Pro Sweep

Page 1 -- 2

Safety

Safety Instructions

The Pro Sweep is designed and tested to offer safe ser-

vice when operated and maintained properly. Although

hazard control and accident prevention partially are de-

pendent upon the design and configuration of the ma-

chine, these factors are also dependent upon the

awareness, concern and proper training of the person-

nel involved in the operation, transport, maintenance

and storage of the machine. Improper use or mainte-

nanceof themachinecanresult ininjuryordeath. Tore-

duce the potential for injury or death, comply with the

following safety instructions.

WARNING

To reduce the potential for injury or death,

comply with thefollowing safetyinstructions.

Before Operating

1. Read and understand the contents of the Operator’s

Manual before operating the machine. Become familiar

with the controls and know how to stop the sweeper

quickly. Additional copies of the Operator’s Manual are

available on the internet at www.Toro.com.

2. Keep all shields, safety devices and decals in place.

If a shield, safety device or decal is defective, illegible

or damaged, repair or replace it before operating the

machine.

3. Make sure that any loose nuts, bolts or screws are

tightenedtoensurethat themachineisinsafeoperating

condition.

4. Make sure that the tow vehicle is carefully selected

to assure the best performance and safe operation of

the Pro Sweep.

5. Assuresweeper interlocksystemfunctionscorrectly

so sweeper brush does not rotate unless sweeper is

positioned below the transport position.

6. Make sure that operator is familiar with tow vehicle

operation.

While Operating

1. Operator should be in the operators position when

operating the tow vehicle and sweeper. Stay away from

the sweeper when the brush is engaged.

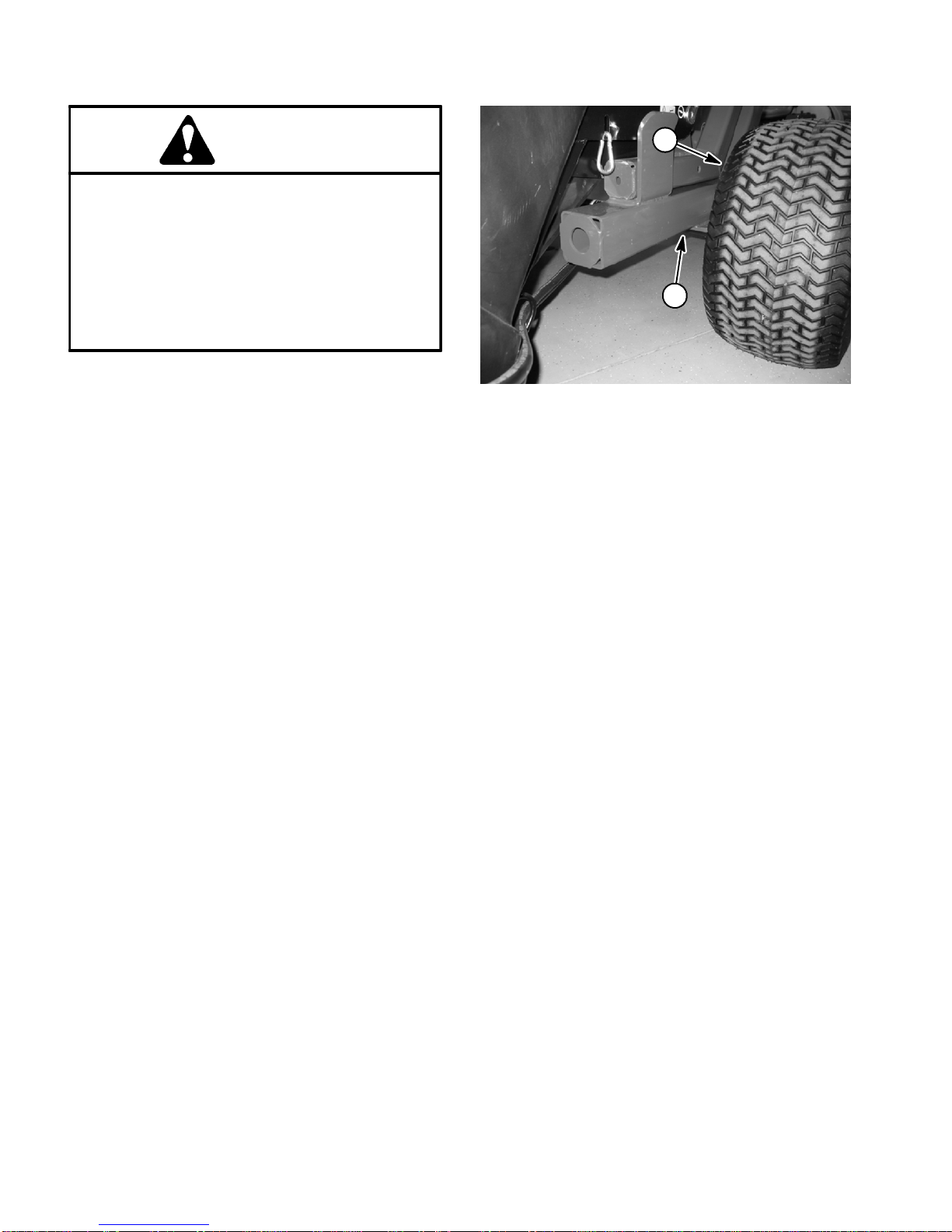

2. Make sure that hitch pin is properly positioned in tow

vehicle and sweeper. Hitch pin should be secured with

hairpin clip.

3. Donotruntowvehicleengineinaconfinedareawith-

out adequateventilation. Exhaust fumes arehazardous

and could possibly be deadly.

4. Do not touch tow vehicle engine, muffler or exhaust

pipe while engine is running or soon after it is stopped.

These areas could be hot enough to cause burns.

5. If abnormal vibration is detected, stop tow vehicle

and sweeper immediately and determine source of

vibration. Correct problems before resuming the use of

sweeper.

6. While operating, the Pro Sweep may exceed noise

levels of 85dB(A) at the operator position. Hearing

protection is recommended for prolonged exposure to

reduce the potential of permanent hearing damage.

7. Before leaving the operator’s position of the tow ve-

hicle:

A. Stop sweeper brush by shutting off vehicle hy-

draulic flow to the sweeper.

B. Make sure that dump hopper is lowered.

C. Ensurethat vehicletractionlever isin neutral,ap-

ply parking brake, stop engine and remove key from

ignition switch.

8. Position sweeper on level surface, empty hopper

and chock sweeper wheels before disconnecting Pro

Sweep from tow vehicle.