Toro 139-5637 User manual

FormNo.3437-588RevB

EngineConversionKit

SubaruPoweredWalk-BehindGreensmaster®Flex™1800,2100,

1820,or2120Mower

ModelNo.139-5637

InstallationInstructions

Introduction

Thisengineconversionkitisonlyformachineswith

followingmodelandserialnumbers:

ModelNumberSerialNumber

04040312000001through315999999

04041312000001through315999999

04044316000001through999999999

04045316000001through999999999

LightKit,Model04064(Flex1800/2100/1820/2120

tractionunits)iscompatiblewiththiskit.

Note:Olderlightkitsarenotcompatiblewiththiskit.

Important:Theseinstallationinstructions

containengineoperationandmaintenance

informationthatsupersedestheengineoperation

andmaintenanceproceduresinyourmachine

Operator’sManual.

Beforeoperatingormaintainingthemachineor

engine,alwaysrefertotheoperatingandsafety

instructionsinyourOperator’sManual.

Savetheseinstructions.

Important:Theenginewarrantyisprovided

bytheenginemanufacturer.Pleaserefertothe

enginemanufacturer'swarrantyandemissions

systemwarrantyincludedintheliteraturepacket.

Thatwarrantyappliesonlytotheengine.Itdoes

notexpandorotherwisealteranyexpressor

impliedwarrantytermsorwarrantyperiodthat

mayapplytotheproductintowhichtheengine

isinstalled.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

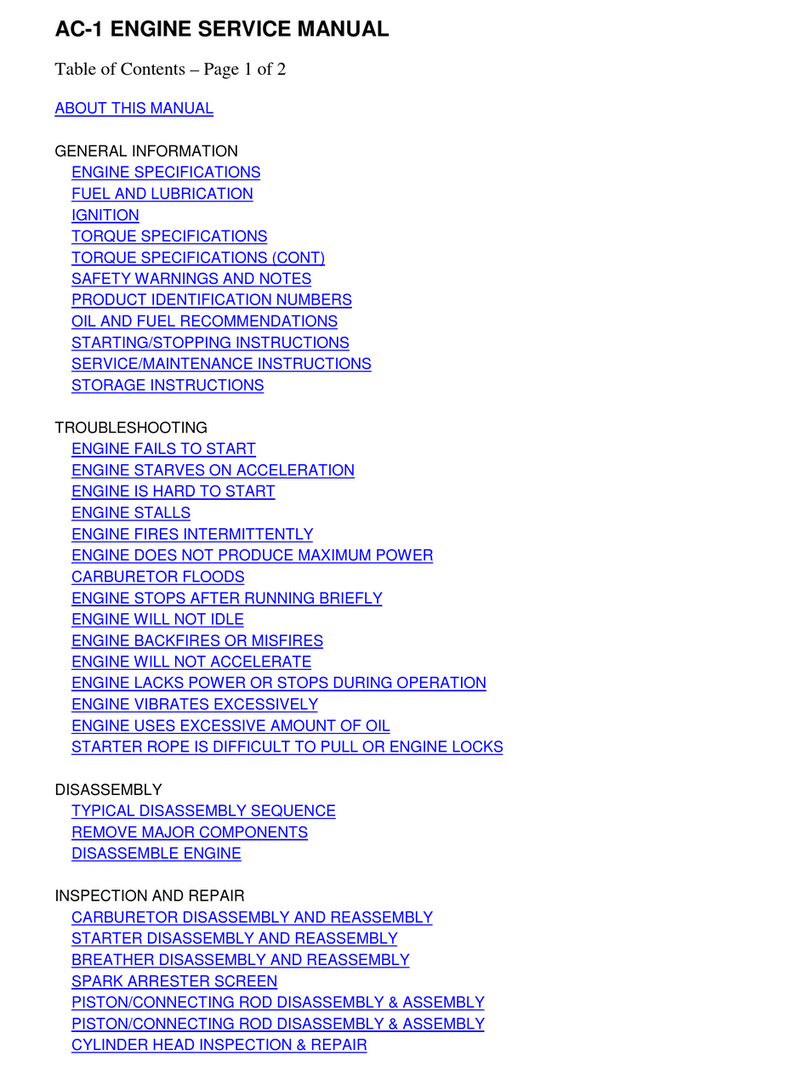

Contents

Introduction...............................................................1

Safety.......................................................................2

SafetyandInstructionalDecals..........................2

Installation................................................................3

1PreparingtheMachine.....................................3

2RemovingtheExistingEngine.........................3

3InstallingtheNewEngine.................................3

4LubricatingandAdjustingtheMachine.............5

ProductOverview.....................................................5

Controls.............................................................5

Operation..................................................................6

FuelSpecications.............................................6

UsingStabilizer/Conditioner...............................6

FillingtheFuelTank............................................6

OpeningandClosingtheFuel-Shutoff

Valve...............................................................7

Maintenance.............................................................8

RecommendedMaintenanceSchedule(s).............8

PreparingtheMachineforMaintenance..............8

ServicingtheEngineOil......................................9

ServicingtheAirCleaner...................................11

ServicingtheSparkPlug...................................12

©2020—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved*3437-588*B

Safety

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

decal130-8322

130-8322

1.Useonlyfuelwithan

alcoholcontentbyvolume

under10%.

3.Donotusefuelwithan

alcoholcontentbyvolume

greaterthan10%.

2.ReadtheOperator's

Manualformore

informationonfuel.

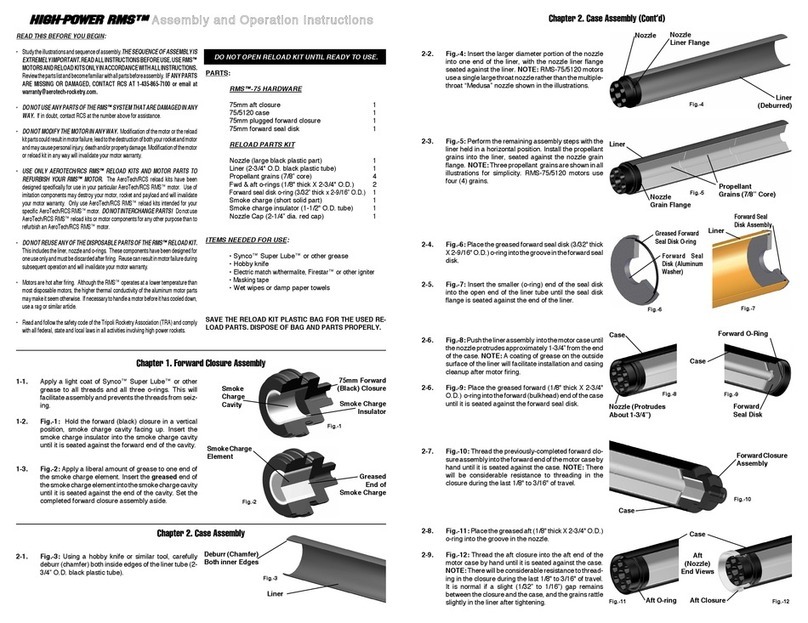

decal133-8062

133-8062

decal138-2138

138-2138

1.Poisonousfumesor

toxicgases,asphyxiation

hazard—donotrunthe

engineinanenclosed

space.

4.Warning—disconnectthe

sparkplugwirebefore

performingmaintenance.

2.Explosionhazard—shut

offtheenginebefore

addingfuel;nore,open

ames,orsmokingwhen

addingfuel.

5.Hotsurfacehazard—do

nottouchthehotsurface.

3.Warning—shutoffthe

engineandclosethe

fuelshutoffvalvebefore

leavingthemachine.

6.Attention—readthe

Operator’sManualfor

informationaboutlling

thefueltank.

2

Installation

Note:Ifthemachineisequippedwithan

incandescentlightkit,youmayneedtoorderanew

kit;contactyourauthorizedT orodistributorformore

information.

1

PreparingtheMachine

NoPartsRequired

Procedure

Preparethemachine;refertoPreparingtheMachine

forMaintenance(page8).

2

RemovingtheExisting

Engine

NoPartsRequired

Procedure

Important:Foradditionalengine-removal

instructionsandillustrations,refertothe

GreensmasterFlex1800/1820/2100/2120Service

Manualonwww.Toro.com.

Important:Retainallremovedpartsforreuse

unlessotherwisenoted.

1.Removethethrottlecablefromtheengine.

2.Disconnecttheelectricalconnectionsfromthe

engineandthehandle.

3.Removeengine-baseassembly(withtheengine

attached)frommachine.

4.Removetheenginefromtheenginebase.

Note:Thecapscrews,washers,andnutscan

bediscarded.

5.Removetheenginecouplerandthesquarekey

fromtheengineoutputshaft.

6.Removetheexistingcouplerguardfromthe

transmissioncover(Figure1).

g314125

Figure1

1.Couplerguard2.Bolt

3

InstallingtheNewEngine

Partsneededforthisprocedure:

1Engine

4Bolt

4Nut

4Spacer

4Washer

1Couplerguard

1Wireharness

Procedure

Important:Foradditionalengine-installation

instructionsandillustrations,refertothe

GreensmasterFlex1800/1820/2100/2120Service

Manualonwww.Toro.com.

1.Use4bolts,4washers,4spacers,and4nutsto

securetheenginetotheenginebase(Figure2).

3

g314123

Figure2

1.Nut4.Enginebase

2.Washer5.Bolt

3.Spacer

2.Performthefollowingstepstoinstallthecoupler

totheengine-outputshaft:

A.Applyanti-seizelubricanttothetopsurface

ofthesquarekeyandpositionthekeyin

theoutput-shaftkeyway.

B.Slidethecouplerontotheoutputshaftuntil

itcontactstheshaftshoulder.

C.Securethecouplertotheoutputshaftwith

the2previously-removedsetscrews.

D.Torquethesetscrewsto7N∙m(65in-lb).

3.Performthefollowingstepstoinstalltheengine

baseassemblytothemachine:

A.Ensurethatthecouplersleeveisplacedon

thetransmission-input-shaftcoupler.

B.Positiontheengine-baseassemblytothe

machine.

C.Carefullyslidetheengine-baseassembly

towardthetransmission,allowingthe

enginecouplertobeinsertedintothe

transmissioncouplersleeve.

Note:Youmayhavetoturntheengine

outputshafttoaligntheenginecouplerwith

thecouplersleeve.

D.Supporttheengine-baseassemblytoallow

forfastenerinstallation.

E.Installandnger-tightenthe2capscrews,

hardenedwashers,andangenutsthat

securetheengine-basereartotherear

frame.

F.Aligntheframeholewiththefrontmounting

bossoftheenginebase.

G.Installandngertightentheangehead

screwandhardenedwasherthatsecures

theenginebasetotheframe.

H.Positiontheengine-basefronttoalignthe

engineandtransmissioncouplers.Fully

tightentheange-headscrewstosecure

theengine-basefront.

I.Fullytightenfastenersatrearofengine

base.

4.Connectthewireharnesstotheappropriate

locationsontheengineandthehandle:

•Engineconnections:

–Connectthegroundwire(terminalring)

toenginewithanexistingnutunderthe

fueltank(Figure3).

g314124

Figure3

1.Groundwire2.Nut

–Refertothefollowingtableforthe

appropriatemachineandenginewire

harnessconnections:

Machine-wire-harness

connector

Engine-wire-harness

connector

BlackRed

GreyBlack

GreenBlue

•Handleconnections:Connectthewire

harnesstotheengineswitch,hourmeter,

interlockmodule,andthelightkitconnections

(ifequipped).

4

5.Connectthethrottlecabletoengine.

6.Usethepreviously-removedboltstosecurethe

newcouplerguardtothetransmissioncover.

4

LubricatingandAdjusting

theMachine

NoPartsRequired

Procedure

1.Lubricatethemachineaccordingtothe

instructionsinyourOperator’sManual.

2.Filltheenginecrankcasewithoil;referto

ServicingtheEngineOil(page9).

3.Adjusttheenginespeedtothefollowing

specications:

Highidle(noload)3450±100rpm

Lowidle(noload)1900±100rpm

ProductOverview

g265059

Figure4

1.Chokelever3.Recoilstarterhandle

2.Fuel-shutoffvalve

Controls

ChokeControl

Thechokecontrolislocatedonthesideoftheengine

(Figure4);youuseittohelpstartacoldengine

Note:Donotstartorrunawarmenginewiththe

chokeintheCLOSEDposition.

•Movethechokeleverallthewaytotheleft

(awayfromstarterhandle)tosetthechoketothe

CLOSEDposition.

•Movethechokeleverallthewaytotheright

(towardstarterhandle)tosetthechoketothe

OPENposition.

Fuel-ShutoffValve

Thefuel-shutoffvalveislocatedonthesideofthe

enginebelowthechokecontrol(Figure4).

Note:Closethefuel-shutoffvalvewhenthemachine

isnotusedforafewdays,duringtransporttoand

fromthejobsite,orwhenthemachineisparked

insideabuilding;refertoOpeningandClosingthe

Fuel-ShutoffValve(page7).

5

Operation

FuelSpecications

Fueltankcapacity:2.0L(0.59USgallons)

Recommendedfuel:Unleadedgasolinewithan

octaneratingof87orhigher((R+M)/2ratingmethod)

Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.

•Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessafuelstabilizer

isused.

•Donotaddoiltogasoline.

•Forbestresults,useonlyclean,fresh(lessthan

30daysold)fuel.

•Usingunapprovedgasolinemaycause

performanceproblemsand/orenginedamage,

whichmaynotbecoveredunderthewarranty

Using

Stabilizer/Conditioner

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountoffuelstabilizer/conditioner

tothegasoline.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.Tominimizethe

chanceofvarnishdepositsinthefuelsystem,usefuel

stabilizeratalltimes.

FillingtheFuelTank

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanyfuel

thatspills.

•Neverllthefueltankinsideanenclosed

trailer.

•Donotllthefueltankcompletelyfull.

Addfueltothefueltankuntilthelevelis6

to13mm(1/4to1/2inch)belowthebottom

ofthellerneck.Thisemptyspaceinthe

tankallowsfueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinanapprovedcontainerand

keepitoutofthereachofchildren.Never

buymorethana30-daysupplyoffuel.

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleased,causingaspark

whichcanignitethefuelvapors.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruck-bedlinersmay

insulatethecontainerandslowthelossof

anystaticcharge.

•Whenpractical,removeequipmentfrom

thetruckortrailerandfuelitonthe

ground.Ifthisisnotpossible,thenfuel

suchequipmentwithaportablecontainer

ratherthanfromafuel-dispensernozzle.

•Ifyoumustuseafuel-dispensernozzle,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

6

WARNING

Fuelisharmfulorfatalifswallowed.

Long-termexposuretovaporscancause

seriousinjuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepyourfaceawayfromthenozzleand

fueltankorconditionerbottleopening.

•Avoidcontactwithskin;washoffspills

withsoapandwater.

1.Parkthemachineonalevelsurfaceandshut

offtheengine.

2.Allowtheenginetocool.

3.Cleanaroundthefuel-tankcapandremoveit

(Figure5).

g265976

Figure5

1.Fuel-tankcap

4.Fillthetankwithfueluntilthelevelisjustinside

themeshlterbasket.

Donotllintothellerneckofthetank.

Important:Donotllthetankmoreabove

thellermeshbecausethefuelneedsroom

toexpand.

5.Installthefuel-tankcapsecurely.

6.Wipeupanyspilledfuel.

OpeningandClosingthe

Fuel-ShutoffValve

Controlfuelowtotheenginewiththefuel-shutoff

valveasfollows:

•T oopenthefuelvalve,turnthefuel-shutoffvalve

handletowardtherecoilstarterhandle(Figure6).

•T oshutthefuelvalve,turnthefuel-shutoffvalve

handleawayfromtherecoilstarterhandle(Figure

6).

g265993

Figure6

1.Turnthefuelvalveleverto

theONposition

2.FuelvalveleverintheOFF

position

7

Maintenance

Important:Refertoyourengineowner’smanual

foradditionalmaintenanceprocedures.

Important:Theenginegearbox(Figure7)does

notrequiremaintenance,asitislledwitha

high-performance,long-lifesyntheticsemi-uid

grease.

g312416

Figure7

1.Gearbox

RecommendedMaintenanceSchedule(s)

MaintenanceService

IntervalMaintenanceProcedure

Aftertherst20hours•Changetheengineoil.

Beforeeachuseordaily•Checktheengine-oillevel.

•Inspecttheair-lterelements.

Every50hours•Cleantheair-lterelements.

Every100hours•Changetheengineoil.

•Inspectandadjustthesparkplug;replaceitifnecessary.

Every300hours•Replacethepaperlterelement(Morefrequentlyindustyoperatingconditions).

•Replacethesparkplug.

PreparingtheMachinefor

Maintenance

WARNING

Whileyouaremaintainingoradjustingthe

machine,someonecouldstarttheengine.

Accidentallystartingtheenginecould

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignition,engage

parkingbrake,andpullthewire(s)offthe

sparkplug(s)beforeyoudoanymaintenance.

Alsopushthewire(s)asidesoitdoesnot

accidentallycontactthesparkplug(s).

Performthefollowingbeforeservicing,cleaning,or

makinganyadjustmentstothemachine.

1.Parkthemachineonalevelsurface.

2.Shutofftheengineandremovethekeyfromthe

machine(ifequipped).

3.Engagetheparkingbrake.

4.Waitforallmovingpartstostopandallowthe

enginetocoolbeforeservicingorstoring.

5.Disconnectthespark-plugwire(Figure8).

8

g265998

Figure8

1.Spark-plugwire

ServicingtheEngineOil

Fillthecrankcasewithapproximately0.56L(19

oz)oftheproperviscosityoilbeforestarting.The

engineusesahigh-qualityoilthathastheAmerican

PetroleumInstitute(API)serviceclassicationofSJor

higher.Selecttheproperoilviscosity(weight)based

ontheambienttemperature.Figure9illustratesthe

temperature/viscosityrecommendations.

g013375

Figure9

Note:Multi-gradeoils(5W-20,10W-30and10W-40)

increaseoilconsumption.Checktheengine-oillevel

morefrequentlywhenyouusetheseoils.

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Theidealtimetochecktheengine-oilleveliswhenthe

engineiscoolorbeforeyouhavestartedtheengine

fortheday.Ifyouhavealreadyrantheengine,allow

theoiltodrainbackdowntothesumpforatleast10

minutesbeforeyouchecktheengine-oillevel.

9

1.Shutofftheengineandwaitforallmoving

partstostop;refertoPreparingtheMachinefor

Maintenance(page8).

2.Positionthemachinesothattheengineislevel,

andcleantheareaaroundtheoil-lltube(Figure

10).

g266053

Figure10

1.Dipstick2.Drainplugandwasher

3.Removethedipstickbyrotatingit

counterclockwise.

4.Removethedipstickandwipetheendclean.

5.Insertthedipstickfullyintotheoil-lltube,but

donotthreaditin.

6.Removethedipstickandchecktheengine-oil

level(Figure11).

g019686

Figure11

1.Fillertube4.Lowerlimit

2.Dipstick5.Drainplug

3.Upperlimit

7.Iftheengine-oillevelisincorrect,addordrainoil

tocorrectthelevel;refertoChangingtheEngine

Oil(page10).

ChangingtheEngineOil

ServiceInterval:Aftertherst20hours

Every100hours

WARNING

Oilmaybehotaftertheenginehasbeenrun,

andcontactwithhotoilcancausesevere

personalinjury.

Avoidcontactingthehotengineoilwhenyou

drainit.

1.Shutofftheengineandwaitforallmoving

partstostop;refertoPreparingtheMachinefor

Maintenance(page8).

2.Raisetheengineoffthegroundandplaceapan

underthedrainplugtocatchtheoil.

3.Removethedrainplug(Figure10).

4.Whentheoilhasdrainedcompletely,lowerthe

enginetotheground,replacethedrainplugand

washer,andtorquetheplugto18N⋅m(13ft-lb).

Note:Disposeoftheusedoilatacertied

recyclingcenter.

5.Removethedipstick,andslowlypouroilintothe

oil-llholeuntiltheoilisatthecorrectlevel.

10

6.Ensurethattheoilisatthecorrectlevelonthe

dipstick;refertoCheckingtheEngine-OilLevel

(page9).

7.Replaceandsecurethedipstick.

8.Wipeupanyspilledoil.

9.Connectthewiretothesparkplug.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily

Every50hours

Every300hours/Yearly(whichevercomesrst)

Important:Donotoperatetheenginewithout

theairlterassembly;extremeenginedamage

willoccur.

1.Shutofftheengineandwaitforallmoving

partstostop;refertoPreparingtheMachinefor

Maintenance(page8).

2.Removethewingnutsecuringtheair-cleaner

cover(Figure12).

3.Removetheair-cleanercover.

Note:Ensurethatnodirtordebrisfromthe

air-cleanercoverfallintothebase.

4.Removethefoamandpaperelementsfromthe

base.

5.Removethefoamelementfromthepaper

element.

6.Inspectthefoamandpaperelements;replace

themiftheyaredamagedorexcessivelydirty.

g265999

Figure12

1.Wingnut4.Paperlterelement

2.Air-cleanercover5.Gasketandairduct

3.Foamelement

11

7.Cleanthepaperelementbytappingitgentlyto

removethedirt.

Note:Donottrytobrushdirtoffthepaper

element;brushingforcesthedirtintothebers.

Replacetheelementiftappingitfailstoremove

thedirt.

8.Cleanthefoamelementinwarm,soapywater

orinanonammablesolvent.

Note:Donotusegasolinetocleanthefoam

elementbecauseitcouldcreateariskofreor

explosion.

9.Rinseanddrythefoamelementthoroughly.

10.Wipedirtfromthebaseandthecoverwitha

moistrag.

Note:Ensurethatdirtanddebrisdonotenter

theairductleadingtothecarburetor.

11.Installtheair-cleanerelementsandensurethat

theyareproperlypositioned.Installthelower

wingnut.

12.Installthecoverandinstalltheupperwingnut

tosecureit.

ServicingtheSparkPlug

ServiceInterval:Every100hours

Every300hours

UseanNGKBPR6ESsparkplugorequivalent.

1.Shutofftheengineandwaitforallmoving

partstostop;refertoPreparingtheMachinefor

Maintenance(page8).

2.Cleanaroundthesparkplug.

3.Removethesparkplugfromthecylinderhead.

Important:Replaceacracked,fouled,or

dirtysparkplug.Donotsandblast,scrape,

orcleantheelectrodesbecauseengine

damagecouldresultfromgritenteringthe

cylinder.

4.Setthegapontheplugto0.7to0.8mm(0.028

to0.031inch)

g000533

Figure13

1.Center-electrodeinsulator3.Airgap

2.Sideelectrode

5.Carefullyinstallthesparkplugbyhand(toavoid

crossthreading)untilitishandtight.

6.Tightenthesparkpluganadditional1/2turnif

itisnew;otherwise,tightenitanadditional1/8

to1/4turn.

Important:Aloosesparkplugcanbecome

veryhotandcandamagetheengine;

overtighteningasparkplugmaydamagethe

threadsinthecylinderhead.

7.Connectthewiretothesparkplug.

12

Notes:

Notes:

Notes:

CaliforniaProposition65WarningInformation

Whatisthiswarning?

Youmayseeaproductforsalethathasawarninglabellikethefollowing:

WARNING:CancerandReproductiveHarm—www.p65Warnings.ca.gov.

WhatisProp65?

Prop65appliestoanycompanyoperatinginCalifornia,sellingproductsinCalifornia,ormanufacturingproductsthatmaybesoldinorbroughtinto

California.ItmandatesthattheGovernorofCaliforniamaintainandpublishalistofchemicalsknowntocausecancer,birthdefects,and/orother

reproductiveharm.Thelist,whichisupdatedannually,includeshundredsofchemicalsfoundinmanyeverydayitems.ThepurposeofProp65isto

informthepublicaboutexposuretothesechemicals.

Prop65doesnotbanthesaleofproductscontainingthesechemicalsbutinsteadrequireswarningsonanyproduct,productpackaging,orliteraturewith

theproduct.Moreover,aProp65warningdoesnotmeanthataproductisinviolationofanyproductsafetystandardsorrequirements.Infact,the

CaliforniagovernmenthasclariedthataProp65warning“isnotthesameasaregulatorydecisionthataproductis‘safe’or‘unsafe.’”Manyofthese

chemicalshavebeenusedineverydayproductsforyearswithoutdocumentedharm.Formoreinformation,gotohttps://oag.ca.gov/prop65/faqs-view-all.

AProp65warningmeansthatacompanyhaseither(1)evaluatedtheexposureandhasconcludedthatitexceedsthe“nosignicantrisklevel”;or(2)

haschosentoprovideawarningbasedonitsunderstandingaboutthepresenceofalistedchemicalwithoutattemptingtoevaluatetheexposure.

Doesthislawapplyeverywhere?

Prop65warningsarerequiredunderCalifornialawonly.ThesewarningsareseenthroughoutCaliforniainawiderangeofsettings,includingbutnot

limitedtorestaurants,grocerystores,hotels,schools,andhospitals,andonawidevarietyofproducts.Additionally,someonlineandmailorder

retailersprovideProp65warningsontheirwebsitesorincatalogs.

HowdotheCaliforniawarningscomparetofederallimits?

Prop65standardsareoftenmorestringentthanfederalandinternationalstandards.TherearevarioussubstancesthatrequireaProp65warning

atlevelsthatarefarlowerthanfederalactionlimits.Forexample,theProp65standardforwarningsforleadis0.5μg/day,whichiswellbelow

thefederalandinternationalstandards.

Whydon’tallsimilarproductscarrythewarning?

•ProductssoldinCaliforniarequireProp65labellingwhilesimilarproductssoldelsewheredonot.

•AcompanyinvolvedinaProp65lawsuitreachingasettlementmayberequiredtouseProp65warningsforitsproducts,butothercompanies

makingsimilarproductsmayhavenosuchrequirement.

•TheenforcementofProp65isinconsistent.

•CompaniesmayelectnottoprovidewarningsbecausetheyconcludethattheyarenotrequiredtodosounderProp65;alackofwarningsfora

productdoesnotmeanthattheproductisfreeoflistedchemicalsatsimilarlevels.

WhydoesToroincludethiswarning?

Torohaschosentoprovideconsumerswithasmuchinformationaspossiblesothattheycanmakeinformeddecisionsabouttheproductstheybuyand

use.T oroprovideswarningsincertaincasesbasedonitsknowledgeofthepresenceofoneormorelistedchemicalswithoutevaluatingthelevelof

exposure,asnotallthelistedchemicalsprovideexposurelimitrequirements.WhiletheexposurefromT oroproductsmaybenegligibleorwellwithinthe

“nosignicantrisk”range,outofanabundanceofcaution,T orohaselectedtoprovidetheProp65warnings.Moreover,ifT orodoesnotprovidethese

warnings,itcouldbesuedbytheStateofCaliforniaorbyprivatepartiesseekingtoenforceProp65andsubjecttosubstantialpenalties.

RevA

This manual suits for next models

4

Table of contents

Other Toro Engine manuals

Popular Engine manuals by other brands

Valor

Valor 1500KN installation manual

Kohler

Kohler PCV850 owner's manual

Detroit Diesel

Detroit Diesel MBE4000 Application and installation guide

O.S. engine

O.S. engine max-12TZ series Owner's instruction manual

YANGDONG

YANGDONG SERIES Y85 Operation & maintenance manual

Lutz

Lutz MA II Translation of the original instruction