Toro 4045 User manual

FormNo.3401-924RevA

4045DirectionalDrill

ModelNo.23825—SerialNo.313000501andUp

ModelNo.23825—SerialNo.314000501andUp

Registeratwww.Toro.com.

OriginalInstructions(EN)*3401-924*A

ThisproductcomplieswithallrelevantEuropeandirectives;

fordetails,pleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

GenuineTorosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

Theenclosed

Engine Owner's Man ual

issuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Forradiofrequencycomplianceinformation,referto

your

Compliance Statement Addendum

thatpertains

toyourcountry.

Introduction

Thismachineisadirectionaldrillintendedforunderground

drillingandpullbackoperationforutilitylinesincluding

electrical,gas,communication,water,etc.Itisdesignedto

operateawidevarietyofattachmentseachofwhichperform

aspecializedfunction.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww.Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA.

AllRightsReserved

Contents

Safety...........................................................................4

Training.................................................................4

Preparation.............................................................4

GeneralOperation..................................................4

DrivingSafety.........................................................5

DrillingSafety.........................................................6

MaintenanceandStorage..........................................8

NoiseandVibrationLevels.......................................8

SafetyandInstructionalDecals.................................9

ProductOverview.........................................................21

Controls...............................................................24

OperatorPlatform..............................................24

ControlPanel.....................................................36

LeftJoystick—ModeI.........................................37

LeftJoystick—ModeII........................................38

RightJoystick—ModeI.......................................39

RightJoystick—ModeII......................................40

RearControlPanel..............................................41

DrillFrameandStabilizerControls........................42

DrivePendant....................................................43

DrillPendant......................................................44

Stake-downLevers..............................................45

Specications........................................................46

Attachments/Accessories........................................46

Operation....................................................................47

UnderstandingHorizontalDirectionalDrilling

........................................................................47

GatheringSiteInformation......................................48

PlanningtheBorePath............................................51

UnderstandingandUsingtheExit-side-lockout

System..............................................................56

PreparingtheJobSiteandtheMachine......................58

DrillingtheBore....................................................68

BackreamingandPullback.......................................72

FinishingtheJob....................................................74

UsingtheTJCApplicator........................................74

MovingaDisabledMachine.....................................76

ReplacingthePipeHolder.......................................76

PositioningtheCab(ModelwithCabonly).................77

OpeningtheDoor(ModelwithCabonly)..................77

OperatingtheAirConditioningandHeating

(ModelwithCabonly).........................................78

OperatingtheWindshieldWipers(ModelwithCab

only).................................................................78

Maintenance.................................................................79

RecommendedMaintenanceSchedule(s)......................79

PremaintenanceProcedures........................................81

OpeningtheFrontHood.........................................81

OpeningtheRear-accessDoor.................................81

UsingtheCylinderLock..........................................82

Lubrication...............................................................83

GreasingtheMachine.............................................83

EngineMaintenance..................................................85

CleaningtheCrankcase-ventTube............................85

ServicingtheAir-cleaningSystem.............................85

ServicingtheEngineOilandFilter............................87

AdjustingtheValveClearance..................................89

FuelSystemMaintenance...........................................90

DrainingWaterfromtheFuelFilter...........................90

DrainingWaterfromtheFuelTank...........................90

PrimingtheFuelSystem..........................................91

ReplacingtheFuelFilters.........................................91

CheckingtheFuelLinesandConnections..................92

DrainingandCleaningtheFuelTank.........................92

ElectricalSystemMaintenance....................................93

ServicingtheBattery...............................................93

ChargingtheBattery...............................................94

Jump-startingtheMachine.......................................94

DriveSystemMaintenance.........................................95

CheckingtheOilLevelfortheStakedown

PlanetaryDrive..................................................95

CheckingtheOilLevelfortheTracksPlanetary

Drive................................................................96

ChangingtheOilfortheTracksPlanetary

Drive................................................................96

CheckingtheOilLevelfortheRotaryMotor

PlanetaryDrive..................................................97

CheckingtheOilfortheThrustMotorPlanetary

Drive................................................................97

CheckingtheOilfortheGearboxDrive.....................98

ChangingtheOilfortheGearboxDrive.....................98

ServicingtheTracks................................................99

CoolingSystemMaintenance....................................100

CheckingtheCoolantLevelintheRadiator..............101

CheckingtheConditionofCooling-system

Components....................................................101

CheckingtheConcentrationoftheCoolant..............101

CleaningtheCoolingSystem..................................101

BeltMaintenance....................................................104

ServicingtheEngine-driveBelt...............................104

HydraulicSystemMaintenance..................................106

ServicingtheHydraulicFluid.................................106

Drilling-FluidPumpMaintenance..............................109

ServicingtheDrilling-uid-pumpOil......................109

PreparingtheDrilling-uidSystemforCold

Weather...........................................................111

CabMaintenance.....................................................113

ChangingtheCabAirFilter....................................113

FillingtheWindshield-washerFluidTank.................113

Cleaning.................................................................114

CleaningwiththeSpray-hoseAttachment................114

CleaningPlasticandResinParts..............................114

Storage......................................................................115

Troubleshooting.........................................................116

Index........................................................................119

3

Safety

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructions,andpayattentionto

thesafetyalertsymbol,whichmeansCaution,Warning,or

Danger—“personalsafetyinstruction.”Failuretocomply

withtheinstructionsmayresultinpersonalinjuryor

death.

Important:Thismachinewasmanufacturedaccording

totheappropriateregulatorystandardsineffectatthe

timeofmanufacture.Modifyingthismachineinany

waymaycauseittobeoutofcompliancewiththose

standardsandwiththeinstructionsinthis

Operator’ s

Man ual

.Modicationstothismachineshouldonlybe

madebyeitherthemanufactureroranAuthorizedToro

Dealer.

Thisproductiscapableofamputatinghandsandfeet.Follow

allsafetyinstructionstoavoidseriousinjuryordeath.

Theowner/usercanpreventandisresponsibleforaccidents

orinjuriesoccurringtopeople,ordamagetoproperty.

Important:Beforeoperatinginanareawith

high-voltagelinesorcables,contacta“One-Call

SystemDirectory”service.IntheUSA,call811or

yourlocalutilitycompany.Ifyoudonotknowyour

localutilitycompany’sphonenumber,callthenational

number(USAandCanadaonly)at1-888-258-0808.Also,

contactanyutilitycompaniesthatarenotparticipants

ofthe“One-CallSystemDirectory”service.Please

refertoDrillingNearUtilityLines(page6)formore

information.

Training

•ReadtheOperator'sManualandothertrainingmaterial.

Note:Iftheoperator(s)ormechanic(s)cannotreadthis

manual,itistheowner'sresponsibilitytoexplainthis

materialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Donotletchildrenoruntrainedpeopleoperateorservice

theequipment.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothing;includingahardhat,safety

glasses,longpants,substantialslip-resistantsafetyshoes

(rubberboots),gloves,andhearingprotection.Tieback

longhair.Donotwearjewelry.

•Inspecttheareawheretheequipmentistobeusedand

ensurethatallobjectsareremovedfromtheareabefore

use.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Donotremovethefuelcaporaddfuelwiththe

enginerunning.Allowtheenginetocoolbefore

refueling.Donotsmokenearthemachinewhenthe

engineisrunning.

–Donotrefuelordrainthemachineindoors.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlesstheyare

functioningproperly.

GeneralOperation

•Donotruntheengineinanenclosedarea.

•Donotoperatewithouttheguardssecurelyinplace.Be

sureallinterlocksareattached,adjusted,andfunctioning

properly.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Keepawayfrommovingmachinepartsandpipes.

•Donotoperatethemachinewhenill,tired,orunderthe

inuenceofalcoholordrugs.

•Donotleavethemachinerunningunattended.Stopthe

engineandremovethekeybeforeleaving.

•Locatethepinch-pointareasmarkedonthemachineand

attachmentsandkeephandsandfeetawayfromthese

areas.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

4

DrivingSafety

Youdrivethemachinetoandfromtheworksitewiththeuse

ofatetheredremote.Whendrivingthemachine,observethe

followingsafetyprecautions:

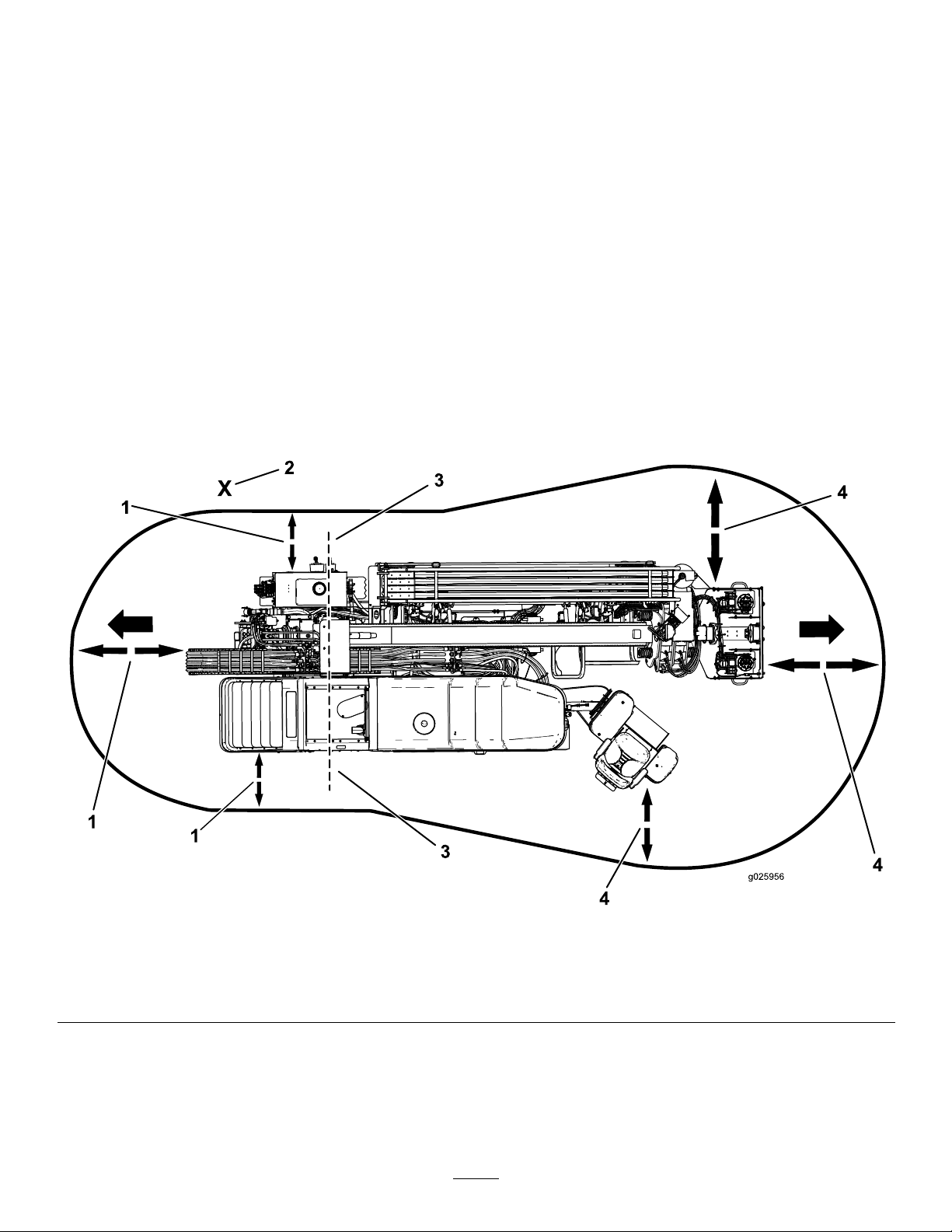

•Operatethedrivependantalongsidethemachineoutside

ofthedangerzone(Figure3).

•Keepallbystandersawaywhilemovingthemachine.

•Donotcarrypassengersonthemachine.

•Watchfortheturning-radiussweepofthedrillframe,as

thecenteroftheturningradiusistheendofthetrack.

•Movingthemachinewiththetetheredremotecan

beerratic;moveslowlywhenusingtheremotefor

movement.

•Usecarewhenloadingorunloadingthemachineontoa

trailer.

•Watchfortrafcwhencrossingroadways.

•Checkforoverheadclearances(i.e.branches,doorways,

electricalwires)beforedrivingunderanyobjectsanddo

notcontactthem.

•Usecarewhendrivingthemachineonsoftorunstable

ground.

Note:Softorunevengroundcanreducestability.

•Whendrivingonaslope,theoperatorshouldbeup-slope

fromthemachine.

Note:Themachinecanbeunstableonslopes.

•Driveinaccordancewiththeweatherconditions.

Note:Drivewithcautionduringadverseweather

conditions.

Thefollowingillustrationdisplaysthesafedistancethatmust

bekeptbyallindividualswhilemovingthemachine.

Figure3

DrivingDangerZone

1.1.8m(6ft)safetydistance3.Turning-radiuscenter

2.Operator4.3m(10ft)safetydistance

5

DrillingSafety

•Alwayslowerthepedestriansafetybarbeforedrilling

(Figure4).

•Ensurethatnooneapproachesapipewhileitisspinning.

Thepipecansnagonclothingandcauseamputation

ordeath.AlwaysengagetheExit-sideLockoutbefore

anyoneapproachesthefrontofthemachine,bit,reamer,

orpipe.

DrillingDangerZone

Thedangerzoneistheareawithinandaroundthemachine

whereapersonisexposedtotheriskofinjury.Thisproximity

includeswhereapersonisreachablebyoperationalmovement

ofthemachine,itsworkingdevices,auxiliaryequipment,or

swinging/fallingequipment.

Thefollowingillustrationdisplaysthesafedistancerequired

byallindividualswhiledrilling.

Figure4

DrillingDangerZone

1.3m(10ft)safetydistance3.1.8m(6ft)safetydistance

2.Pedestriansafetybar

DrillingNearUtilityLines

Important:Beforeoperatinginanareawith

high-voltagelinesorcables,contacta“One-CallSystem

Directory”service.IntheUSA,call811oryourlocal

utilitycompany.Ifyoudonotknowyourlocalutility

company’sphonenumber,callthenationalnumber

(USAandCanadaonly)at1-888-258-0808.Also,contact

anyutilitycompaniesthatarenotparticipantsofthe

“One-CallSystemDirectory”service.

6

UtilityLineColor

Refertothefollowingtablefortheproperutilitylineandthecorrespondingutilitylinecolor(USAandCanada).

UtilityLineUtilityLineColor

ElectricRed

Telecommunication,alarmorsignal,cables,orconduitOrange

Naturalgas,oil,steam,petroleum,orothergaseousorammable

material

Yellow

SeweranddrainGreen

DrinkingwaterBlue

Reclaimedwater,irrigation,andslurrylinesPurple

TemporarysurveymarkingsPink

ProposedexcavationlimitsWhite

ElectricalLineSafety

WARNING

Ifyouleavetheseatofthemachineortouch

anypartofthemachinewhenitischargedwith

electricity,seriousinjuryordeathcouldresult.

Donotleavetheseatofthemachineifthemachine

ischargedwithelectricity.

Intheeventofanelectricstrikethatchargesthemachine,the

Zap-AlertElectricStrikealarmsystemwillsoundforaslong

asthemachineischargedwithpower.

Note:Immediatelycontacttheproperemergencyandutility

authoritiestosecuretheareainthecasethatthemachineis

chargedandyoucannotleavetheseatofthemachine.

Note:Itispossibletostrikeautilitylinewithoutthemachine

becomingcharged.

•Thealarmwillsoundifthedrillcontactsanelectrical

powersource.

•Itislikely(butnotalwaysthecase)thatthepower-source

interrupterorbreakerwilltrip,buttoensureyoursafety,

considerthatthemachinemaybeconductingelectricity.

•Donotattempttoleavethemachine.

Important:Youwillbesafeaslongasyoudonot

leavetheseatofthemachine.

•Touchinganypartofthemachinemaygroundyou.

•Donotallowanotherindividualtotouchorapproach

themachinewhencharged.

•Thealarmmaysoundifacommunicationlineisbroken,

butuntilyouarecertain,youmustconsiderthealarmto

beanelectricstrike.

GasLineSafety

WARNING

Ifyoudamageagasline,animmediateexplosion

andrehazardcouldoccur.Leakinggasisboth

ammableandexplosiveandmaycauseserious

injuryordeath.

•Donotsmokewhileoperatingthemachine.

•Shutoffthemachineandremovethekey.

•Removeallindividualsfromtheworkarea.

•Immediatelycontacttheproperemergencyand

utilityauthoritiestosecurethearea.

WaterLineSafety

Ifyoudamageawaterline,apotentialoodhazard

couldoccur.

•Shutoffthemachineandremovethekey.

•Removeallindividualsfromtheworkarea.

•Immediatelycontacttheproperemergencyand

utilityauthoritiestosecurethearea.

CommunicationLineSafety

Important:RefertoElectricalLineSafety(page7)ifa

communicationlineisdamaged.

CAUTION

Ifyoudamagetheber-opticcableandlookinto

theexposedhighly-intenselight,youmayharm

youreyes.

•Shutoffthemachineandremovethekey.

•Removeallindividualsfromtheworkarea.

•Immediatelycontacttheproperemergencyand

utilityauthoritiestosecurethearea.

7

MaintenanceandStorage

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservice.

•Lowerthethrustframe,stoptheengine,andremove

thekey.Waitforallmovementtostopbeforeadjusting,

cleaning,orrepairing.

•Cleandebrisfromattachments,drives,mufers,and

enginetohelppreventres.Cleanupoilorfuelspillage.

•Lettheenginecoolbeforestoring,anddonotstorenear

aame.

•Donotstorefuelnearamesordrainindoors.

•Parkthemachineonlevelground.

•Donotallowuntrainedpersonneltoservicethemachine.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Disconnectthebatterybeforemakinganyrepairs.

Disconnectthenegativeterminalrstandthepositive

last.Reconnectpositiverstandnegativelast.

•Chargebatteriesinanopen,wellventilatedarea,away

fromsparkandames.Unplugthechargerbefore

connectingordisconnectingitfromthebattery.Wear

protectiveclothinganduseinsulatedtools.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyourface,

eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparksand

amesawayfromthebattery.

•Keepallpartsingood-workingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Ifanymaintenanceorrepairrequirestheframetobein

theraisedposition,securetheframeintheraisedposition

withthehydrauliccylinderlock;refertoInstallingthe

CylinderLock(page82).

•Keepnutsandboltstight.

•Keepequipmentingoodcondition.

•Donottamperwithsafetydevices.

•Keepthemachinefreeofgrass,leaves,orotherdebris

build-up.Cleanupoilorfuelspillage.Allowthemachine

tocoolbeforestoring.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Donotremovethefuelcaporaddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

refueling.Donotsmokewhilerefuelingthemachine.

–Donotrefuelthemachineindoors.

–Donotstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Donotllacontainerwhileitisinsideavehicle,

trunk,pick-upbed,oranysurfaceotherthanthe

ground.

–Keepcontainernozzleincontactwiththetankduring

lling.

•UseonlygenuineTororeplacementpartstoensurethat

originalstandardsaremaintained.

•Keepyourbodyandhandsawayfrompinholeleaks

ornozzlesthatejecthighpressurehydraulicuid.Use

cardboardorpapertondhydraulicleaks;donotuse

yourhands.Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjuryrequiringsurgerywithina

fewhoursbyaqualiedsurgeonorgangrenemayresult.

NoiseandVibrationLevels

WARNING

Theoperatormustwearhearingprotectionwhen

operatingthemachine.Failuretowearhearing

protectionmaycausehearingloss.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’searof92

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN791.

SoundPower

Thisunithasaguaranteedsoundpowerlevelof110dBA,

whichincludesanUncertaintyValue(K)of3.75dBA.

Thesoundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO4871.

VibrationLevel

Measuredvibrationlevelforrighthand=1.8m/s2

Measuredvibrationlevelforlefthand=1.3m/s2

Measuredvibrationlevelforwholebody=0.03m/s2

UncertaintyValue(K)=0.02m/s2

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO20643.

8

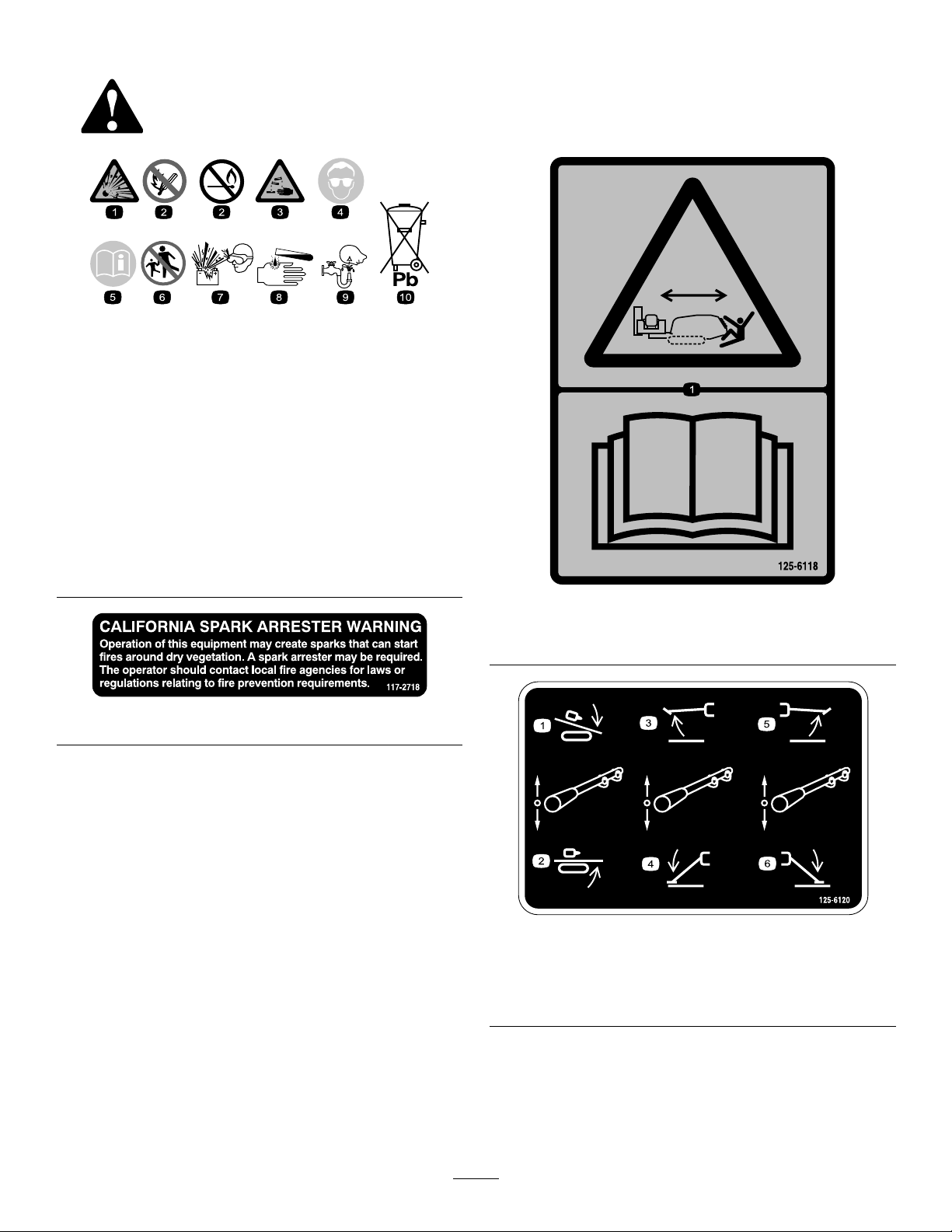

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard6.Keepbystandersasafe

distancefromthebattery.

2.Nore,opename,or

smoking.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries

3.Causticliquid/chemical

burnhazard

8.Batteryacidcancause

blindnessorsevereburns.

4.Weareyeprotection9.Flusheyesimmediately

withwaterandgetmedical

helpfast.

5.ReadtheOperator's

Manual.

10.Containslead;donot

discard.

117-2718

125-6118

1.Crushinghazard,machinemovement—readtheOperator’s

Manual.

125-6120

1.Lowerdrillcarriage4.Lowerleftstabilizer

2.Raisedrillcarriage5.Raiserightstabilizer

3.Raiseleftstabilizer6.Lowerrightstabilizer

9

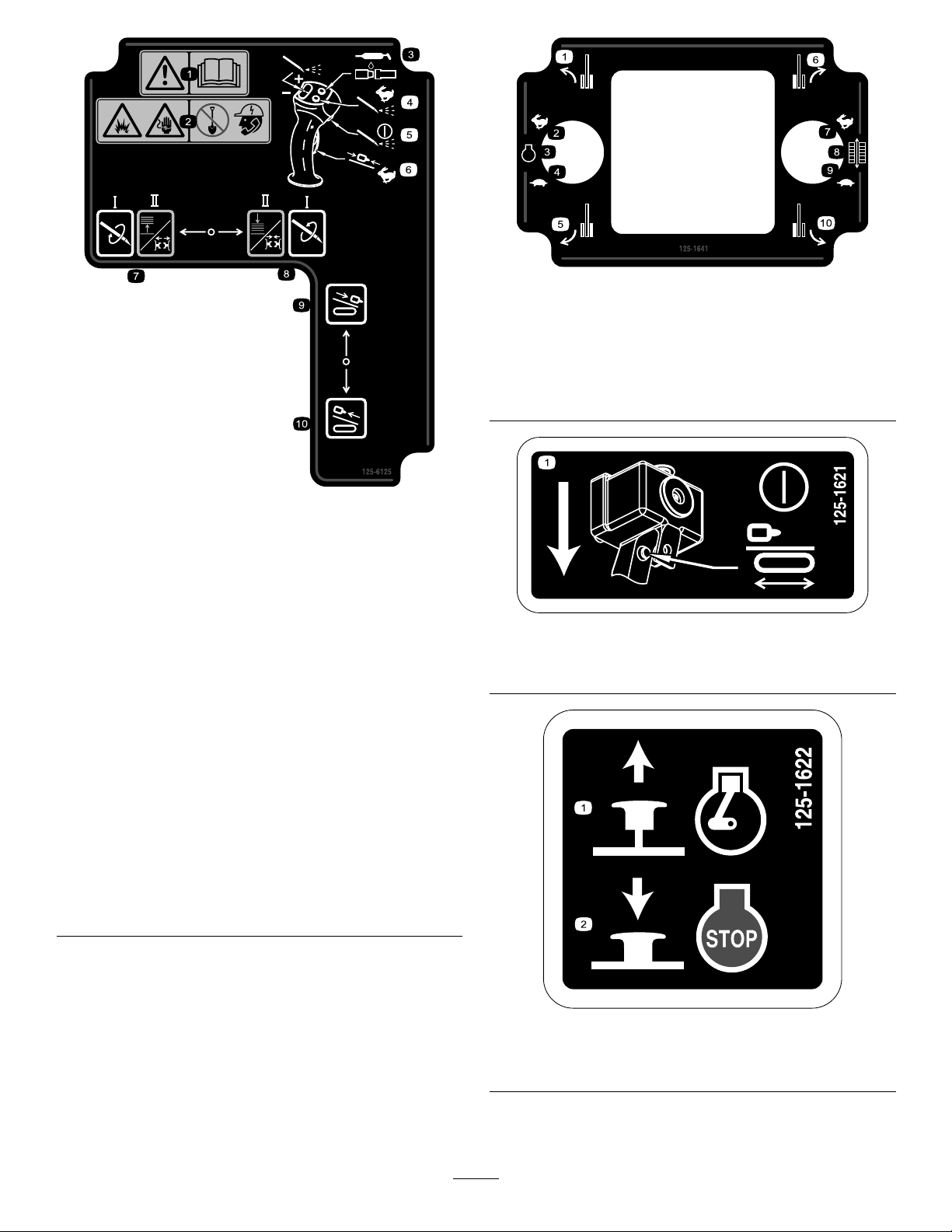

125-6137

125-6108

1.Thrownobjecthazard—readtheOperator’sManual.

125-6694

1.Tie-downpoint

125-8473

1.Explosionhazard—wear

eyeprotection.

3.Firehazard—keepopen

amesaway.

2.Causticliquid/chemical

burnhazard—rinse

affectedareaandseek

medicalassistance.

4.Poisonhazard—donot

tamperwiththebattery.

10

125-6114

1.Storedenergyhazard—donotusetools;readthe

Operator’sManual.

125-6119

1.Entanglementhazard—keepawayfrommovingobjects.

125-6126

1.Entanglementhazard—keepawayfrommovingparts.

125-6131

1.Warning—stayatleast3m(10ft)awayfromthemachine.

11

125-6115

1.Crushinghazard—deploycylinderlocksbeforeperforming

maintenance.

125-6110

1.Crushinghazard—donotstandunderanypartofthe

machine.

125-6128

1.Highpressureuidhazard,injectionintothebody—read

theOperator’sManualbeforeperformingmaintenance.

125-6130

1.Warning—readtheOperator’sManual;stayatleast3m(10ft)awayfromthefrontandrearofthemachineand1.8m(6ft)

awayfromthesidesofthemachine.

12

125-6109

1.Electricalshockhazard—whentheZap-Alertsystemis

activatedbyapowerstrike,donotleavetheoperator’s

positionortouchthegroundandthemachineatthesame

time;themachinewillbeenergizedwithelectricalpower.

125-6111

1.Stakeup6.Stakeup

2.Stakedown7.Stakespin

counterclockwise

3.Stakespin

counterclockwise

8.Stakedown

4.Stakespinclockwise9.Stakespinclockwise

5.Leftstake10.Rightstake

125-6123

1.Loadpipesfrombackrowrst.

125-6124

1.Centerthepipejointbetweentheupper(makeup/breakout

wrench)andlowerwrenches(stationarywrench).

13

125-6107

1.Crushinghazardofhandandfoot—keephandsandfeet

away.

125-6116

1.Fallinghazard—donotmovethemachinewhensomeone

isintheoperator’sposition.

125-6140

1.Rotatethechair.

125-6152

1.Moveseatforwardsandbackwards.

14

125-6158

ModelwithCabonly

1.Engine—start13.Withtriggerreleased,rockforwardtorotatebaskettoward

pipecam,rockbackwardtorotatebaskettowarddrillframe.

2.Pressdowntostoptheengine14.Withtriggerreleased,upperbuttonclosespipegripper,lower

buttonopenspipegripper.

3.Pulluptostarttheengine15.Withtriggerpressed,rockforwardtorotatetheupperwrench

(makeup/breakoutwrench)counterclockwisetoloosenajoint;

rockrearwardtorotatetheupperwrench(makeup/breakout

wrench)clockwisetotightenajoint.

4.ResetZap-Alertsystem16.Withtriggerpressed,pressfrontorrearbuttontoresume

thepreviouslysetauto-drillspeed;pressandholdthefront

buttontoincreasetheauto-drillspeed;pressandholdthe

rearbuttontodecreasetheauto-drillspeed.

5.Zap-Alertsystemtriggered17.ModeI—lefttriggerreleased,extendspipegrippertowarddrill

frame;lefttriggerpressed,openslowerwrench(stationary

wrench).ModeII—spindrillspindleclockwise.

6.Unlockexit-sidelockout18.ModeI—lefttriggerreleased,extendspipegrippertowardpipe

holder;lefttriggerpressed,closeslowerwrench(stationary

wrench).ModeII—spindrillspindlecounterclockwise.

7.Resetexit-sidelockout19.ModeI—lefttriggerreleased,lowerspipeelevator;left

triggerpressed,opensupperwrench(makeup/breakout

wrench).ModeII—lefttriggerreleased,extendspipegripper

towarddrillframe;lefttriggerpressed,opensupperwrench

(makeup/breakoutwrench).

8.Engagedrivemovementandsetupfunctions20.ModeI—lefttriggerreleased,raisespipeelevator;left

triggerpressed,closesupperwrench(makeup/breakout

wrench).ModeII—lefttriggerreleased,extendspipegripper

towardpipeholder;lefttriggerpressed,closesupperwrench

(makeup/breakoutwrench).

9.Engagedrillcarriagemovementandotherdrillfunctions21.Exit-sidelockout—drill-enabledlight

10.TurntheworklightOnorOff22.Transmitter-battery-statusLight

11.Swingthecabinorout23.Increaseordecreasetheenginespeed

12.Windshield-wipercontrol24.Rotatethecabclockwiseorcounterclockwise

15

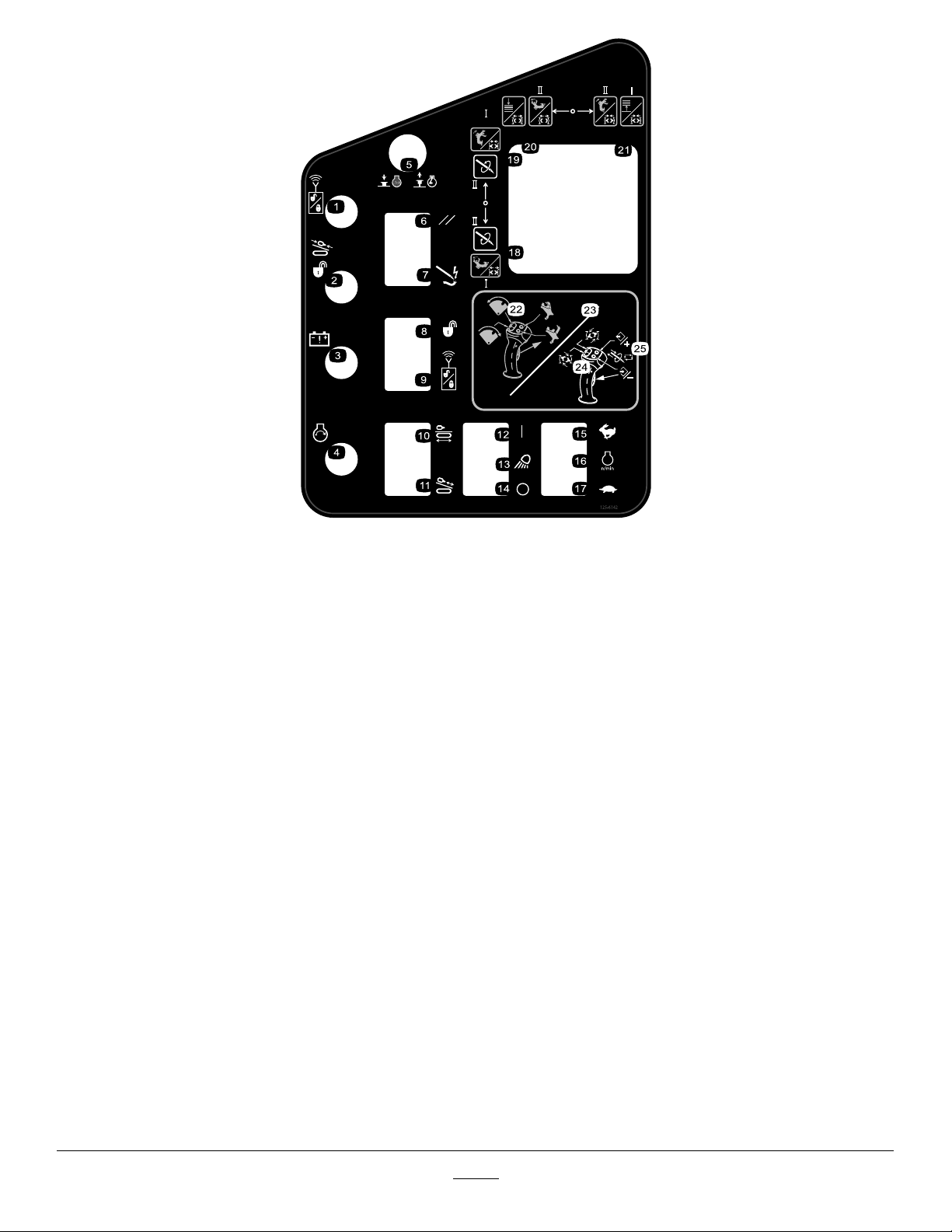

125-6142

1.Exit-sidelockout—resetlight14.Worklights—Off

2.Exit-sidelockout—drill-enabledlight15.Pressandholdtoincreaseenginespeed.

3.Transmitter-battery-statuslight16.Enginespeed

4.Engine—start17.Pressandholdtodecreaseenginespeed.

5.Pressdowntostoptheengine;pulluptostarttheengine.18.ModeI—lefttriggerreleased,extendspipegrippertowarddrill

frame;lefttriggerpressed,openslowerwrench(stationary

wrench).ModeII—spindrillspindleclockwise.

6.ResetZap-Alertsystem19.ModeI—lefttriggerreleased,extendspipegrippertowardpipe

holder;lefttriggerpressed,closeslowerwrench(stationary

wrench).ModeII—spindrillspindlecounterclockwise.

7.Zap-Alertsystemtriggered20.ModeI—lefttriggerreleased,lowerspipeelevator;left

triggerpressed,opensupperwrench(makeup/breakout

wrench).ModeII—lefttriggerreleased,extendspipegripper

towarddrillframe;lefttriggerpressed,opensupperwrench

(makeup/breakoutwrench).

8.Unlockexit-sidelockout21.ModeI—lefttriggerreleased,raisespipeelevator;left

triggerpressed,closesupperwrench(makeup/breakout

wrench).ModeII—lefttriggerreleased,extendspipegripper

towardpipeholder;lefttriggerpressed,closesupperwrench

(makeup/breakoutwrench).

9.Resetexit-sidelockout22.Withtriggerreleased,rockforwardtorotatebaskettoward

pipecam,rockbackwardtorotatebaskettowarddrillframe.

10.Engagedrivemovementandsetupfunctions23.Withtriggerreleased,upperbuttonclosespipegripper,lower

buttonopenspipegripper.

11.Engagedrillcarriagemovementandotherdrillfunctions24.Withtriggerpressed,rockforwardtorotatetheupperwrench

(makeup/breakoutwrench)counterclockwisetoloosenajoint;

rockrearwardtorotatetheupperwrench(makeup/breakout

wrench)clockwisetotightenajoint.

12.Worklights—On25.Withtriggerpressed,pressfrontorrearbuttontoresume

thepreviouslysetauto-drillspeed;pressandholdthefront

buttontoincreasetheauto-drillspeed;pressandholdthe

rearbuttontodecreasetheauto-drillspeed.

13.Worklights

16

125-6125

1.Warning—readthe

Operator’sManual.

6.Pressandholdtomove

thedrillcarriageathigh

speedupordownthedrill

frame.

2.Explosionhazard;

electricalshock

hazard—donotdigbefore

callinglocalservices.

7.ModeI—spindrillspindle

clockwise.ModeII—left

triggerpressed,openthe

lowerwrench(stationary

wrench);lefttrigger

released,raisethepipe

elevator.

3.Presstoapplythread-joint

compound.

8.ModeI—spindrillspindle

counterclockwise.Mode

II—lefttriggerpressed,

closethelowerwrench

(stationarywrench);left

triggerreleased,lowerthe

pipeelevator.

4.Pressandholdfor

maximumdrillinguid

pressure;releasetostop

theow.

9.Thrustthedrillcarriage

forward.

5.Presstoturnthe

drilling-uidpumpon

oroff.

10.Pullthedrillcarriage

rearward.

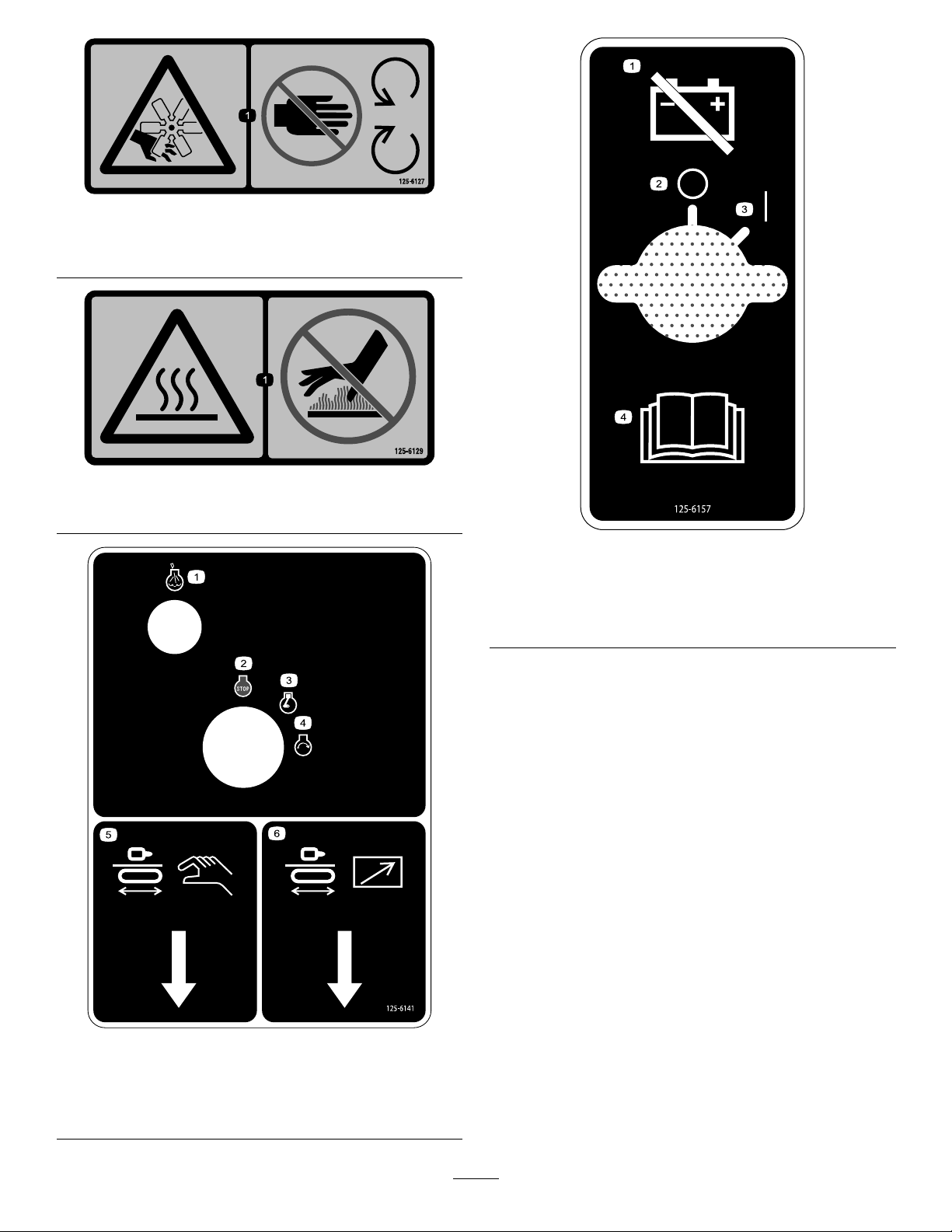

125-1641

1.Forwardleft6.Forwardright

2.Increaserpm7.High

3.Enginespeed8.Trackspeed

4.Decreaserpm9.Low

5.Reverseleft10.Reverseright

125-1621

1.Presstheoperatorpresenceswitchtoenablemachine

movement.

125-1622

1.Pulluptostarttheengine.2.Pushdowntostopthe

engine.

17

125-6127

1.Cutting/dismembermenthazard,fan—keepawayfrom

movingparts.

125-6129

1.Hotsurface—keepawayfromhotsurfaces.

125-6141

1.Engine—heatinglight4.Engine—start

2.Engine—stop5.Drill-pendantreceptacle

3.Engine—run6.Drive-pendantreceptacle

0000

0000

0000

125-6157

1.Disconnectthebattery

power.

3.On/Start

2.Off/Stop4.ReadtheOperator’s

Manual.

18

125-6113

1.Warning—readtheOperator’sManual.4.Warning—keepawayfrommovingparts;keepallguardsand

shieldsinplace.

2.Warning—donotoperatethemachineunlessyouaretrained.5.Warning—wearhearingprotection.

3.Warning—keepbystandersawayfromthemachine.6.Explosionhazard,electricalshockhazard;donotdigbefore

callinglocalutilities.

125-6117

1.Fallinghazard—donotstandonthemachinewhileitis

moving.

125-6139

1.Liftpointandtie-downpoint

125-6135

19

125-1623

1.Forwardlefttrack/forwardrotary11.Wrenchmakeup(forupperwrench)

2.Reverselefttrack/reverserotary12.Raisepipeelevator

3.Drillinguidpumpon13.Lowerpipeelevator

4.Forwardrighttrack/forwardcarriage14.Reversecamrotation

5.Reverserighttrack/reversecarriage15.Forward(towardoperator)camrotation

6.Tightenlowerwrench(stationarywrench)16.Tightenpipegrip

7.Loosenlowerwrench(stationarywrench)17.Loosenpipegrip

8.Tightenupperwrench(makeup/breakoutwrench)18.Reversedrillspindle

9.Loosenupperwrench19.Forward(towardoperator)drillspindle

10.Wrenchbreakout(forupperwrench)

20

Other manuals for 4045

2

This manual suits for next models

1

Table of contents

Other Toro Drill manuals

Popular Drill manuals by other brands

Ferm

Ferm FRCD-16/550 user manual

Haussmann

Haussmann J0Z-SP15-1314 Operator's manual

Central Machinery

Central Machinery 91977 Assembly and operating instructions

Scheppach

Scheppach CID40-20Li Translation of original instruction manual

Worx

Worx WU362 Safety and operating manual original instructions

Milwaukee

Milwaukee K 540 S Original instructions