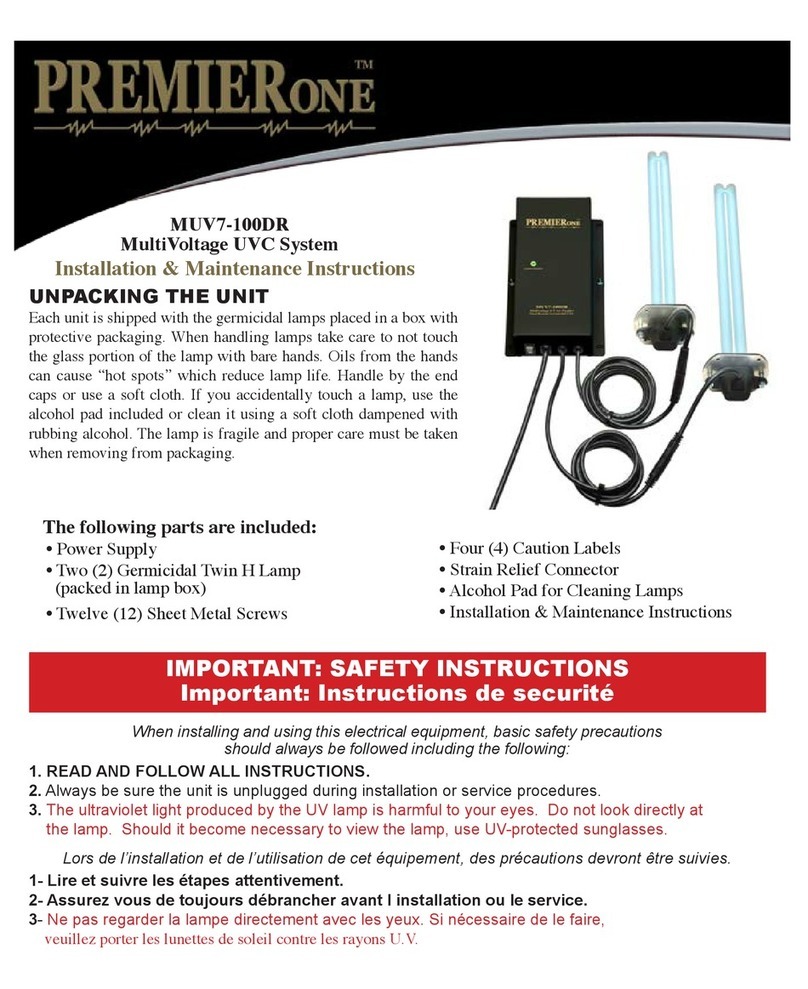

PremierOne

PremierOne MUV7-100DR Installation & maintenance instructions

Healthy Climate Solutions

Healthy Climate Solutions SLIMLINE HCC14-23 installation instructions

Hyundai

Hyundai HYUAP580 instruction manual

Midea

Midea MBF2733PC user manual

COMPLETE COMFORT

COMPLETE COMFORT CC14-23 Installation instructions and homeowner's manual