Toro 4045 User manual

FormNo.3395-934RevA

CamSensorImprovementsKit

4045DirectionalDrill

ModelNo.132-4165

InstallationInstructions

WARNING

CALIFORNIA

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

Safety

SafetyandInstructionalDecals

125-6184

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescriptionQty.Use

Thrustwasher1

Washer1

1Flangelocknut1

Installtherod-loaderspacer.

Rod-loadersensor1

Bracket1

Plate1

Flangenut2

Bolt(M6–1x16mm)2

Hexnut(M10)1

Flatwasher2

Bolt(M10–1x40mm)1

Bolt(M4x10mm)2

Nut(M4)2

2

Sensorharnessadapter1

Installtherod-loadersensor.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved*3395-934*A

ProcedureDescriptionQty.Use

Bracket1

Bolt(M12-13/4x60mm)2

Locknut(M12)2

Hexnut(M10)1

Bolt(M4)2

Sensorassembly1

Nut(M4)2

Cotterpins2

Sensorharnessadapter1

3

Sensor-connectorclip1

Installtherodcamsensor.

4Gasket1Removingtherotarypumpsupplyand

drainorices.

Monitorcap1

5Decal1Installthecapanddecal.

1

InstallingtheRodLoader

Spacer

Partsneededforthisprocedure:

1Thrustwasher

1Washer

1Flangelocknut

Procedure

RefertolocationhighlightedinFigure1forthisprocedure.

Figure1

1.Supporttherodloaderassemblytoensurethatthe

pivotpinassemblyisabletomove.

2.Removethesensorassemblyandbracketandsetaside

thehardware(Figure2).

Figure2

3.RemovetheretainingboltandnutasshowninFigure3.

Figure3

1.Retainingnut(existing)2.Retainingbolt(existing)

4.Movetherod-loaderassemblytothesidetocreatea

gapforthewasher.

2

Important:Movetherodloaderassemblyasfar

aspossiblesothatthereisnotagapbetweenthe

rod-loaderpivotandtheloaderassembly(Figure

4).

5.Slidethepivotpinouttoallowtheinstallationforthe

washer(Figure4).

Figure4

1.Washer3.Pivotpin

2.Ensurethereisnogap

here.

6.Installthethickwasher.

Note:Ifthegapisnotlargeenoughforthethick

washer,installthethinwasher.

7.Installthepivotpin.

8.Installtheretainingboltpreviouslyremovedandthe

locknutincludedinthiskitasshowninFigure5.

Figure5

1.Flangelocknut(new)2.Retainingbolt(existing)

9.Torquetheboltto23to29N-m(17to21ft-lb).

2

InstallingtheRodLoader

Sensor

Partsneededforthisprocedure:

1Rod-loadersensor

1Bracket

1Plate

2Flangenut

2Bolt(M6–1x16mm)

1Hexnut(M10)

2Flatwasher

1Bolt(M10–1x40mm)

2Bolt(M4x10mm)

2Nut(M4)

1Sensorharnessadapter

Procedure

1.Applythread-lockingcompoundtotheboltsremoved

inStep2in1InstallingtheRodLoaderSpacer(page

2)andlooselyinstallthebracketusingtheboltsand

R-clampasshowninFigure6.

Figure6

2.Looselyinstalltheplateonthebracketusing2bolts

(M6–1x16mm)and2angenutsasshowninBox

AofFigure7.

3

Figure7

1.Flangenut7.Applythread-locking

compoundwhen

tighteningthesebolts.

2.Bolts(M6–1x16mm)8.Sensor-magnetbolt

3.Bolt(M10–10x40mm)9.Bolt(M4x10mm)

4.Flatwashers10.Sensor

5.Hexnut11.Nut(M4)

6.Pivotpin

3.Installthebolt(M10-1x40mm),2atwashers,and

thehexnut(M10)ontothebracketplateandpivotpin

asshownBoxBofFigure7.

Note:Usethewasherstocenterthebracketandplate.

4.Tightenallofthehardwarethatissecuringthebrackets

tothemachine(BoxCofFigure7).

5.Torquetheboltsto972to1198N-cm(86to106in-lb).

6.Torquethebolts(M6)to972to1198N-cm(86to106

in-lb).

7.Removethebolt(M10–1x40mm),2atwashers,and

thehexnutfromthebracketplateandpivotpin(Box

BofFigure7).

8.Installthesensormagnetboltandhexnutintothe

pivotassemblyasshowninBoxDofFigure7.

9.Installthesensorontothebracketusing2bolts(M4

x10mm)and2nuts(M4–0.7inch)asshowninBox

EofFigure7.

Note:Usethread-lockingcompoundontheboltsif

thelocknutsarenotnylonlocknuts.

10.PlacethecamassemblyintheHOMEpositionand

ensurethatthenotchinthemagneticsensorboltis

linedupwiththewiresonthesensorasshownin

Figure8.

Figure8

1.Notch

11.Ensurethatthegapbetweenthemagneticsensorbolt

andthesensoris0.12to0.24inch.

12.Securethesensortothebracketwithacabletieas

showninFigure9.

g0297 13

Figure9

13.Torquethebolts(M4)to2.2to2.7N-m(19to23ft-lb).

14.Attachthesensor-harnessadaptertotheR-clampon

thebracketandattachtheadaptertothesensoras

showninFigure9.

15.Usethesensorharnessadaptertoconnectthesensor

tothewiringharnessofthemachine.

4

3

InstallingtheRodCamSensor

Partsneededforthisprocedure:

1Bracket

2Bolt(M12-13/4x60mm)

2Locknut(M12)

1Hexnut(M10)

2Bolt(M4)

1Sensorassembly

2Nut(M4)

2Cotterpins

1Sensorharnessadapter

1Sensor-connectorclip

Procedure

RefertolocationhighlightedinFigure10forthisprocedure.

Figure10

1.Removethecotterpinsontheelevatorcylinder(Figure

11).

Note:Donotdisconnectthehydraulichoses.

Figure11

2.Placetheelevatorcylinderasidetogainaccesstothe

sensorbracket.

3.Removethesensorassemblyandbracketasshownin

BoxAofFigure12.

Figure12

1.Locknuts(M12)4.Hexnut(M10)

2.Bolts(M12-13/4x60mm)5.Flatwashers

3.Bracket6.Bolt(M10)

4.Looselyinstallthenewbracketwith2bolts(M12-1

3/4x60mm)and2locknuts(M12)asshowninBox

BofFigure12.

5

5.Installthebolt(M10-1x40mm),2atwashers,and

thehexnut(M10)ontothebracketplateandpivotpin

asshownBoxCofFigure12.

Note:Usethewasherstocenterthebracketandplate.

6.TightenthehardwareasshowninBoxDofFigure12.

7.Torquethebolts(M12)to80to100N-m(59to73

ft-lb).

8.Removethebolt(M10-1x40mm),2atwashers,and

thehexnutfromthebracketplateandpivotpin(Box

CofFigure12).

9.Installthesensor-magnetboltandhexnutintothe

pivotassemblyasshowninBoxAofFigure13.

Figure13

1.Hexnut4.Bolts(M4x10mm)

2.Sensor-magnetbolt5.Nuts(M4)

3.Cotterpins

10.Installthesensorontothebracketusing2bolts(M4x

10mm)and2nuts(M4)asshowninBoxBofFigure

13.

Note:Usethread-lockingcompoundontheboltsif

thelocknutsarenotnylonlocknuts.

11.PlacethecamassemblyintheHOMEpositionand

ensurethatthenotchinthemagneticsensorboltis

linedupwiththewiresonthesensorasshownin

Figure14.

Figure14

12.Ensurethatthegapbetweenthemagneticsensorbolt

andthesensoris0.12to0.24inches.

13.Ifyourbracketdoesnothaveahole,measurein11/14

inchfromtheedgeofthebracketasshowninFigure

15anddrilla1/4inchhole.

Figure15

1.11/4inch3.Sensor-connectorclip

2.Sensor

14.Attachthesensor-connectorcliptothesensoras

showninFigure15.

15.Plugthesensor-connectorclipintotheholeasshown

inFigure16.

6

Figure16

1.Sensor2.Sensor-harnessadapter

16.Attachthesensor-harnessadaptertothesensoras

showninFigure16.

17.Connectthesensor-harnessadaptertothewiring

harnessonthemachine.

18.SecurethewiringharnesstotheR-clampwithacable

tieasshowninFigure17.

Figure17

1.Wiringharness(existing)

19.Torquetheboltsto2.2to2.7N-m(19to23in-lb).

20.Installtheelevatorcylinderwiththe2cotterpins

includedinthiskitasshowninBoxCofFigure13.

21.Usethesensorharnessadaptertoconnectthesensor

tothemachineswiringharness.

4

RemovingtheRotaryPump

SupplyandDrainOrices

Partsneededforthisprocedure:

1Gasket

Procedure

Important:Allowtheenginetocool.

1.Placeadrainpanundertheyrotarypump

2.Capoffthecasedrainlinefromtherotarypumpto

minimizehydraulicuidloss.

Figure18

1.Boltstoberemoved2.Capoffthecasedrainline

3.Cleantheexternalsurfaceoftherotarypump.

4.Unplugthewiringharnessfromthepumpcontrol.

5.Removethe6boltsasshowninFigure18.

6.Removethecontrolfromthepumphousing.

Note:Oilwilldrainfromthecasewhenthehousing

isremoved.

7.Useneedlenoseplierstopulltheretainingclip(T40)

fromthecontrol(Figure19).

7

Figure19

1.T40,T30,andT20orices

8.Removethespring(T30)andsupplyorice(T20)from

thecontrol(Figure19).

9.Cleanthesealingsurfacesofthepumphousingand

controlhousing

10.Installthecontrolhousingontothepumpusingthe

newgasket.

Important:Thecontrollinkagepinonthecontrol

mustbeinsertedintotheswash-platelinkinthe

pump.

Note:Usepetroleumjellytohelpholdtheswash-plate

linkinplacewhilethecontrolisinstalled.

Note:Therewillberesistancewhenthefrontedge

ofthecontrolistiltedawayfromthepumphousingif

thecontrollinkagepinisinsertedintotheswash-plate

linkcorrectly.

Note:Ifthecontrollinkagepinisnotproperly

insertedintotheswash-platelink,thepumpwillnot

returntoneutralandtherotarymotorwillspinupon

enginestartup.

11.Installthe6retainingbolts;torquetheboltsto16N-m

(12lb-ft).

12.Connectthecasedrainlineandchecktheyhydraulic

uidlevel;refertotheOperator’sManualforthemachine.

13.Connectthewiringharnesstotherotarypumpcontrol.

14.Wipeupanyspilledoil.

15.Startthemachinetotesttherotarypump.

Note:Iftherotaryoutputspinswhenthemachine

isstartedbuttherotationcommandisnotgiven,the

controllinkagepinisnotproperlyinsertedintothe

swash-platelink.Removeandcapthecasedrainline

andrepeattheabovesteps.

CheckingtheNeutralAdjustment

1.Installa1000psigaugeineachofthedisplacement

controlports(M4andM5).

Figure20

1.M72port(adjustingscrew)3.M5port(displacement

controlport)

2.M90port(locknut)4.M4port(displacement

controlport)

2.Disconnecttheelectricalconnectorfromtherotary

pumpcontrol,startthemachine,andbringittohigh

idle.

3.Loosenthelocknut(M90)witha10mmand13mm

hexwrench.

4.Usinga3mmor4mminternalhexwrench,rotate

theadjustingscrew(M72)clockwiseuntilthepressure

increasesin1ofthepressuregauges.

Note:Notetheangularpositionofthewrench.

5.Rotatetheneutral-adjustingscrewcounterclockwise

untilthepressureincreasesbyanequalamountasthe

othergauge.

Note:Notethepositionofthewrench.

6.Rotatetheadjustingscrew(M72)clockwisehalfthe

distancebetweenthelocationnotedinstep(4or5).

Note:Thegaugesshouldreadthesamepressure(case

pressure),indicatingthatthecontrolisinitsNEUTRAL

position.

7.Holdtheneutral-adjustingscrewstationaryandtighten

theneutral-adjustinglocknutto7N-m(62lb-in)forthe

6mmscrewor13N-m(120lb-in)forthe8mmscrew .

8.OncetheNEUTRALpositionisset,stoptheengine,

removethegauges,andremovethegaugeports.

9.Connecttheelectricalconnectortotherotarypump

control.

8

5

InstallingtheCapandDecal

Partsneededforthisprocedure:

1Monitorcap

1Decal

Procedure

Gentlyliftthemonitorawayfromtheconsoleusinga

at-headscrewdriverinthegapsasshowninBoxAofFigure

21.

Figure21

1.Gapsbetweenthemonitorandconsolepanel

Insertthemonitorcapintotheportonthebackofthe

monitorandinstallthemonitorbackontotheconsole(Box

BofFigure21).

InstallthedecalasshowninFigure22.

Figure22

1.Decal

9

Notes:

10

Notes:

11

Other manuals for 4045

2

This manual suits for next models

1

Other Toro Drill manuals

Popular Drill manuals by other brands

EINHELL

EINHELL BT-CD 24 I operating instructions

Festool

Festool C 18 Li Original operating manual

Hitachi

Hitachi FDV 16VB2 Technical data and service manual

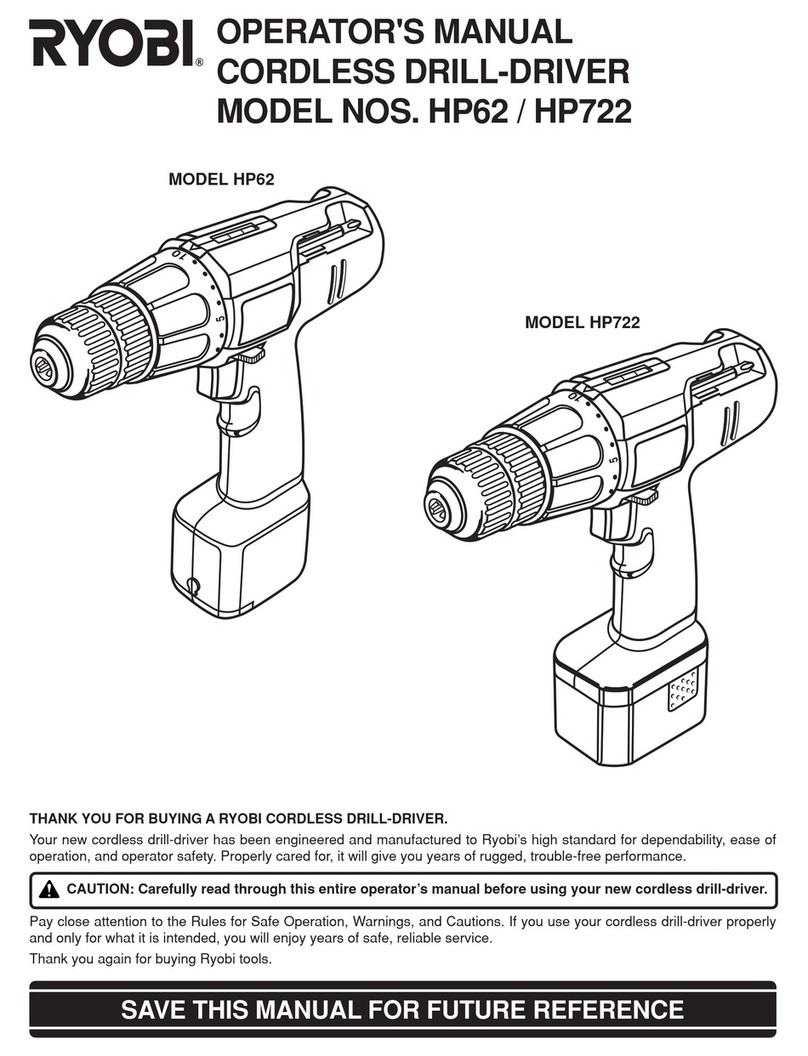

Ryobi

Ryobi HP62 Operator's manual

Black & Decker

Black & Decker 7264 owner's manual

Florida Pneumatic

Florida Pneumatic FP-985 General Safety Information & Replacement Parts