Toro GTS 120 User manual

2-CYCLE GTS 120 ENGINE SERVICE MANUAL

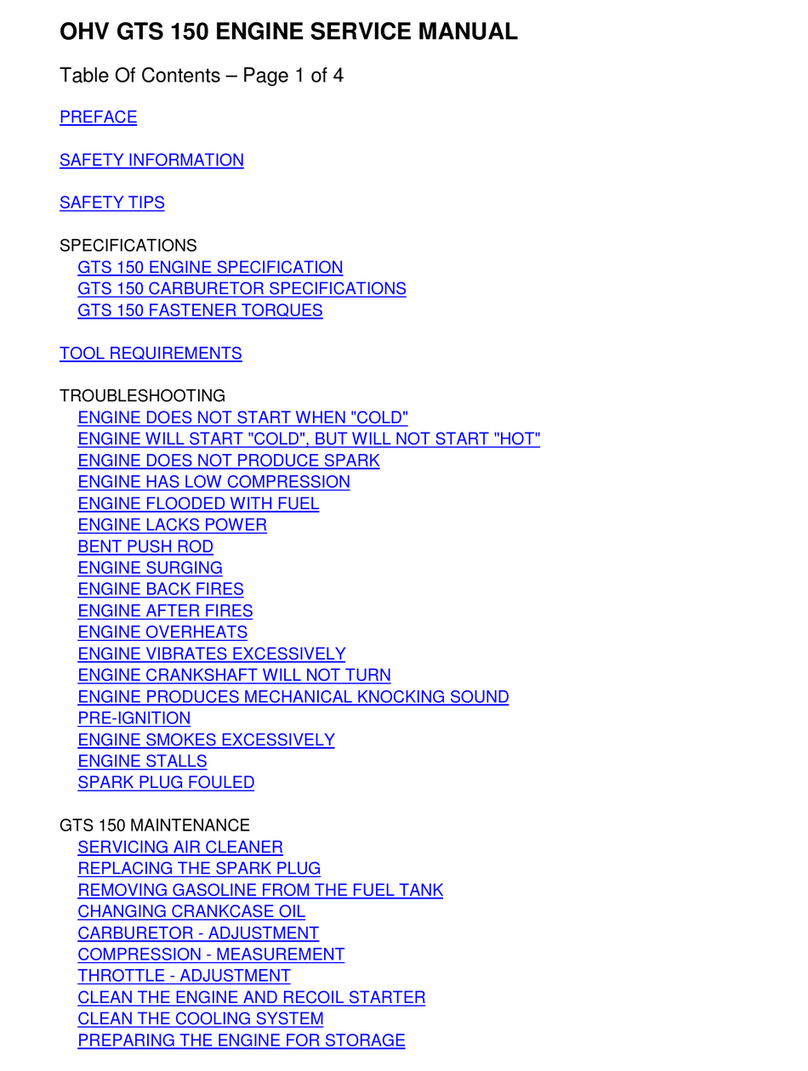

Table of Contents – Page 1 of 1

PREFACE

I. GENERAL INFORMATION

SAFETY INSTRUCTIONS

MAINTENANCE

MODEL AND SERIAL NUMBERS

TWO-CYCLE ENGINE THEORY AND OPERATION

CARBURETOR THEORY AND OPERATION

SPECIAL TOOLS LIST

II. MAINTENANCE

AIR CLEANER

SPARK PLUG

EXHAUST SYSTEM

DECARBONING CYLINDER HEAD

IGNITION TIMING (MODEL 47PZ2 ONLY)

IGNITION TIMING (DIAL INDICATOR)

CONTACT POINTS AND CONDENSER MODEL47PZ2 ONLY

IGNITION COIL

GOVERNOR

GOVERNOR OPERATION

FUEL TANK

CARBURETOR

STORAGE

III. TROUBLESHOOTING AND TEST PROCEDURES

PRELIMINARY TROUBLESHOOTING

ENGINE BRAKE AND IGNITION SWITCH

BBC APPLICATIONS

FUEL TANK

TESTING COMPRESSION

CRANKCASE

ENGINE TROUBLESHOOTING CHART

IV. ENGINE REMOVAL, DISASSEMBLY, ASSEMBLY AND REPAIR INSTRUCTIONS

ENGINE REMOVAL

ENGINE DISASSEMBLY AND REPAIR

RECOIL STARTER REPAIR

CARBURETOR REPAIR

ENGINE ASSEMBLY AND REPAIR

SERVICE DATA SPECIFICATIONS

PREFACE

This service manualwas written expressly forTORO Two-Cycle Rotary Mowers.

All

units with the modelnumber

47P22,47PD3,47PE4,

and

47PF5

engines

have beentaken intoconsideration.

The ToroCompany has made every

effort

tomakethis service manuala useful

tool for the serviceand maintenanceof your

TORO

Rotary Mower Engine.To

assure proper and effectiveperformance, you areurgedto readthis manual

carefully.

The purpose

of

this manualisto providethe Service Dealerwithworking

guidelinesof maintenance,troubleshooting,test,and overhaul procedures.

The ToroCompany reservesthe righttochangeproduct specifications or this

manualwithout notice.

The ToroCompany

Service

Department

COPYRIGHT ALL RIGHTS RESERVED

The

Toro

Company

1986

MINNEAPOLIS,

MN

55420

U.S.A.

i

TABLE

OF

CONTENTS

.

GENERAL INFORMATION

1-1

Safety Instructions

................................................................................

1-1

Modeland Serial Numbers

...................................

.,.

...................................

1-2

EngineSpecifications

.............................................................................

1-5

FastenerTorque Specifications

...................................................................

1-5

SpecialTools

......................................................................................

1-6

II.>

MAINTENANCE

..............................................................................

11-1

TOPIC PAGEE

1

....................................................................

Maintenance

.......................................................................................

1-2

Two-cycleEngineTheoryand Operation

..........................................................

1-2

CarburetorTheory andOperation

.................................................................

1-4

Air Cleaner

.......................................................................................

11-1

SparkPlug

.......................................................................................

11-1

Exhaust System

..................................................................................

11-1

DecarboningCylinder Head

......................................................................

11-2

IgnitionTiming(Model47PZ2 Only)

..............................................................

11-2

IgnitionTiming(DialIndicator)

11-3

Contact PointsandCondenser (Model47PZ2 Only)

..............................................

11-3

Ignition Coil (Model 47P22Only)

.................................................................

11-3

GovernorOperation

..............................................................................

11-5

....................................................................

Ignition Coil(Models47PD3.47PE4. 47PF5)

..................

..................................

11-4

Governor

..................................................................

......................

11-4

FuelTank

11-5

Carburetor

.......................................................................................

11-6

Storage

11-6

111

.

TROUBLESHOOTINGAND TEST PROCEDURES

111-1

Spark Intensity

..................................................................................

111-1

........................................................................................

...........................................................................................

..........................................

PreliminaryTroubleshooting

.....................................................................

111-1

Engine Brakeand IgnitionSwitch

................................................................

111-1

BBCApplications

................................................................................

111-2

FuelTank

.....................................................

..................................

111-2

TestingCompression

............................................................................

111-2

Crankcase

111-3

.......................................................................................

EngineTroubleshootingChart

...................................................................

111-4

IV

.

ENGINE REMOVAL, DISASSEMBLY, ASSEMBLY AND REPAIR INSTRUCTIONS

........

1v-1

Engine Disassembly and Repair

................................................................

1v-1

RecoilStarter Repair

............................................................................

1v-1

.................................................................................

Engine Removal

1v-1

CarburetorRepair

1v-2

ServiceData Specifications

......................................................................

1v-4

MaintenanceRecord

1v-6

MaintenanceRecord

1v-7

...............................................................................

............................................................................

............................................................................

SAFETY INSTRUCTIONS

Your rotary moweratthetimeof its manufacture,

meets the bladesafety requirementsof theCon-

sumer ProductSafety Commissions Safety Stan-

dard for Walk Behind Power Lawn Mowers.

A

representativesample was testedandverifiedby

an independent laboratory for compliance with

the B71.1-1980Specifications of the American

National Standards Institute. However, improper

use or maintenance by the operator orowner

can still result in injury. To reducethe potential

for injury follow these safetyinstructions.

6.Wear long pants and substantialshoes.

Do

notoperatethemowerwhilewearing

sandals, tennis shoes,sneakersorshorts.

Do not wear loose fitting clothingthat could

get caught in movingparts.

7.

If

long grass will becut, setthe height-of-cut

in the highest position. Aftermowing, rein-

spect the area and remove alldebris. Then

lower the height-of-cut and mow the grass

again.

8. Since gasoline ishighly flammable, handle it

carefully

This machine is equipped with abladebrake

whichisdesignedto stop the blade within

3

A. Use an approvedgasoline container.

B.

Donot

fill

thefuel tank when the engineis

seconds when the control lever is released.

Checkto besurethe control and brakefunction hot or running.

correctly before each useof the mower. Repair C. Do not smoke while handling gasoline.

D.

Fillthefuel tank outdoors and up to about

any defective or damaged safety components

beforeoperationiscommenced.To further one-half inchfromthe top of thetank, not

the filler neck.

reducethe possibility of injury, always stop the E. Wipeup any spilled gasoline.

enginebefore leaving the operator’s position.

While Operating

9. Cutting the grass with a rotary mower de-

Thissafetysymbolmeans

mands attention.Always maintain secure

WARNING

or

CAUTION

-

footing, balanceand control.

PERSONALSAFETY INSTRUCTION

-

10. Cut the grass during the daytimeor when

Read the instruction because

it

has to

there

is

adequate artificial light. Cutslopes

do

with safety. Failure to comply with

from side to side, but avoid slopeswhen the

theinstructionmayresult in personal

grass iswet.

If

possible, mowwhenthe grass

injury.

isdry for best results.

11.Keepface,hands and feetawayfromthe

BeforeOperating

mower housingand cutter blade while the

1.

Operateyour mower only after reading the engineis running. Stay behind the handle

Operators Manual.

A

replacement manualis

available by sending the completemodel 12. Duringoperation thegrass defector

or

com-

and serial number to:The Toro Company, plete baggingassemblymust beinstalledon

8111 Lyndale Avenue South, Minneapolis, themower.

Minnesota

55420.

Attn: Publications. 13. Stopthe engineand waitfor allmoving parts

2.

Never allow children to operate the mower to stop before removing the bag, bagging

or adults tooperate mower without assembly, oruncloggingthedischarge

properinstructions. chute.

If

the chute must be unclogged, pull

3. Becomefamiliar with the controls and know the hightension wire from the spark plugto

howto stop the enginequickly. preventthe possibility

of

accidental starting.

4.

Keep everyone,especiallychildren andpets, Use a stick to remove theobstruction.

away from the areaof operation. Remove 14.

If

a solid object is hit by the blade or

if

the

sticks,stones, wire and anyother debris that mower vibrates abnormally, stop theengine

might be picked up and thrownbythe blade. immediately. Disconnect the high tension

5.

TAMPERING WITH

OR

DEFEATING

A

wire from the spark plugtoprevent the

SAFETY DEVICE

OR

COMPONENT WHICH possibility of accidental starting.Then check

RESULTSINNONCONFORMANCE WITH

A

the mowerfor possible damage, bent blade,

an obstruction or loose parts.Repair the

-

SONAL INJURY. Eachtime before operating mower before using it again.

the mower, check for damage or abnormal 15. Stoptheenginebeforeadjustingthe

wear.

If

a safetydevice,shield,or decal

is

height-of-cut.

defective ordamaged, repair or replace it 16.

If

a gravel driveway, road orpathmust be

before operation iscommenced. crossed, stop the engine

so

loose sand and

until the engine andall moving parts stop.

SAFETY STANDARD, MAY RESULTINPER-

1-1

rocksare not thrown.

17.

Beforeleavingthe operator’sposition behind

the handle, stop the engine and wait for all

movingparts to stop. Do not walk infront of

the mower while the engine isrunning. Dis-

connectthe hightension wire from thespark

plug

if

the mower will be unattended.

18.

Do

nottouch any part oftheenginewhile it is

runningor shortly after it is stoppedbecause

the enginewillbe hot enoughtocausea

burn.

Muffler

is

extremely hot.Keep

children and pets away.

I

MAINTENANCE

19.

Beforethemoweris serviced oradjusted,

stopthe engine andremovethe key fromthe

switch. Disconnectthe high tension wire from

thespark plug toprevent the possibility of

accidental starting.

20.

Toassurethe mower is in safe operating

condition, keep all nuts, bolts andscrews

tight. Assurethe blade capscrew istightened

to the propertorque.

21.

If

major repairs are ever needed or

if

assis-

tanceis desired, contact an Authorized

TORO Service Dealer.

22.

If

the mower must be tipped when it is

servicedor adjusted,drain thegasoline from

the fuel tank.

23.

If

a guard,safety device orsafety decalis

damaged, replace the defective part(s) be-

fore operatingthe mower.

24.

To reduce potential fire hazards, assurethe

mower is free

of

excessive grease,grass,

leaves and accumulationsof dirt.

25.

The grass bag must always beingood con-

dition; therefore, check itbeforeeach useto

assure the bag is not torn

or

deteriorated.

Always replace a defective grass bag.

26.

Allow the engine to cool before storing the

mowerinany enclosure suchas a garageor

storage shed.

Do

not store the mower near

any open flameorwhere gasoline fumes

may be ignited by a spark.

27.

Do not overspeedthe enginebychanging

the governorsettings. Recommended speed

of the engine is

3000

rpm. To assure safety

andaccuracy, have anAuthorized TORO

Service Dealercheck the enginespeed with

atachometer.

28.

At the time of manufacturethe mower con-

formed to the safety standards in effect for

rotary mowers. To assure optimum perfor-

mance and continuedsafety certification of

the mower, use genuineTORO replacement

parts and accessories. Replacement parts

andaccessories madebyother manufac-

turers may result in nonconformance with

the safety standards.

MODEL AND SERIAL NUMBERS

The TOROTwo-cycleRotary Mowerhastwosets

of identification numbers.Thereis a model and

serial numberto identify the engine and a model

and serial number to identify the chassis. The

engine identification numbers are stamped into

the blower housing behindthe air cleaner.Model

47PF5 engines built for

1986

have the engine

identification numbersstamped inthe blower

housingabovethespark plug. Enginemodels

47PE4and 47PF5 haveserial numbersthat start

withthenumber

1,

2

or

3.The

number

1

indicates

a

zone start application. The number

2

indicates

BBC applicationandthenumber

3

indicates

commercial application.

The chassisidentification numbersarelocatedon

a decal on the back

of

themower housing, between

the rear wheels.

In any correspondence concerning the mower,

supply the model and serial numbers to assure

thatthecorrectinformationand replacementparts

are obtained. Genuine TORO replacement parts

may beordered throughyour

local

TORO Autho-

rizedService Dealer.

TWO-CYCLE ENGINE THEORY AND

OPERATION

Theory

Two-cycleengines have special advantages

which make their usemore practical in certain

applications. Two-cycle engines arelightweight

with an excellent power to weightratio and can

beoperated in any position. They are also

notably easy to maintainand service becauseof

their uncomplicateddesign.

The TOROTwo-cycleEngine usedontheTORO

Rotary Mowers is a third-port, loop scavenged

design. This design name describesthe path of

thefuel

/

air mixtureintothe crankcase and com-

bustion chamber, and the exhausting of spent

gases.

Ina loop-scavengeengine, a high pressurearea

is created in the crankcase by the downward

movement of the piston. Pressurizedfuel-air

mixture rushesinto the combustionchamber

through the intake ports and is directed toward

the cylinder head.Thisfresh mixturethenstrikes

the cylinder head and loops down forcingburnt

gases in the combustion chamber out through

1-2

the exhaust ports. The third port design engine

has the carburetor mounted on the side of the

cylinder. Thepassage from the carburetor into

the crankcase is called the third port.

All

ports

within the engine areopened and closedby the

piston skirt as the piston movesupand down

within the cylinder.

Operation

The piston closes all engine ports as it moves

toward thecombustion chamber(Figure1-1). The

movingpistoncreates ahighpressureinthecom-

bustion chamber and a partial vacuum in the

crankcase.

Intake Ports Closed

Co

Figure1-1

At

apointslightlybeforetopdead center(BTDC) of

thepistontravel, from the plug ignitesthe

fuel air mixture(Figure1-2).Also, atthis time, the

third portopensallowingthefreshfuel/air mixture

torush into thecrankcase to equalizethe partial

vacuum.

Intake Ports Closed

\

Figure 1-2

When the fuel is ignited by the sparkplug, the

expanding gases fromtheburningfuelin thecom-

bustionchamberforcethepistondownthecylinder,

closing thethird-portandincreasingthe pressure

inthe

crankcase.At

apointapproachingthebottom

ofthestroke,theexhaustportopensand theburnt

1-3

gases beginto beexpelled fromthe combustion

chamber(Figure1-3).

__-

--l_____m_

Intake Ports Closed

Exhaust Port

I

Third

PortClosed

~

Figure

1-3

At a point of piston travel slightly before bottom

dead center (BBDC)

the

fueltransfer ports,on the

sides of the cylinder walls, are uncovered and

thecompressedfuel/air mixtureinthe crankcase

-is allowed to enter the combustionchamber

wherethey help expel theburnt gases and

charge the chamber for the followingpiston

stroke (Figure1-4).

Intake Ports

Open

Exhaust

Change

__-__

Figure 1-4

CARBURETOR THEORY AND OPERATION

Theory

The carburetor receives fuel from the tank and

mixes

it

with air in therightproportionsto

provide a highly combustible mixture to the

engine.

As the piston moves up on the compression

stroke a partial vacuum is created within the

engine crankcase, causingthe greater atmos-

phericpressuretoforceairtoflowthroughthe

carburetor into the cylinder. The velocity of the

air increases as it flows through the carburetor

venturi and the air pressure is reducedat this

pointto less thanatmospheric pressure. The

differences of pressure in the venturi of the

carburetor causes atmospheric pressureto push

rawfuelfromthe

float

bowlintotheair

stream,where

it breaks up into a fine spray, or becomes atomized,

andmixes withthe airstream (Figure

1-5).

Float

Bowl

ToEngine

Figure

1-5

Operation

When startingtheengine,an extra richmixtureis

required.The chokeplateisclosedbytheopera-

tor to providean approximate

8:1

ratio of fuel to

air for this rich mixture. Closing the choke plate

further reducesthe air pressurearea inthe

venturi to increase the fuel drawn into the car-

buretor bore. Inthis condition fuel is drawnfrom

the float bowl through the pilot system ports as

well as the main discharge tube to achieve the

proper starting mixture(Figure

1-6).

Pilot

Jet

Pilot System

Pilot Air Fitting

COLD START

Figure

1-6

Fuelatomization becomes moreefficient,due to

heat, oncetheengine has reachednormal

operating temperature.

As

a result, theengine

doesnotrequirethe rich mixtureit did for

starting and the choke plate must be moved

to

the open position. The engine speed is now

regulated by the throttleplate.In no load condi-

tions a small portion of the fuel may be drawn

from the main discharge tube, however the pri-

mary fuel supply is drawn from the pilot circuit.

1-4

Air passingthrough the pilot jetfrom the pilotair

fitting draws fuel outof the pilot jet orificefrom

thefloatbowl.Thisfuelpre-mixeswiththe

incoming air, thenisdischargedintothe car-

buretor bore where the fuel becomes atomized

(Figure

1-7).

NO

LOAD

Figure

1-7

As

the throttle plate isopened to compensate for

loadsthe engine is being placedunder,the main

discharge tubebecomes the mainsourceof fuel.

Opening the throttle plate increases the flowof

air through the venturi andstrengthens the low

pressure area at the main discharge tube. Fuel

discharge increases at the main dischargetube

as

it

decreasesfrom thepilot system. Air

is

drawn from the air correction jet through holes

alongthe lengthof the maindischargetube.This

pre-mixes air with the fuel before it enters the

carburetor bore for more efficient atomizing of

:hefuel (Figure

1-8).

/pilot

System

Float

Bowl

UNDER LOAD

Figure

1-8

ENGINE SPECIFICATIONS

~---

Model

47P22

Type 2cycle, single cylinder piston

ported, aircooled

Rotation(viewedfrom output end) Counter-clockwise

Displacement 121cc (7.38cu.in)

~-

Bore 58 mm(2.28 in)

Stroke 46 mm(1.81in)

Crankshaft 24.9mm(.98in) forged steel

RatedOutput

3.5

Hp

@

3600RPM

Torque.73kg-m(5.28 ft-lb)

@

3000

RPM

CompressionRatio 6:1

Compression

Gas-OilRatio

50:

1

Gasoline UnleadedRegular

TTO

Oil 2cycle oil

FuelTank Capacity

Air Cleaner

Carburetor Mikuni

BV-15std.

mainjet #80

HighAltitude Jet

Governor MechanicalFlyweight

8.4kps/cm2 20psi)to

10.5 kps/cm (1

50

psi)

1.89

I

(2 qt)

Two stagefoam element

#77.5

--

-~

SparkArrester Muffler Optional(PN 81-0200)

47PD3

#76.3

#72.5

Starter Recoilonly

~-

SparkPlugNGK-BPMR6A NGK-

BPMR4A

IgnitionTiming 22" 2" BTDC

IgnitionTiming, PistonPosition 1.76-2.51mm (.069-.099in) BTDC

~-

Contact PointGap.35 mm (.014in)

IgnitionCoil AirGap .38-.50mm (.015-.020in)

Float Height Setting (BlackFloat)

*

N/A 11/16"

*The blackfloat may beusedonthese enginesas a replacement. Part number

81-0970.

.

N/A

*

N/A

FASTENER TORQUE SPECIFICATIONS

Adapter Plate HousingCapscrews(3/8-16UNC) 2.9-4.6 Kg-m(21

-33

ft-lb)

BladeCapscrew 6.2-8.3 Kg-m (45-60ft-lb)

FlywheelNut (M 10) 4.0-5.0 Kg-m(29-36ft-lb)

Muffler Nuts(M 8) 90-120Kg-Cm (100-140in-lb)

Air CleanerLock Nuts(M6) 60-90 Kg-Cm(70-1

05

in-lb)

Adapter Plate EngineCapscrews (M8) 90-120Kg-Cm (100-140in-lb)

Crankcase Capscrews (M 6) 80-95 Kg-Cm(70-110in-lb)

Shroud

&

MufflerCapscrews (M6) 40-70Kg-Cm(45-80in-lb)

Ignition Switch Mounting Capscrew(M6) 80-115Kg-Cm(90-1

30

in-lb)

Air CleanerMountingCapscrew (M

5)

17-26Kg-Cm(20-30in-lb)

RecoilStarterCupCapscrews(M6) 80-95Kg-Cm(70-110in-lb)

RecoilMountingCapscrews(M 6) 35-65Kg-Cm(40-75 in-lb)

RecoilCenter Capscrew(use thread lock compound) 80-95Kg-Cm(70-110in-lb)

Spark Plug(M 14) 70-1

05

Kg-Cm(80-120in-lb)

Throttle Plate Capscrews (M6) 80-95 Kg-Cm(70-110in-lb)

.-

.

-..-

__-

1-5

SPECIAL TOOLS LIST

ITEM

1

2

3

4

5

6

7

8.

9

10

11

12

13

14

15

16

17

18

19

20

21

22

DESCRIPTION

PART

NO.

Flywheel Puller..

..................................

41-7650

StarterCupWrench

................................

45-1390

SparkTester

......................................

41-7890

Continuity Light

...................................

36-4050

Tachometer..

..

.................................

42-2730

Ohmmeter(Multimeter).

Feeler Gauges

Micrometer.

Spark PlugGappingTool

CompressionGauge..

TimingTester..

....................................

41-7900

...........................

....................................

.......................................

..........................

.............................

Threebond#1104(Loctite#515).

.................

505-80

Loctite

#242

(Threebond#1342).

.................

505-76

Timing Dial Indicator..

Dial Indicator..

Cylinder GaugeSet..

Spark PlugSocket..

CoilGauge

.38-.50mm

(.015-.020 in)

Torque Wrench(ft-lb)

Torque Wrench(in-lb).

Magnetic

“V”

Blocks..

Dial IndicatorStand

.............................

....................................

..............................

...............................

...............

..............................

.............................

.............................

...............................

CAUTION: To reduce poten-

tial accidents, never perform

an adjustment or maintenance proce-

dure while the engine is running. Pull

the high tension wire

off

the spark plug

to prevent an accidental start.

AIR

CLEANER

The air cleaner must be maintained properly to

ensure foreign materials cannot damage the

engine

or

foulthecarburetor. The air cleaner

element must be cleanedafterevery

50

hoursof

engine operation,or morefrequently

if

theengine

isoperated industy

or

dirty conditions.

Lift the cover tabs securing the air cleaner cover

tothe housingandremovethecover(Figure2-1).

Clean the inside

of

the cover and housing if it

is

dirty.

Figure2-1

If the air cleaner element is dirty remove it from

the housing

for

cleaning.

DO

NOT ALLOW DIRT

TO ENTER BEHIND THE ELEMENTOR ENGINE

DAMAGE WILL RESULT. Washthe element in a

solution of liquid detergent and water. Squeeze

the element to remove the dirt. Do not twist the

element or the elementmaytear.Press the

element in adryraguntil itis completelydry.

Saturate the element with approximately five

teaspoonsof SAE

30

oil andsqueezetodistribute

the oilthoroughly.

Theelementmust be dampened with oil to

function properly.Replacetheelementandinstall

the cover. Assure that the cover snaps in place

and isseatedsecurelyontheaircleaner housing.

IMPORTANT: DO NOT OPERATE THE ENGINE

WITHOUTAN

AIR

CLEANERELEMENTOR

EXTREME ENGINE WEAR AND DAMAGE WILL

RESULT.

SPARK PLUG

Many timesan inspectionof the spark plug can

determinewhethertheengine isfunctioning

properly. A spark plugwhichisfunctioning

normallywill show slightelectrode wear with

brown

or

greyishtan deposits. Oilfouledand

black carbon fouled plugsare caused by a rich

carburetor mixture, weak spark, or improper

gasoline to oil mixture. Excessivelyworn elec-

trodes ora blisteredinsulator indicatespark plug

overheating. Look for incorrectignition timing,

cooling fins clogged withdebris,improper gaso-

line to oil mixtureand dirty carburetor, any of

which may cause this trouble.

IMPORTANT:

A

CRACKED,FOULED

OR

DIRTY

SPARKPLUGMUSTBEREPLACED.DONOT

TRODES.GRITMAYEVENTUALLYRELEASE

AGE.

The recommended sparkplusisanNGK-BPMRGA

or

NGK-BPMR4A (Champion RCJ8Y). See Page

1-5.

Theairgap betweentheelectrodes should beset

at

.8

mm

(.032in)

(Figure2-2). Since the air gap

increases gradually through use, the spark plug

should beremovedafterevery25 hours of opera-

tiontocheck itscondition.Cleanthe area around

the spark plug to prevent foreign materialfrom

falling into thecylinder.Install thespark plug with

the metal gasket and tighten to 70-105Kg-Cm

(80-120 in-lb).

SAND BLAST, SCRAPE OR CLEAN

THE

ELEC-

FROMTHEPLUGAND CAUSEENGINE DAM-

(.032

in)

EXHAUST SYSTEM

Oneimportant part of the maintenance for all

two-cycleengines is thecleaning

or

de-carboning

of the exhaustsystem.This is donetoassure the

unobstructed flowof exhaust gases and carbon

particles from the combustion chamber.

A

se-

verelycarbonedmuffler,spark arresterscreen or

exhaust portwillcausepoorstartingand

low

poweroutput.To de-carbon theexhaust system,

11-1

removethe muffler from the engine by removing theloosecarbon from the muffler usingcom-

the tworetainingnutsandthe throughbolt(Figure pressed air.Installthe mufflerusing a new gasket

2-3). and attach it with proper fasteners tightened to

the correcttorque. See page

1-5.

DECARBONING CYLINDER HEAD

Ifthe exhaust ports andmufflershow signs ofex-

cessivecarbon buildup,

it

may be necessary to

de-carbonthecylinderhead.Toaccomplishthisthe

entireengine must be disassembled to allow

access into the combustion chamber.(See Dis-

assembly Instructions PageIV-1.)Remove the

carbon deposits fromthe piston and thecylinder

chamber usinga wooden stick.TAKE CARE NOT

TOSCRATCHTHEPISTON

OR

CYLINDER

CHAMBER AND DO NOT USE A METAL TOOL TO

REMOVE THE DEPOSITS.

Figure2-3

Check thecylinder exhaust port.

If

necessary,

remove the carbondeposits from the port using

a woodenstick.Also clean thesmall hole nextto

theexhaust port.Thisholeactsas a compression

relief to lessen theforcerequiredto start the

engine.

If

plugged, the recoilstarter will be hard

to pull(Figure2-4).

POSITS, ROTATE THE CRANKSHAFT TO

CLOSETHEEXHAUSTPORTWITHTHEPIS-

TON.THISWILLPREVENTLOOSECARBON

DEPOSITSFROMFALLINGINTOTHECYLIN-

DER.TAKECARENOTTOSCRATCHTHE

PISTON AND DO NOT USE

A

METAL TOOLTO

REMOVE THE DEPOSITS.

IMPORTANT:WHENREMOVINGCARBONDE-

\

Beforeinstallingthe mufflercheckfor cracksand

leaks. Inspect theinletand outlet for carbon

buildup. Remove excessivedepositswith a

scraping tool and soak the muffler in solvent to

remove wet oil deposits. Allow to air dry or dry

with compressedair.Remove the muffler heat

shieldand tap the muffler bodywith a plastic

hammer

to

loosen the carbondeposits. Blow all

11-2

IGNITION

TIMING

(MODEL

47P22

ONLY)

To check the timing

it

isnecessaryto remove the

aircleaner toview theflywheel. (See Disassembly

Instructions.)The flywheel has a group of three

raised marks on itsouter edge. The center mark

correspondsto BTDCandtheothersrepresent

thetoleranceof plusor minus2O.Connect onelead

ofthe timing testertotheengine frame (ground).

(A

timing testermustbeused. An Ohmmeter orconti-

nuitylight will not indicate the positionof thecon-

tact points.) Disconnect the wire at the ignition

switch under the fueltank and connectthe other

testerleadto this wire(Figure2-5).Turn theengine

crankshaftinitsnormalrotation,counter-clockwise

as viewed fromthe outputend. Thecontact points

should open, asindicatedbythetimingtester, when

the pointer on thecrankcasehousingpointsto the

Centerofthe

three

marks on theflywheelcasting.

If

thetiming iswrong theflywheelmustberemoved

andthe contact pointsre-gappedor replaced.

Models 47PD3, 47PE4 and 47PF5 usesolid state

ignition systems and have their timing fixed at

BTDC.

Figure2-4

Figure

2-5

IGNITION TIMING(DIAL INDICATOR)

The ignitiontiming may bemoreaccurately

checkedusinga dial indicator. Removethe spark

plugwire and sparkplugandinsertthedialindica-

tor into the spark plug hole. Rotatetheengine

crankshaftuntilthedialindicatorregistersthepis-

tonattopdeadcenterand“zero”thedial. Connect

one leadof atiming tester to the engineframe.

(A

timingtester must beused.An Ohmmeteror con-

tinuity lightwill notindicatethepositionofthe

con-

tactpoints.) Disconnectthe wire at the ignition

switch under the fuel tank and connectthe other

tester leadto thiswire (Figure 2-6). Slowlyrotate

the crankshaft clockwise, as viewed fromthe out-

putend,untilthe tester signalsthe contact points

are opening.

If

thetestersignals between1.76 mm

(.069

in) and 2.51 mm

(.099

in)of piston travel, as

read on the dial indicator, the engine is properly

timed. Ifthetiming iswrong theflywheel must be

removed andthe contact points re-gapped.

Figure2-6

CONTACT POINTSAND CONDENSER

MODEL47P22ONLY

The contact points and condenser dowear out

through use and their performance level is

affected by dust, moisture andcorrosion. Inspec-

tion of these componentsrequiresremovalof the

flywheel.

(See Disassembly Instructions.) With theflywheel

removed, inspect forwearofthecam follower

and burningor pitting of the contact points.The

surfaceof the contact pointsshouldhaveagrey,

frosted appearance

if

wearing normally.

If

the

contact points are cratered orhave surface

buildupthey should becleanedor replaced.The

contacts can be cleaned with an electrical

sol-

vent andcontact pointsandpaper. Ensure thatall

dust and dirt

is

removed after sanding. Cratering

of the points indicates the condenser may be

faulty.Verify the condition ofthe condenser

through tests with anignition analyzer.

If

an

analyzer isnot available the condenser must be

consideredfaulty and should

be

replaced.When

installing newor reconditioned contact points

ensure thatthewiring isroutedthroughthechannel

in the crankcase housing and under the ignition

coil.FAILURETOROUTETHEWIRESPROPERLY

WHEEL

AND

CAUSE

A

SHORT CIRCUIT. Adjust

thecontactpointsto

.35

mm(.014 in) air gap,using

a feeler gauge, with the cam follower onthe high

pointof thetimingcam (Figure

2-7).

Checkthetim-

ing using either method previously described. It

may be necessary to readjust the contact point

gaptoobtain thetiming specification.

MAY ALLOW THE WIRING TO CONTACT THE FLY-

Contact Point

Assembly

Condenser

I

Cam

Follower

Figure

2-7

IGNITION COIL

Whenever the flywheel is exposed the ignition

coilconditionand air gapshouldbechecked.

Inspectthe ignitioncoil

for

acrackedcasing, loose

laminations,damagedwires and overheating.The

ignition coil air gap is

.38-50

mm(.015-.020 in).

A

non-metallicflexible gauge suchasshownin the

SpecialTools Section should beused. Toadjust,

rotate the flywheel magnetsaway from the igni-

tion coiland loosenthe two ignition coil retaining

capscrews. Insert the gaugebetweenthe coil

laminationsandtheflywheel (Figure2-8).Tighten

the retaining capscrewsto hold the adjustment.

Figure

2-8

11-3

The ignition coilcontains two separate windings

inside the coil casing (Figure 2-9). Use an Ohm-

meterto check theresistancelevelsof each wind-

ing. Tocheck theprimary winding,disconnectthe

ignitionswitchwire andconnectthe positivelead

of theOhmmeterto the ignition coillead.Connect

thenegative leadtotheengineframe (ground).

The

primary winding resistance is ohms

(Rxl

scale). To check the secondary winding, disconnect

the high tension wire at the spark plug.Connect

the positiveleadof theOhmmetertothe highten-

sionwire.Connectthe negativeleadtotheengine

frame (ground).The secondary coil resistance

should be 5800-7940ohms

(Rxl

000

scale). The

ignition coil must be replaced

if

the resistance

levels areincorrect.

Ignition Switch Wire High Tension Wire

\

ohms

Primary

Coil

Secondary

Coil

(R

x

1000

scale)

5800-7940

ohms

Ground

Model

47P22

Figure 2-9

The ignition coilused on models 47PD3, 47PE4,

and 47PF5consists of the main coil,hightension

wire andignition killwire (See Figure2-1

0).

Testingof thecoilmaybecompletedwitha

Graham

Lee ignition tester model number31-SMXH.In-

structionsfor testing are includedwith the tester.

High Tension

Wi

Figure 2-1

0

GOVERNOR

The governor linkage is factory preset to regu-

latetheenginespeed at

3000

150 RPM.

Check theadjustment of the governor

if

the

engine is suspectedof improperspeed. To gain

access to the governor linkage removal of the

air cleaner is recommended. (See Disassembly

Instructions.) Beforeadjusting the governor,

inspect the control linkage forbent, broken and

worn parts. Loosen the governorarm clamping

bolt and use ascrewdriver to spreadthe gover-

nor arm clamp (Figure 2-11).

Figure 2-11

Adjust the governor by holding the governor

lever tothe rightwhile turning the governorshaft

to the right. Hold theadjustment and tighten the

clamp bolt(Figure 2-12).

Figure 2-1

2

Connect the return spring to the center hole in

the governor spring bracket.The centerhole

should govern the engine speed at the recom-

mended

3000

RPM.The top hole will raise the

engine speed 150

RPM

and the bottomhole will

lower the engine speed 150RPM. Engine speed

can beverified using a tachometersuch aslisted

in theSpecial Tools Section. (Seepage

1-6).

II

-4

GOVERNOR

OPERATION

(Referto Figure 2-13.) Asload on the enginein-

creasestheenginespeedwillstartto

decrease.As

theengineslows downthe centrifugalforceofthe

flyweights (1) will decrease. The governor return

spring(4)willcausethegovernorcollar(2)tomove

indirection(A).

The

governorarm(3)willalso move

indirection(A)causingthethrottleto

open

untilthe

centrifugal force

of

the flyweights are in balance

withthegovernor returnspring.As the loadonthe

enginedecreasesthe enginewill speed upcaus-

ingtheflyweightstomove outforcingthegovernor

collarindirection(B).

The

collarwillact againstthe

governor arm moving it indirection (B) and also

moving the throttle in direction

(B).

The engine

speedwill drop until onceagainthe flyweight and

returnspringare inbalance (Figure 2-13).

1

Figure2-1

3

Models 47PD3,47PE4 and 47PF5are equipped

with variable throttles.The linkageisdescribedin

(Figure 2-14).

A

mountingboss wasadded tothe

castingof the enginetoaccommodatethe throttle

linkage assembly. The boss does not exist on

model47PZ2enginesthereforethevariablethrot-

tle linkagewill not retrofit. Model47PF5 engines

willincludeaweldstud onthegovernorlinkagefor

ease of reassembly (See Figure 2-1

5).

Governor

Arm

Governor

Spring

Figure2-14

Figure2-1

5

FUEL

TANK

!

CAUTION:

Thegasolinein

thefueltankisexplosive.

Alwaysdrain or

fill

tankoutdoors,

awayfromfireandflame.

Do

not

smoke when fuel vapors are present.

Fortheengineandcarburetortofunction properly

the fuel supply mustbeclean. Stale,dirty and im-

properlymixedfuelwillcausestartingandrunning

difficulties.To assure a clean fuel supply the fuel

tank may be removedandflushed with fresh fuel.

(See Disassembly Instruction.)

A

non-replaceable

sinteredbronzefuelfilter is insetintothefuel tank

outlet.Insome cases,the filter can be cleanedby

backflushingwith solvent or byblowinglow pres-

sure compressed air through the fitting on the

bottomof thefuel tank. Commercial engines have

areplaceable inlinefuel filterlocatedbetween the

fueltank

andcarburetor.The

replacementfuelfilter

isToroPart Number56-6360(Figure2-16).Period-

icallyinspectthevent in thefueltankcap. Remove

anyforeignmaterialswhichmayplugthe

vent.The

gasket inside the capmay be removedto permit

further cleaningof the vent area.

Fuel

Cap

(molded intolank).

Fuel

Filter

Inline

FuelFilter

Part

No.

56-6360

Figure2-16

11-5

CARBURETOR

The non-adjustable carburetorhas a numberof

small orifices which control the flowof fuel and

air to obtain the proper combustable mixtures.

If

stale or dirty fuelentersthe carburetor, deposits

canformcausing adverse changestothis

cornbustable mixture.To clean the carburetor it

must first be removedanddisassembled.(See

DisassemblyInstructions.)Soak allmetal partsin

carburetor cleaner to remove deposits. THE

BOWL SEAL, FLOAT

AND

NEEDLEVALVE

TORCLEANER

OR

DAMAGEMAYRESULT.

Replace any damaged or questionable compo-

nents before reassembly (Figure2-1 7).

SHOULDNOTBECLEANEDWITHCARBURE-

PilotJet

Float Pivot Pin Needle Valve

Bowl

Seal

Engine Model47P22

Bowl

Carburetor

Standard Main Jet

#80

Toro

Part

No.

81-1040

Optional High-altitude

Main

Jet

#77.5

Tor0

Part

No.

81 -1

050

Figure2-17

Carburetors used onmodels 47PD3,47PE4 and

47PF5 (seeFigure2-18), use a metalchokeshaft

with a plastic bushing,an atmospheric venttube

and analcohol resistantfloat.The floats used on

47PZ2 carburetorsshould bereplacedwitha 81-

0970

float.

This

float is black

and

isequippedwitha

metalhinge.Correctfloatheightis17.5 mm(11/16

in). The standard mainjet is a number 76.3 (part

number 81-1940). There is a lean, number 72.5,

mainjet (part number81-2340)availablefor high

altitudeconditions.

The standard mainjet on 47PZ2 carburetorsisa

number

80

(partnumber81-1 040) withahigh alti-

tude(77.5 jet part number 81-1

050)

option.

Models47PD3,47PE4and47PF5arealso

equipped with aheat deflector and insulator as

showninFigure2-18).Model 47PZ2wasbuiltwith-

out insulatorsor heat deflectors.This model may

be fitted witha heat shield kitnumber81 -221

0

to

prevent hot restart problems.

47PD3,47PE4,47PF5

Engine Model

Carburetor

Standard MainJet

Toro

Part

No.

81-1940

High Altitude Main Jet

Toro

Part

No.

81-2340

Figure

2-

18

STORAGE

Drainthe gasoline

from

the

fuel

tank.

Afterthegas-

olineisdrained,startthe engine andlet

it

rununtil

all fuelisexpended. Movethe recoilstartera num-

berof timestoassure

all

fuelisexpended.

All

gas-

olinemust beremovedtoprevent gumlikevarnish

deposits from formingin the fuelsystem. Pullthe

hightensionwire

off

thespark plug. Cleanthearea

around the plug toprevent dirt from entering the

cylinder when the plug isremoved. Removethe

plug from the cylinder head and pour two tea-

spoons of two-cycle oil into thespark plug hole.

Pull the recoil starter handle slowly to distribute

the oilinsideof thecylinder.Install thespark plug

andtightentothe recommendedtorque.DO NOT

INSTALLTHE HIGH TENSIONWIRE

ON

THE

SPARK PLUG.Pullthe recoilstarter slowly untila

positiveresistanceisfelt. This willensurethecom-

bustionchamberissealedby

the

pistontoprevent

any damagewhich might be causedby the envi-

ronment. Cleanthedirt andchafffromthe outside

of

thecylinder,cylinderheadfinsandblower hous-

ing. Theair cleaner assemblyshould beserviced

as mentioned earlier in thissection. For lawn

mower storageinstructionsrefertothe Operators

Manual.

111.

TROUBLESHOOTING AND TEST PROCEDURES

Generally all gasoline-powered products require

some form of service

or

repair during their life-

time. The amount of time and expense involved

in repairing a productcan be greatly impacted

by the amount of time required toinitially deter-

mine the cause of the difficulty. Therefore, it is

recommendedto make thesepreliminarychecks

beforeproceeding tosecondarytroubleshooting

procedures.

PRELIMINARY TROUBLESHOOTING

Ignition System

1. Check the ignition switch and wiring

2.

Ensure the sparkplug isthe correct type

3.

Check thespark plug for the correct gap,

damagedandexcessively carboned

or

burnt

electrodes

4.

Check the spark intensity.

1.

Check the choke position and controls

2.

Check the throttle (if

so

equipped)andgover-

3. Ensurethefuel is fresh, clean and of the

4.

Check the fuel filter.

1. Check for housing and element damage

2.

Check for dirty element

3.

Check for toomuch

or

toolittleoilin the

Fuel System

nor mechanism

proper gas-oil mixture

Air Cleaner

element

Compression

page

111-2)

1.

Check the cylinder compression. (Referto

Crankcase

1. Ensure the crankcase is sealed. (Refer to

page

I11-3)

Spark Intensity

The ignition system canbechecked

for

spark in-

tensity usingthesparktester listed in theSpecial

ToolsSection of this manual (Figure

3-1).

Figure

3-1

1. Pull

off

thespark plugconnector andremove

the sparkplug.

2.

Inspect the spark plug for wear, carbon

deposits and damage.(SeeMaintenance

Section) Replace theplug

if

damaged, burnt,

or

fouled.

3. Check for the correct spark plug gap and

adjust,

if

necessary, to

.8

mm

(.032

in)by

bending the outer electrode. Do not pry

against the inner electrode

or

the insulator

may bedamaged.

4.

Attach the spark tester as shown and verify

the tester gapis set at

4.2

mm (.166 in).

5.

Pull the starter and observeforspark. THE

SPARKMAYBEDIFFICULTTOSEE

IN

WELL LIGHTEDAREAS.

A

CAUTION:

Do

nottestfor

sparkwheregasolinehas

been spilledor inflammable vapors may

exist.

A

fire could result.

6.

If

no spark is viewed, refer tothe trouble-

shootingchart. (Page

111-4)

ENGINE

BRAKE

AND IGNITION SWITCH

As a safetymeasurethe engine is designed to

stop within three seconds after the control bar is

released. Releaseof the control bar grounds the

magneto through the ignition switch to prevent

ignitionandallows the spring activated brake

pad to engage the flywheel.

The engine brake andignitionswitch are con-

trolled by one common control cable activated

bythe control bar on the mower handle. To start

the engine the controlbar is raised and held

againstthe handle. This pulls the brake pad

away from the flywheel and simultaneously de-

pressesthe plunger on theignition switch.

THE ENGiNEBRAKESYSTEMSHOULD

BE

TION

OR

INJURY MAY RESULT.To troubleshoot

the engine brakeand ignition switch:

1. Removethe fuel tank for ease of inspection.

(See DisassemblyInstructions page IV-1).

2.

Ensure that the brakespring forcesthe brake

pad against the flywheel when the control

bar is inthe ‘STOP”positionandthat thepad

clearstheflywheel when the control bar is in

the ‘START” position.

MAINTAINED

IN

PROPERWORKINGCONDI-

111-1

3.

4.

Disconnect

the

wire leadingto the ignition

switch and connect acontinuity testertothe

switchwireandengine frame(Figure

3-2)

with

the control barin the

“STOP”

position there

should becontinuity through theswitch.With

the controlbar in the“START” position,there

should be

NO

continuitythrough the switch.

Adjust thecable

or

replacetheswitch which-

ever is necessary to assure that the switch

and brake assemblyarefunctioningproperly.

Figure

3-2

BBC

APPLICATIONS

EnginesequippedwithaBladeBrake Clutch(BBC)

mechanism, Models 47PD3,47PE4 and 47PF5

with serial numbers that start with

2.....,

are fitted

with an ignition killswitch that ismounted on the

throttle linkage. (SeeFigure

3-3.)

The ignitionwire

isconnectedto the killswitch terminal.

When the lift bailisreleasedthe BBC mechanism

willstop the blade andleavethe enginerunning.To

stoptheenginethe throttlecontrolisbroughttothe

stop positionwhich will bring thegovernor spring

lever in contact with the killswitch grounding the

ignitionand stoppingthe engine.

I

I

Spring

Lever

Kill

Switch

Bracket

Figure

3-3

FUEL TANK

If

the enginestalls or will notstartthere may bea

fuelrestriction orblockage.The fuelcap con-

tains aventwhich,

if

plugged, will prevent fuel

from entering the carburetor.

1.

2.

3.

Remove the fuel cap and inspect the vent.

Clean

if

necessary.

Visually inspect the bottom of the fuel tank

for dirt or other contaminants.

If

dirt, water

or

other contaminantsare

present the tank shouldbe flushed with a

smallamount of freshfuel. Thisismosteasily

accomplished whenthefueltank isremoved.

(See DisassemblyInstructionspage

IV-1).

a

CAUTION: The gasoline in the

fueltank

is

explosive.Always

drain

or

fill

tank outdoors, away from fire

andflame.

Do

notsmokewhenfuel

vapors are present.

4. Toensurethe fuel filter isnotplugged, remove

the fuel lines and check the fuel filterfor ease

offuelflow.Insomeinstances,thefiltermaybe

cleaned by back-flushingwith solvent or low

pressure compressed air.

NOTE:

The bronzesintered filter in the fueltank is

not replaceable,howeverthe remote mountedin-

line fuel filter found oncommercial engines maybe

replaced using Toro Part Number 56-6360. See

Figure

2-1

6.

TESTING COMPRESSION

A

compression test of theenginecanprovide

vital information on thegeneral condition of the

workingpartswithinthe engine. This test will

indicate a worncylinder, piston,

or

rings, and

generally determinewhether theengineisre-

pairable

or

if

it should bereplaced.

1.

Remove the spark plug and install a com-

pressiongaugeintothesparkplughole

(Figure3-4).

Figure3-4

111-2

2.

Pull the starter rope rapidlyseveral times

until the compression reading on the gauge

stabilizes.

3.

If

thecompression readingisbelow

6.5

kps-cm2

(92

psi),

cylinder,

pistonorringdamageshould

besuspected.

A

new engine should have

8.4

kps-cm2

(1

20

psi)

1

0.5

kps-cm2

(1

50

psi).

An engine withlow compression must bedis-

assembled and inspected for damage of the

internal components. (See Disassembly Instruc-

tions.)Check all components to the specifica-

tions listed in theServiceDataSection of this

manual. Replace all parts which fall outside of

these specifications. Theengine contains a cast

iron cylinder liner, which is not replaceable.

Special factory processesare required to install

this liner.

CRANKCASE

The engine relies on a tightly sealed crankcase

in order tofunction properly. The downward

movementof the piston causes the crankcaseto

be pressurized. This pressure is required to

expell the exhaustgasesfrom the combustion

chamber and to supply a freshfuel mixture for

the compression stroke. The upward movement

of the piston on the compression stroke creates

a vacuum to draw fresh fuel into the crankcase.

In both instances a tightly sealed crankcase is

the keyto efficient performance. The mostlikely

places of leakageare at the governor shaft seal,

crankshaft seals and at the seam of the crank-

case halves. The simplest means

of

detecting a

crankcase leak isto check for wet,oily deposits

around the seal areas.

111-3

ENGINE TROUBLESHOOTING CHART

The possiblecauses have beenarrangedwith

The following troubleshooting chart lists the the most easily inspected items to be checked

symptoms,causes and remedies of common listed first. Utilizing the chart inthis manner

Will

engine malfunctions. Once the symptom lessen the amount

Of

time required torepair the

beendetermined, systematically eliminate the engineandlimitthepossibility

Of

incorrectly

possiblecauses until the actualcause is found. diagnosing

the

cause of

the

difficulty.

SYMPTOMS

Installcorrect spark plug, page

1-5

Reset air gap .8mm (.032")

Replace sparkplug

Replace sparkplug

Empty carb

&

tank refillw/fresh

Empty carb&tank refillw/fresh mi)

Clean or replace cap

__-

Check linesfor restriction

Clean

or

replacefilter

Squeeze excessoil

from

filter

Reseal crankcase andreplaceseals

Readjust See page

11-4

__-

Readjust refer

to

page 111-2

Replaceignitionswitch

Cleanall exhaust ports

Clean

or

replace See page

11-1

Check linkageandcable adjustment

Check linkageandgovernor adj.

Replaceneedle

Replace cracked bowlfloat

Repairor replacestarter

Repairor replace

Replaceflywheel

____-._-

_-

Replaceignition coil

d replaceworn parts

Diagnoseandreplacebroken parts

111-4

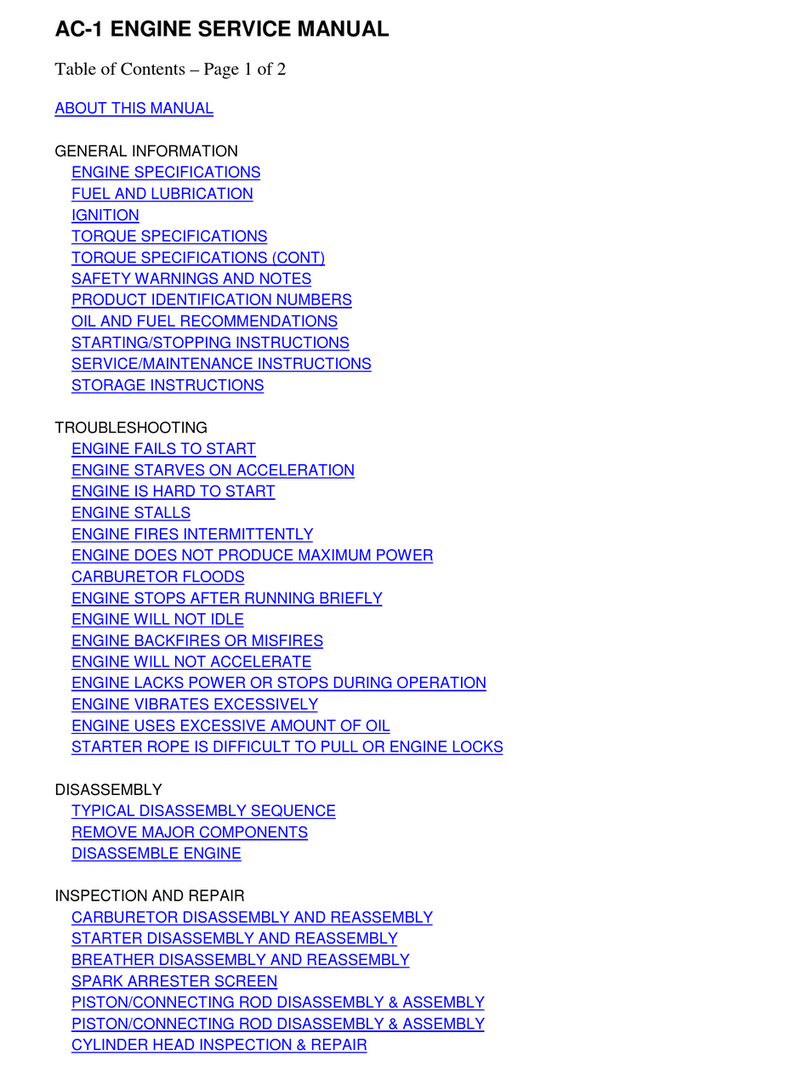

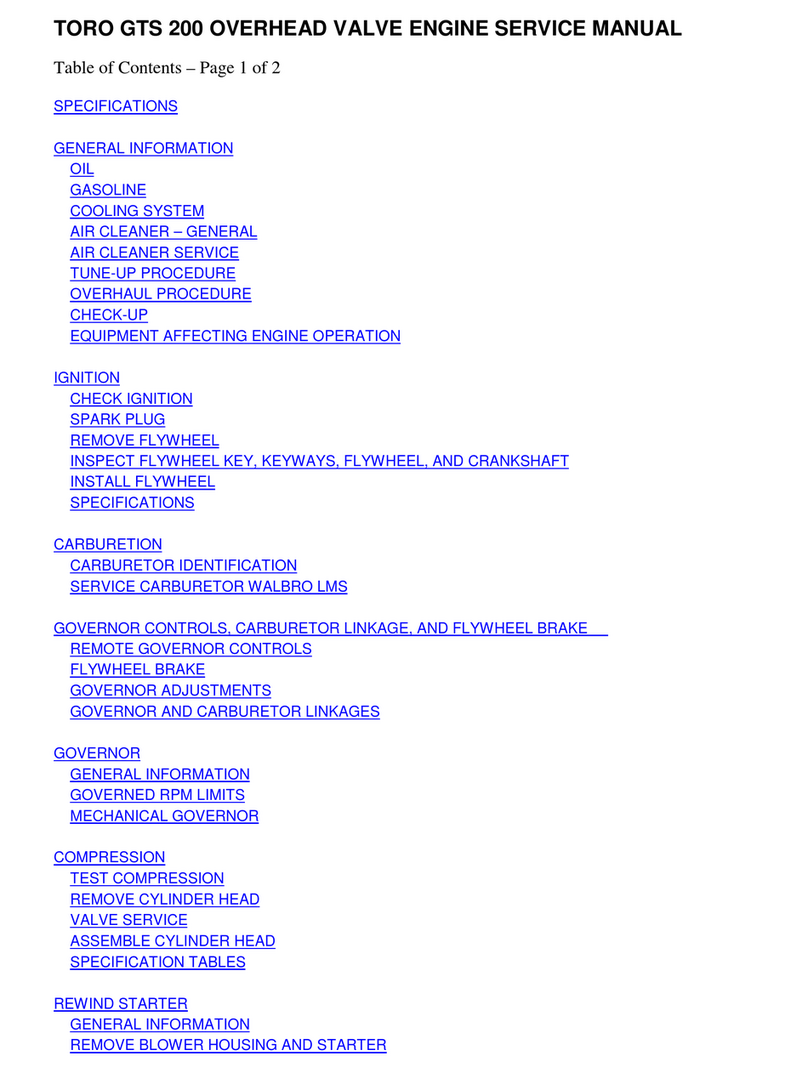

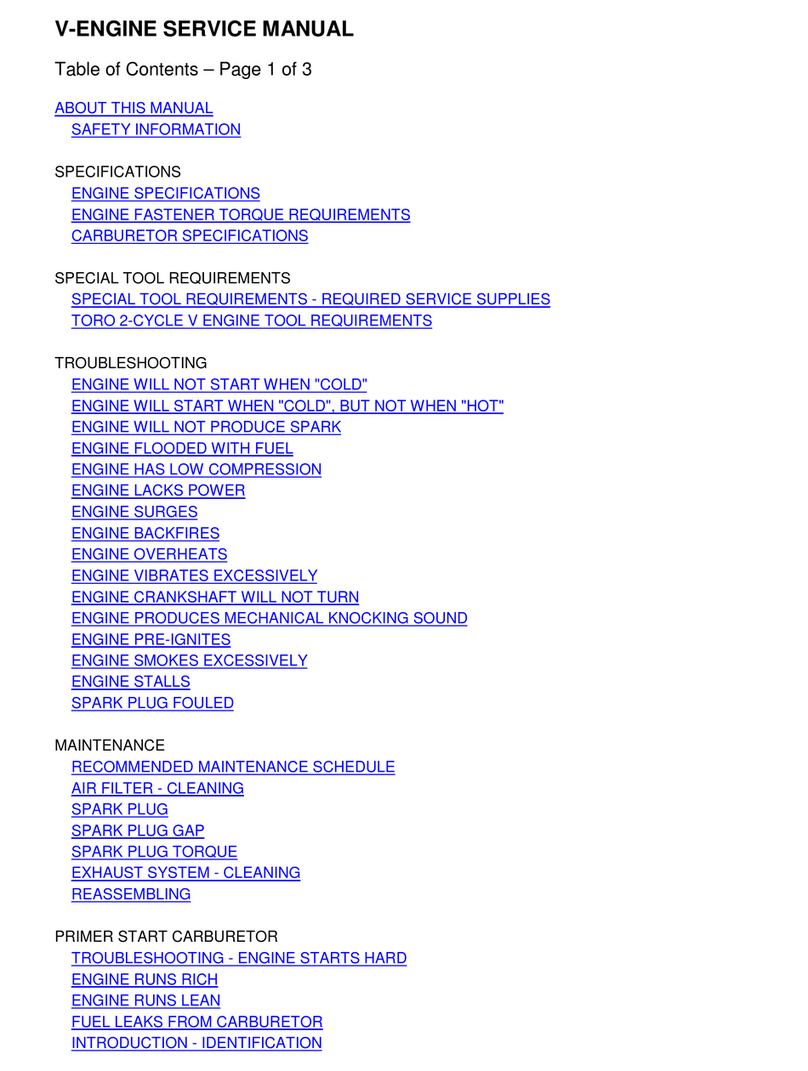

This manual suits for next models

4

Table of contents

Other Toro Engine manuals

Toro

Toro AC-1 User manual

Toro

Toro Power Plus P216V User manual

Toro

Toro 138-2139 User manual

Toro

Toro GTS 200 User manual

Toro

Toro 139-5637 User manual

Toro

Toro Z Master 500 Series User manual

Toro

Toro V User manual

Toro

Toro LC175FDS User manual

Toro

Toro Prior LC1P65FA User manual

Toro

Toro 139-5636 User manual

Popular Engine manuals by other brands

Lombardini

Lombardini 25 LD 425-2 Use and maintenance

Lenze

Lenze g500-S Mounting and switch-on instructions

Graco

Graco SaniForce A Series Instructions - parts

Siemens

Siemens SIMOTICS DC 1GH6 operating instructions

Ingersoll-Rand

Ingersoll-Rand 4IRQ2N Operation & maintenance manual

Bukh

Bukh DV36/48 Workshop manual