Toro 303447 Operating instructions

C

o

S

m

(Re

v

o

mme

r

m

all E

n

v

. 6-12)

r

cial E

q

ng

ine

T

q

uip

m

T

roub

l

m

ent S

e

l

eshoo

t

e

rvice

T

t

in

g

T

raini

n

ng

Program Study Workbook

To The Technician: The following Program Study Workbook is designed to enhance

your understanding of small engine operation and troubleshooting.

The format is designed to increase your comprehension of important concepts and

material that are addressed in the manual.

This Service Training material should also be utilized as future reference materials to be

used one your return back at your workplace.

If you still have questions or want further explanations/clarifications, talk with other

attendees here, and/or the Training Instructor for additional explanation or discussion.

Make the most productive use of your time in this program. The clearer the

understanding you have of the information provided the more effective you become to

your employer.

The Toro Company © 2012 The Toro Company

8111 Lyndale Ave South All Rights Reserved

Bloomington, MN 55068 U.S.A.

Printed in the U.S.A.

GoodafternoonandonbehalfoftheToroCompany,

thanksforattendingthisinformationalsessiononSmall

EngineTroubleshooting.

Ifthroughthecourseofthispresentation,youhaveany

questionspleasefeelfreetoask.

Thissessionisforyouandnooneshouldleavewithout

gettingtheirquestionsasked.

Smallenginesareanimportantcomponentofmanyof

themachinesthatareneededtomaintainturfareasand

performothermaintenancejobs.

Smallenginesareveryreliableandwithpropercareand

maintenancewilllastalongtime

However,whiletheyaredependablecomponents,when

theydonotperformasneeded,theycanbeoneofthe

mostfrustratingdevicesinourselectionoftoolsand

machines.

Themostcommoncomplaintaboutsmallenginesisthat

they“WONTSTART”

Thesecondmostcommoncomplaintisthatitruns,but

runspoorly.

Inthisprogramwewilldiscusswhatisneededforthese

enginestostart,whatisneededfromthemtorun

properlyandwhattestsandtroubleshootingstepscanbe

usedwheneitherofthesetwosituationsare

encountered.

Let'sexaminehowtoidentifytheproblemyoumayface

withasmallengine.

Ifyouhaveano‐startissueorapoorperformanceissue,

therearesomeFactsthatweneedtounderstandwhen

troubleshootingtheseengines.

WewilllookattheFACTS

F—Fuel

A–Air

C–Compression

T–Timing

S–Spark

Fortheenginetorunproperlyweneedtohave,Fuel,Air,

Compression,Timing&Spark.

Thesewillbediscussedinmoredepthlaterinthis

program.

Tobegin,weneedtoidentifytheenginetogetthecorrect

enginespecs,testingspecsandadjustmentinformation.

Theenginewillnormallyhavean“EngineIdentification”

numberontheengine.

Itmaybeontheenginehousing,onthevalvecoveroron

anenginesideplate.

Thesenumbersmayincludeamodel,type,andcode

BriggsandStrattonforexample,providethefollowing

informationthroughtheirnumberingsystem.

Modelprovidesengineconfigurationinformation.

Typelistspecificparts,paintcolor,OEMinformation.

Codeprovidesspecificmanufacturingdateandplant

information.

ThisisanexampleofabasicBriggs&Strattonenginenumber.

Model303447Type1234‐01Code01061201

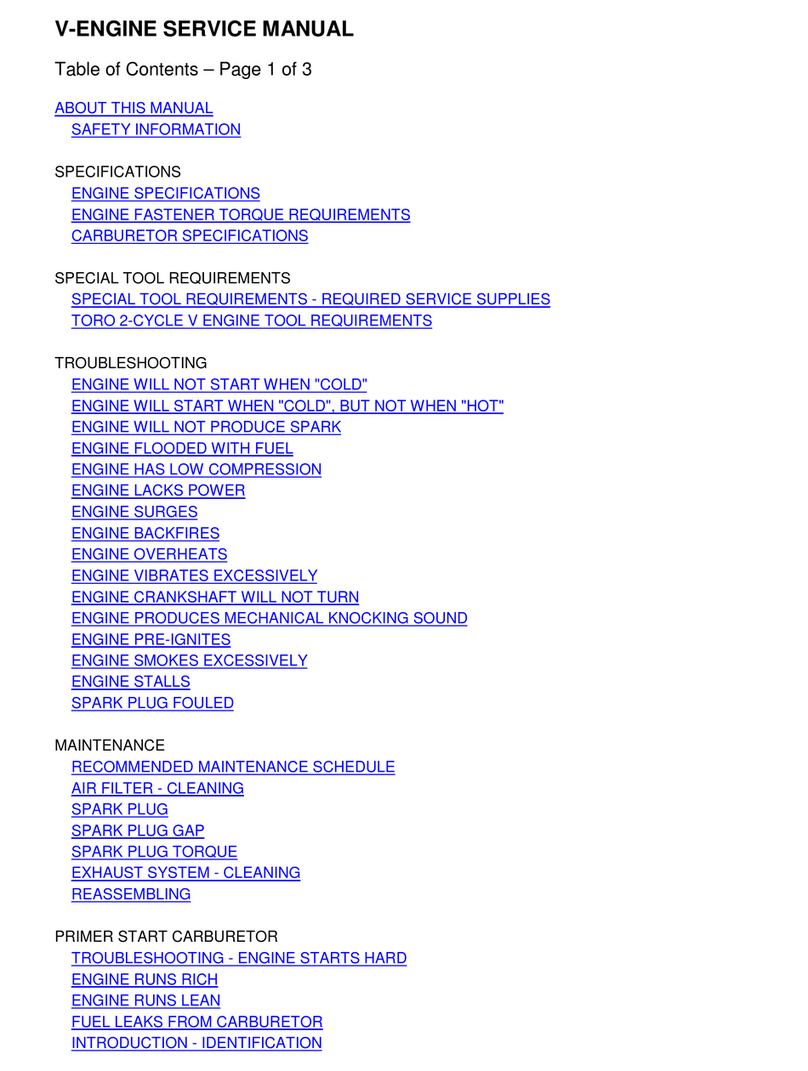

A

Cubic Inch

Displacement

B

Basic Design

Series

C

Crankshaft, Carburetor,

Governor

D

PTO Bearing, Reduction Gear,

Auxiliary Drive, Lubrication

6

8

9

10

11

12

13

16

17

18

19

22

23

24

25

26

28

29

30

32

35

40

42

46

0-9

A-Z 0 - Horizontal Shaft, Diaphragm

Carburetor, Pneumatic Governor

1 - Horizontal Shaft, Vacu-Jet

Carburetor, Pneumatic Governor

2 - Horizontal Shaft, Pulsa-Jet

Carburetor, Pneumatic or

Mechanical Governor

3 - Horizontal Shaft, Flo-Jet

Carburetor, Pneumatic Governor

4 - Horizontal Shaft, Vacu-Jet

Carburetor, Mechanical Governor

5 - Vertical Shaft, Vacu-Jet

Carburetor, Pneumatic or

Mechanical Governor

6 - Vertical Shaft

7 - Vertical Shaft, Flo-Jet

Carburetor, Pneumatic or

Mechanical Governor

8 - Vertical Shaft, Flo-Jet

Carburetor, Mechanical Governor

9 - Vertical Shaft, Pulsa-Jet

Carburetor, Pneumatic or

Mechanical Governor

0 - Plain Bearing / DU, Non-

Flange Mount

1 - Plain Bearing, Flange

Mounting

2 - Sleeve Bearing

Flange, Mounting, Splash Lube

3 - Ball Bearing, Flange

Mounting, Splash Lube

4 - Ball Bearing, Flange

Mounting, Pressure Lubrication

on Horizontal Shaft

5 - Plain Bearing, Gear Reduction

(6 to 1), CW Rotation, Flange

Mounting

6 - Plain Bearing, Gear Reduction

(6 to 1), CW Rotation, Flange

Mounting

7 - Plain Bearing, Pressure

Lubrication on Vertical Shaft

8 - Plain Bearing, Auxiliary Drive

(PTO) Perpendicular to

Crankshaft

9 - Plain Bearing, Auxiliary Drive

(PTO) Parallel to Crankshaft

Usingthepreviouschart,wecanseethatthe303447refertothefollowingenginespec.

30CubicInch,designseries3,horizontalcrankshaft,ballbearing,pressurelubricatedenginewithan

electricstartedandgeardrivealternator.

ThetypenumberlistspecificationnormallyrelatedtotheOEMoptionsandrequirement.

Thisincludedtheenginepaintcolor,governedspeedandOEMinformation.

Thecodetellsusthatthisenginewasbuilt,June12,2001online1,plant1.

Allofthisinformationisneededtoproperlytest,adjustandrepairtheengine.

FortheenginetorunthereareEight(8)eventsarerequiredfora2or4cycleenginetooperate.

First,Airisdrawnintothecylinder

Thecorrectamountoffuelismeteredintotheair

Theairandfuelaremixed

Theairfuelmixtureiscompressed

Thesparkplugfiresstartingcombustion

Combustioncausesarapidriseintemperature.Theincreasedtemperaturecausespressuretoincrease

whichproducesaforceonthepiston.

Theconnectingrodandcrankshaftconvertsthelinearmotiontorotarymotion.

Theburntgasesareexpelledfromtheengine.

Donotconfusetheseeventswiththefourstrokes(events)ofafourcycleengine.

Everyonehasheardofthefourstrokeorfourcycleengine.

Afour‐strokeengine,alsoknownasfour‐cycle,isaninternalcombustionengineinwhichthepiston

completesfourseparatestrokes—intake,compression,power,andexhaust—duringtwoseparate

revolutionsoftheengine'scrankshaft,andonesinglecombustioncycle.

INTAKEstroke:ontheintakeorinductionstrokeofthepiston,thepistondescendsfromthetopofthe

cylindertothebottomofthecylinder,reducingthepressureinsidethecylinder.Amixtureoffuelandair,

isforcedbyatmosphericpressureintothecylinderthroughtheintakeport.Theintakevalve(s)then

close.Thevolumeofair/fuelmixturethatisdrawnintothecylinder,relativetothevolumeofthe

cylinderiscalled,thevolumetricefficiencyoftheengine.

Detail

PistonmovesfromTDCtoBDC

Intakevalveopen

Exhaustvalveclosed

Pistonmovementcausesanareaoflowpressuretodevelopinthecombustionchamber.

Higherambientatmosphericpressureforcesairthroughtheintakesystem.

Ingascarburetedenginetheairpicksupthefuelasitpassesthroughthecarburetor.

Ingasfuelinjectedenginesthegasisaddedtotheairthroughaninjector.

InDieselenginesthefuelisinjectedintothecylinderattheendofthecompressionstroke.

180degreesofrotation

Anythingthatrestrictstheflowofairwillreduceengineperformance.

COMPRESSIONstroke:withbothintakeandexhaustvalvesclosed,thepistonreturnstothetopofthe

cylindercompressingtheair,orfuel‐airmixtureintothecombustionchamberofthecylinderhead.

Detail

PistonmovesfromBDCtoTDC

Intakevalveclosed

Exhaustvalveclosed

Pistonmovementreducesthevolumeofthecombustionchamber‐‐increasespressure.

Pressureofcompression=60to80psi.

Anypressurethatescapesreducestheperformanceoftheengine.

360degreesofrotation

Inorderfortheenginetorun,theairandfuelmixtureiscompressedinthecylinder.Thisincreasesthe

densityofthefuelairmixtureandallowsforamoreefficientcombustionprocess,andhigherpower

output.

CompressionratioisacomparisonbetweenthevolumeofthecylinderatBDCtothevolumeofthe

cylinderatTDC.

Ratiosof6to8:1arecommonforgasolineenginesand18to20:1forDieselengines.

POWERstroke:thisisthestartofthesecondrevolutionof

theengine.WhilethepistonisclosetoTop DeadCenter,

thecompressedair–fuelmixtureinagasolineengineis

ignited,usuallybyasparkplug,orfuelisinjectedintothe

dieselengine,whichignitesduetotheheatgeneratedin

theairduringthecompressionstroke.Theresulting

massivepressurefromthecombustionofthecompressed

fuel‐airmixtureforcesthepistonbackdowntoward

bottomdeadcenter.

Detail

PistonmovesfromTDCtoBDC

Intakevalveclosed

Exhaustvalveclosed

Rapidburningcausesrapidriseintemperature.

Rapidriseintemperaturecausesincreasedpressure.

Pressureinducesaforceonthepiston.

Forceonpistonproducestorqueoncrankshaft.

540degreesrotation

EXHAUSTstroke:duringtheexhauststroke,thepiston

onceagainreturnstotopdeadcenterwhiletheexhaust

valveisopen.Thisactionevacuatestheburntproductsof

combustionfromthecylinderbyexpellingthespentfuel‐

airmixtureoutthroughtheexhaustvalve(s).

Detail

PistonmovingfromBDCtoTDC.

Intakevalveclosed

Exhaustvalveopen

Wastegassesareexpelledfromthecylinder.

720degreesofrotation

Therearesomespecificcharacteristicsrelatedtoafour

cycleengine

Twocompleterevolutionsofthecrankshaftpercycle

resultsinapowerimpulseeveryotherrevolution.

Theseenginesaremorepopularthan2cycle

Theydorequiremorepartsthat2cycle.

Lessexhaustemissionsthan2cycle.

Typicallubricationsystemrestrictsangleofoperationdue

toeithersplashlubefromthesump,orpressure

lubricated,pullingoilfromthesump.

Theyarealsonormallymoredurablethan2cycle.

Inthe2strokecyclealleighteventsoccurintwostrokes,onerevolutionofthecrankshaft.

Thesparkplugfiresandthepistonmovesawayfromthecylinderhead.

Simultaneouslytheair‐fuel‐oilinthecrankcaseiscompressed.

Asthepistonreachesthebottomofthestroketheexhaustportisexposed.

Cylinderpressurecausesgassestoflowouttheport.

Furthermovementofthepistonandtheintakeportisexposed

Crankcasepressurecausesair‐fuel‐oiltoflowintothecombustionchamber.

Asthepistonmovestowardsthecylinderheadtheintakeandexhaustportsarecoveredandtheair‐fuel‐

oilchargeiscompressed.

Assoonastheintakeportiscovered,furtherpistonmovementcauseslowpressureinthecrankcaseand

anewchargefillsthecrankcase.

Therearesomespecificcharacteristicsrelatedtoatwo

cycleengine

Onerevolutionpercyclemeansapowerimpulseevery

revolution.

Fewerparts=lessweight

Usesscavengingtoexpelexhaustgases.

Higherfuelconsumption

Morenoise

Higheroperatingspeed

Higheroperatingtemperature

Greaterexhaustemissions

Smallsizeandweightforequalhorsepower.

Operateinmulti‐positions

Shorterexpectedlife

Earlierwementionsthe“FACTS”requiredforengine

operation.

Let'sexaminehowtoidentifytheproblemyoumayface

withasmallengine

ThiswillrequirealookattheFactsthatareneededto

maketheenginerun,andrunproperly.

Let'sbeginwithFuel.

WhenlookingatFUELthereareafewquestionstoask…

Doesithaveanyfuel?

Istheshutoffvalveclosed?

Isthefueldilutedwithwater?

AlcoholcontentofFuel?

Isthefuellineblocked?

Isthefueltankcapcloggedorunvented?

Isfuelinthecarburetor?

In recent years, small engines have run into issues

due to federally mandated changes in fuel

requirements.

This deals with the “Oxygenated” fuel that are

becoming more common in the country.

This started back in 1990 with the clean air act.

Clean Air Act 1990 requires gasoline to be modified

with oxygen additives in nonattainment zones.

Nonattainment zone: areas of the country that

exceed ozone levels.

There are Two common additives;

Alcohol

Methyl Tertiary Butyl Ether (MTBE)

Alcohol

Two types

Ethanol: distilled from grains and sugar containing

plants

Methanol: distilled from natural gas

The addition of alcohol to gasoline increases the

available oxygen during the combustion process.

Up to 10% ethanol acceptable for most small

engines.

Methanol is not normally recommended for small

engines.

MTBE

Removed from market because of health concerns.

Alcoholcontentcanplayamajorroleinperformanceissuesrelatedtosmallengines.

Theblendingofalcoholwithgasolinecaninsomeareasbeinconsistentwithalcoholcontentsometimes

beinghigherthanthedesired10%

Tocheckthealcoholcontestoffuel,thereareavarietyoftestdevicestoassistwiththis.

Thiskit,availablefromKohlerallowstheusertoquicklyandeffectivelytestfuelforalcoholcontent.

Tocheckalcoholcontent,addwatertothetester,uptothewaterline.

Thenaddgasolineuptotheneckofthetester.

Putonthecapandshake.

Thewaterwillmixwiththealcoholwhilethegasandthewaterwillremainseparated.

Setasideforacoupleminutesandthennotewherethewater/fuelseparationlineis.

Comparethatseparationlinetothelineonthetester.

Thiswillindicatethepercentageofalcoholinthefuel.

Ideallythisshouldbe10%.

Next,let'slookatAIR

Airisrequiredtoprovidetheoxygenneededfor

combustion,andtheenginealsoneedsasufficient

amountofair,forcompressiontobeadequate.

Insmallenginesthereareonlytwoareathatcanrestrict

theflowofairintotheengine.

Firstisthethrottleplateinthecarburetororintake

manifoldinfuelinjectedengines.

Theotherlocationistheairfilter.Thiscanbeanair

restrictionpointifnotproperlymaintained.

Theprimaryfunctionofanairfilteristodeliverbothhigh

airflowanddirtprotection.

Bothairflowanddirtprotectionarecriticaltoengine

performance.

Thebasictypesofairfiltersare.

Oiled‐foam,thisisafoamtypematerialwhichisoiledto

capturedirtparticlesandkeepsthemfromenteringthe

engine.

Thesetypesoffiltersarenormallycleanedandre‐oiledas

amaintenanceprocedure

Papertypefiltersusedapleatedpaperelementwith

holesofaspecificsizedesignedtocapturedirtparticles

alsoofaspecificsize.

Thesecanalsobecleanedasamaintenanceprocedure.

Dual‐elementfiltersareacombinationofbothtypes.

Theyconsistofapaperelementcoveredbyanoiled‐foam

element.

AirCleanerService–

Airfiltersshouldbecleanedpermanufactures

recommendations

Oiled‐Foamtypeelementscanbecleanedusingsoapand

water.Addasmallamountofoilandsqueezetosaturate

theelement.

Papertypeelementscanbecleanedbytappinggentlyon

aflatsurfaceorbyusingcompressedair.

Someenginemanufacturesmaynotrecommendusingcompressedairwhencleaningfilters.Ifyou

choosetoyoucompressedairtocleanapaperelementfilter,itisrecommendedthatthefilterbe

cleanedwithlowpressureair.

Thisreducesthelikelihoodthatthepaperelementisdamagedduringthecleaningprocess.

Arecommendationistoattachanairpressureregulatortothehosethatisusedforfiltercleaning.

Settingtheregulatorfor10‐20PSIwillnormallydoasufficientjobofcleaningwithoutriskingdamageto

theelement.

ThenextitemtolookatisCompression.

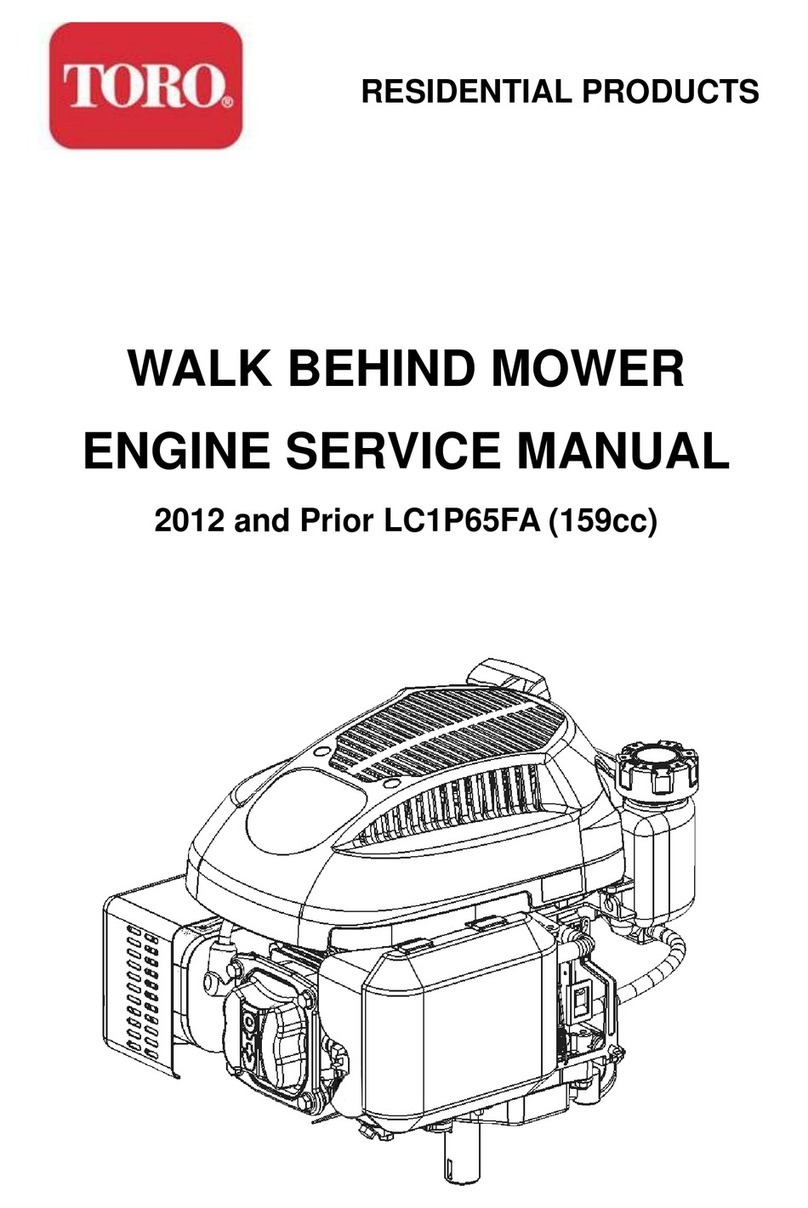

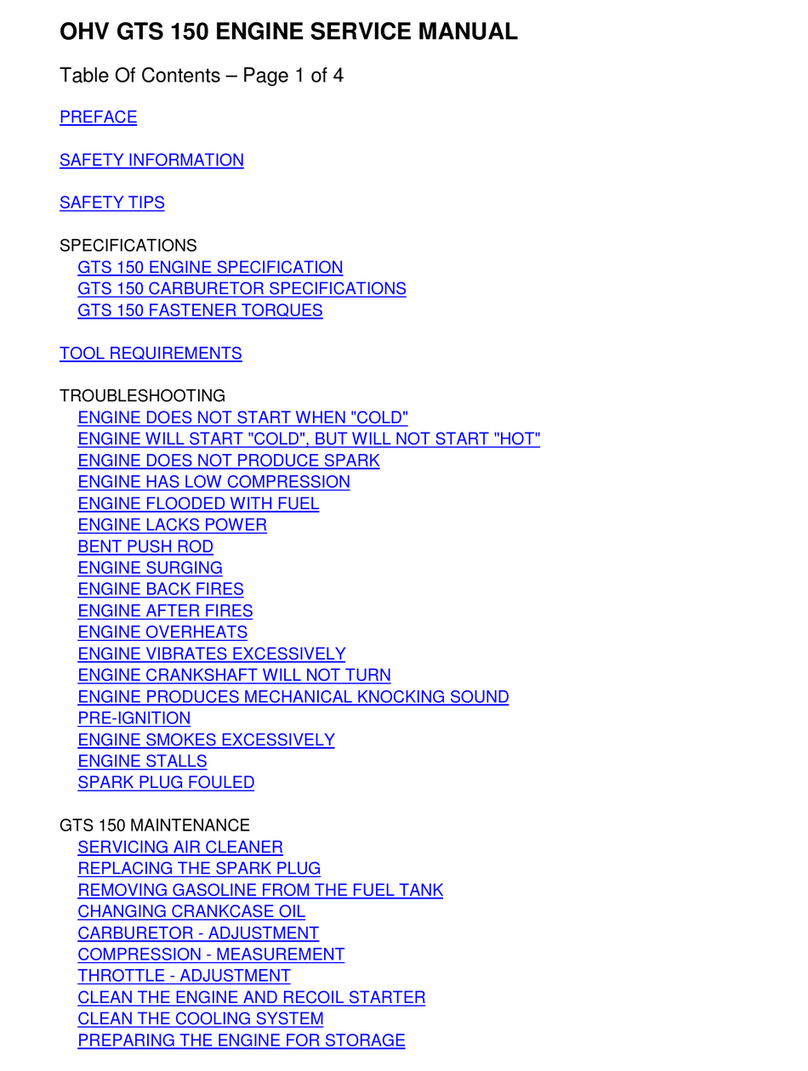

Other Toro Engine manuals

Popular Engine manuals by other brands

Toshiba

Toshiba EQP Global IEC Series Installation Instructions and Maintenance Manual

Iveco Motors

Iveco Motors NEF Series Use and maintenance

Lombardini

Lombardini 15 LD 500 Use and maintenance

Selve

Selve SEE-NHK quick start guide

DR

DR RV340 Safety & Operating Instructions

Xtreme Power

Xtreme Power 62027 owner's manual

WEG

WEG W21 instruction manual

Briggs & Stratton

Briggs & Stratton Vanguard 540000 Series Operator's manual

Briggs & Stratton

Briggs & Stratton PowerBuilt Snow 120000 Series Operating & maintenance instructions

Shibaura

Shibaura N843L Workshop manual

Coulisse

Coulisse CM-01 manual

Bettcher

Bettcher Ultra Drive UN-99 Operating instructions and spare parts lists