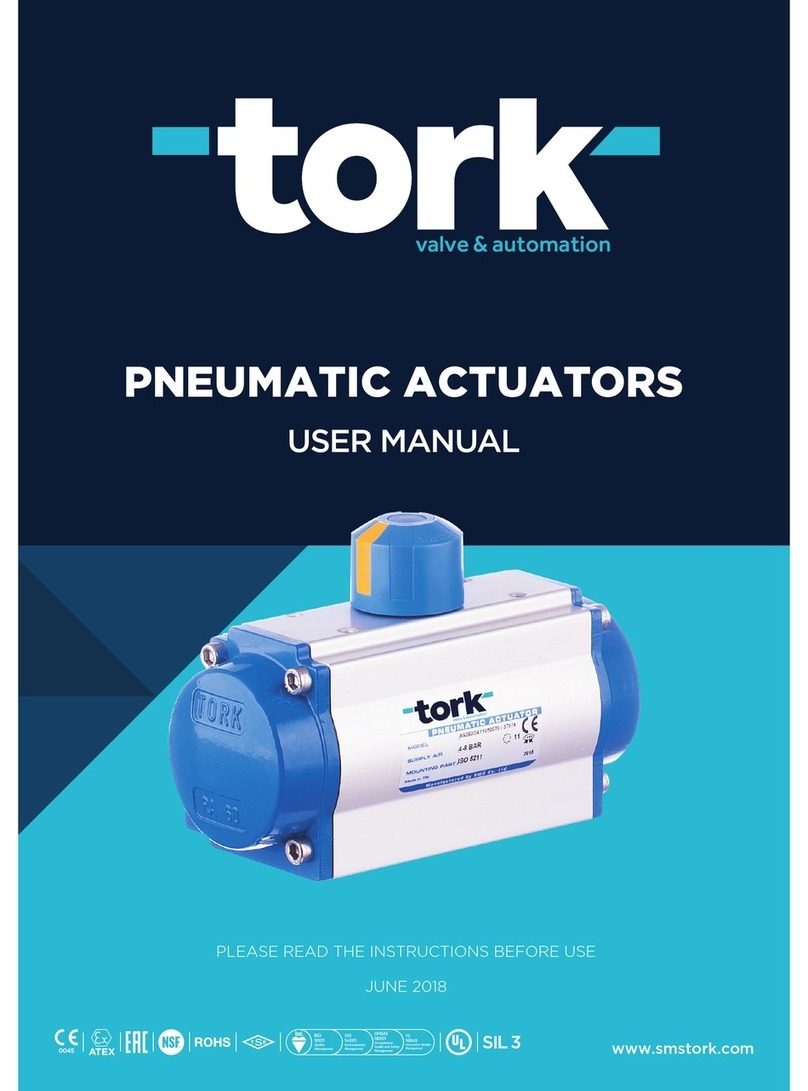

SMS-TORK Endüstriyel Otomasyon Ürünleri San. Tic. Ltd. Şti.

2

Read the operating instructions first.

INDEX

• Follow the safety instructions.

• These operating instructions are part of the product.

• Retaing the operating instructions for life of the product.

• Forward instructions to future users or owners of the product.

Target Group:

This document contains information for installation, commissioning and maintenance personnel.

1. Safety instructions....................................................................................................................................................................

1.1. Security basics............................................................................................................................................................................

1.2. Warnings and precautions................................................................................................................................................

1.3. References and symbols....................................................................................................................................................

1.4. Handwheel safety instructions.......................................................................................................................................

2. Identity.....................................................................................................................................................................................................

2.1. Intended use of the product................................................................…………………...……………………………..…….

2.2. Reasons for use..........................................…………………………………………..........................………………….............….….

2.3. Purpose of the document..............................………………………………………………….........................…………...…..

2.4. Coding system..........…………………………………………………………………………………….........................…………..…...

2.5. Label information..........………………………………………………………………………….........................…………..…...........

2.6. Technicial features...……………………………………………………………………………………..........................…………..…

2.7. Optional features.........................……………………………………………………………………........................…………......…

3. Transport, Storage, Packaging, Warranty and Protection measures......................................

3.1. Transport...………………………………………………………………………………………..........……………………………….....….…

3.2. Storage................………………………………………………………………………………………………………......…………...…...….

3.3. Packaging……….............……………………………………………………………………………………………………………...…......

3.4. Warranty conditions............…………………………………………………………………………………….............................

3.5. Protection measures..............…………………………………………………………………………………….............................

4. Assembly.............................................................................................................................................................................................

4.1. Actuator operation..................…………………………………………………………......................…………….…………..….....

4.2. General structure of the actuator.....…...............………………………………………………………...........................

4

4

4

5

5

5

5

6

6

6

7

8

8

9

9

9

9

10

11

11

11

12

4.3. Mounting position of the actuator......................……………………………………………………….............................

4.4. Mounting of the actuator to the valve and flange dimensions........….................…………………..….

4.5. Manual Control...............………………………………………………………………………………...........................………………...

4.6. Cam, torque switch and limit switch settings.............…......................................................……...........……....

4.7. Stoppers……...........………………………………………………………………………………………....…...........................……….…..

4.8. Technical Dimensions...………………………………………………………………………………………..........................……....

4.9. Atex......................................…………………………………………………………………………………………........................….……...

4.10. Proportional control card......................………………………………………………………………........................….……..

4.11. PIU potentiometer unit....................................……………………………………………………….............................…..……

5. Control Parameters...................................................................................................................................................................

5.1. Manual control with handwheel.......................…………………………........................….…………………………..…….

5.2. Manual control via electronic card.............................................……………..................…………………………..…….

5.3. Proportional control via electronic card............................................………………..................……………..…….

5.3.1 Control signal selection........…………………………………...............................…………….…………..…

5.3.2 Output signal selection (Feedback).......…………….......................…………..………………..…..

5.3.3 Error Positions.................………………………………………………….............................………………..……

5.3.4 Reversible Control signals............……………………………………..........................………………..…

5.3.5 Reversible output signals...............……………………………………............................………..…….…

5.3.6 Automatic calibration.......................………………………………...........................……………….....……

5.3.7 Restarting in protection mode.................................................................…………………....…….…

5.3.8 LEDs and their meanings.......……………………………………………..............................…….....…….

6. Electrical Connections..........................................................................................................................................................

6.1. 230V AC Proportional Electric Actuator Connection Diagram........................................….……….

6.2. 24V DC Proportional Electric Actuator Connection Diagram.......................………...…...….….......

6.3. 230V AC ON/OFF Electric Actuator Connection Diagram........................................…....……….....

6.4. 24V DC ON/OFF Electric Actuator Connection Diagram................................................……….......

7. Spare Parts.......................................................................................................................................................................................