Toro DD4045 Quick start guide

FormNo.3419-198RevB

4045DirectionalDrill

SoftwareVersionsA–C

ModelNo.23823/A/C/TE/W—SerialNo.315000001andUp

ModelNo.23825/A/C/TE/W—SerialNo.315000001andUp

SoftwareGuide

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

Wheneveryouneedservice,genuineT oroparts,or

additionalinformation,contactanAuthorizedService

DealerorT oroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.

YoumaycontactTorodirectlyatwww.T oro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

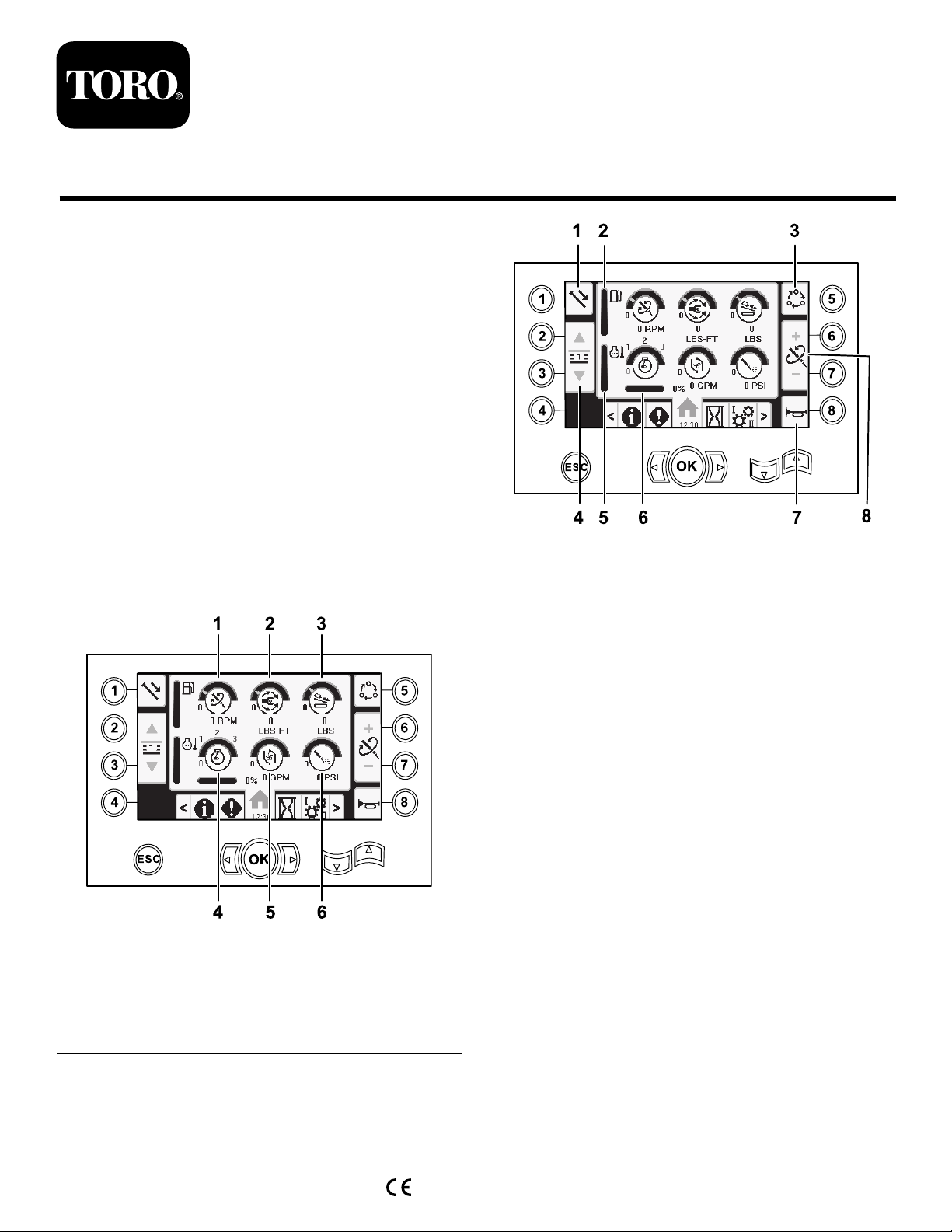

MainInformationScreen

Thisistherstscreenthatappearsaftertheinitial

splashscreen.T onavigatebetweenscreens,usethe

leftandrightarrows.

g214633

Figure1

1.Drillspeed(rpm)4.Enginespeed(rpm)

2.Rotarytorque5.Drilling-uidowrate

3.Thrustforce6.Drilling-uid/Air-hammer

pressure

g214634

Figure2

1.Pipefunctions5.Enginetemperaturegauge

2.Fuelgauge6.Enginedroop

3.Limitsettingoptions7.Horn

4.Selectpiperow8.Thrustforce,drillspeed

(rpm),orrotarytorque

adjustment

GototheMudorAirHammerSelectionScreen(page

12)toswitchbetweenmudpressureandairhammer

functions.

Pushbutton1toswitchbetweenthepipefunctions

pullpipe,pushpipe,andneutral.

Pushbutton5toswitchbetweenthrustforce,drill

speed(rpm),androtarytorquelimits.

Usetheupanddownarrowstosetthelimitsfor

maximumdrillspeed(rpm),rotarytorque,andthrust

force.

•Thrustforce:Changethethrustforcelimitby

pushing6or7.

•Drillspeed(rpm):Changethedrillspeedrpmlimit

bypushing6or7.

•Rotarytorque:Changetherotarytorquelimitforce

bypushing6or7.

©2019—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved*3419-198*B

g213150

Figure3

1.Pullpipe4.Thrustforce

2.Pushpipe5.Drillspeed(rpm)

3.Rotarytorque

SmartTouch™Home

Screen

SmartTouchmodeallowstheoperatortoloadand

unloadpipesfromtherodboxwithlessjoystick

operationtoreduceoperatorfatigue.

UsetheCarriageSettingsScreen(page10)toturn

SmartTouchmodeonandoff.

Note:ThePush/PullIconshaveagreenbackground

whenSmartTouchmodeisonandaribbonappears

atthebottomofthescreenshowingasequenceof

thesteps.

Important:NeverswitchbetweenPush/Pull

modesduringthechosenoperation.Useneutral

(manual)modetoswitchbetweenPush/Pull;refer

toCarriageSettingsScreen(page10)toturn

SmartTouchmodeoff.

TheSmartT ouchscreensappearsalongthebottomof

thehomescreenasshownbelow.

g231722

Figure4

PullingPipeinSmartTouchMode

StarttheSmartT ouchmodewiththecamassemblyin

thehomeposition(row4ofthepipebox).

Important:Ensurethatyouholdthelowersection

ofthecamrockerswitch,ontheleftjoystick,

completelydownuntiltheactioniscompletein

eachstep(Figure5).

g210060

Figure5

Holdtheuppersectionofthecamrockerswitch,

ontheleftjoystick,completelydownuntilall

actionsarecompletetogotothepreviousstepin

thesequence(Figure6).

g210061

Figure6

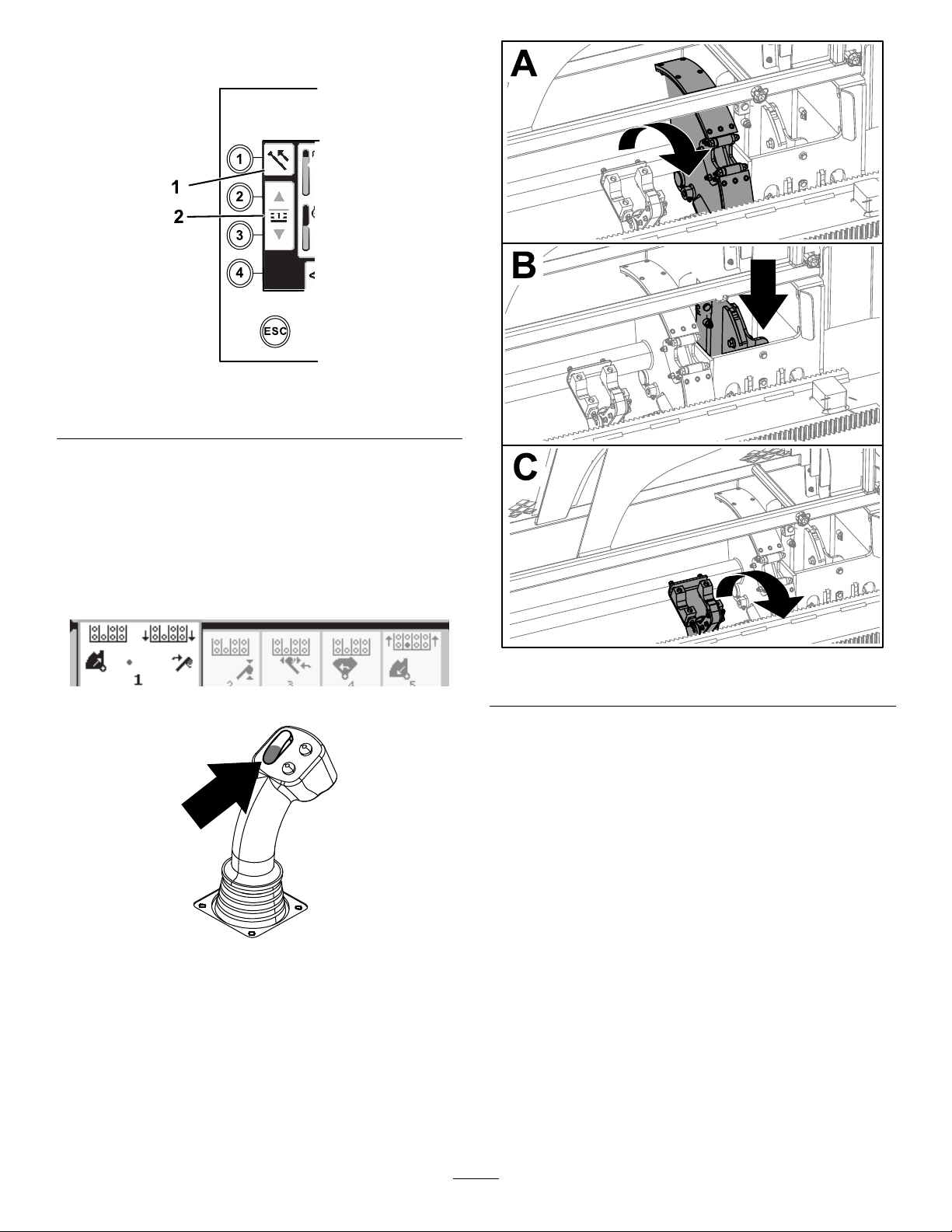

1.Pushbutton1toselectthepullpipeoption

(Figure7).

2

2.Pushbuttons2and3toselecttherowwhere

youwanttoplacethepipe(Figure7).

g232381

Figure7

1.Pullpipe2.Selectpiperow

3.Holdthelowersectionoftherockerswitch

(Figure9)untilthefollowing3thingshappen

(Figure10):

A.Thecamassemblyrotatestowardthe

operatorstation.

B.Theelevatorlowers.

C.Theloaderarmsrotatetothedrillpipe.

g231712

Figure8

g210462

Figure9

g232376

Figure10

3

4.Releasetherockerswitchtoproceedtothenext

stepinthesequence(Figure11).

g231713

Figure11

5.Breakthepipeconnection;refertoRemoving

DrillPipesintheOperator’sManual.

6.Holdtheupperbuttononthejoysticktogripthe

pipe(Figure12andFigure13)andreleasethe

button.

g210533

Figure12

g232377

Figure13

7.Holdthelowersectionoftherockerswitch

(Figure15)untilthearmsrotatewiththepipe

backtothehomepositionandthegrippersopen

asthepipeentersthecamassemblypocket

(Figure16).

g231714

Figure14

g210462

Figure15

g232378

Figure16

4

8.Releasetherockerswitchtoproceedtothenext

stepinthesequence(Figure17).

g231715

Figure17

9.Holdthelowersectionoftherockerswitch

(Figure18)untilthecamassemblyrotatestothe

selectedrowunderthepipebox(Figure19).

g210462

Figure18

g232379

Figure19

10.Releasetherockerswitchtoproceedtothenext

stepinthesequence(Figure20).

g231716

Figure20

11.Holdthelowersectionoftherockerswitch

(Figure21)untiltheelevatorputsthepipeback

inthepipeboxandthecamrotatestothehome

position(Figure22).

g210462

Figure21

g232380

Figure22

12.Releasetherockerswitchtostartthepull-pipe

processagain.

5

PushingPipeinSmartTouchMode

StarttheSmartT ouchmodewiththecamassemblyin

thehomeposition(row4ofthepipebox).

Important:Ensurethatyouholdthelowersection

ofthecamrockerswitch,ontheleftjoystick,

completelydownuntiltheactioniscompletein

eachstep(Figure23).

g210060

Figure23

Holdtheuppersectionofthecamrockerswitch,

ontheleftjoystick,completelydownuntilall

actionsarecompletetogotothepreviousstepin

thesequence(Figure24).

g210061

Figure24

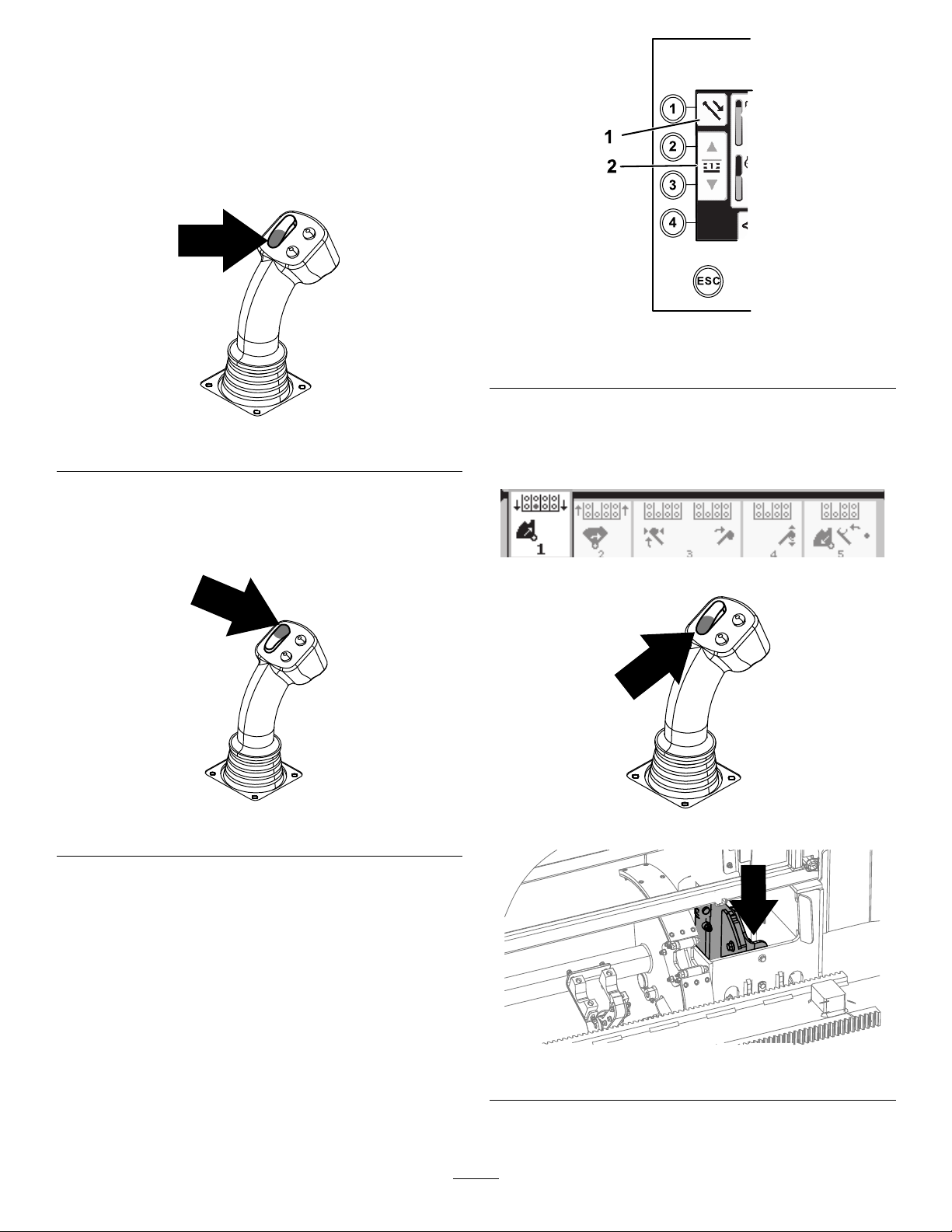

1.Pushbutton1toselectpushpipe(Figure25).

2.Pushbuttons2and3toselecttherowwhere

youwanttogetthepipe(Figure25).

g232387

Figure25

1.Pushpipe2.Selectpiperow

3.Holdthelowersectionoftherockerswitch

(Figure27)untilthecamassemblyrotatestothe

selectedrowandtheelevatorlowersthepipe

intotheopening(Figure28).

g231717

Figure26

g210462

Figure27

g232382

Figure28

6

4.Releasetherockerswitchtoproceedtothenext

stepinthesequence(Figure29).

g231718

Figure29

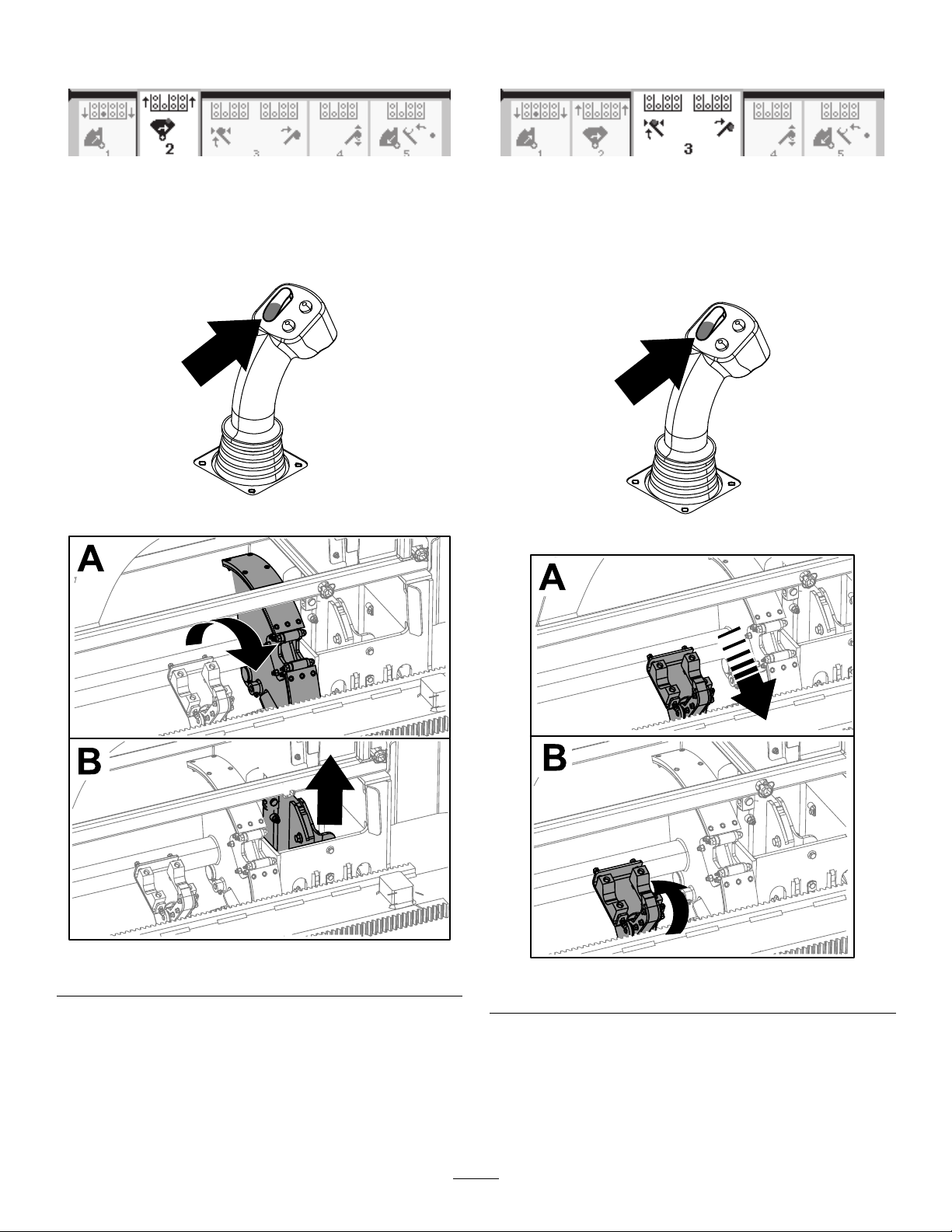

5.Holdthelowersectionoftherockerswitch

(Figure30)untilthecamassemblyfullyrotates

forwardtotherackandtheelevatorsliftthe

remainingpipeintothepipebox(Figure31).

g210462

Figure30

g232383

Figure31

6.Releasetherockerswitchtoproceedtothenext

stepinthesequence(Figure32).

g231719

Figure32

7.Holdthelowersectionoftherockerswitch

(Figure33)untiltheloaderarmsrotatetoward

thepipebox.Astheyrotatepastthecam

assemblythepipegripperscloseonthepipe,

bringingittothedrillstring(Figure34).

g210462

Figure33

g232384

Figure34

7

8.Releasetherockerswitchtoproceedtothenext

stepinthesequence(Figure35).

g231720

Figure35

9.Makethepipeconnection;refertoAddingDrill

PipesintheOperator’sManual.

10.Holdthelowerbuttononthejoystick(Figure

36)toreleasethepipe(Figure37)andrelease

thebutton.

g210527

Figure36

g232385

Figure37

11.Holdthelowersectionoftherockerswitch

(Figure39)untiltheloaderarmsrotatebackand

thecamassemblyreturnstothehomeposition

(row4)(Figure40).

g231721

Figure38

g210462

Figure39

g232386

Figure40

12.Releasetherockerswitchtostartthepush-pipe

processagain.Thecamassemblygoesto

therowpickedinstep2ofPullingPipein

SmartTouchMode(page2).

8

HoursScreenOptions

MachineHoursScreen

Toaccessthisscreen,pushbutton1ontheHours

screen.

Thisscreenshowstheoperatinghoursofthe

machine.YoucannotchangeMachine1butyoucan

resetMachine2.

g213163

Figure41

MudUseScreen

Toaccessthisscreen,pushbutton2ontheHours

screen.

Thisscreenshowsthemudvolumeused.

Toswitchbetweengallonsandliters,refertoFigure

51,LanguageandUnitsOptionsScreen(page11).

Youcannotchangethetotalmud,butyoucanreset

thedailymudusingbutton8.

g034784

Figure42

LubricationandMaintenance

Screens

Toaccessthisscreen,pushbutton3ontheHours

screen.

Thesescreensprovidetheuserwiththedaily

maintenanceschedulesintheincrementslistedbelow.

Toresetthemaintenanceinterval,navigatetothe

ParametersOptionsScreen(page11),pushthedown

arrowtoscrolltothemaintenanceoptionsscreen,and

enterpinnumber12356.

Pushthefollowingbuttonstoattainthesubsequent

maintenanceschedule:

•Button3—10-hour/Daily(Figure43)

•Button5—50-hour(Figure44)

•Button6—250-hour(Figure45)

•Button7—500-hour(Figure46)

•Button8—1,000-hour(Figure47)

g034777

Figure43

g034778

Figure44

9

g034779

Figure45

g034780

Figure46

g034781

Figure47

SettingsScreenOptions

CarriageSettingsScreen

Pushbutton1ontheSettingsscreen.

Usethisscreentochangethecarriagesettings.Use

theupanddownarrowstorotatebetweenpushpipe,

pullpipe,andneutral.

PushtheOKbuttontoturnSmartT ouch™onandoff.

g233212

Figure48

ControlModeScreen

Pushbutton2ontheSettingsscreen.

Usethisscreentoselectbetweenthe2joystick

controloptions.Pushtheupanddownarrowstoto

switchbetweenModeIandModeII.

g224024

Figure49

•ModeI—Therightjoystickcontrolsthethrustand

therotationfunctions.Theleftjoystickcontrolsthe

wrenchandpipeloaderfunctions.

•ModeII—Therightjoystickcontrolsthethrustand

thepipeloaderelevatorfunction.Theleftjoystick

controlstherotation,wrench,andpipeloader

functions.

10

ParametersOptionsScreen

Pushbutton3ontheSettingsscreen.

Thepinnumbertochangetheparametersis

73236531.

Pushthedownarrowtoscrolltothemaintenance

optionsscreentoresetthemaintenanceinterval.

Enterpinnumber12356.

g224027

Figure50

LanguageandUnitsOptions

Screen

Pushbutton5ontheSettingsscreentoaccessthe

languageandunitsScreen.Pushtheupanddown

arrowstoswitchbetweenEnglishunitsandmetric

units.

g224026

Figure51

ScreenSettings

Pushbutton6ontheSettingsscreentoswitch

betweenzoomdelay,brightness,anddayornight

mode.Usetheupanddownarrowstoadjustthe

parameters.

TheMainDrillingScreenzoomsintothedrilling

functions.Thesesettingsadjustthedelayonhow

longittakestozoom.

g224028

Figure52

ClockSettingsScreen

Pushbutton7ontheSettingsscreentoswitch

betweentheclockoptions.Usetheupanddown

arrowstoadjusttheparameters.

Onceyouareonthisscreen,pushbutton7torotate

betweendate,time,and12/24.

g224023

Figure53

11

MudorAirHammerSelection

Screen

Pushbutton8ontheSettingsscreentoaccessthis

screen.Usetheupanddownarrowstoswitchbeen

mudandairhammer.

Thisupdatesthedisplayonthehomescreen(Figure

1).

g233213

Figure54

I/OScreens

JoystickI/OScreen

Pushbutton1ontheI/Oscreentorotatebetweenthe

DrillandSetupoptions.Theiconturnsgreenwhen

theassociatedfunctionisactuated.

Whentherockerswitchontheleftcontrolpanelisin

theDrillposition,theupperlefticonturnsgreenand

thejoystickvoltagescanbecheckedaswellasverify

the2-Speed,andExitSideLockoutinputs.

WhentherockerswitchisintheSetupposition,the

upperrighticonisgreen.Thesetuppositionallows

youtomovethemachineandpreparefordrilling.

g224025

Figure55

•Therotaryvoltagerangesfrom0.0to8.5Vand

canbepresentforeithermake(uppericon)or

break(lowericon)astheselectedrotaryjoystickis

moved.

•Thecarriageindicatesavoltagerangefrom0.0to

10.0Vinthejoystickselecteddirectionforthrust

orpullback.

•Thelowerlefticonindicatesthecarriageposition

ofwrench,load,orcarriagebackasthecarriage

movestothemostrearwardpositions.

•Thelowercentericonindicatesifthe2-speed

selectionofthecarriagespeedhasbeenselected.

•ThelowerrighticonindicatesthestatusoftheExit

SideLockout(ESL).Iftheindicatorisblack,the

carriageandrotaryactionsareinhibited.

EngineI/OScreen

Toaccessthisscreenpushbutton2ontheI/Oscreen.

Thisscreendisplaysengineinformation.

g213149

Figure56

1.Enginespeed(rpm)6.Air-lterindicator

2.Engine-oilpressure7.Hydraulic-uidlter

3.Batteryvoltage8.Engineload

4.Enginetemperature9.Enginedroop

5.Hydraulic-uid

temperature

Enginespeed(rpm)icon:displays,instepsof100,

theenginespeed(rpm).

Engine-oilpressureicon:displaystheengine-oil

pressure(barorpsi).

Batteryvoltageicon:displaysthebatteryvoltage.

12

•Iftheengineisshutoff,thevoltageismeasured

bytheTorocontroller.

•Iftheengineisrunning,thevoltageissuppliedby

enginecontroller.

Enginetemperatureicon:displaystheengine

coolanttemperaturemeasuredatthereservior.The

temperaturedropsto40°Fwhentheengineisshutoff.

Airltericon:theairltericonisgreenunlessthe

lterispluggedthentheindicatorisred.

Hydraulic-uidltericon:thehydraulic-uidlter

iconisgreenunlessthelterispluggedthenthe

indicatorisred.

Engineloadicon:displaysthepercentoftheengine

load.

Enginedroopicon:selecttheallowableengine

droopof80,90,or100%.Thedroopvalueisthe

lowestpointbelowlow-loadspeed(rpm)(under75

percentload)thattheenginemaydecreasebefore

thedrivetotherotaryheadisdecreasedtomaintain

thelowestvalue.Pushtheupanddownarrowsto

selectthedroopvalue.

CamArmI/OScreen

Toaccessthisscreenpushbutton3ontheI/Oscreen.

Usethisscreentoadjustthecamandpipeloader

calibrationoptions.

g213146

Figure57

1.Pushbutton3tocalibrate.

The2voltagesonthebottomindicatetheloader

armandcamactualvoltagefromthesensors.The

voltagesrangefrom1.0to4.0V.Anyvoltagehigher

orlowerindicateseithersensorfailureorincorrect

calibration.

AuxiliaryI/OScreen

Toaccessthisscreenpushbutton5ontheI/Oscreen.

Alliconschangefromblacktogreenwhenyou

operatetheassociatedfunctions.

g213173

Figure58

1.Raise/Lowerelevator5.Loaderarm

2.Breakoutwrench6.Rotatepipecam

3.Upperorlowerwrench7.TJCgrease

4.Gripper

ControllerI/OScreen

Toaccessthisscreenpushbutton6ontheI/Oscreen.

g213147

Figure59

1.Seatswitch5.Mudpumpstatus

2.Exitsidelockout6.Mudpumpow

3.Pedestriangate7.Processorindicator

4.Camoverrideinput

13

Seatswitchicon:showsanarrowoutwhenthe

operatorseatisempty;theswitchshowsagureicon

whenyouareintheoperatorseat.

•Showstheseatwithanerrorwhentheoperator

seatisunoccupied

•Showstheseatwithagurinewhentheoperator

seatisoccupied

Exitsidelockouticon:changesfromblacktogreen

wheninoperation.

Pedestriangateicon:

•ShownintheUPpositionwithagurine:thegate

isnotinthecorrectpositionfordrilling

•ShownintheDOWNposition:thegateiscorrectly

positionedfordrilling

Camoverrideinputicon:turnsgreenwhenthe

overridebuttonispushedonthejoystick.

Mudpumpstatusicon:

•Black:mudpumpisoff

•Yellow:mudpumpisinstandby

•Green:mudpumpisinon

•Greenwith100:mudpumpisinmaxow

Mudpumpowicon:indicatestheinputfromthe

rockerswitchonthejoystick.

•Whentherockerswitchisactuatedup,the

indicatorturnsgreenwithablueup/increasearrow.

•Whentherockerswitchisactuateddown,the

indicatorturnsgreenwithabluedown/decrease

arrow.

•Theiconisblackwhentherockerswitchisnot

pressed.

Processorindicatoricon:showsaredXtoindicate

aproblemwiththeexpansionprocessorlocatednext

tothemaincontroller.

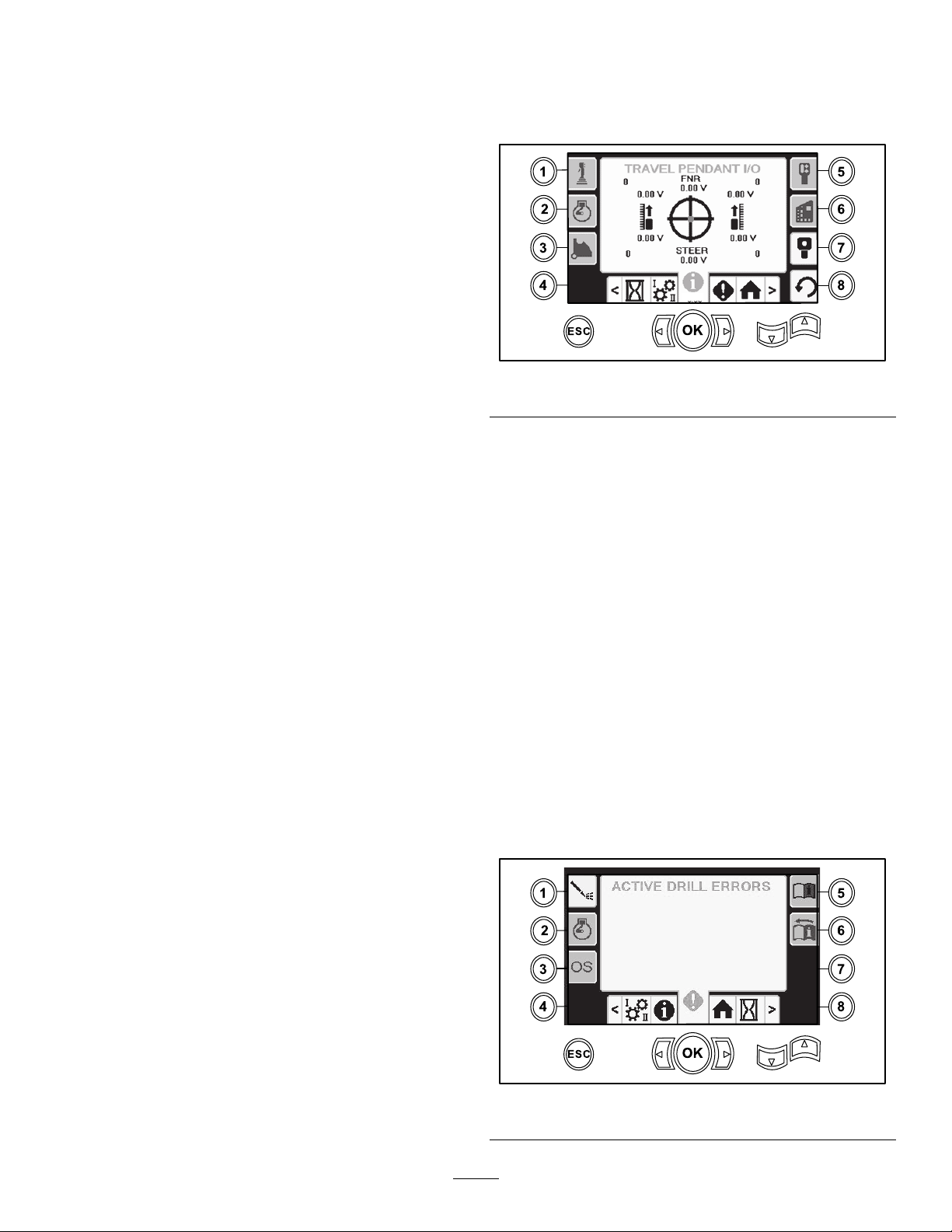

TravelPendantI/OScreen

Toaccessthisscreenpushbutton7ontheI/Oscreen.

Thetravelpendantscreenshowsthevoltageand

positionofthejoysticklocatedonthependant.

g213169

Figure60

Thereddotappearsinthecenterofthetargetand

theFNR(forward,neutral,reverse)andSteervoltage

shows2.5Vpriortoallowingthedrilltomove.Ifthe

reddottravelsoutsideoftheoutermostblackring,

serviceorreplacethependantwithanewpendant.

Theindicatorstotherightandleftofthecircleshow

thedirectionofthetracktravel.Thevoltagesshow

arangefrom0to10.0V.

ErrorsandMachine

InformationScreens

DrillErrorsScreens

Toaccessthisscreenpushbutton1ontheErrorsand

MachineInformationscreen.

Thisscreendisplaysanydrillerrors.

Usetheupanddownarrowstoscrollthroughthe

errors.ContactyourAuthorizedServiceDealerfor

codesthatcannotbecleared.

g213168

Figure61

14

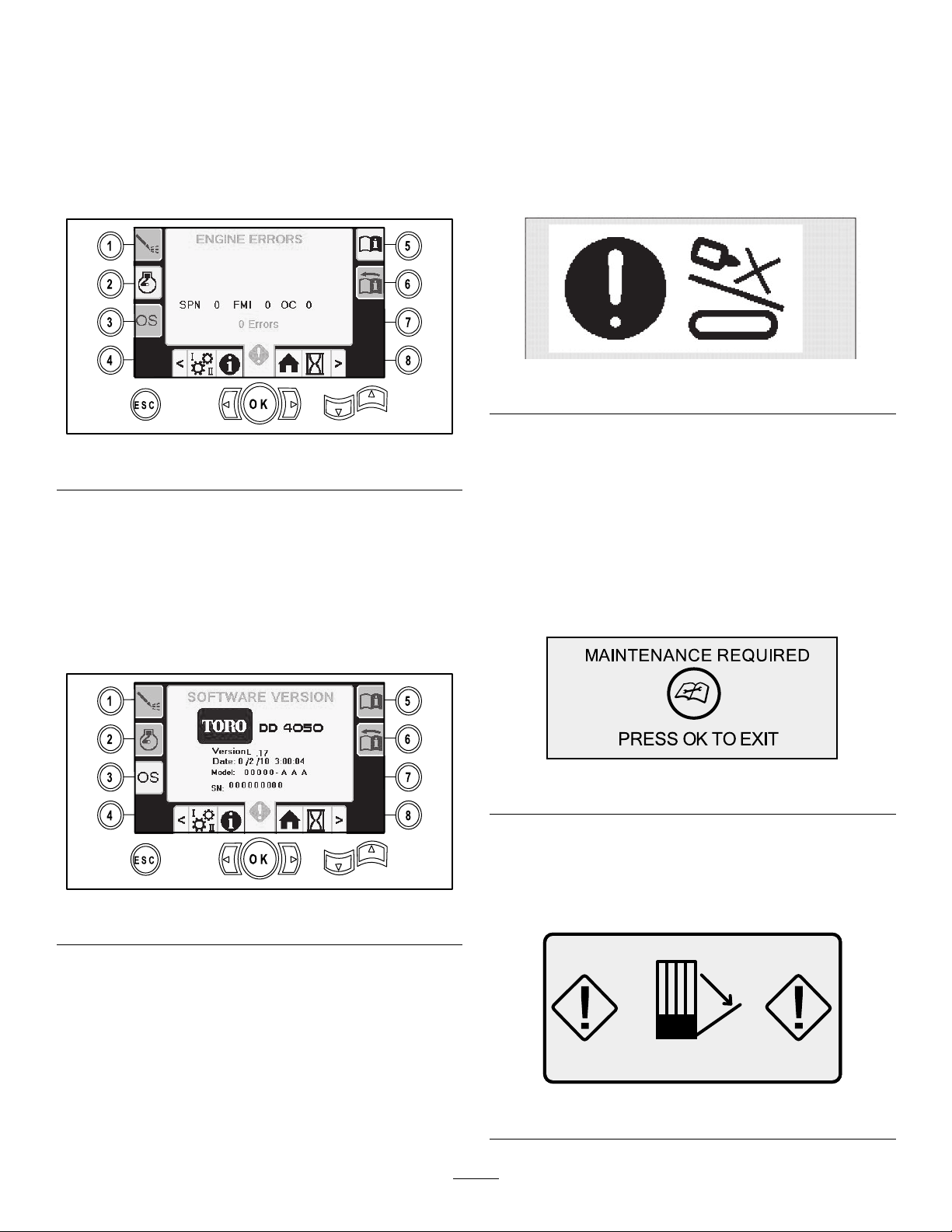

EngineErrorsScreen

Toaccessthisscreenpushbutton2ontheErrorsand

MachineInformationscreen.

Thisscreendisplaysanyengineerrors.

Usetheupanddownarrowstoscrollthroughthe

errors.ContactyourAuthorizedServiceDealerfor

codesthatcannotbecleared.

g213170

Figure62

MachineInformationScreen

Toaccessthisscreenpushbutton3ontheErrorsand

MachineInformationscreen.

Thisscreendisplaysthemachineinformation

includingthemodel,serialnumber,andsoftware

version.

g213171

Figure63

CarriageCrashWarningIcon

Thecarriagecrashwarningscreen(Figure64)

appearsifthefollowingoccurs:

•Thecarriageisinthedrillareaandyoutryto

operatetheloaderarmorpipecamor

•Youtrytooperatethecarriagewhentheloader

armorpipecamisnotinthehomeposition.

g210794

Figure64

Toclearthiswarning,dothefollowing:

•Movethecamassemblytothehomeposition

and/or

•Reversethecarriage

MaintenanceRequiredIcon

Thisicon(Figure65)displayswhenmaintenanceis

required.

g223939

Figure65

PedestrianGateWarningIcon

Thisicon(Figure66)displaysifthepedestriangateis

notintheloweredposition.

g223940

Figure66

15

Other manuals for DD4045

1

This manual suits for next models

8

Other Toro Drill manuals