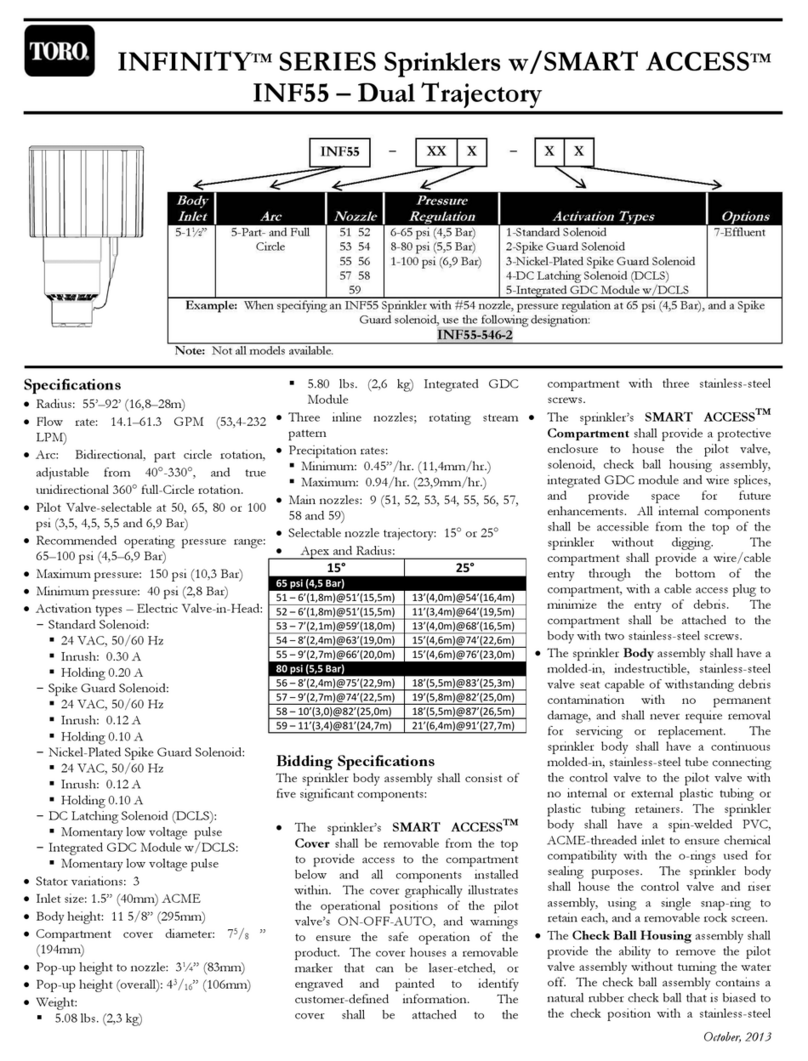

Front Nozzle Performance Charts

Back Nozzle Performance Charts

855RB-5154 Performance Chart 855RB-5558 Performance Chart

Front

Nozzle

Positions

Nozzle Set 51

(Yellow)

Nozzle Set 52

(Blue)

Nozzle Set 53

(Brown)

Nozzle Set 54

(Orange)

Nozzle Set 55

(Green)

Nozzle Set 56

(Gray)

Nozzle Set 57

(Black)

Nozzle Set 58

(Red)

102-4587 102-4588 102-4589 102-0728 102-0729 102-0730 102-4261 102-4260

Blue Gray Red Gray Orange Gray Orange Gray Blue Gray Blue Gray Orange Gray Blue Gray

102-2925 102-2910 102-2928 102-2910 102-2926 102-2910 102-2926 102-2910 102-2925 102-2910 102-2925 102-2910 102-2926 102-2910 102-2925 102-2910

Back

Nozzle

Positions

Red Plug Red Plug Red Plug Red Plug Red Plug Red Plug Red Plug Red Plug

102-4335 102-4335 102-4335 102-4335 102-4335 102-4335 102-4335 102-4335

PSI rad/ft gpm rad/ft gpm rad/ft gpm rad/ft gpm rad/ft gpm rad/ft gpm rad/ft gpm rad/ft gpm

60 55 16.1 63 20.3 69 23.4 75 31.3 — — — — — — — —

70 56 17.4 66 21.8 70 25.3 76 33.8 — — — — — — — —

80 57 18.5 68 23.3 72 27.0 77 36.0 80 39.1 85 41.0 88 45.4 92 49.7

90 58 19.4 70 24.5 75 28.5 79 38.1 83 41.5 87 43.5 91 48.2 94 52.8

100 59 20.5 72 25.9 76 30.0 80 40.2 86 43.7 90 45.7 94 50.6 96 55.3

Stator 102-1939 Yellow 102-1940 White

Conver. 855RB-5154 855RB-5558

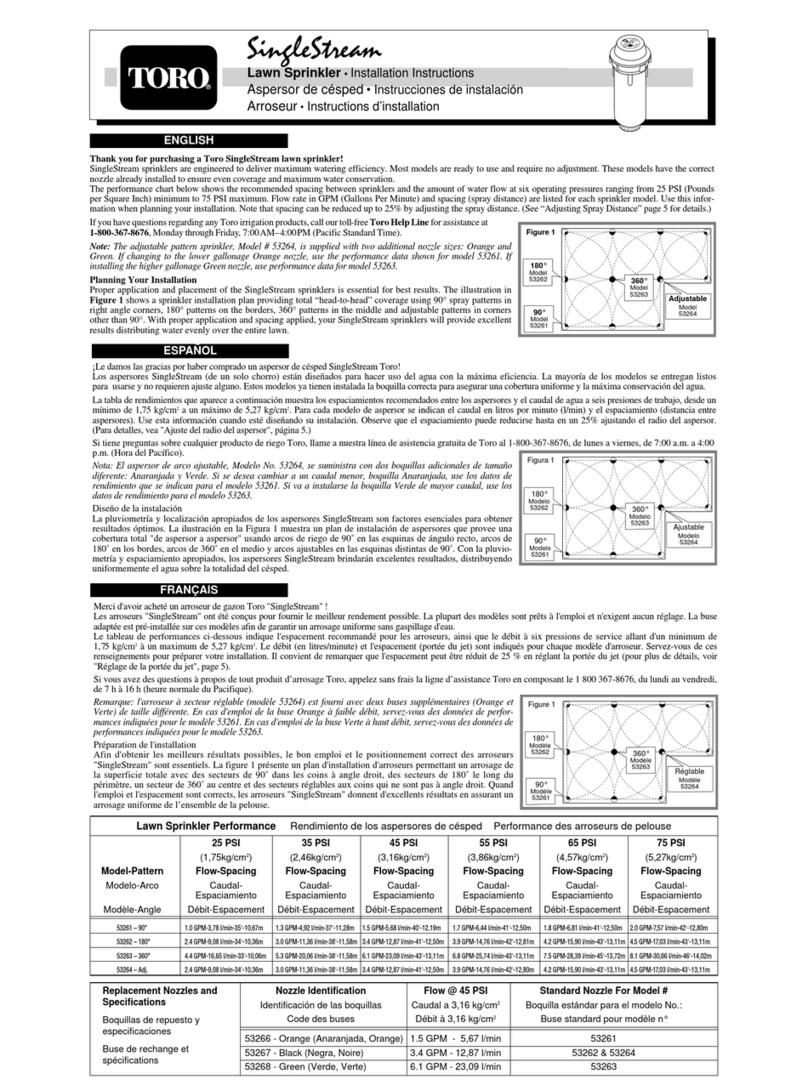

DT54RB-5154 Performance ChartDT54RB-5558 Performance Chart

Front

Nozzle

Positions

Nozzle Set 51

(Yellow)

Nozzle Set 52

(Blue)

Nozzle Set 53

(Brown)

Nozzle Set 54

(Orange)

Nozzle Set 55

(Green)

Nozzle Set 56

(Gray)

Nozzle Set 57

(Black)

Nozzle Set 58

(Red)

102-0725 102-7001 102-0727 102-7002 102-6908 102-0730 102-4261 102-4260

Red Plug Red Plug Red Plug Red Plug Red Plug Red Plug Red Plug Red Plug Red Plug Red Plug Red Plug Red Plug Red Plug Brown Red Plug Brown

102-4335 102-4335 102-4335 102-4335 102-4335 102-4335 102-4335 102-4335 102-4335 102-4335 102-4335 102-4335 102-4335 102-6883 102-4335 102-6883

Back

Nozzle

Positions

Yellow Blue Yellow Orange Yellow Red Yellow Beige Yellow Beige Yellow Red Yellow Gray Yellow Gray

102-6937 102-2925 102-6937 102-2926 102-6937 102-2928 102-6937 102-2929 102-6937 102-2929 102-6937 102-2928 102-6937 102-4965 102-6937 102-4965

PSI rad/ft gpm rad/ft gpm rad/ft gpm rad/ft gpm rad/ft gpm rad/ft gpm rad/ft gpm rad/ft gpm

60 59 14.6 62 17.4 68 24.3 71 28.2 — — — — — — — —

70 60 15.7 63 18.8 70 26.3 75 30.6 — — — — — — — —

80 61 16.4 64 20.0 72 27.6 78 32.6 83 39.5 85 42.7 87 45.9 91 50.2

90 62 17.8 66 21.3 74 29.9 80 34.7 85 41.6 88 44.9 90 48.5 93 52.8

100 63 18.1 67 23.6 75 30.4 81 36.7 87 43.7 90 46.8 93 51.2 95 55.4

Stator 102-6929 Blue 102-1940 White

Conver. DT54RB-5154 DT54RB-5558

Not recommended at these pressures. Radius shown in feet.

Toro recommends the use of a 11⁄4" swing joint at flows over 25-GPM (95-LPM). Sprinkler radius data collected in Toro’s zero wind test facility per ASAE standard S398.1.

Actual site conditions must be considered when selecting the appropriate nozzle.

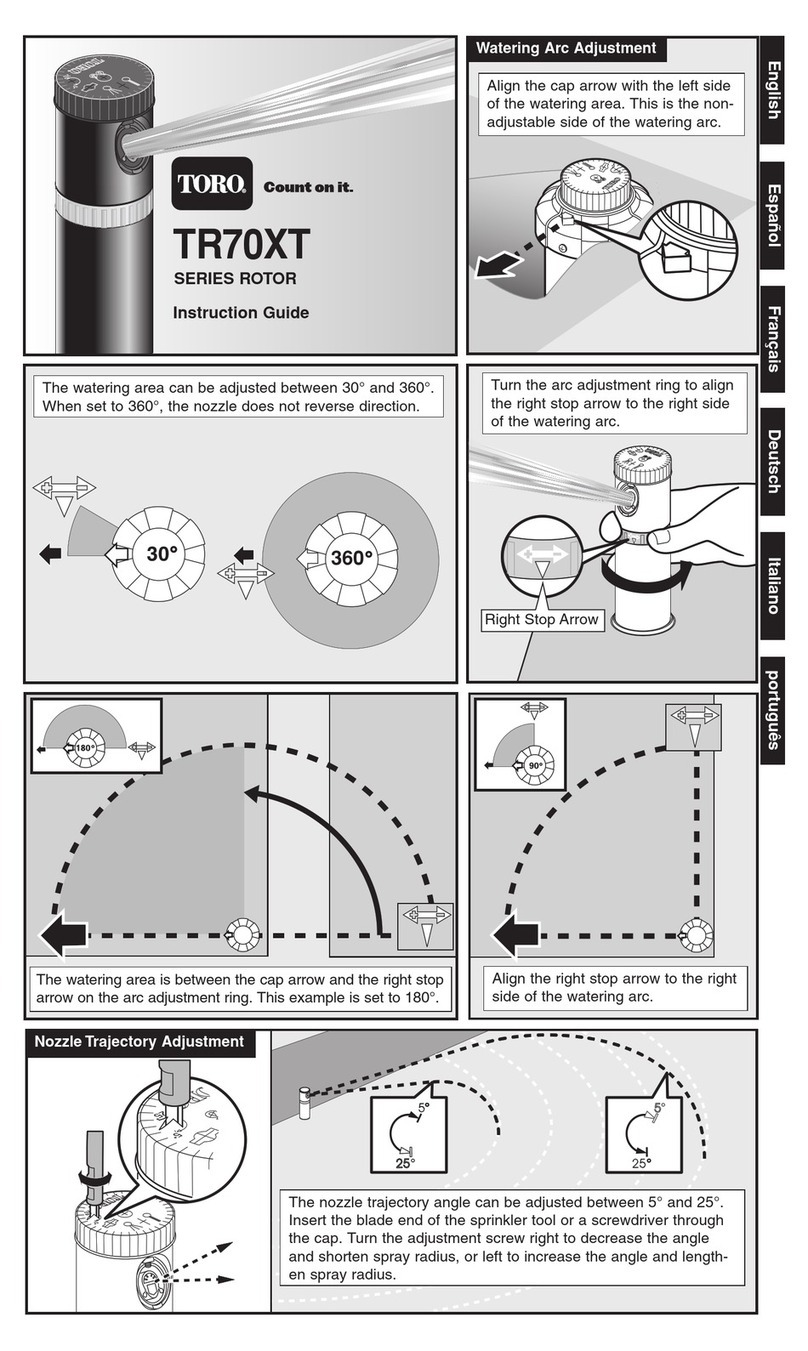

DT55RB-5154 Performance ChartDT55RB-5558 Performance Chart

Front

Nozzle

Positions

Nozzle Set 51

(Yellow)

Nozzle Set 52

(Blue)

Nozzle Set 53

(Brown)

Nozzle Set 54

(Orange)

Nozzle Set 55

(Green)

Nozzle Set 56

(Gray)

5Nozzle Set 57

(Black)

Nozzle Set 58

(Red)

102-6906 102-0726 102-6907 102-0728 102-6955 102-6935 102-6936 102-6909

Yellow Brown Yellow Yellow Yellow Yellow Yellow Yellow Yellow Green Green Green Green Green Green Green

102-5670 102-5671 102-5670 102-6884 102-5670 102-6884 102-5670 102-6884 102-5670 102-6885 102-6531 102-6885 102-6531 102-6885 102-6531 102-6885

Back

Nozzle

Positions

Red Plug Red Plug Red Plug Red Plug Red Plug Red Plug Red Plug Red Plug Red Plug Red Plug Red Plug Red Plug Red Plug Red Plug Red Plug Red Plug

102-4335 102-4335 102-4335 102-4335 102-4335 102-4335 102-4335 102-4335 102-4335 102-4335 102-4335 102-4335 102-4335 102-4335 102-4335 102-4335

PSI rad/ft gpm rad/ft gpm rad/ft gpm rad/ft gpm rad/ft gpm rad/ft gpm rad/ft gpm rad/ft gpm

60 56 15.2 57 20.1 66 24.3 68 28.0 — — — — — — — —

70 58 16.5 60 21.7 67 26.2 71 30.4 — — — — — — — —

80 59 17.5 62 23.1 68 27.8 72 31.7 76 39.7 80 43.1 83 48.2 85 53.0

90 60 18.4 64 24.5 71 28.8 74 34.5 78 43.1 81 45.1 86 51.2 87 56.0

100 61 19.3 66 25.3 72 30.3 75 36.5 80 45.5 82 49.0 90 54.5 89 59.0

Stator 102-1939 Yellow 102-1940 White

Conver. DT55RB-5154 DT55RB-5558

Nozzles 65 PSI 80 PSI

Part # Description Color Radius GPM Radius GPM Profile

Nozzles 65 PSI 80 PSI

Part # Description Color Radius GPM Radius GPM Profile

102-6937 Inner Nozzle

w/ Yellow Restrictor Yel/Yel 29 3.7 30 4.1

102-6531 Inner Nozzle

w/ White Restrictor Grn/Wht 31 4.3 33 4.6

102-6883 Intermediate Nozzle Brown 38 2.8 38 2.8

102-6884 Intermediate Nozzle Yellow 41 4.1 43 4.5

102-6885 Intermediate Nozzle Green 42 5.4 45 6.0

102-2925 Intermediate Nozzle Blue 40 2.8 42 3.2

102-2926 Intermediate Nozzle Orange 44 4.3 45 4.8

102-2927 Intermediate Nozzle Gray 46 5.1 47 5.4

102-2928 Intermediate Nozzle Red 48 6.5 50 7.0

102-2929 Intermediate Nozzle Beige 51 8.1 53 9.1

© 2011 The Toro Company • Irrigation Division • www.toro.com Form Number 373-0581 Rev. A