Toro AC-1 User manual

AC-1 ENGINE SERVICE MANUAL

Table of Contents – Page 1 of 2

ABOUT THIS MANUAL

GENERAL INFORMATION

ENGINE SPECIFICATIONS

FUEL AND LUBRICATION

IGNITION

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS (CONT)

SAFETY WARNINGS AND NOTES

PRODUCT IDENTIFICATION NUMBERS

OIL AND FUEL RECOMMENDATIONS

STARTING/STOPPING INSTRUCTIONS

SERVICE/MAINTENANCE INSTRUCTIONS

STORAGE INSTRUCTIONS

TROUBLESHOOTING

ENGINE FAILS TO START

ENGINE STARVES ON ACCELERATION

ENGINE IS HARD TO START

ENGINE STALLS

ENGINE FIRES INTERMITTENTLY

ENGINE DOES NOT PRODUCE MAXIMUM POWER

CARBURETOR FLOODS

ENGINE STOPS AFTER RUNNING BRIEFLY

ENGINE WILL NOT IDLE

ENGINE BACKFIRES OR MISFIRES

ENGINE WILL NOT ACCELERATE

ENGINE LACKS POWER OR STOPS DURING OPERATION

ENGINE VIBRATES EXCESSIVELY

ENGINE USES EXCESSIVE AMOUNT OF OIL

STARTER ROPE IS DIFFICULT TO PULL OR ENGINE LOCKS

DISASSEMBLY

TYPICAL DISASSEMBLY SEQUENCE

REMOVE MAJOR COMPONENTS

DISASSEMBLE ENGINE

INSPECTION AND REPAIR

CARBURETOR DISASSEMBLY AND REASSEMBLY

STARTER DISASSEMBLY AND REASSEMBLY

BREATHER DISASSEMBLY AND REASSEMBLY

SPARK ARRESTER SCREEN

PISTON/CONNECTING ROD DISASSEMBLY & ASSEMBLY

PISTON/CONNECTING ROD DISASSEMBLY & ASSEMBLY

CYLINDER HEAD INSPECTION & REPAIR

AC-1 ENGINE SERVICE MANUAL

Table of Contents – Page 2 of 2

INSPECTION AND REPAIR - Continued

CRANKCASE INSPECTION & REPAIR

MAJOR COMPONENTS INSPECTION & REPAIR

REASSEMBLY

TYPICAL ASSEMBLY SEQUENCE

ENGINE REASSEMBLY

INSTALL AIR FILTER BASE, AIR FILTER AND AIR FILTER COVER

ASSEMBLE HANDLE

ASSEMBLE COVERS

!

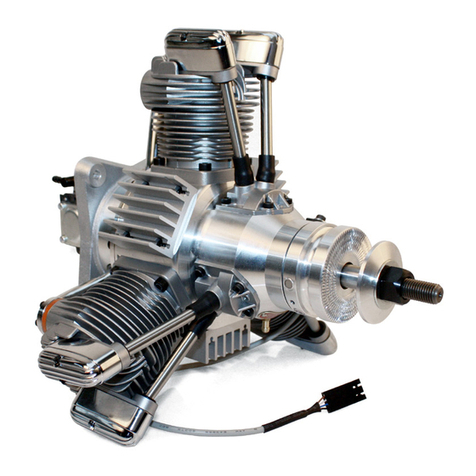

ABOUT THIS MANUAL

This Service Manualwas written expressly for the Toro AC-1 Four Stroke Engine. The Toro Company has made

every effort to make the informationinthis manual complete and correct.We are hopefulyou' findthis manual a

valuable addition to your service shop.

If

you have any questions or comments regarding the information inside,

please contact usat the following address:

The Toro Company

Consumer Service Training Department.

81

11

Lyndale Avenue South

Bloomington,MN

55420

The Toro Company reserves the right to change product specifications orthis manual without notice.

Copyright@

All

Rights Reserved

1996

The Toro Company

Table

Of

Contents

Engine Specifications

...............................

FuelandLubrication

...............................

ignition

......................................

Torque Specifications

...............................

SafetyWarningsAndNotes

...........................

Product IdentificationNumbers

..........................

OilAndFuelRecommendations

.........................

RecommendedOilType

..........................

Checking the Oil

..............................

ChangingtheOil

.............................

Recommended Fuel Type

.........................

Definitionof Blended Fuels

Use of Blended Fuels

...........................

Use of Fuel Additives

...........................

.

.........................

1-3

1-4

1-4

1-4

1-6

1-7

1-7

1-7

1-8

1-9

1-9

1-9

1-9

1-9

Starting/stoppingInstructions

...........................

1-10

To StarttheEngine

............................

1-10

To StoptheEngine

............................

1-11

Service/maintenanceInstructions

........................

1-11

AirFilter

..................................

1-11

SparkPlug

................................

1-12

CarburetorAdjustment

..........................

1-12

HighSpeedMixtureAdjustments

.....................

1-15

RockerArmtoValveClearanceAdjustment

...............

1-15

SparkArresterScreen

..........................

1-16

Storageinstructions

...............................

1-17

To Reactivate Unit for Service

.......................

1-17

SpecialTools

...................................

1-18

Definitionof Optimum Setting for Idle Speed Mixture and

1

-2

j

Item

Engine Type

Displacement

Stroke

Average Compression

Piston Rings Side Clearance

Top Piston Ring Width

Top Piston Ring End Gap

Middle Piston Ring Width

Middle Piston Ring End Gap

Oil Piston Ring Width

OilPiston Ring End Gap

Rocker ArmtoValve Clearance

B

~

~~ ~~

___

~__~

__~

~~-~___

~~~

-

_____~.

~

~ ~~

_-

~-

~____

__~_____--

~~~

-~

~__

~-

-

~~

-

~~

__

~~

_-

~~

-~

~

Air-cooled, 4-Cycle

~~

1

-3

11

Approx Fuel Tank Capacity

18

oz

(530

ml)

TORQUE SPECIFICATIONS

tem

Carburetor/Air Filter Base Plate Mounting Screws

Carburetor Mount Insulator Screws

Clutch Housing/Drum Assembly Screws

Clutch Rotor

Cylinder Head Hex Nuts

Cylinder Screws

Spark Plug

Rear Engine Cover Screw

Front Engine Cover Screws

~ ~~ ~

~~~~~

-

~

-

~~

~~

_.

~

.

~

_~~_~~~-_____-~_--

--~__

-

~~

~

-.

.

-.

..

_.._..____

~

-

..___

__

~~

.

.

.

-

-

~

1-4

SAFETY WARNINGS AND NOTES

The purpose of safety symbolsisto attract your atten-

tionto possible dangers. The safety symbols and the

explanations with them, deserve your careful attention

and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions or

warnings they give are not substitutes for proper acci-

dent prevention measures. Some general warnings

follow.

WARNING:SpringUnderTension!

The rope starter on these engines contains a flat wire

spring thatis undertension.Weareye and hand protec-

tion when replacing worn or broken spring,incase it

should uncoil asit ishandled. Allow spring tension to

becompletelyrelievedandmakesurepulleydisen-

.

gages from spring before removing the pulley retain-

ers, pulley, and starter spring from housing.

,

WARNING:ElectricalShock!

Never touch electrical wires or components while the

engine is running. They can be sources of electrical

shock.

1

-6

/-

WARNING:HotSurfaces!

The muffler, cylinder, crankcase, trimmer cutting head,

and other engine surfaces get extremely hot from op-

eration. These surfaces remain hot for a short period

of time after the engineisstopped. To prevent severe

burns, allow the engineto cool completely before serv-

icing.

I

WARNING:ExplosiveFuel!

Gasoline may be presentinthe fuel tank, carburetor,

fuel lines, or crankcase. Gasolineisextremely flamma-

ble and its vapors can explode

if

ignited. Keep sparks,

flames, and other sources of ignition away from the en-

gine.

Do

not smoke while servicing the engine. Never

use gasoline as a cleaning agent.

Store gasoline onlyinapproved containers,

in

well-

ventilated, unoccupied buildings, away from sparks,

~

flames, or other sources of ignition.

Do

not

fill

the fuel

tank while the engineis hot or running, since spilled

fuelcouldignite

if

itcomes incontactwithhotparts

or

.

sparksfromignition.

Do

notstarttheenginenear

spilled fuel.

Do

not smoke while handling gasoline or

fillingthefueltank.

i

WARNING:CrackedOrBrokenFlywheelFins

Can Become Projectiles!

Be careful not to crack or break any flywheel cooling

fins. They could fly

off

during operation.

If

cooling fin:

are cracked or broken, replace the flywheel.

I

PRODUCTIDENTIFICATION

NUMBERS

When ordering parts, orinany communication involv-

ing an engine or product, always give the:

ModelNumber,and

SerialNumber

These numbers are located on a decal (or decals) af-

fixedtothe unit (Figure 1-1). The identification de-

.

will be located on the metal boom. The actual

location will vary depending on the type of product.

Figure1-1.ProductIdentificationDecal

1.0762.005

OILAND FUEL

RECOMMENDATIONS

WARNING: ExplosiveFuel!

Gasoline

Is

extremelyflammable and itsvapors

provedcontainers, inwell-ventilated, unoccupied

buildings,away from sparks orflames. Do not fill

the fueltank while the engineis hot orrunning,

since spilled fuel could ignite if

it

comes

in

contact

with hot partsor sparks from Ignition.Do not start

the enginenear spilledfuel. Donotsmoke while

handlinggasoline. Never use gasolineas a clean-

ingagent.

,.

canexplode if ignited. Storegasolineonly inap-

NOTE:

READ

THESEINSTRUCTIONS

CAREFULLY

BEFOREAttempting TO START

OR

OPERATE

THIS UNIT. Using old oil or fuelcancauseengine

damage. This type ofdamage will void theengine

warranty

RecommendedOilType

Toro 4-cycleoil is recommended for useinthis engine

(Figure 1-2).

If

another brand 4-cycleoil is used, use a

high

qualitySAE

30

weight oilof API (AmericanPe-

troleum Institute) service classSG,

SF,

SH.

Using the proper type and weight ofoilinthe oil panis

extremely important. Check theoil before each use

and change theoil regularly. Failureto use the correct

oil, or using dirty oil, can cause premature engine

wear and failure.

TORO,

FOUR-CYCLE

ENGINE

OIL

I--------

Figure1-2.Recommended OilType.

3.6051.002

1

-7

Checking the

Oil

The importance of checking and maintaining the

proper oil levelinthe oil pan cannot be overempha-

sized. Check the oil

BEFORE EACH USE

as follows:

1.

Makesurethe engine is stopped, level and is cool

so

the oil has had time to. drain into the oil pan

(Figure

1-3

for straight shaft units or Figure

1-4

for curved shaft units).

Figure

1-3.

Level Engine

-

Straight Shaft Unit.

3.6051.020

Figure

1-4.

Level Engine

-

Curved Shaft Unit.

3.6051.004

2.

To keep dirt, grass clippings, etc. out of the engine,

clean the area around the oil

fill

plug before remov-

ing it.

3.

Remove theoil

fill

plug; wipe theoil

off.

Reinsert it

into the crankcase. Thread the oil

fill

plug into the

oil pan.

4.

Remove theoil

fill

plug and check the oil level

(Figure

1-5).

1

-8

Figure

1-5.

RemovingOil FillPlug.

2.6051.005

The oil level should be up to the top of the dipstick

(Figure

1-5).

Full

(3.40z/lOOml)

Add Oil

L

Figure

1-6.

Oil Level

3.6051.006

5.

If

the oil levelis low, add theoil to the top

of

the dipstick (see Figure

1-6).

Always check the

level with the dipstick before adding more oil.

L

I

Changing the Oil

Fora new engine, change the oil after the

first

10

hours

of operation. Thereafter, change theoil after

every

25

hours

or before storing the unit for an ex-

tended period of time.

Change theoil while the engineisstillwarm. The oil

will flow freely and carry away more impurities.

Change theoil as follows:

1.

Remove the oil

fill

plug.

2. Pour the oil into a container by

tipping

in a vertical position (Figure

1-7

tipping the trimmer

7).

Be sure to allow

ample time for complete drainage. Dispose of oil

properly.

Figure

1-7.

Pouring Oil.

3.6051.007

3. Fill the oil pan, with 3.4 oz

(100

ml) of new oilof the

proper type, to the top of the dipstick.

4.

Reinstall the oil

fill

plug and tighten securely.

NOTE:

Make sure the O-ringis inplace on theoil

fill

plug when checking and changing the oil.

NOTE:

To prevent extensive engine wear or damage,

always maintain the proper oil levelinthe crankcase.

Never operate the engine with the oil level below the

bottom of the dipstick

Recommended Fuel Type

Use clean, fresh, regular grade unleaded gasoline less

than

60

days old.

NOTE:

Alcohol blended fuel absorbs moisture

(water). Aslittle as

1

%

moistureinthe fuel can cause

fuel to separate and form acids when stored.

If

these types of fuel must be used, use freshfuel (less

than

60

days old).

Definition

of

Blended Fuels

Today's fuels are often a blend of gasoline and oneOr

more oxygenates such as ethanol, methanol or MTBE

(ether).

Use of Blended Fuels

If

you choose to use a blended fuel or its use is un-

avoidable, the following precautions are recom-

mended.

1.

Alwaysusefreshfuel.

2. Use the special additive Toro Gas Conditioner/

Stabilizer, STA-BIL

(R)

or an equivalent.

3. Drain the fuel tank and run the engine dry before

storing the unit.

Useof Fuel Additives

The use of fuel additives, such asToroGas Condi-

tioner/Stabilizer, STA-BIL Gas Stabilizer or an equiva-

lent, will inhibit corrosion and minimize the formation

of gum deposit. Add

0.8

oz (23 ml) per gallon of fuel

per instructions on the container. NEVER add fuel ad-

ditives directly to the unit's fuel tank. Using a fuel addi-

tive can keep fuel fresh for up to

60

days.

1-9

STARTING/STOPPING

INSTRUCTIONS

To

Start

the Engine

1.

Set the unit on the ground, check the oil levelinthe

oil pan, and put the ignition switchinthe “RUN”

(I)

position (Figure 1-8).

Figure 1-8. Ignition Switch and Throttle Trigger.

3.6051.008

2.

FULLY PRESS AND RELEASE the primer bulb

5

to

7

times (Figure 1-9).

NOTE:

For a warm engine, go directlyto step

5

(place the choke lever directlyinthe “PARTIAL” choke

position).

3.

Place the choke lever

in

the FULL “CHOKE” posi-

tion (Figure 1-9).

---Run position

choke

Partial Choke

Figure

1-9.

PrimerBulb,ChokeLeverandChoke

,

Positions.

3.6051.009

4.

With the unit on the ground, pull the starter rope

quickly until the engine sounds likeitwants to run

(no more than

5

pulls) (Fig. 1-10).

Figure 1-1

0.

Pulling the Starter Rope.

3.6051.010

1-10

5.

Place the choke leverinthe “PARTIAL” choke posi-

tion (see Figure1-9on page 1.4). Pull the starter

rope quickly until the engine starts (no more than

5

pulls).

6.

If

the engine does not start, repeat steps

2

to 8.

7.

Run the engine for

30

seconds, with the throttle

lever fully squeezed (see Figure 1

-6),

towarm up.

Place the choke leverinthe “RUN” position

(Figure 1-9).

NOTE:

Incolder weather, run the engine for

2

to

3

minutes to warm up.

To

Stop the Engine

Place the ignition switchinthe “STOP position (see

Figure 1-8).

SERVICE

/

MAINTENANCE

INSTRUCTIONS

Air Filter

NOTE:

CLEAN AND

RE-OIL

THE

AIR

FILTER

EVERY 10HOURS

OF

OPERATION. The air filteris

one of the most important areas to maintain.

If

it isnot

maintained as follows, poor engine performance and

severe engine damage can result.

1. Remove the three

(3)

screws on the carburetor/air

filter cover assembly. Remove the air filter cover

and air filter. Referto

Part

3

-

Engine

Disassembly

\

2.

Wash the air filterindetergent and water

(Figure 1-11). Rinse the air filter thoroughlyin

clean water and allow

it

to dry.

L

Figure 1-1 1. Washing Air Filter Element.

3.6051.011’

3.

Apply clean SAE

30

oiltothe air filter (Figure 1-12).

I

I

Figure1-1

2.

OilingAirFilter Element.

3.6051.012

4. Squeeze the air filterto ensure that theoil isspread

throughout the entire filter (Figure 1-13).

1-11

L

Figure 1-13. Squeezing ExcessOilfrom Air Filter

Element.

3.6051.013

5.

Reinstall the air filterinthe carburetor/airfilter

base. Referto

Part

5

-

Engine Reassembly

Spark Plug

Use a Champion RDZ19H spark plug. Every 50

hours

of operation, remove the spark plug, checkitscondi-

tion, and reset the gap or replace with a new plug as

necessary. Allow the engine to cool before removing

the spark plug.

WARNING: ElectricalShock!

Never touch electrical wires or components while the

engineisrunning. They can be sources of electrical

shock.

1. Before removing the spark plug, clean the area

around the base of the spark plugto keep dirt and

debris out of the engine.

2.

Disconnect the spark plug wire and remove the

spark plug from engine.

3.

Inspect the spark plug for carbon buildup and clean

if

necessary. Replace the plug

if

it isbadly burnt or

if

reuseisquestionable.

1-12

NOTE:

Donotcleanthesparkplug inamachine

~

which uses abrasive grit. Some grit could remain on

the spark plug and enter the engine causing extensive

damage.

4. Check the spark plug gap using a wire feeler gauge.

Set the gap to

0.025 in

(0.635

mm)(Figure 1-14).

5.

Reinstall the spark plug and torqueto

100-110 in-lb

(1 1.3-1 2.3

N-m).

Figure 1-14. Spark Plug Gap.

3.6051.014

CarburetorAdjustment

-

These engines are equipped with a diaphragm-type

carburetor.Thecarburetorhasbeencarefully cali-

~

brated at the factory.Inmost cases, no further adjust-

ment will be required.

The condition of the air filterisvery important to the

(

eration of the trimmer. A dirty air filter will restrict the

air flowto the carburetor. Thisinturn upsets the fuel-

air mixtureinthe carburetor. The resulting symptoms

are often mistaken for an out-of-adjustmentcarburetor

Therefore, check the condition of the air filter before

adjusting the carburetor. Referto “Air Filter“ Serv-

ice/Maintenance Instructions.

I-

-

If

the following conditions are experienced,it may be

necessary to adjust the carburetor.

The engine will not idle

The engine hesitates or stalls on acceleration.

The

loss

of engine power, which is not corrected

by cleaning the air filter, muffler, spark arrester

screen or adjusting the rocker arm to valve

clearance

The engine operatesinan erratic or fuel-rich

condition

NOTE:

Follow these carburetor adjustment proce-

dures carefully. An incorrectly adjusted carburetor can

cause severe engine damage.

Make sure the unitisfully assembled before

making carburetor adjustments.

Fortrimmers

and

brushcutters, make sure

the boom, cutting head, and line guard are installed

and the cutting line is extended to its full cutting length.

The carburetor has three basic adjustments: the idle

speed adjustment, the idle speed mixture adjustment,

and the high speed mixtureadjustment(Figure 1-15).

Mixture Needle

Figure

1-1

5.

Carburetor Adjustments.

3.6051.015

407000001-Use the following carburetor adjustment

instructions:

1.

Initial Idle Speed Setting:

Turn the idle speed

screw untilitstops.

2.

Initial High Speed Mixture and Idle

Speed

Mix-

ture Settings:

Turn both the high speed mixture

and idle mixture needles

in(clockwise)

until they

are lightly seated.

3.

Turntheneedles

out

the

following number

of

turns:

HighSpeedMixtureNeedle:1turn

IdleSpeedMixtureNeedle:

1

turn

NOTE:

Turn the high speed mixture and idle mixture

needles finger-tight. Do not force the needles with a

screwdriver as this can damage the tips of the needles

and the seatsinthe carburetor body.

4. Start the engine and let it run for

3

to

5

minutes

with the throttle lever fully squeezed.

5.

Release the throttle trigger and let the engine idle.

Turn the idle speed screw

out (counterclock-

wise)

until the speed decreases and the bump

head stops rotating.

6.

Final Idle SpeedandMixtureAdjustments:

Adjust the idle speed screw and idle speed mix-

ture needle for the smoothest engine idle using

the following procedure.

Do

not squeeze throttle

trigger when adjusting the idle speed screw and

idle speed mixture needle.

a.Setthe idle speed mixture needle

at the optimum setting

(Figure 1-16). See “Definition of Optimum

Setting” on page

1-1

5.

1-13

b

b. Squeeze the throttle trigger.

If

the engine

falters or hesitates as

it

accelerates, turn the

idle speed mixture needle

out (counterclock-

wise) 1/16 turn at a time

until the engine ac-

celerates rapidly.

c.

If

the idle speed has changed significantly be-

cause of steps a. and b. above, readjust the

idle speed screw.

7.

FinalHighSpeedMixtureSetting:

Adjust the high speed mixture needle as follows:

a. Squeeze the throttle trigger and

run the unit at high speed for

3

to 5 minutes.

b. While squeezing the throttle trigger fully, set

the high speed mixture needle at the optimum

setting. See “Definition of Optimum Setting”

on page1-15.

NOTE:

The high speed mixture needle adjustment

must be the last adjustmentmade

on

the carburetor.

If

the idle speed mixture needleisadjusted, the high

speed mixture needle must be readjusted.

8.

Make sure the air filter cover is reinstalled securely

before placing the unit back into service.

For Units with Engine Serial Number 407000001

and Greater-Use

the following carburetor adjust-

ment instructions:

1.

Initial Idle Speed Setting:

Back the idle speed

screw (Figure 1-15)

out (counterclockwise)

until

it

does not contact

the carburetor throttle lever.

Then turn the screw

in (clockwise)

untilit

just be-

gins

to move the throttle lever; then continue turn-

ing

2

full turns.

2.

Initial High Speed Mixture and idle Speed

Mixture Settings:

Turn both the high speed mix-

ture and idle speed mixture needles

in (clock-

wise)

until they are

lightly seated.

1-14

3.

Turn the needles

out (counterclockwise)

the

following number of turns:

High Speed Mixture Needle: 1 1/8 turns

Idle Speed Mixture Needle1 1/8 turns

NOTE:

Seat the high speed mixture and idle speed

mixture needles using finger pressure. Forcing the mix-

ture needles will damage the tips of the needles and

the seatsinthe carburetor body.

4.

Start the engine and letit run for

3

to 5 minutes

with the throttle lever fully squeezed.

5.

Release the throttle trigger and let the engine idle.

If

the engine stops, turn the idle speed screw

in

~

(clockwise) 1/8 turn

at a time (as required) until

the engine idles.

6.

FinalHighSpeedMixtureNeedleAdjustment:

a. While squeezing the throttle trigger fully, set

the high speed mixture needle at the optimum

setting. See “Definition of Optimum Setting”.

NOTE:

After the final high speed mixture needle ad-

justment is made, no more high speed mixture needle

adjustmentstothe carburetor are necessary.

7.

Final Idle

Speed

and Idle Speed Mixture

Adjustments:

Adjusttheidle speed screw and

’

idlespeed mixture needle for the smoothest en-

gineidleusingthefollowingprocedure.Donot

~

squeeze the throttle trigger when adjusting the idle

speed screw and idle speed mixture needle.

a.Settheidlespeedmixtureneedleatthe

~

optimum setting (Figure 1-16). See “Definition’

of Optimum Setting”.

b. Turn the idle speed mixture needle

out

(counterclockwise) 1/8 turn

tothe rich side

~

of optimum.The engine should idle and accel-

erate smoothly.

8.

FinalIdleSpeed Adjustment:

Adjusttheidle

speed by turning the idle speed screw

in(clock-

wise)

or

out (counterclockwise)

until the cutting

head does not rotate.

Do

not squeeze the throttle

trigger when adjusting the idle speed screw.

9.

Make sure the air filter coveris reinstalled securely

before placing the unit back into service.

Definitionof Optimum Setting forIdle Speed

Mixture and High Speed Mixture Adjustments

Always set the idle speed mixture needle and high

speed mixture needle at the optimum setting.To find

the optimum setting, use the following procedure.

1.Turnthe adjusting needle

out (counterclockwise)

from the preliminary setting until the engine speed

decreases (rich). Note the position of the needle.

2.

Turn the adjusting needle

in(clockwise).

The en-

gine speed may increase as the needleisturned

in(lean). Note the position of the needle.

3.

Set the adjusting needle

midway

between the rich

and the lean settings (Figure 1-16).

Midpoint

Adjust to Lean

I

Figure 1-16. Optimum Setting.

3.6051.016

Rocker Armto Valve Clearance Adjustment

Every

50

hours

of operation, remove therocker

arm

cover and check the rocker armtovalve clearance.

1.

Remove the four

(4)

screws from the engine cover.

Remove the engine cover. Remove the rocker arm

cover. Referto

Part

3

-

Engine Disassembly.

2.

Position the crankshaft

so

that the pistonisat the

top of the compression stroke (both rocker arms

are free and loose).

3.

Measure the clearance between the valve stems

and rocker arms, using a

flat

feeler gauge (Figure

1-17).

Figure 1-17. Measuring the Rocker Armto Valve

Clearance.

3.6051.017

The recommended rocker armtovalve clearance for

both the intake and exhaustis

.003-.006

in

(.076

mm-,152 mm).

b

4.

If

the clearance is not within specification, adjust as

follows:

a.Turn the adjusting nut (Figure 1-18), using a

5/16 in (8 mm) wrench or nut driver.

To

increase the rocker arm to valve clearance,

turn

the adjusting nut counterclockwise.

To

decrease the rocker arm to valve clearance,

turn

the adjusting nut

clockwise.

b. Recheck the clearance with a flatfeeler gauge

and readjust as necessary (see Figure 1-1

7).

5.

Reinstall the rocker arm cover, using a new gasket.

Torque the rocker arm cover screw to

20-30 in-lb

(2.2-3.4 N.m).

Figure 1-18. Adjusting Nuts.

2.6051.018

6. Install the breather hose to the air filter base.

7.

Reinstall the engine cover and screws. Refer to

Part

5

-

Engine Reassembly.

Torque the top screws to

15-20 in-lb(1.7-2.2 Nom).

Torque the front screw to

20-25 in-lb(2.2-2.8 Nom).

Torque the rear screw with washer to

30-35 in-lb(3.5-

4.0

Nom).

Spark Arrester Screen

This unitisequipped with a spark arrester screen.

Every

50

hours

of operation, check the spark arrester

screen for debris and/or deposits.

WARNING:HotSurfaces!

Make sure the muffleris cool before checking the

spark arrester screen to prevent injury.

1. Remove the spark arrester cover screw and cover

(Figure 1-1

9).

Figure 1-1

9.

Spark Arrester Screen.

3.6051.019

2.

Push the spark arrester screen out of the cover.

3.

Inspectthesparkarresterscreen.

If

the screen is clean, reinstall the screen,

cover and screw.

If

the screen is plugged,

replace it.

4.

Torque the screw to

15-20 in-lb(1.7-2.2 N-m).

1-16

Table of contents

Other Toro Engine manuals