5

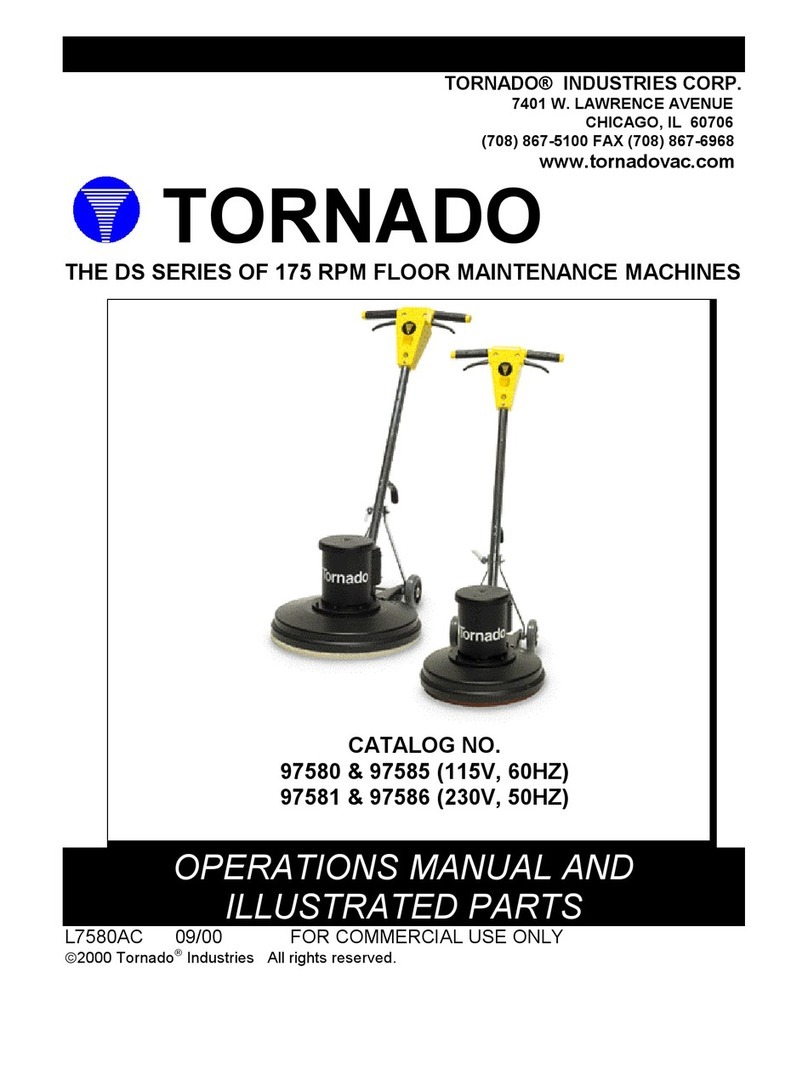

OPERATING AND MAINTENANCE INSTRUCTIONS

OPERATION OF THE MACHINE

Your Tornado® Floor Machine is ready for operation as soon as it is unpacked. Remove the machine

from the pallet and discard bolts.

Before any operation should begin, please read your Kawasaki Owners Manual.

The unit comes shipped without fuel in the tank. Be careful not to overfill the tank. The best method for

filling the tank is to have the full tank weighed at the filling station. The steel tank should weigh no more

than 43 pounds. Also, adjust the handle to a comfortable position and insert the locking pins. Then,

with two 3/4” wrenches tighten the two main bolts in the handle support to 40-50 ft/lbs.

Check the engine oil level. The unit will come shipped with oil. Always keep the engine oil level

between the full and add marks on the dipstick. Replace the oil by performing the following steps :

-Park your Pro-Glazer on a level surface and make sure the engine is stopped.

-Turn the oil cap counter clockwise and then lift from the fill tube.

-Wipe the dip stick clean and push it back into the oil fill tube until the cap seats, and then

withdraw it to check the oil level. (Do not screw in to check level.) Oil level should be

between the “ADD” and “FILL” marks. Add oil if necessary.

-Replace oil cap and tighten.

-If the oil is low, add API Service Classification SF, SG, SH, or SJ oil having a SAE viscosity

grade appropriate for the expected temperatures as indicated in the Kawasaki Owners

Manual.

The machine is shipped with the battery connected.

Inspect all fuel hoses and fittings for leaks. Repair any leaks immediately.

Check the carb filter and air filter for debris. Clean and replace if necessary.

Connect fuel hose to tank by (hand tightening) the hose fitting to the tank. Make sure the connection is

tight to prevent leaks.

PRO-GLAZER STARTING PROCEDURE

The Pro-Glazer PG K17-28 is equipped with a 12-volt starter and key switch.

1. Tilt machine back so the floor pad is off the floor.

2. Turn the fuel tank knob slowly until you hear the flow of the fuel into the fuel system.

3. Place throttle cable into the choke position. Note: Never operate this machine with the engine

throttle control set to the choke position.

4. Turn the key switch fully counterclockwise to the “Start” position and hold it there until the engine

starts. Do not crank more than 5 seconds at a time, and wait at least 15 seconds between tries

when cranking. See Trouble Shooting Table if the engine does not start after several tries.

5. After the engine starts, move the throttle to the slow position. Do not operate buffer until the engine

has warmed up sufficiently, recommended as 3-5 minutes at idle.

6. Lower pad to floor in the slow position, and operate at full throttle.