T5 Series Sprinklers

December 2013

Specifications

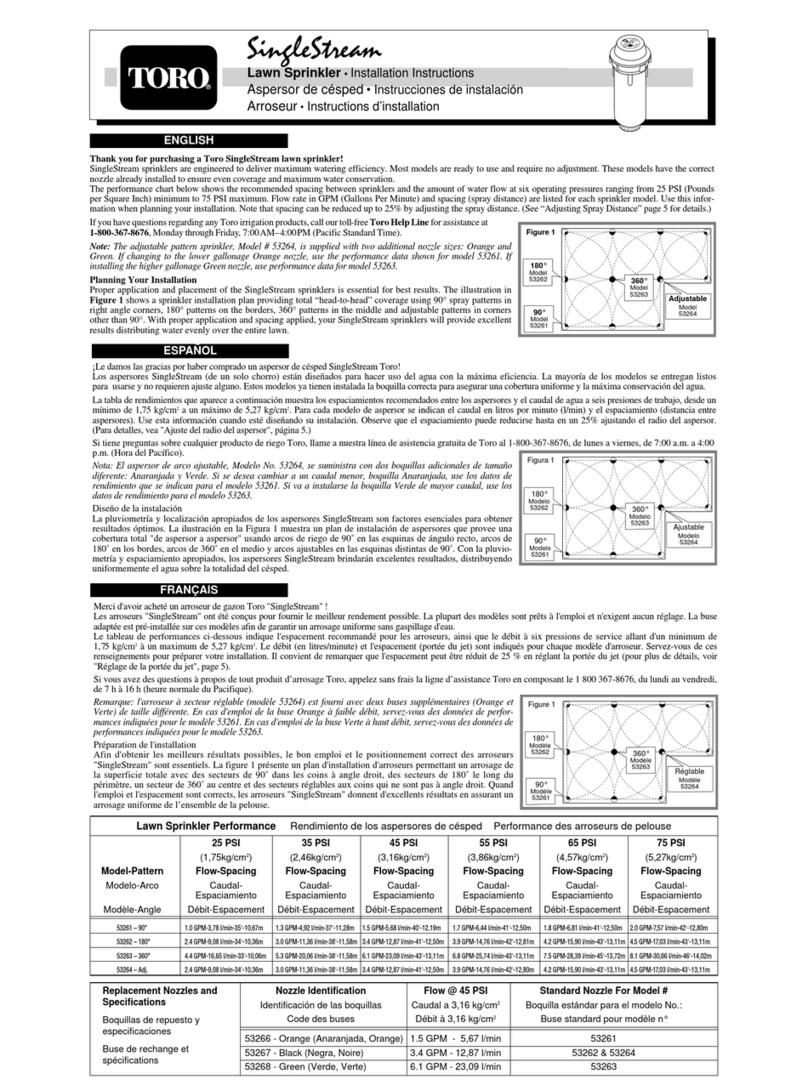

Radius: 25’-50’ (7,6 –15,2m)

Flow rate: .76-9.63 gpm (2,8-36,5

lpm)

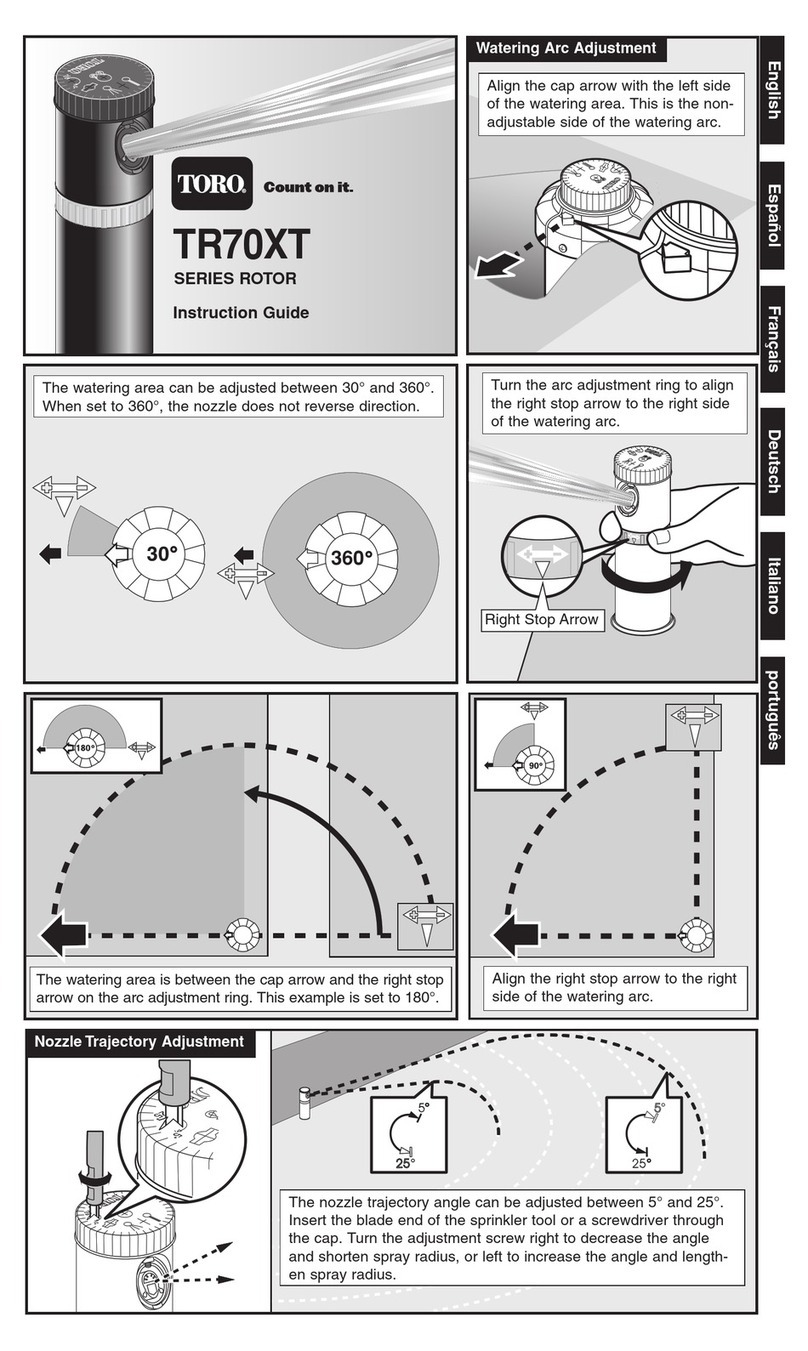

Arc: Reversing, part-circle/full

circle rotation, adjustable from 40-

360

Recommended operating pressure

range: 25-70 psi (1,7-4,8 Bar)

Check valve capable of checking up

to 7’ (2,1m) of elevation difference

Inlet size: 3/4”(20mm) NPT

Overall height: 7.5”(190mm)

Body diameter: 2.25 ” (57mm)

Pop-up to nozzle: 5” (127,0mm)

Weight: .49 lbs. (.22 kg.)

Precipitation rates:

-Minimum: .20”/hr. (5,1 mm/hr.)

-Maximum: .86”/hr. (21,8

mm/hr.)

Radius reduction screw retains

nozzle and provides up to 25%

radius reduction

Two nozzle trees: Eight standard

angle (25°) nozzles (1.5, 2.0, 2.5,

3.0, 4.0, 5.0, 6.0, 8.0). Four low

angle (10°) nozzles (1.0, 1.5, 2.0,

3.0)

Bidding Specifications

This sprinkler shall be

capable of reversing full-circle and

part-circle operation and be a gear-

driven rotary type. The sprinkler

shall be of a pop-up design with a

overall height to nozzle of 5”

(127mm), and a cap diameter of 2.6”

(66,0mm). The sprinkler shall have a

3/4” (20mm) NPT female-threaded

inlet. The sprinkler shall be capable

of covering ___ feet radius at ___

pounds per square inch pressure with

a discharge rate of ___ gallons per

minute.

Water distribution shall be via

a single pressed-in nozzle mounted in

a 1.44” (36,6mm)-diameter plastic

nozzle turret and retained by the

radius reduction screw. There shall

be two nozzle trajectory angles

available –a standard angle of 25°

and a low angle of 10°. The standard

angle nozzle set shall cover a flow

range of 1.15-9.70 gpm (4.35-36.72

lpm) flow and a radius range of 33’-

50’ (10,1-15,2m). The low angle

nozzle set shall cover a flow range of

.74-3.70 gpm (2,80-14,01 lpm) flow

and a radius range of 25’-36’ (7,6-

11,0m). All of the sprinkler nozzles

shall have molded-in text for easy

identification of radius and flow

performance capabilities. A stainless-

steel radius reduction screw shall be

provided for fine-tuning the radius

up to a 25% reduction. All nozzles

shall be sized to allow any particle

capable of passing through the riser

screen to pass through the nozzle.

The arc of the sprinkler shall

be top-adjustable with the provided

tool, wet or dry. The sprinkler shall

enable the user to fast forward

(advancing in the same direction as

the gear drive) the nozzle turret in

either direction (wet or dry). The left

and right arc limits shall be hard

stops, so that the user can palpate the

arc limits. The sprinkler shall be

adjustable from a minimum of 40°

part-circle to maximum of 360°

reversing full circle. When using the

arc adjustment tool, the left arc

position shall be fixed and be readily

identified by a manually fast

forwarding to the hard stop. The

right arc shall be the adjustable

position when using the arc

adjustment tool.

The sprinkler shall also be

available with an optional RapidSet™

arc adjustment which allows arc

adjustment with no tools. When

adjusting the arc with this method,

the right arc position shall only be

adjustable in the clockwise direction,

by clutching the nozzle turret beyond

the hard right stop. Similarly, the left

arc position shall be adjusted in the

counterclockwise direction by

Specifying Information –T5 Series Sprinklers

P –5”

Lawn

Pop-Up

S –Shrub

HP –12”

High-Pop

1.5–1.5 GPM

2.0–2.0 GPM

2.5–2.5 GPM

3.0–3.0 GPM

4. 0–4.0 GPM

5. 0–5.0 GPM

6. 0–6.0 GPM

8. 0–8.0 GPM

RS–RapidSet™

Arc

Adjustment

10LA-1.0 GPM

15LA-1.5 GPM

20LA-2.0 GPM

30LA-3.0 GPM

Example:

When specifying a T5 Series Sprinkler with check valve, RapidSet™ arc adjustment, and 2.5 gallon

nozzle, use the following designation: T5PCK2.5-RS

*Check-O-Matic standard on all shrub models.