FormNo.3440-983RevA

EngineConversionKit

SubaruPoweredWalk-BehindGreensmaster®1000Mower

ModelNo.139-5636

InstallationInstructions

Thisengineconversionkitisonlyformachineswith

followingmodelandserialnumbers:

ModelNumberSerialNumber

04038315000001through315000500

04039315000001through316999999

04054315000001through999999999

04055315000001through999999999

04056315000001through999999999

Lightkit,Model04063(xed-headtractionunits)is

compatiblewiththiskit.

Note:Olderlightkitsarenotcompatiblewiththiskit.

Introduction

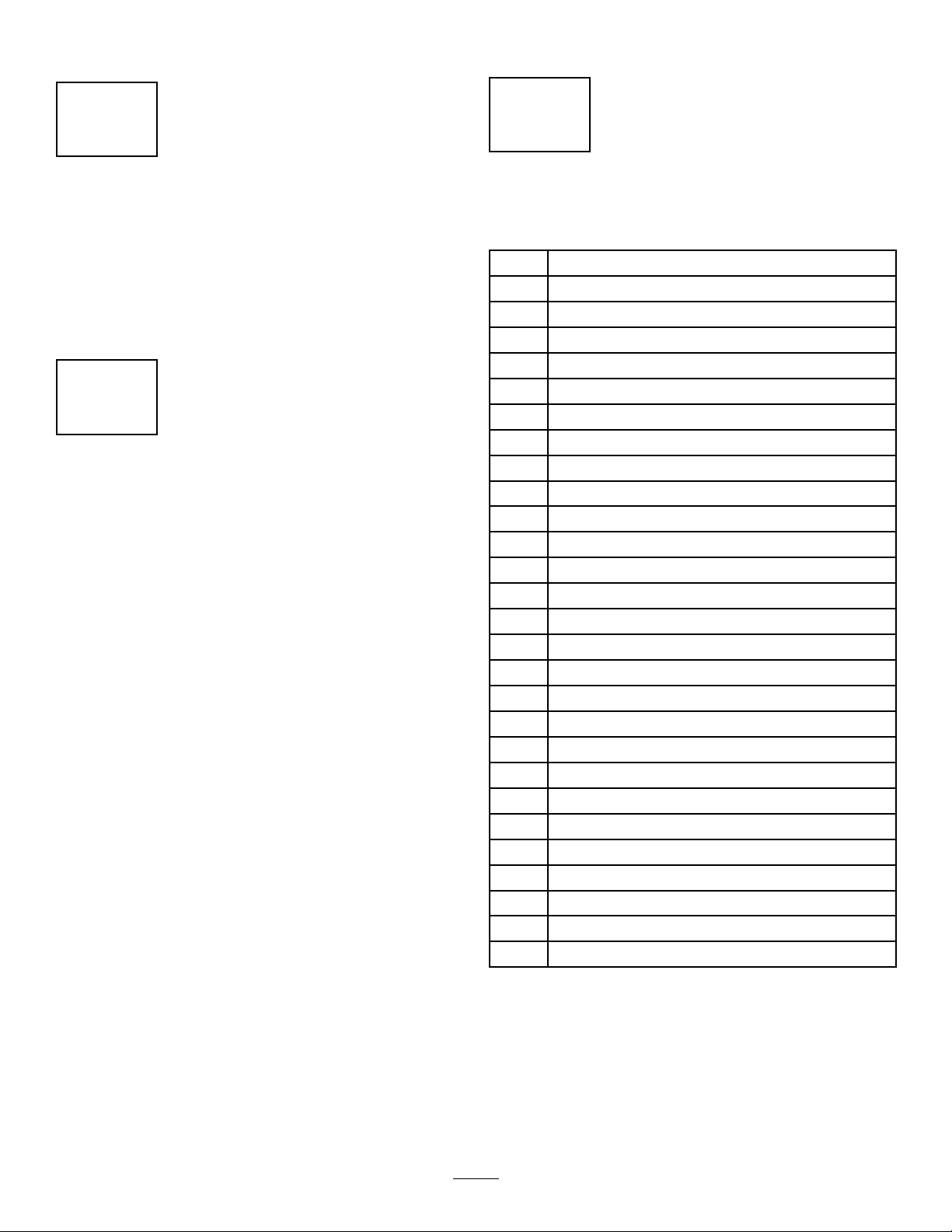

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Ifyourequireasparkarrester,contactyourAuthorized

ServiceDealer.

Important:Theseinstallationinstructions

containengineoperationandmaintenance

informationthatsupersedestheengineoperation

andmaintenanceproceduresinyourmachine

Operator’sManual.

Beforeoperatingormaintainingthemachineor

engine,alwaysrefertotheoperatingandsafety

instructionsinyourOperator’sManual.

Savetheseinstructions.

Important:Theenginewarrantyisprovided

bytheenginemanufacturer.Pleaserefertothe

enginemanufacturer'swarrantyandemissions

systemwarrantyincludedintheliteraturepacket.

Thatwarrantyappliesonlytotheengine.Itdoes

notexpandorotherwisealteranyexpressor

impliedwarrantytermsorwarrantyperiodthat

mayapplytotheproductintowhichtheengine

isinstalled.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Contents

Introduction...............................................................1

Safety.......................................................................2

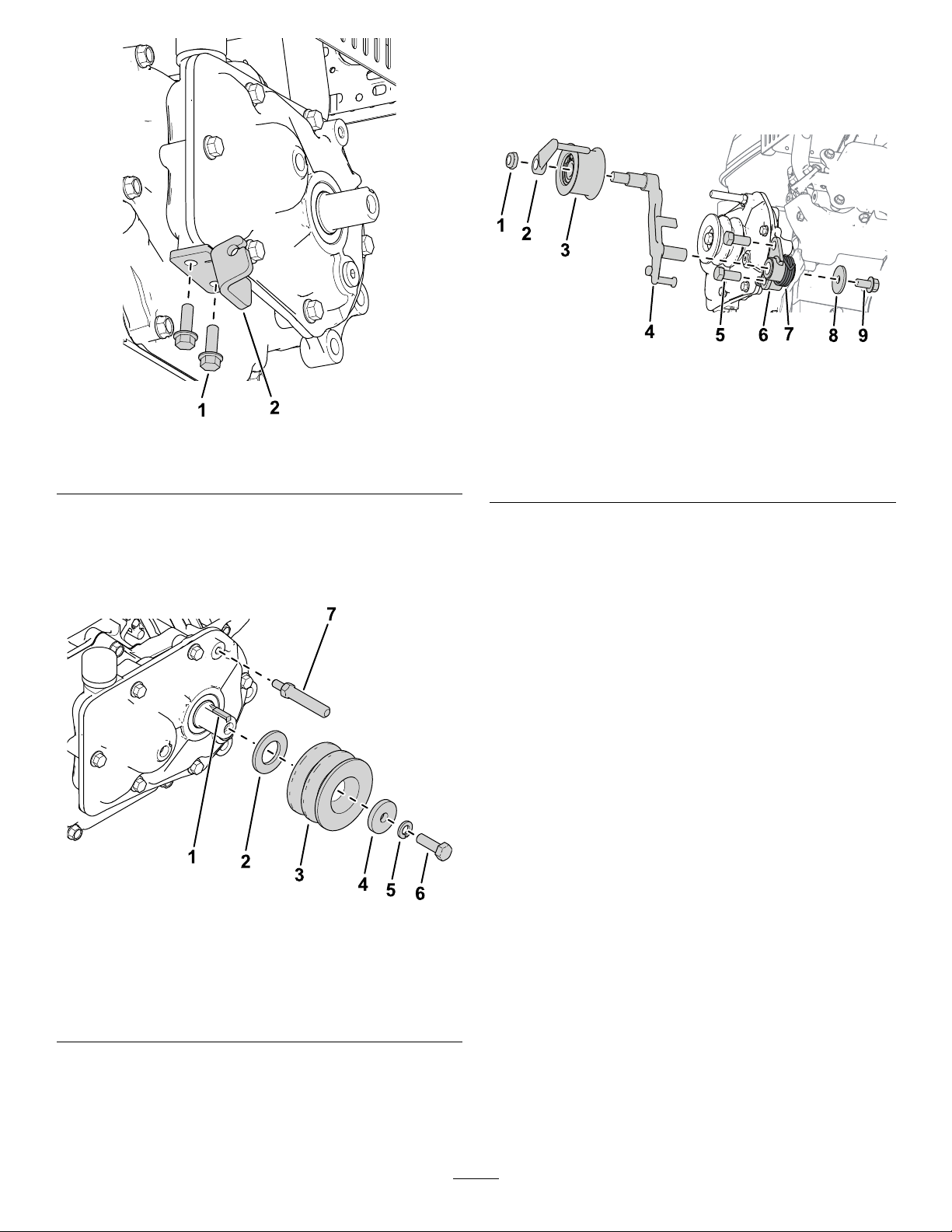

SafetyandInstructionalDecals..........................2

Installation................................................................3

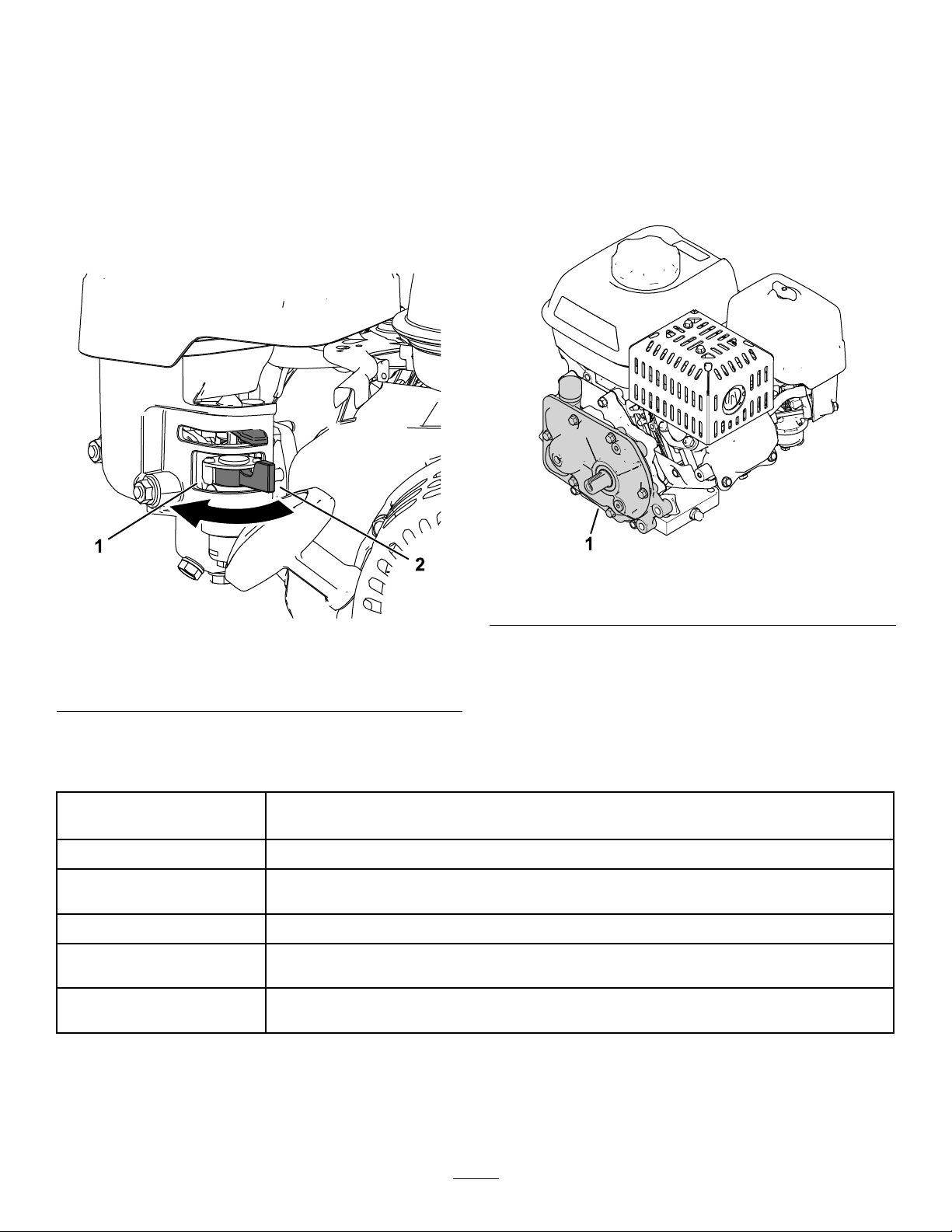

1PreparingtheMachine.....................................3

2RemovingtheExistingEngine.........................3

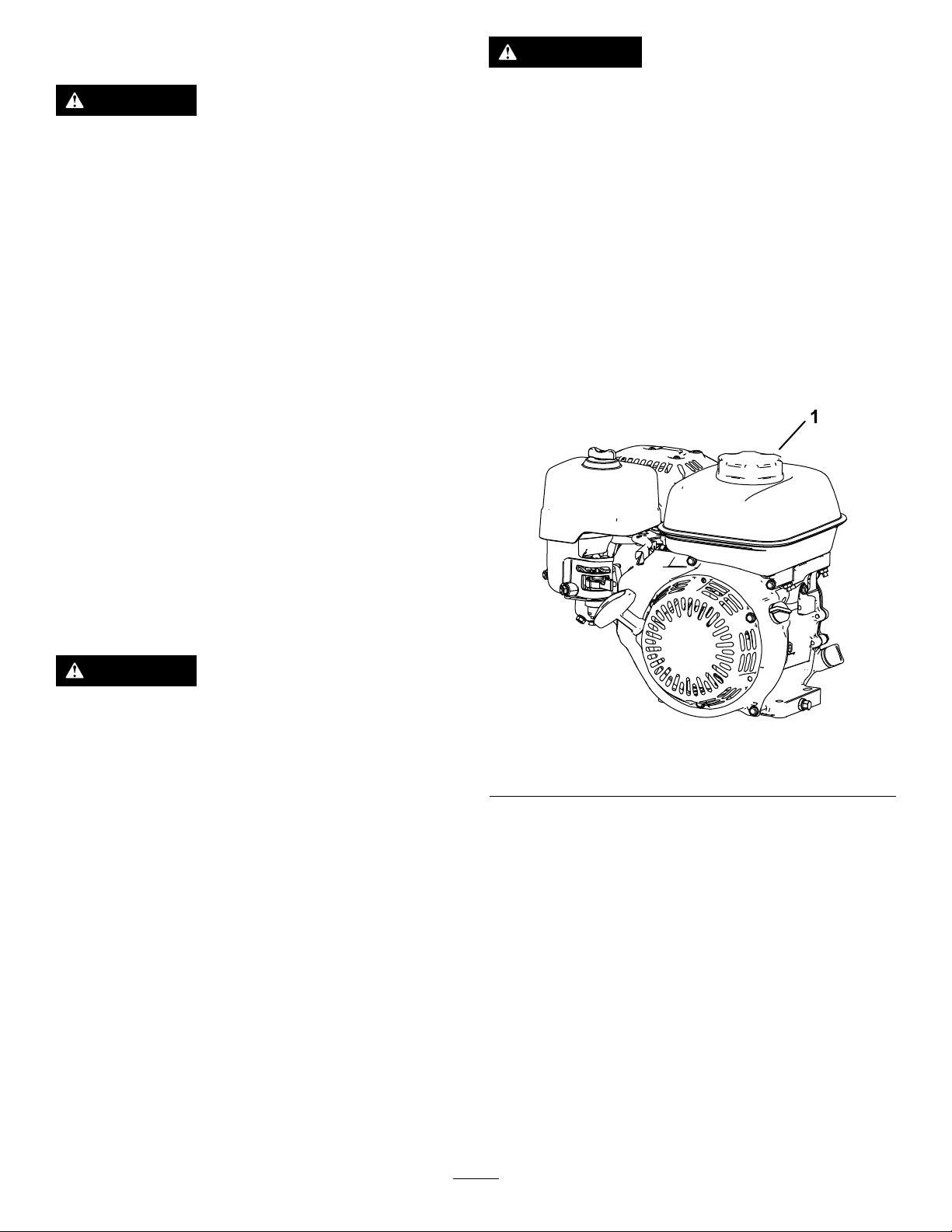

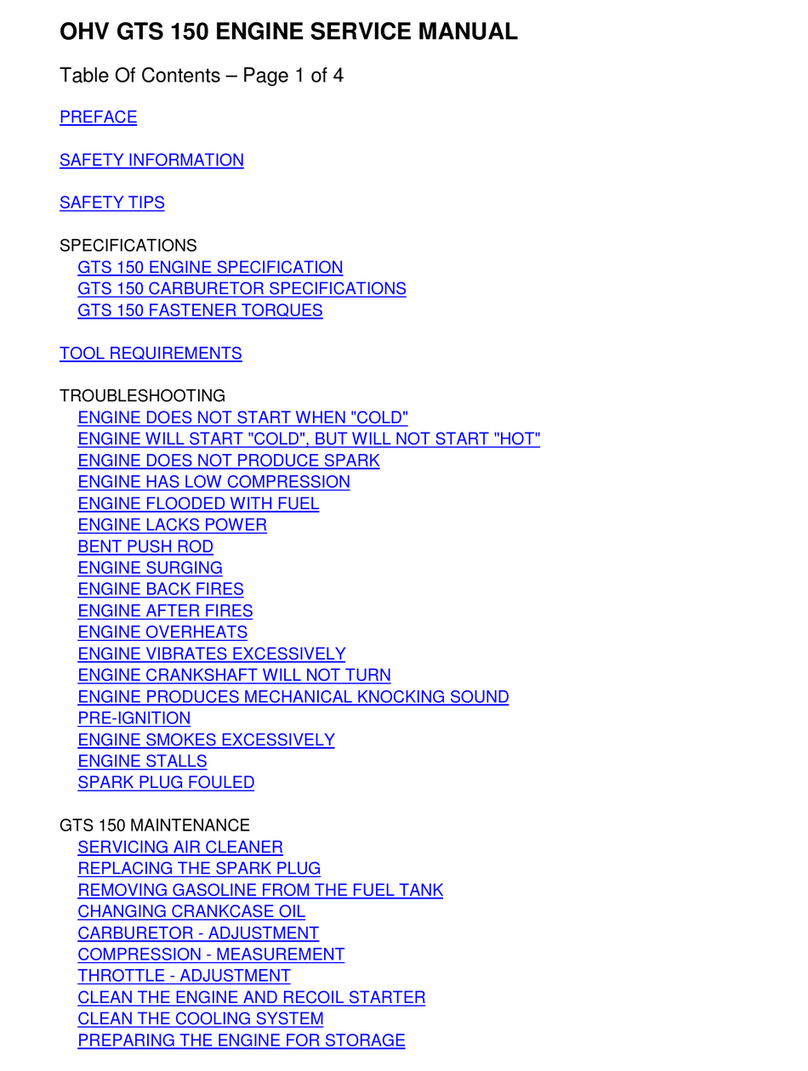

3InstallingtheNewEngine.................................3

4LubricatingandAdjustingtheMachine.............6

ProductOverview.....................................................7

Controls.............................................................7

Operation..................................................................7

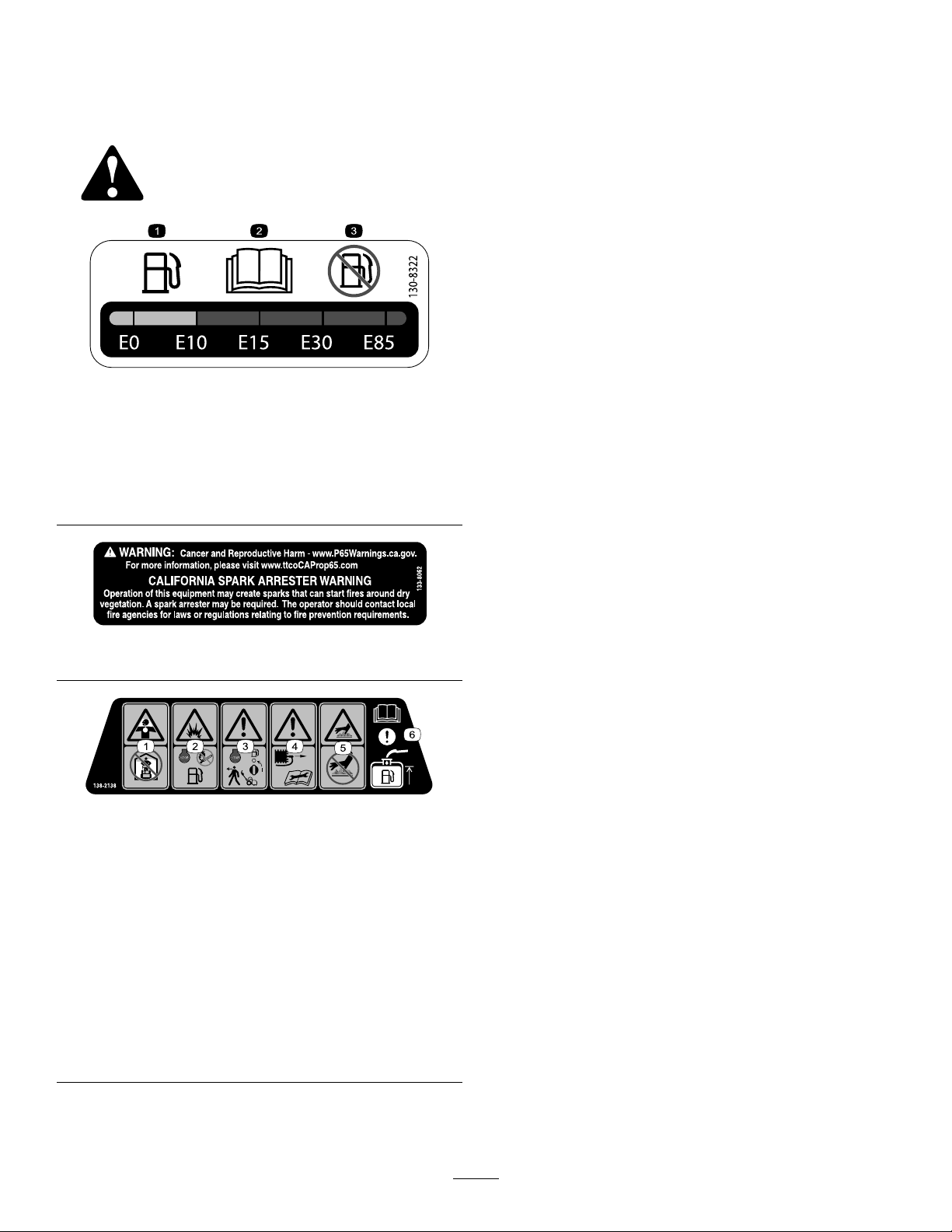

FuelSpecications.............................................7

UsingStabilizer/Conditioner...............................7

FillingtheFuelTank............................................8

OpeningandClosingtheFuel-Shutoff

Valve...............................................................9

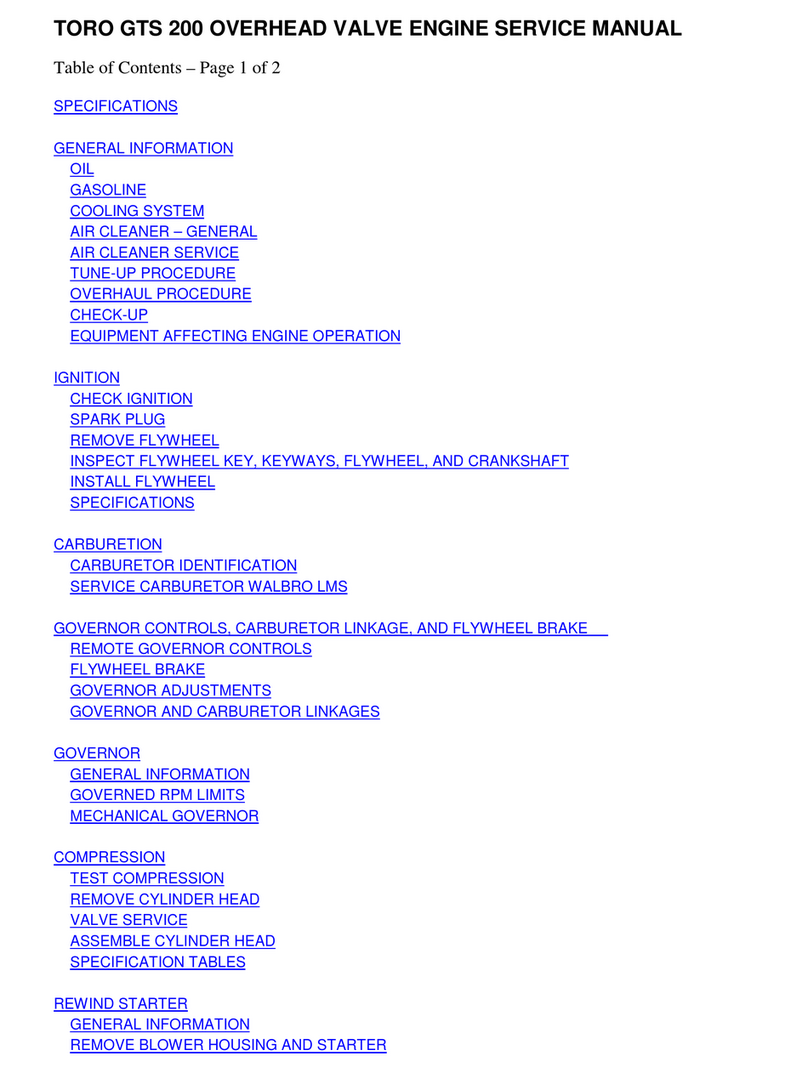

Maintenance.............................................................9

RecommendedMaintenanceSchedule(s).............9

PreparingtheMachineforMaintenance............10

ServicingtheEngineOil....................................10

ServicingtheAirCleaner..................................12

ServicingtheSparkPlug...................................13

©2020—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved*3440-983*A