Toro 44713 User manual

FormNo.3424-682RevA

HydraulicPowerPack

ProPass200TopDresserwithTow-TypeChassis

ModelNo.44713—SerialNo.403300001andUp

InstallationInstructions

ThisproductcomplieswithallrelevantEuropeandirectives.Fordetails,pleaseseetheDeclarationof

Incorporation(DOI)atthebackofthispublication.

WARNING

CALIFORNIA

Proposition65Warning

TheengineexhaustfromthisproductcontainschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,orotherreproductiveharm.

Batteryposts,terminals,andrelatedaccessoriescontainleadandlead

compounds,chemicalsknowntotheStateofCaliforniatocausecancerand

reproductiveharm.Washhandsafterhandling.

Safety

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

decal115-2047

115-2047

1.Warning—donottouchthehotsurface.

decal119-6844

119-6844

1.Cutting/dismembermenthazardofhand,conveyor—stay

awayfrommovingparts,keepallguardsandshieldsin

place.

decal119-6807

119–6807

1.Warning—nostep

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved*3424-682*A

decal119-6829

119–6829

1.ReadtheOperator'sManual.

2.Maximumloadof907kg(2000lb)resultsinanaxleweight

of1,530kg(3320lb)andatongueweightof145kg(320

lb).

3.Emptyhopperhasanaxleweightof599kg(1320lb)anda

tongueweightof48kg(105lb).

decal133-8062

133-8062

2

Installation

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

DescriptionQty.Use

Hydraulictankassembly1

Hoseguidemountingbracket1Preparethemachine

Engineassembly1

Bolt(1/2x5inches)2

Battery1

Batteryholddown1

Batterymountstrap1

Batterybolt2

Batteryboltspacer2

Washer2

Flangenut2

Mounttheengine.

Hoseguide1

Hydraulicreturnhose(hose#3)1

Hydraulicsuctionhose(hose#4)1

Bolt(1/4x3/4inch)4

Locknut(1/4inch)4

Bolt(3/8x1inch)4

Locknut(3/8inch)4

Flatwasher4

Installthehydraulicsystem.

Nopartsrequired–Completetheinstallation.

3

Important:Thiskitcanonlybeappliedto

aProPassthatisequippedasatow-behind

machine.

PreparingtheMachine

CAUTION

Installingthekitbeforedisconnectingall

externalhydraulicandelectricalsources

mayexposeyoutoelectricshockand/or

pressurizedhydraulicuid,causingserious

injuryordeath.

Beforeinstallingthepowerpack,disconnect

allexternalhydraulicandelectricalpower

sources.

1.Parkthemachineonalevelsurface,lowerthe

jackstand,disconnectitfromthetractionunit,

andchockthefrontandbackofthewheels.

2.FollowingtheinstructionsgivenintheOperator’s

Manualforthemachine,removetheTwin

Spinnerandsecurethehydraulicpowerand

returnhoses.

Important:SomeProPassmodelshavea

pre-drilledchassisrearwall.Ifyourmachine

hasapre-drilledchassisrearwall,referto

MountingtheEngine(page5).

3.Removeandretainthe2mountingboltsfrom

thechassisrearwalltoallowthehydraulictank

tobemounted.

4.Ensurethatthechassisrearwallisclearto

mountthehydraulictank.

5.Removethehydraulictankassemblyfromthe

crate.

6.Supportthehydraulictankfromunderneathand

positionthetankagainstthechassisrearwall.

Thetankshouldbecenteredevenlyfromleftto

rightandshouldbepositionedvertically(Figure

1).

g013856

Figure1

1.Hydraulictank

7.Ensurethattheinletandoutletttingsandthe

hoseguidemountingbracketalltcleanlywithin

theroundholesinthechassisrearwall(Figure

2).

g013857

Figure2

1.Holesinthechassis

8.Ensurethatthehydraulictankislevel.

9.UsingC-clamps,orsimilardevices,temporarily

clampthehydraulictankrmlyinplaceonthe

chassisrearwall.

10.Ensurethatthehydraulictankisstilllevel.

11.Markthepositionofthehydraulictankmounting

holesontothechassisrearwall.

12.Unclampandremovethehydraulictank.

13.Centerpunchthepositionofthemarkedholes.

14.Drilla7/16inchdiameterholethroughthe

chassisrearwallineachmarkedandpunched

position.

15.De-burreachhole.

4

MountingtheEngine

1.Ensurethatthehitchtubeiscleanandfreefrom

dirtordebris.

2.Unpacktheengineassembly.

3.Loosen,butdonotremove,the2boltsand

nutssecuringtheenginemountbracketstothe

enginemountingplate(Figure3).

g013858

Figure3

1.Mountingbolt(2)

4.Removethe2nutsholdingthebatteryhold

downstrapsinplaceandsetthenuts,washers

andbolttubeofftotheside(Figure4).

g013861

Figure4

1.Batteryholddownstrap2.Batteryholddownbolt(2)

5.Removethebatteryfromitspositiononthe

assemblyandrestthelteronthebaseplate.

6.Chargethebattery;refertoActivatingand

ChargingtheBattery(page12).

7.Havesomeonehelpyoutopositiontheengine

assemblyontothehitchtube.

Ensurethattheenginemountbracketsstraddle

thehitchtube(Figure5)andthattherearofthe

enginemountplateisapproximately25mm(1

inch)fromthehitchtubereceiver(Figure6).

g013911

Figure5

1.Hitchtube

g013859

Figure6

1.Oneinch

5

8.Insertthe2bolts(1/2x5inches)throughthe

enginemountbracketholes,ensuringthataat

washeristtedagainsteachouterfaceofthe

enginemountbracket,andensuringthatthe

boltspassbeneaththebottomofthehitchtube.

Handtightenthe2nuts(1/2inch)asshownin

Figure7.

g013860

Figure7

1.Hitchtube2.Mountingbolt(2)

9.Adjusttheenginemountbracketsothatitistight

tothehitch.Fullytightenthe2boltsthatyou

loosenedinstep3.

10.Ensurethattheenginemountingplateislevel

andfullytightenthe2bolts(1/2x5inches)

throughtheenginemountbracketlowerholes.

11.Placethebatteryontothebatterytray,

positioningtheterminalsasshowninFigure8.

12.Positionthebatteryholddownonthebattery

(Figure8).

13.Holdthebatterymountstraparoundthe

undersideofthehitchtube(Figure8).

14.Ontherightside,installabatteryboltthrough

thewasher,batterymountstrap,enginemount

plate,batterytray,batteryboltspacer,andhold

down.Looselyinstallaangenut(Figure8).

Note:Ensurethattheboltsareinstalledfrom

thebottom.

15.Ontheleftside,installabatteryboltthrough

thewasher,batterymountstrap,enginemount

plate,batterytray,batteryboltspacer,andhold

down.Looselyinstallaangenut(Figure8).

16.Ensurethateverythingisconcentricandtighten

thenuts.

g013862

Figure8

1.Batterybolt(2)4.Batterymountstrap

2.Washer(2)5.Flangelocknut(2)

3.Bolttube

6

InstallingtheHydraulic

System

1.Unpackthehoseguide,hydraulicreturnhose

(hose#3),hydraulicsuctionhose(hose#4),4

bolts(1/4x3/4inch)and4locknuts(1/4inch).

Note:Removethehosesecuredtothehose

guide,hydraulicreturnhoseandhydraulic

suctionhoseforshipping.

2.Using2bolts(1/4x3/4inch)andange

locknuts,attachthehoseguidetothebracket

onthehydraulictank(Figure9).

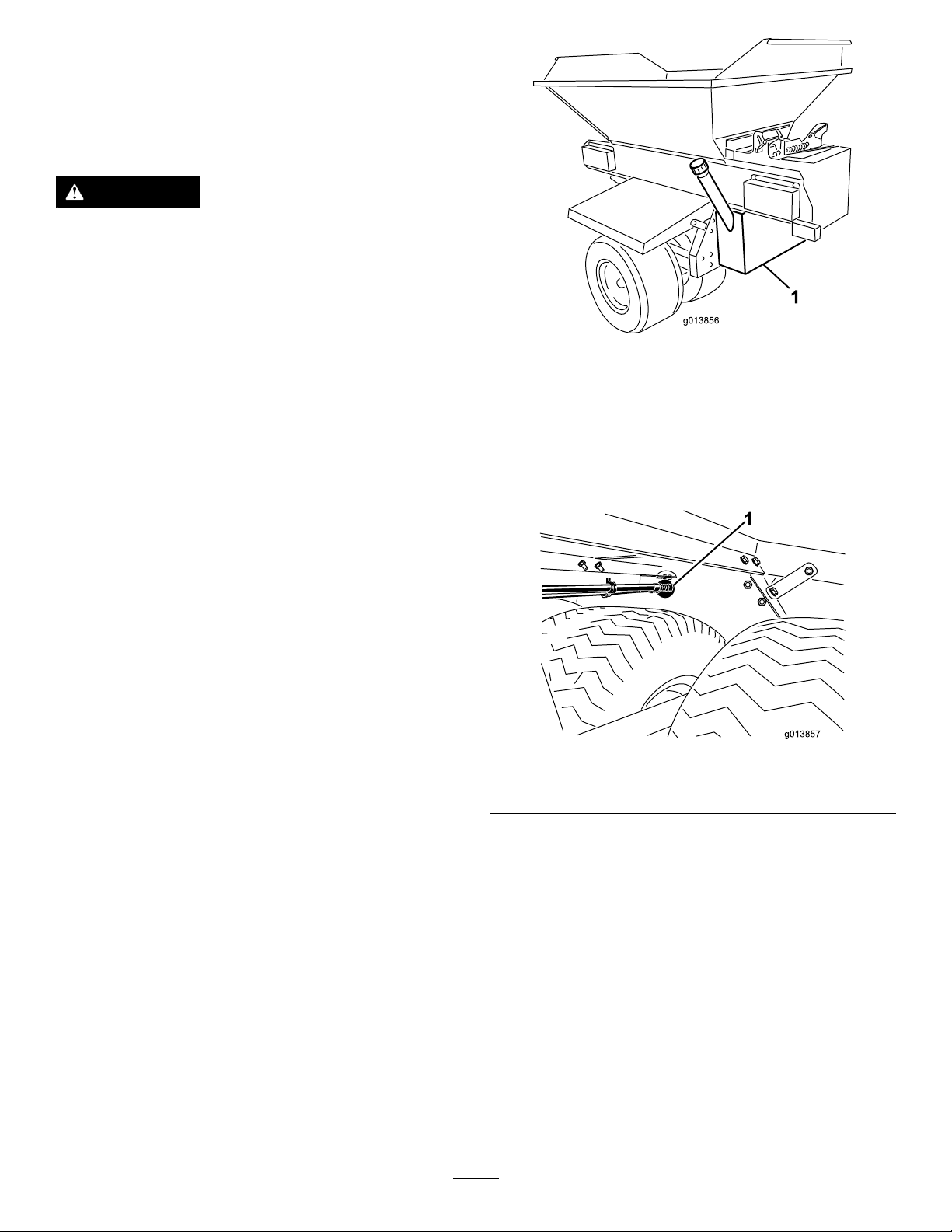

g013863

Figure9

1.Hoseguide

Note:Removethe2mountingboltsmustfrom

thechassisrearwall.Usetheremovedbolts

tomountthetank.

3.Unpack4bolts(3/8x1inch)andnylonlocknuts.

Supportingthehydraulictankfrombelow,pass

thehoseguideandhydraulichoses#3and#4

throughthelargecentralholeinthechassisrear

wallandlocatethehydraulictankagainstthe

chassisrearwall.T emporarilyclamp,orbolt,the

hydraulictankinplace.

Note:Thehoseguideshouldbefedthrough

thecenterholeonthefrontsideofthechassis.

2peoplemayberequired.

4.Installthehydraulicreturnhose(#3)andthe

hydraulicsuctionhose(#4)totheappropriate

ttingsonthehydraulictank.

Note:Hose#3andhose#4donothavethe

samettings;eachhosewilltonlyintothe

correctttinginthehydraulictank.

Note:Whenmountingthehoses,ensurethat

thereisadequateclearanceforthetires.

5.Thehoseguideshouldsitontopofthetabfrom

theverticallegofthebatterytray(Figure10).

Iftheholesinthehoseguidedonotmatchthe

holesinthebatterytraytab,thehoseguide

lengthmaybeadjustedbylooseningthebolts

attachingthehoseguidetothehydraulictank

bracketandslidingthehoseguideforwardor

totherearasrequired.

g013864

Figure10

1.Hoseguide

6.Attachthehoseguidetothebatterytraytab

using2bolts(1/4x3/4inch)andangelocknuts

(Figure10).

7.Mountthehydraulictanktothechassisrear

wallusingthepreviouslyremovedmounting

bolts,aswellasthebolts(3/8x1inch),nylon

locknuts,andatwashersfromthekit,Tighten

thefasteners.

8.Connecthydraulichose#3tothelteroutlet

(Figure11).

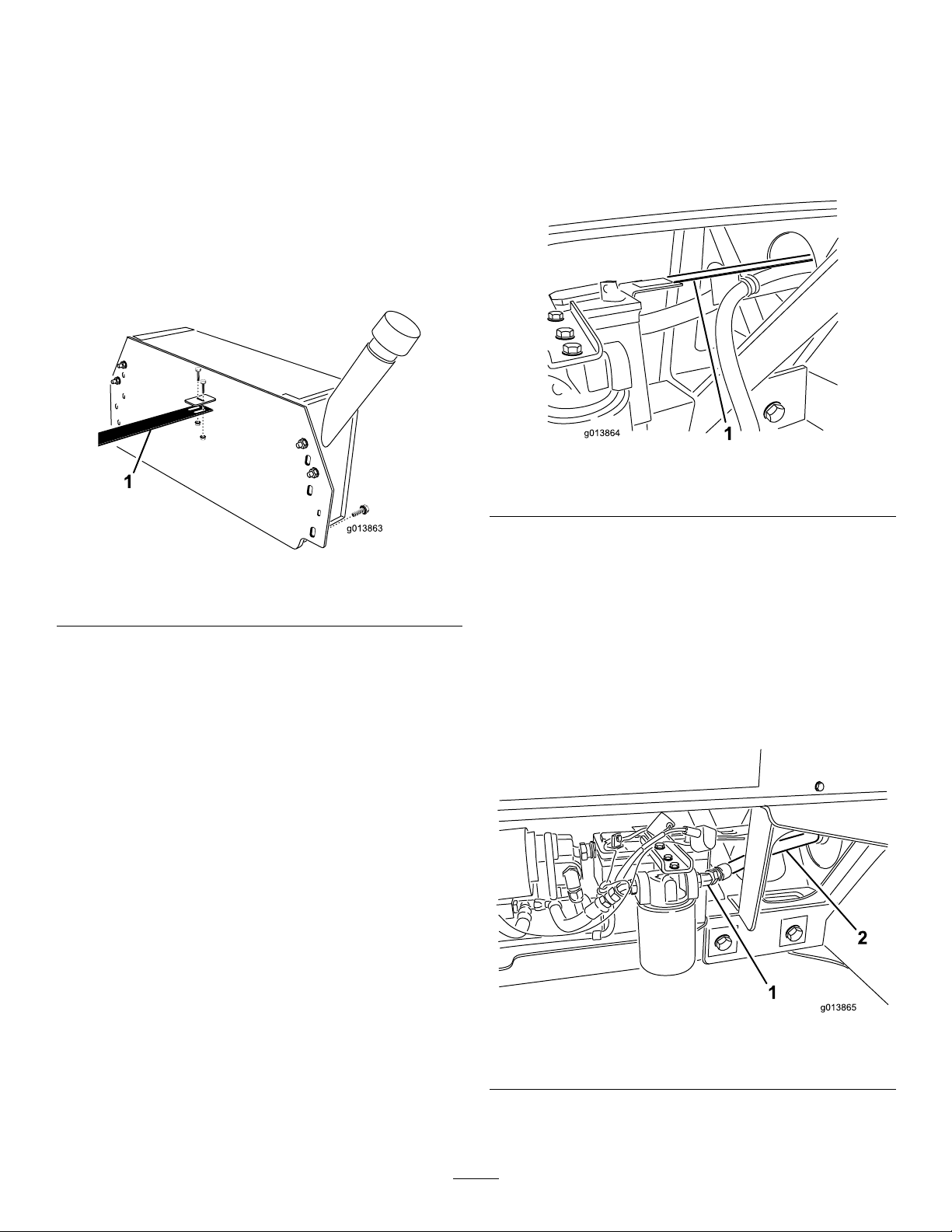

g013865

Figure11

1.Filteroutlet2.Hydraulichose#3

7

9.Connecthydraulichose#4tothesuctionsideof

thehydraulicpump(Figure12).

g013908

Figure12

1.Hydraulicpump2.Hydraulichose#4

10.OntheSHversion(Model44701)removethe

fastenerssecuringthecovertothefrontofthe

machineandsetthecoveraside(Figure13).

g013845

Figure13

1.Cover

11.Identifythepressureandreturnconnectionson

themachinebasemodel.RefertoFigure14

fortheSHversionsandFigure15fortheEH

versions.

g014215

Figure14

SHversionshown

1.Pressure2.Return

g259001

Figure15

EHversionshown

1.Return2.Pressure

8

12.Ifpressureandreturnhoseswerepreviously

installedatthelocationsshowninFigure14and

Figure15,removethem.

Note:Ensurethatthehosesdonotcontact

anyhot,sharp,ormovingparts.Trytoattainas

muchclearancefromthemuferaspossible.

13.Connectthehydraulichosestothehydraulic

controlpanel.RefertoFigure14andFigure16

ontheSHversionsandFigure15andFigure

17ontheEHversions.

g013867

Figure16

SHversionshown

1.Hoserouting

g013866

Figure17

EHversionshown

1.Hoserouting

14.Tightenallofthehydraulicconnectionsand

fasteners.

CompletingtheInstallation

1.RettheTwinSpinnerassembly.

2.Connecttheblackcableandtheblackpre-routed

cabletothebatterynegativeterminalandthe

whitecableandtheredpre-routedcabletothe

batterypositiveterminal.

3.Plugtheintermediatewireharnessintothe

powerharnessconnectoronthemachine

(Figure18orFigure19).

g013946

Figure18

1.Powerharness2.Intermediatewireharness

g013948

Figure19

1.Powerharness2.Intermediatewireharness

9

4.Filltheenginewithapproximately1L(34oz)

oftheproperviscosityoilbeforestarting;referto

ServicingtheEngineOil(page10).

Important:Theengineisshippedfromthe

factorywithoutoil;attemptingtostartthe

machinebeforeyoullitwithoilwillcause

enginedamage.

5.Checkthelevelofoilbeforetheengineisrst

started;refertoServicingtheEngineOil(page

10).

6.Fillthehydraulictankwiththeproperhydraulic

uid;refertoServicingtheHydraulicSystem

(page11).

Important:Thehydraulicsystemwillnot

completelyllwithuiduntilthesystemis

poweredup.Checkthehydraulicuidlevel

andadduidasnecessarytoensurethatitis

atthecorrectlevelafterusingthehydraulic

systemforthersttime.

Operation

CAUTION

Ensurethatallcontrolsystemsareturnedoff

whenworkingonthepowerpack.

ServicingtheEngineOil

Important:Theengineisshippedwithoutoil.

Refertotheengineowner’smanualforadditional

information.

Theengineisshippedfromthefactorywithoutoil;it

mustbelledwithapproximately1L(34oz)ofoil

beforestarting.

Checkthelevelofoilbeforetheengineisrststarted

anddailythereafter.

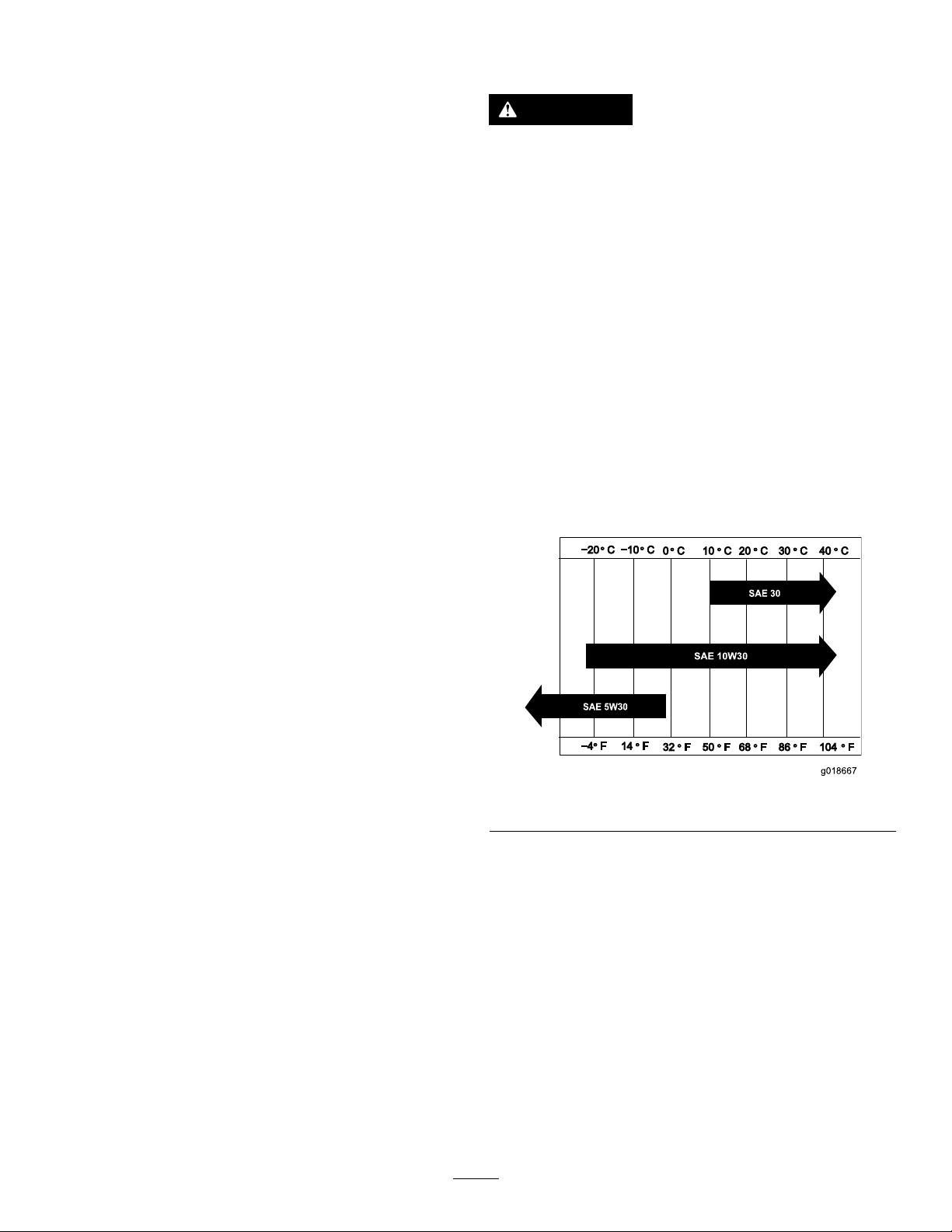

Theengineusesanyhigh-qualityoilhavingthe

AmericanPetroleumInstitute-APl-“service

classication"SJ,SLorequivalent.Oilviscosity

-weight-mustbeselectedaccordingto

ambienttemperature.Figure20illustratesthe

temperature/viscosityrecommendations.

g018667

Figure20

1.Positionthemachinesothattheengineislevel.

2.Cleantheareaaroundtheoilllercap/dipstick.

3.Removetheoilllercap/dipstickbyrotatingit

counterclockwise.

4.Wipethedipstickcleanandinsertitintotheller

port.Donotscrewitintotheport.

5.Removethedipstickandcheckthelevelofthe

oil.

6.Ifthelevelisnearorbelowthelowerlimitmark

onthedipstick,addonlyenoughoiltoraiselevel

totheupperlimitmark.

Important:Donotoverllthecrankcase.

7.Checktheengineoillevelagain.

10

8.Installtheoilllercap/dipstickandwipeupany

spilledoil.

Important:Ensurethattheengineoilisatthe

properlevel.Iftheengineoillevelisnotcorrect,

theenginewillcrankbutwillnotstart.

ServicingtheHydraulic

System

Themachineisshippedfromthefactorywithout

hydraulicuid;youmustllitwith32.9L(8.7US

gallons)ofhighqualityhydraulicuid.Checkthelevel

ofhydraulicoilbeforethemachineisrststartedand

dailythereafter.Therecommendedhydraulicuids

areasfollows:

ToroPremiumTransmission/HydraulicTractorFluid

(Availablein5gallonpailsor55gallondrums.Seeparts

catalogorT orodistributorforpartnumbers.)

Alternateuids:IftheTorouidisnotavailable,other

petroleum-basedUniversalTractorHydraulicFluids

(UTHF)maybeusedprovideditsspecicationsfall

withinthelistedrangeforallthefollowingmaterial

propertiesanditmeetsindustrystandards.Wedo

notrecommendtheuseofsyntheticuid.Consult

withyourlubricantdistributortoidentifyasatisfactory

product.

Important:Thehydraulicsystemwillnot

completelyllwithuiduntilthesystemis

poweredup.Checkthehydraulicuidleveland

adduidasnecessarytoensurethatitisatthe

correctlevelafterusingthehydraulicsystemfor

thersttime.

Note:Torowillnotassumeresponsibilityfordamage

causedbyimpropersubstitutions,souseonly

productsfromreputablemanufacturerswhowillstand

behindtheirrecommendation.

MaterialProperties:

Viscosity,ASTMD445cSt@40°C55to62

cSt@100°C9.1to9.8

ViscosityIndexASTM

D2270

140to152

PourPoint,ASTMD97-35°Fto-46°F

IndustrySpecications:

APIGL-4,AGCOPoweruid821XL,FordNewHolland

FNHA-2-C-201.00,KubotaUDT,JohnDeereJ20C,

Vickers35VQ25,andVolvoWB-101/BM

Note:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditivefor

thehydraulicsystemoilisavailablein2/3oz(20ml)

bottles.Onebottleissufcientfor15to22L(4to

6USgallons)ofhydraulicoil.Orderpartnumber

44-2500fromyourAuthorizedT oroDistributor.

FuelSafety

•Useextremecareinhandlingfuel.Itisammable

anditsvaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

•Donotaddordrainthefuelinanenclosedspace.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheaterorotherappliance.

•Ifyouspillfuel,donotattempttostarttheengine;

avoidcreatinganysourceofignitionuntilthefuel

vaporshavedissipated.

FillingtheFuelTank

FuelTankCapacity:6.1L(1.6USgallons)

RecommendedFuel:

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher(R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan10%

ethanolbyvolume,suchasE15(contains15%

ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessafuelstabilizer

isused.

•Donotaddoiltogasoline.

11

ActivatingandCharging

theBattery

Useonlyelectrolyte(1.265specicgravity)toll

batteryinitially.

1.Cleanthetopofthebatteryandremovethevent

caps(Figure21).

Important:Donotaddelectrolytewhilethe

batteryisinthemachine.Youcouldspillit,

causingcorrosion.

g001196

Figure21

1.Ventcaps

2.Carefullylleachcellwithelectrolyteuntilthe

platesarecoveredwithabout6mm(1/4inch)of

uid(Figure22).

g001197

Figure22

1.Electrolyte

3.Allowapproximately20to30minutesforthe

electrolytetosoakintotheplates.Rellas

necessarytobringtheelectrolytetowithinabout

6mm(1/4inch)ofthebottomofthellwell

(Figure22).

WARNING

Chargingthebatteryproducesgasses

thatcanexplode.

Neversmokenearthebatteryandkeep

sparksandamesawayfrombattery.

4.Connecta3to4ampbatterychargertothe

batteryposts.Chargethebatteryatarateof3

to4ampsuntilthespecicgravityis1.250or

higherandthetemperatureisatleast16°C(60°

F)withallcellsgassingfreely.

5.Whenthebatteryischarged,disconnectthe

chargerfromtheelectricaloutletandbattery

posts.

Note:Afterthebatteryhasbeenactivated,

addonlydistilledwatertoreplacenormalloss,

althoughmaintenance-freebatteriesshouldnot

requirewaterundernormaloperatingconditions.

WARNING

Batteryterminalsormetaltoolscould

shortagainstmetaltractorcomponents

causingsparks.Sparkscancausethe

batterygassestoexplode,resultingin

personalinjury.

•Whenremovingorinstallingthe

battery,donotallowthebattery

terminalstotouchanymetalpartsof

thetractor.

•Donotallowmetaltoolstoshort

betweenthebatteryterminalsand

metalpartsofthetractor.

OperatingTips

•Connecttheclevishitchtothetowvehicle.Usea

high-strengthhitchpinapprovedfortowvehicles.

•Turnonthefuelvalve,placethethrottlelever

athalfthrottle,engagethechoke,andstartthe

engine.Oncetheenginestarts,turnoffthechoke

andincreasethethrottletomaximum.

•T estthemachineoperation.Ensurethatthere

arenohydraulicleaksandmakeanyadditional

adjustments.

•Aftertestingthehydraulicsystem,checkthe

hydraulicuidandaddmoreifrequired.

Note:Ensurethatthependantandanycordsdo

notdragonthegroundduringoperation.

12

DeclarationofIncorporation

TheT oroCompany,8111LyndaleAvenueSouth,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)tothedirectiveslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsontocertain

ToromodelsasindicatedontherelevantDeclarationsofConformity.

ModelNo.SerialNo.ProductDescriptionInvoiceDescriptionGeneralDescriptionDirective

44713315000001andUpHydraulicPowerPackPROPASSHYDPOWER

PACKHydraulicPowerPack2006/42/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedT oromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:AuthorizedRepresentative:

MarcelDutrieux

ManagerEuropeanProductIntegrity

ToroEuropeNV

Nijverheidsstraat5

2260Oevel

Belgium

JohnHeckel

Sr.EngineeringManagerTel.+3216386659

8111LyndaleAve.South

Bloomington,MN55420,USA

August15,2018

EEA/UKPrivacyNotice

Toro’sUseofYourPersonalInformation

TheT oroCompany(“T oro”)respectsyourprivacy.Whenyoupurchaseourproducts,wemaycollectcertainpersonalinformationaboutyou,eitherdirectly

fromyouorthroughyourlocalTorocompanyordealer.T orousesthisinformationtofullcontractualobligations-suchastoregisteryourwarranty,

processyourwarrantyclaimortocontactyouintheeventofaproductrecall-andforlegitimatebusinesspurposes-suchastogaugecustomer

satisfaction,improveourproductsorprovideyouwithproductinformationwhichmaybeofinterest.T oromayshareyourinformationwithoursubsidiaries,

afliates,dealersorotherbusinesspartnersinconnectiontheseactivities.Wemayalsodisclosepersonalinformationwhenrequiredbylaworin

connectionwiththesale,purchaseormergerofabusiness.Wewillneversellyourpersonalinformationtoanyothercompanyformarketingpurposes.

RetentionofyourPersonalInformation

Torowillkeepyourpersonalinformationaslongasitisrelevantfortheabovepurposesandinaccordancewithlegalrequirements.Formoreinformation

aboutapplicableretentionperiodspleasecontact[email protected].

Toro’sCommitmenttoSecurity

YourpersonalinformationmaybeprocessedintheUSoranothercountrywhichmayhavelessstrictdataprotectionlawsthanyourcountryofresidence.

Wheneverwetransferyourinformationoutsideofyourcountryofresidence,wewilltakelegallyrequiredstepstoensurethatappropriatesafeguardsare

inplacetoprotectyourinformationandtomakesureitistreatedsecurely.

AccessandCorrection

Youmayhavetherighttocorrectorreviewyourpersonaldata,orobjecttoorrestricttheprocessingofyourdata.Todoso,pleasecontactusbyemail

at[email protected].IfyouhaveconcernsaboutthewayinwhichT orohashandledyourinformation,weencourageyoutoraisethisdirectlywithus.

PleasenotethatEuropeanresidentshavetherighttocomplaintoyourDataProtectionAuthority.

374-0282RevC

CaliforniaProposition65WarningInformation

Whatisthiswarning?

Youmayseeaproductforsalethathasawarninglabellikethefollowing:

WARNING:CancerandReproductiveHarm—www.p65Warnings.ca.gov.

WhatisProp65?

Prop65appliestoanycompanyoperatinginCalifornia,sellingproductsinCalifornia,ormanufacturingproductsthatmaybesoldinorbroughtinto

California.ItmandatesthattheGovernorofCaliforniamaintainandpublishalistofchemicalsknowntocausecancer,birthdefects,and/orother

reproductiveharm.Thelist,whichisupdatedannually,includeshundredsofchemicalsfoundinmanyeverydayitems.ThepurposeofProp65isto

informthepublicaboutexposuretothesechemicals.

Prop65doesnotbanthesaleofproductscontainingthesechemicalsbutinsteadrequireswarningsonanyproduct,productpackaging,orliteraturewith

theproduct.Moreover,aProp65warningdoesnotmeanthataproductisinviolationofanyproductsafetystandardsorrequirements.Infact,the

CaliforniagovernmenthasclariedthataProp65warning“isnotthesameasaregulatorydecisionthataproductis‘safe’or‘unsafe.’”Manyofthese

chemicalshavebeenusedineverydayproductsforyearswithoutdocumentedharm.Formoreinformation,gotohttps://oag.ca.gov/prop65/faqs-view-all.

AProp65warningmeansthatacompanyhaseither(1)evaluatedtheexposureandhasconcludedthatitexceedsthe“nosignicantrisklevel”;or(2)

haschosentoprovideawarningbasedonitsunderstandingaboutthepresenceofalistedchemicalwithoutattemptingtoevaluatetheexposure.

Doesthislawapplyeverywhere?

Prop65warningsarerequiredunderCalifornialawonly.ThesewarningsareseenthroughoutCaliforniainawiderangeofsettings,includingbutnot

limitedtorestaurants,grocerystores,hotels,schools,andhospitals,andonawidevarietyofproducts.Additionally,someonlineandmailorder

retailersprovideProp65warningsontheirwebsitesorincatalogs.

HowdotheCaliforniawarningscomparetofederallimits?

Prop65standardsareoftenmorestringentthanfederalandinternationalstandards.TherearevarioussubstancesthatrequireaProp65warning

atlevelsthatarefarlowerthanfederalactionlimits.Forexample,theProp65standardforwarningsforleadis0.5μg/day,whichiswellbelow

thefederalandinternationalstandards.

Whydon’tallsimilarproductscarrythewarning?

•ProductssoldinCaliforniarequireProp65labellingwhilesimilarproductssoldelsewheredonot.

•AcompanyinvolvedinaProp65lawsuitreachingasettlementmayberequiredtouseProp65warningsforitsproducts,butothercompanies

makingsimilarproductsmayhavenosuchrequirement.

•TheenforcementofProp65isinconsistent.

•CompaniesmayelectnottoprovidewarningsbecausetheyconcludethattheyarenotrequiredtodosounderProp65;alackofwarningsfora

productdoesnotmeanthattheproductisfreeoflistedchemicalsatsimilarlevels.

WhydoesToroincludethiswarning?

Torohaschosentoprovideconsumerswithasmuchinformationaspossiblesothattheycanmakeinformeddecisionsabouttheproductstheybuyand

use.T oroprovideswarningsincertaincasesbasedonitsknowledgeofthepresenceofoneormorelistedchemicalswithoutevaluatingthelevelof

exposure,asnotallthelistedchemicalsprovideexposurelimitrequirements.WhiletheexposurefromT oroproductsmaybenegligibleorwellwithinthe

“nosignicantrisk”range,outofanabundanceofcaution,T orohaselectedtoprovidetheProp65warnings.Moreover,ifT orodoesnotprovidethese

warnings,itcouldbesuedbytheStateofCaliforniaorbyprivatepartiesseekingtoenforceProp65andsubjecttosubstantialpenalties.

RevA

ToroGeneralCommercialProductWarranty

ATwo-YearLimitedWarranty

ConditionsandProductsCovered

TheT oroCompanyanditsafliate,T oroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

8111LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:[email protected]

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-T oro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto,brakepadsand

linings,clutchlinings,blades,reels,rollersandbearings(sealedor

greasable),bedknives,sparkplugs,castorwheelsandbearings,tires,

lters,belts,andcertainsprayercomponentssuchasdiaphragms,

nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecalsor

windows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.T orowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.T oromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedT oroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EPA)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheToroimporter.374-0253RevC

Table of contents

Other Toro Power Pack manuals