Toro 41569 User manual

All Rights Reserved

Printed in the USA

1

2002 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

Hose Reel Kit

Multi-Pro5600 Sprayer

Model No. 41569

Form No. 3328-916

Installation Instructions

Installation

Note: Determine the left and right sides of the machine from the normal operating position.

Note: For an electrical schematic and flow diagram, refer to the Parts Catalog.

Note: You will need to purchase Teflon tape before installing this kit.

Description Qty. Use

Hose reel support

Flange-head bolt, 3/8 x 1 inch

Flange nut, 3/8 inch

Hose reel strap

Hose reel assembly

Flange-head bolt, 5/16 x 1 inch

Flange nut, 5/16 inch

1

10

10

2

1

1

1

Assemble the frame.

Control box support bracket

Flange-head bolt, 1/2 x 1/2 inch

Flange nut, 1/2 inch

Control valve assembly

S53 tee fitting

Plastic hose clamp, large (1 inch)

Plastic hose clamp, small (1/2 inch)

Control box mounting bracket

Flange-head bolt, 5/16 x 3/4 inch

Flange nut, 5/16 inch

Ball valve assembly

Flange-head bolt, 1/4 x 3/4 inch

Flange nut, 1/4 inch

Rubber trim piece

Short hose, 1/2 inch dia

Plastic barbed fitting, 1/2 inch

1

1

1

1

2

4

6

1

2

2

1

4

2

1

3

1

Install the flow control box.

2

Description UseQty.

Pressure gauge

Reducer fitting and nut

Plastic fitting, small

Control box cover

Silver fitting, small

Red tubing

Toggle switch

Momentary switch

Rear control box wire harness

Fuse, 10 amp

Switch wire cover

Flange-head bolt, 1/4 x 3/4 inch

Flange nut, 1/4 inch

Knob

1

1

1

1

1

1

1

1

1

1

1

9

4

1

Install the switches, gauge, and cover

Long hose with fitting, 1/2 inch dia

Spray gun

Plastic hose clamp, small (one extra one

included)

1

1

2Connect the spray hose

Preparing the Machine

1. Ensure that the machine is empty of all fluids. If

chemicals have been used in the machine, flush the

system thoroughly with clean water then drain the

water; refer to your vehicle Operator’s Manual for

instructions.

2. Disconnect the negative battery terminal from the

battery.

3. On the tank saddle on the right side of the machine,

locate the third hole from the front of the machine.

Measure and mark a location on the tank saddle

2 inches (5 cm) behind the center of the 3rd hole

(Fig. 1).

Note: If a hole already exists at this location, skip to the

Assembling the Frame section.

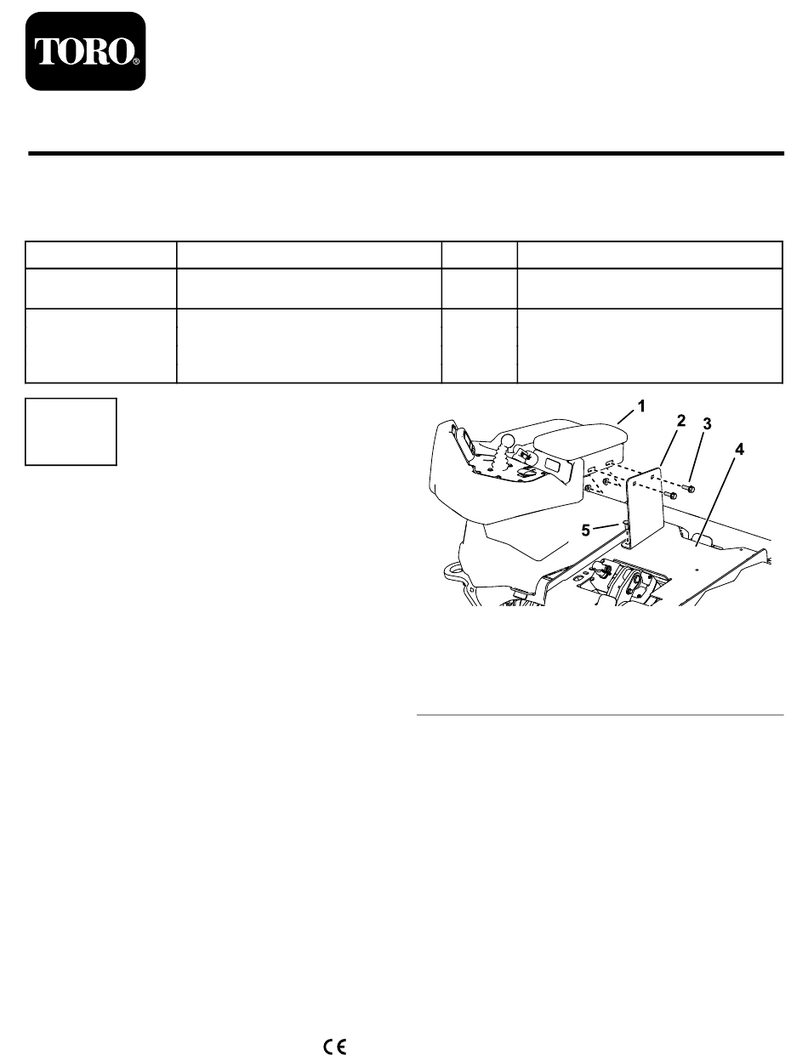

m-6343

1

2

Figure 1

1. 2 inches 2. 10 inches

4. From your mark, measure 10 inches (25 cm) rearward

and mark that location (Fig. 1).

5. Drill 2 holes (7/16 inch dia) at the marked locations,

centered vertically in the tank saddle (Fig. 1).

3

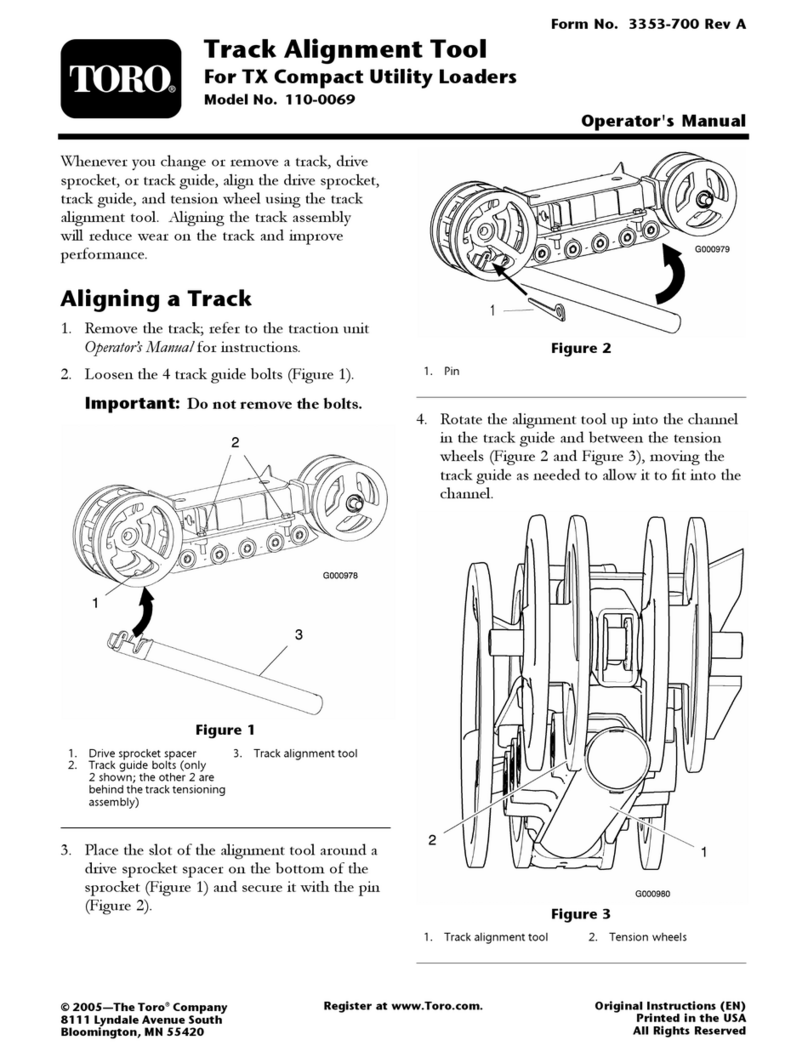

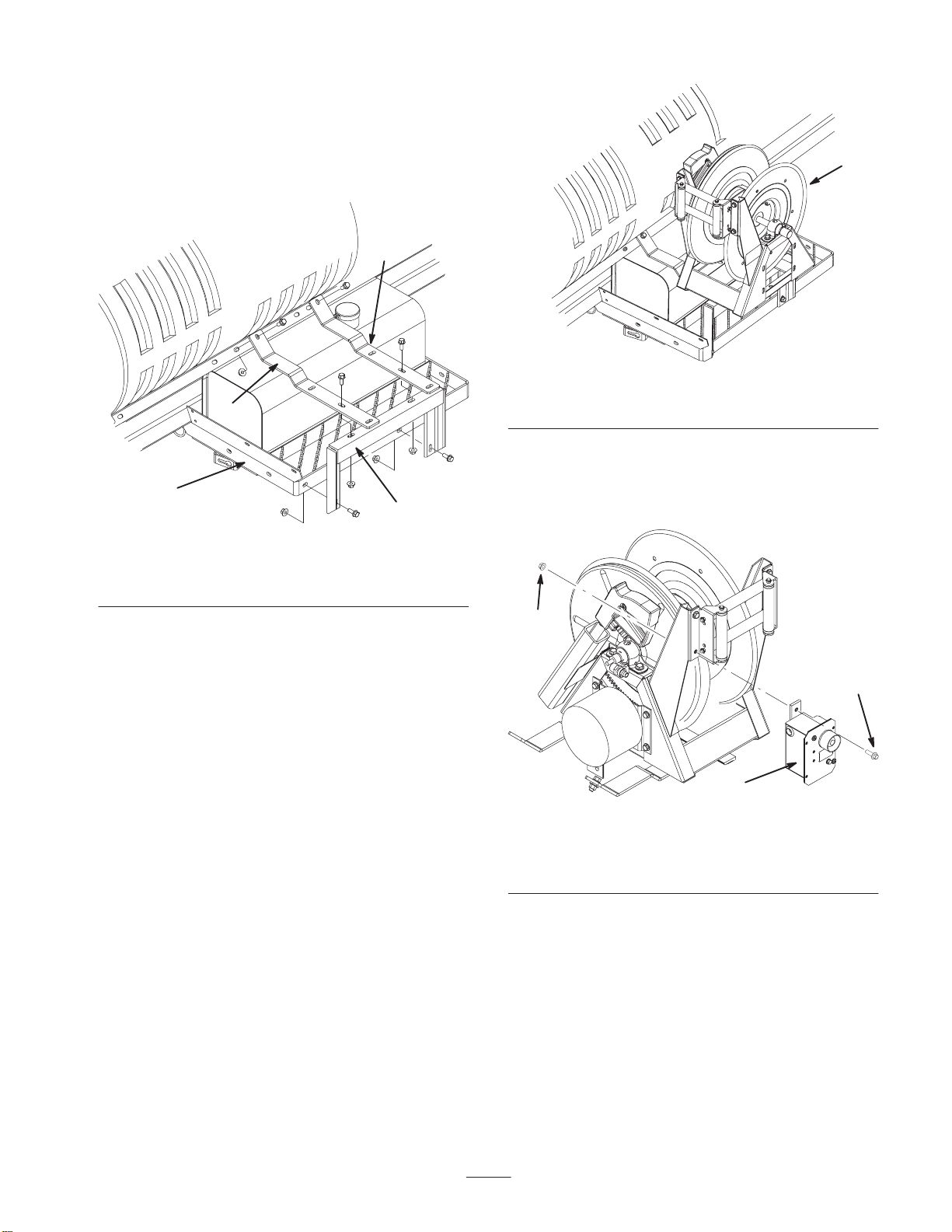

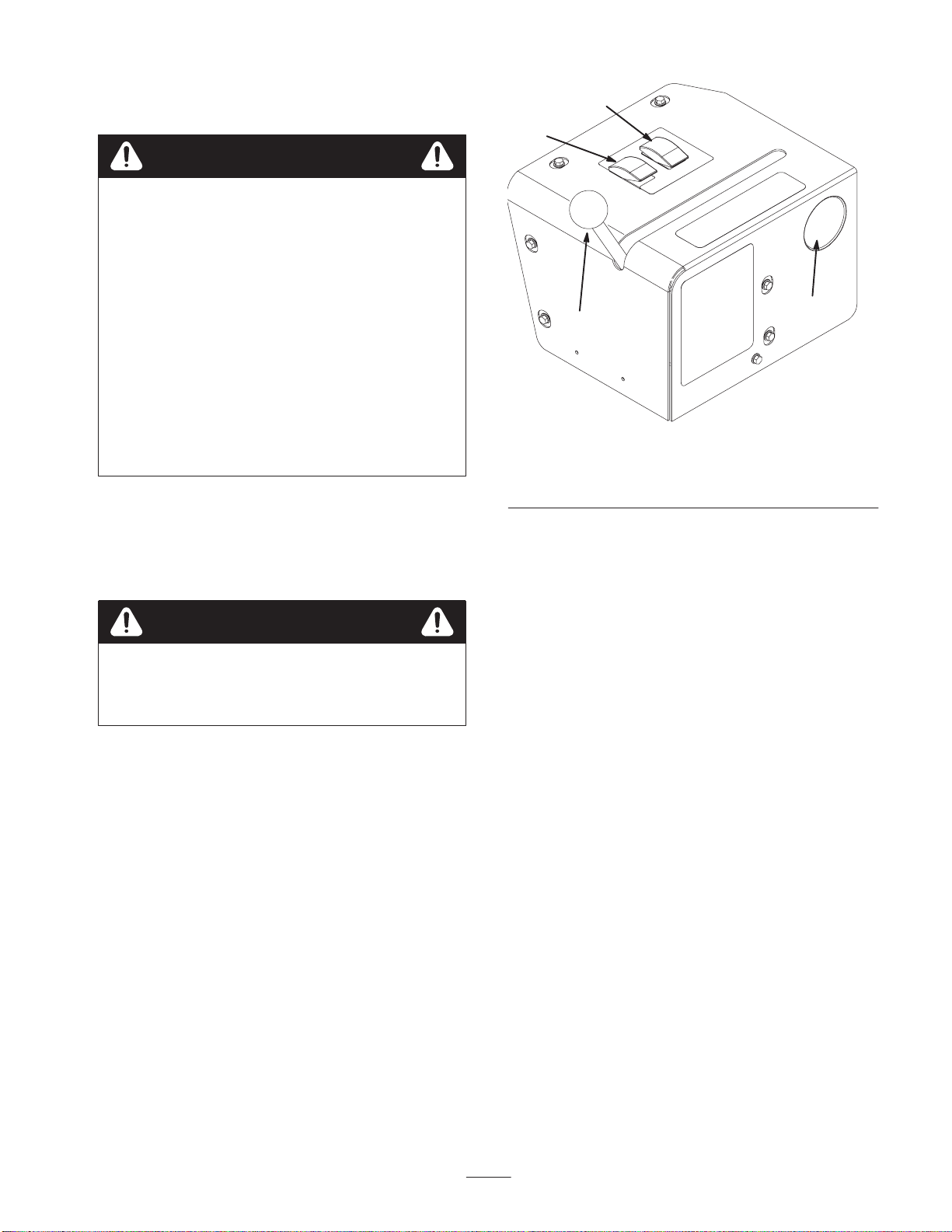

Assembling the Frame

1. Install the hose reel support to the hydraulic reservoir

mount (Fig. 2) using 2 flange-head bolts (3/8 x 1 inch)

and 2 flange nuts (3/8 inch). Do not fully tighten the

nuts to allow for adjustment later.

m–6349 1

2

3

3

Figure 2

1. Hose reel support

2. Hydraulic reservoir mount 3. Hose reel straps

2. Install the ends of the 2 hose reel straps to holes in the

tank saddle that you located and/or drilled earlier

(Fig. 2) using 2 flange-head bolts (3/8 x 1 inch) and

2 flange nuts (3/8 inch).

3. Attach the hose reel support to the hose reel straps

(Fig. 2) using 2 flange-head bolts (3/8 x 1 inch) and

2 flange nuts (3/8 inch).

4. Level the straps and hose reel support and then tighten

all fasteners.

5. Install the hose reel assembly onto the hose reel straps

(Fig. 3) using 4 flange-head bolts (3/8 x 1 inch) and

4 flange nuts (3/8 inch).

m-6350

1

Figure 3

1. Hose reel assembly

6. Remove and discard the bolt and nut from the lower

inside roller support on the hose reel and install the

electrical box in that hole (Fig. 4), using a flange-head

bolt (5/16 x 1 inch) and a flange nut (5/16 inch).

m–6351 1

3

2

Figure 4

1. Electrical box

2. Flange-head bolt,

5/16 x 1 inch

3. Flange nut, 5/16 inch

7. Route the hose reel ground wire (plain black wire with

an eye-ring coming from the hose reel motor) behind

the hydraulic tank and forward around the frame.

8. Connect the end of the ground wire to the battery

grounding stud on the machine, located behind the

battery box and passenger seat, under the frame (Fig. 5).

4

m–6398

1

2

Figure 5

1. Ground wire 2. Grounding stud

9. Route the power wire from the electrical box, behind

the saddle supports, and under the seat box to the area

under the driver’s seat.

10.Connect the power wire to the solenoid under the

driver’s seat (Fig. 6).

m–6352

1

2

Figure 6

1. Power wire from the electrical box on the hose reel.

2. Solenoid

Installing the Flow Control Box

Preparing the Machine

Prepare/install the mounting post as follows:

•If you have a standard boom on your machine, drill one

hole (11/32 inch dia) in the right-side boom holder,

3-5/8 inches (9.2 cm) above the center of the lowest

hole (Fig. 7).

Note: Check the position of the right boom holder. It

should be installed as far down in the mounting slots as

possible. If it is not, loosen the mounting fasteners,

slide it down, and tighten the fasteners.

m–6353

1

3-5/8 inches (9.2 cm)

2

Figure 7

1. Right boom holder 2. Drill this hole,

11/32 inch dia

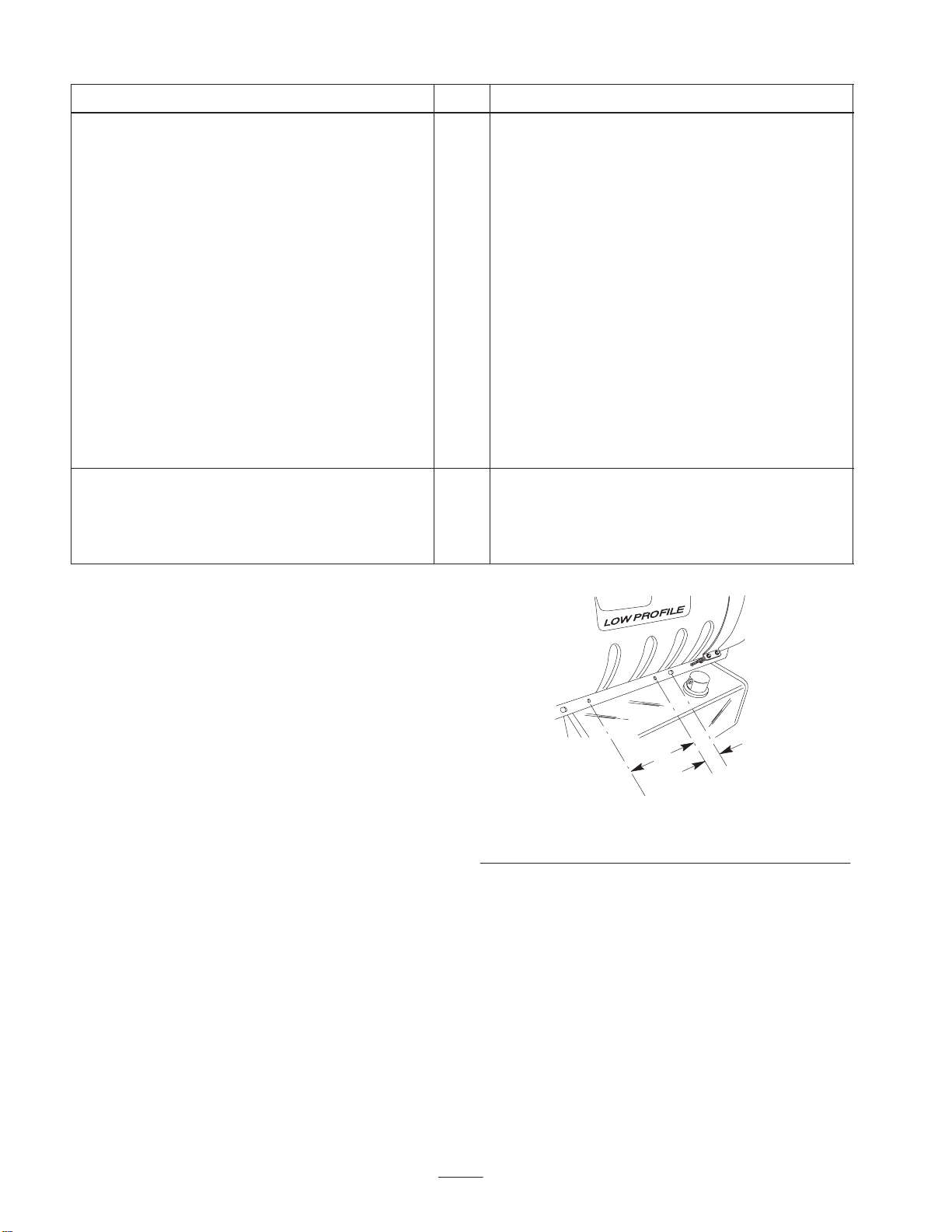

•If you have the covered booms or do not have booms,

install the control box support bracket to the right rear

boom frame (Fig. 8) using existing hardware and a

flange-head bolt (1/2 x 1/2 inch) and a flange nut

(1/2 inch).

m–6354

1

4

3

2

3

5

Figure 8

1. Control box support

bracket

2. Right rear boom frame

3. Existing hardware

4. Flange-head bolt,

1/2 x 1/2 inch

5. Flange nut, 1/2 inch

5

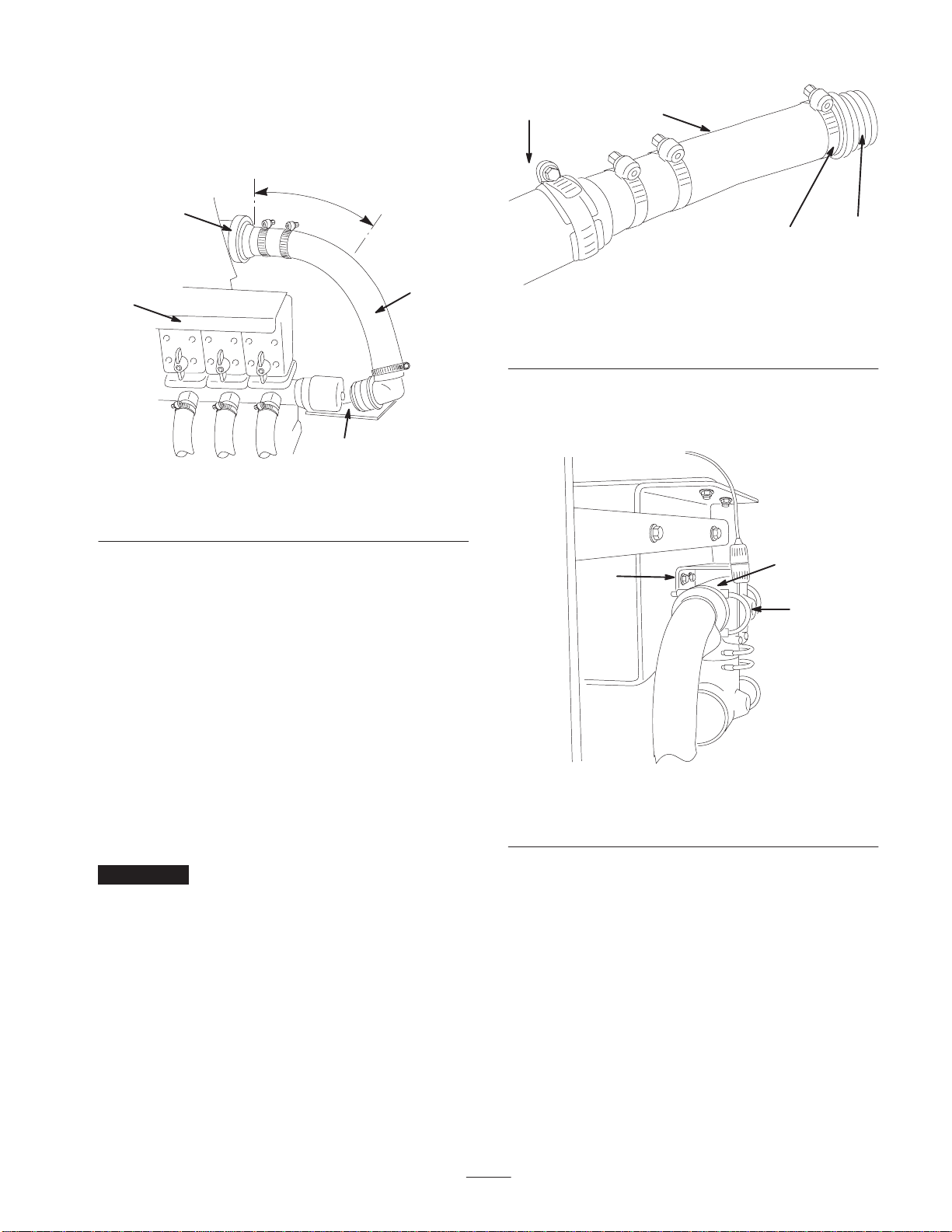

Tapping into the Machine Hoses

1. Remove the retainer securing the end of the boom

supply hose connected to the tee located to the right of

the boom supply valves and disconnect it (Fig. 9).

m–6356

12

3

8 inches (20 cm)

4

Figure 9

1. Boom supply valves

2. Boom supply hose 3. Disconnect here

4. Flow meter

2. Cut the boom supply hose 8 inches (20 cm) to the right

of the flow meter (if equipped) or 32 inches (81 cm)

from the supply tee (located directly behind the boom

valves) using a hacksaw (Fig. 9). Remove the hose

clamp from the loose end and discard the hose and

fitting.

3. Remove the barbed fitting and retainer from the control

valve assembly (Fig. 14).

4. Apply a liberal amount of liquid soap to the barb of the

fitting and to the inside of the hose coming from the

flow meter or supply tee as applicable.

5. Slide a large ratcheting hose clamp (removed from the

hose in step 2) over the hose and install the fitting all

the way into the hose, securing it with the hose clamp

(Fig. 10).

Important The fitting may be very difficult to push

into the hose. It is very important, however, that you get it

all the way into the hose, ensuring that it will not leak. You

may need to remove the hose from the machine at the flow

meter.

m–6375

1

23

4

Figure 10

1. Hose

2. Ratcheting hose clamp 3. Fitting

4. Flow divider

6. Remove the fasteners securing the tee behind the boom

supply valve so that the tee will drop down, hanging on

the hoses (Fig. 11).

m–6376

21

3

Figure 11

1. Tee behind boom supply

valves 2. Fasteners

3. Port (drill hole here)

7. Carefully drill a hole (1/4 inch dia) in the face of the

port on the back of the tee (Fig. 11).

8. Replace the tee on the back of the boom supply valves,

securing it with the fasteners you removed previously.

6

9. Cut the by-pass hose half way between the boom valves

and the tank (Fig. 12).

m–6380

1

2

3

3

Figure 12

1. By-pass hose

2. Agitation hose 3. S53 tee fitting

10.Using liquid soap on the barbs, insert an S53 tee fitting

assembly into the break and secure it using 2 large,

plastic hose clamps (Fig. 12).

11. Cut the agitation supply hose in half (Fig. 12).

12.Using liquid soap on the barbs, insert an S53 tee fitting

assembly into the break and secure it using 2 large,

plastic hose clamps (Fig. 12).

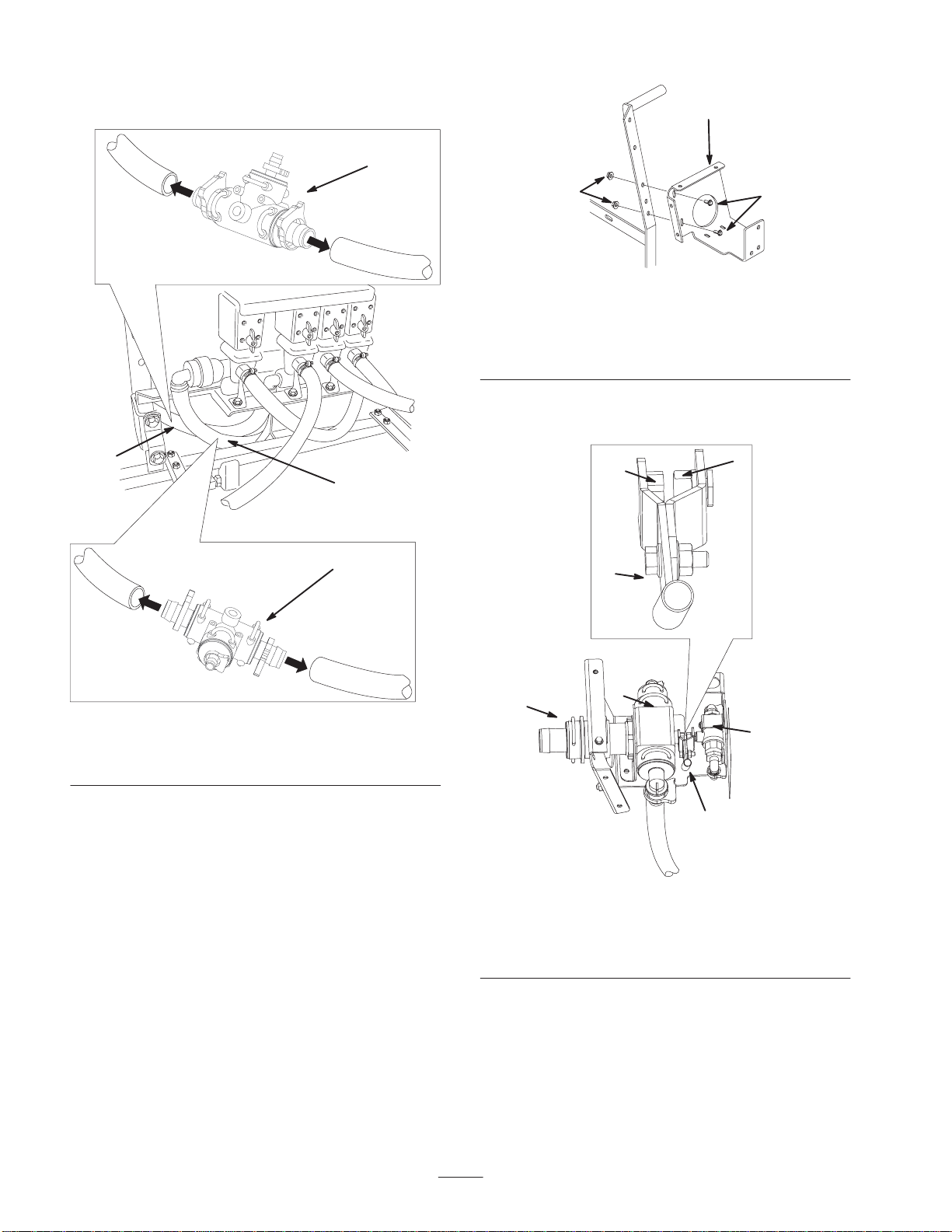

Installing the Control Valves

1. Install the control box mounting bracket to the boom

holder or control box support bracket as appropriate

(Fig. 13) using 2 flange-head bolts (5/16 x 3/4 inch) and

2 flange nuts (5/16 inch).

m–6355

2

1

2

Figure 13

1. Control box mounting

bracket

2. Flange-head bolt,

5/16 x 3/4 inch

3. Flange nut, 5/16 inch

2. Connect the end of the lever assembly on the small ball

valve assembly to the control valve assembly (Fig. 14).

m–6382

1

3

55

4

4

2

Figure 14

1. Control valve assembly

2. Fitting and retainer

3. Small ball valve assembly

4. Lever assembly

5. Axis of the lever

assembly

7

3. Connect the fitting you installed into the boom supply

hose to the control valve assembly, securing it with the

retainer you removed previously (Fig. 15).

m–6383

1

2

4

3

5

Figure 15

1. Connect the boom supply

hose to the control valve

assembly here.

2. Control valve assembly

3. Large hose

4. Connect the large hose

from the control valve

assembly to the boom

supply valves here.

5. Rubber trim

4. Install the control valve assembly onto the control box

mounting bracket (Fig. 14) using 2 flange-head bolts

(1/4 x 3/4 inch) but do not tighten the fasteners.

5. Install the small ball valve assembly to the control box

mounting bracket (Fig. 14) using 2 flange-head bolts

(1/4 x 3/4 inch) and 2 flange nuts (1/4 inch) but do not

tighten the fasteners.

6. Align the axis of the levers on each valve and the valves

(Fig. 14) You may need to loosen the hose clamps

securing the flow meter to the machine to get

everything to fit well.

7. Tighten all hardware.

8. Connect the fitting on the large hose on the control

valve assembly to the fitting on the right side of the

boom supply valves (Fig. 15).

9. Disconnect the large hose from the control valve and

look inside the valve (Fig. 15). You should see an

opening in the check ball curving up. If not, rotate the

ball until the opening is fully visible and it curves up.

10.Connect the large hose to the control valve (Fig. 15).

11. Place the rubber trim piece over the frame edge to

protect the hose (Fig. 15).

12.Connect the end of a short 1/2 inch hose to the open

fitting on the S53 tee that you installed into the agitation

hose and route it to the rear 1/2 inch barb on the small

ball valve assembly (Fig. 16).

m–6384

2

1

3

Figure 16

1. Right side of the control

box mounting bracket 2. From agitation hose

3. From by-pass hose

13.Cut the hose to the appropriate length to remove excess

slack and then connect the hose to the rear fitting.

14.Secure the hose to the fittings using 2 small plastic hose

clamps.

15.Connect the end of a short 1/2 inch hose to the open

fitting on the S53 tee that you installed into the by-pass

hose and route it to the front 1/2 inch barb on the small

ball valve assembly (Fig. 16).

16.Cut the hose to the appropriate length to remove excess

slack and then connect the hose to the front fitting.

17.Secure the hose to the fittings using 2 small plastic hose

clamps.

18.Wrap Teflon tape counterclockwise around the threads

of a barbed fitting (1/2 inch) and install it into the inlet

port on the side of the hose reel (Fig. 17).

m–6385

12

3

Figure 17

1. Inlet port

2. Barbed fitting, 1/2 inch 3. Hose

8

19.Connect a 1/2 inch hose to the open fitting on the

control valve assembly (Fig. 18).

m–6386

1

2

Figure 18

1. Control valve assembly 2. Hose

20.Connect the end of the hose to the fitting on the hose

reel (Fig. 17) and secure both ends with 2 small plastic

hose clamps.

Installing the Control Switches and

Pressure Gauge

1. Wrap Teflon tape counterclockwise around the threads

of the gauge and install the reducer fitting onto the

gauge (Fig. 19).

m–6387

1

2

3

4

5

Figure 19

1. Pressure gauge

2. Bracket (inside of the

control box cover)

3. Nut

4. Reducer fitting

5. Black plastic fitting

2. Install the black plastic fitting into the reducer fitting on

the gauge (Fig. 19).

3. Install the pressure gauge into the bracket under the

circular opening inside the control box cover, securing

it with the nut packaged with it (Fig. 19).

Note: The face of the gauge must face the circular opening

of the cover.

4. Wrap Teflon tape counterclockwise around the threads

of the small silver fitting that is packaged with the red

tubing and install it into the port you drilled out on the

tee in front of the boom valves (Fig. 11).

5. Install the two switches into the rectangular holes on the

top of the cover (Fig. 20). Install the momentary switch

(switch that does not stay in either position when you

are not pressing it) into the hole marked with the

continuous variable and plus (+) and minus (–) signs.

Note: The small square hole on the bottom of the switches

should be oriented toward the long slot in the cover.

m–6388

1

23

Figure 20

1. Control box cover

2. Toggle switch 3. Momentary switch

9

6. Disconnect the connectors under the dash between the

manual control box and the spray harness (Fig. 21).

m–6389

1

3

2

Figure 21

1. Existing manual control

box harness

2. Spray harness

3. T-end of the new, rear

control box harness

m–6399 1

23

4

Figure 22

1. Rear control box harness

2. T-end

3. Middle lead with eye-ring

connector and spade

connector.

4. Switch connectors

7. Connect the T-end of the new rear control box harness

between the manual control box harness and the spray

harness (Fig. 21 and 22).

8. Route the rear control box harness through the dash,

under the vehicle, through the wire harness rings, and

back to the control box (Fig. 23 and 24).

m–6394

1

Figure 23

1. Wire harness rings

m–6395

1

1

Figure 24

1. Rear control box harness routed to the control box area

9. Route the middle lead into the engine compartment and

along the front of the engine through the cable guides

securing the main wire harness.

10

10.Connect the middle lead with the spade connector to the

open lead on the fuse box under the driver’s seat

(Fig. 22 and 25).

m–6396

1

2

3

4

Figure 25

1. Middle lead with a spade

connector

2. Open position on the fuse

block

3. Middle lead with an

eye-ring connector

4. Ground terminal block

11. If necessary, install a 10 amp fuse in the position where

you connected the wire.

12.Connect the middle lead with the eye ring connector to

a ground stud on the ground terminal block (Fig. 25).

13.Connect the connector with mostly green and yellow

wires to the spray selection switch (toggle style switch)

(Fig. 26).

m–6397

2

1

4

3

Figure 26

1. Spray selection switch

2. Connector with mostly

green and yellow wires

3. Rate control switch

4. Connector with

multi-colored wires

14.Connect the connector with the multi-colored wires to

the rate control switch (momentary switch) (Fig. 26).

15.Install the switch wire cover over the switches and

around the wires (Fig. 27) and secure it with

4 flange-head bolts (1/4 x 3/4 inch) and 4 flange nuts

(1/4 inch).

m–6391

1

2

Figure 27

1. Switch wire cover 2. Wire harness

16.Connect the small red tube to the silver fitting you

installed in step 4 and the other end to the fitting on the

bottom of the pressure gauge.

17.Install the control box cover to the control box

mounting bracket (Fig. 28), using 5 flange-head bolts

(1/4 x 3/4 inch).

m–6390

2

2

1

3

2

Figure 28

1. Control box cover

2. Flange-head bolt,

1/4 x 3/4 inch

3. Knob

18.Install the knob onto the valve control lever (Fig. 28).

11

Connecting the Spray Hose

1. Wrap Teflon tape counterclockwise around the threads

of the hose fitting on the long hose and install the fitting

into the connecting tube on the reel (Fig. 29).

m–6393

Figure 29

2. Connect the free end of the long hose to the fitting on

the gun (Fig. 30).

m–6392

2

3

1

Figure 30

1. Spray gun

2. Hose fitting 3. Hose

3. Secure the end of the hose with a small plastic hose

clamp.

4. Connect the negative battery wire to the battery and

turn the ignition key to the Run position.

5. Press the hose wind button and carefully guide the hose

onto the reel.

Hands, loose clothing, long hair, and jewelry could

get caught in the hose and reel while rewinding

and cause injury.

•Keep your hands clear of the reel and hose while

it is rewinding.

•Do not wear loose clothing or jewelry and tie up

long hair.

Caution

Safety Instructions

Improper use or maintenance by the operator or owner

can result in injury. To reduce the potential for injury,

comply with these safety instructions and always pay

attention to the safety alert symbol, which means

CAUTION, WARNING, or DANGER—“personal

safety instruction.” Failure to comply with the

instruction may result in personal injury or death.

Read also the safety and operation instructions in the

vehicle Operator’s Manual.

•Do not aim the hand sprayer at any person or animal.

Fluids under high pressure can penetrate skin and cause

severe injury, possibly resulting in amputation or death.

Hot liquids and chemicals can also cause burns or

injury. If any part of the body comes in contact with the

spray stream, immediately consult a physician familiar

with injected fluid injuries.

•Do not place your hand or any other part of you body in

front of the spray nozzle.

•Do not leave the equipment under pressure when you

are not present.

•Do not use the hand sprayer if the hose, trigger lock,

nozzle, or any other part is damaged or missing.

•Do not use the hand sprayer if there are any leaks in any

hoses, fittings, or other components.

•Do not spray near power lines.

•Do not drive while spraying with a hand sprayer.

•Wear rubber gloves, safety goggles, and a full body

protective suit when spraying chemicals with the hand

sprayer.

12

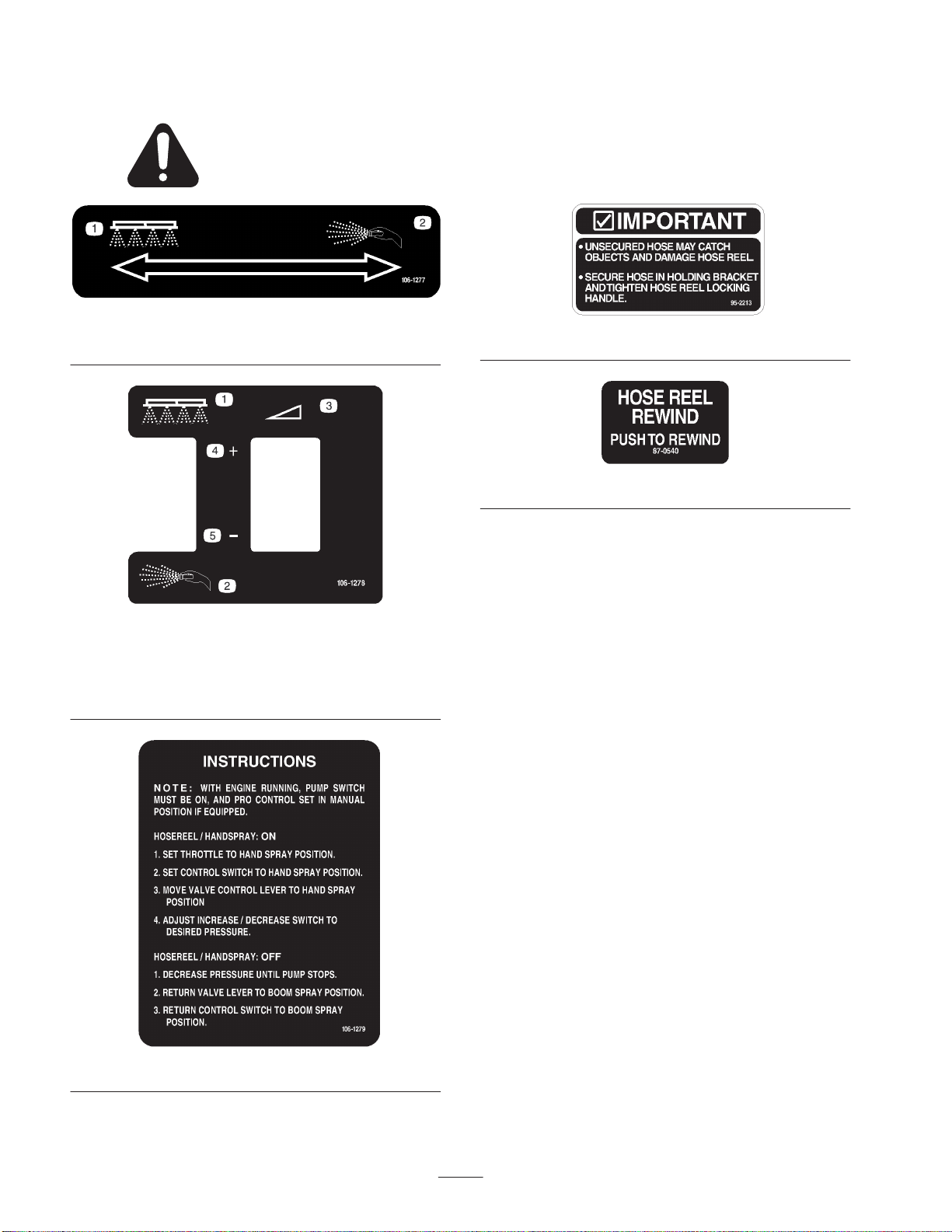

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near any area

of potential danger. Replace any decal that is damaged or lost.

106-1277

1. Boom spray 2. Hand spray

106-1278

1. Boom spray

2. Hand spray

3. Continuous variable

setting

4. Increase

5. Decrease

106-1279

95-2213

87-0540

13

Operation

Fluid under pressure can penetrate skin and cause

injury.

•Keep your body and hands away from nozzles

that eject high pressure fluid.

•Do not aim the sprayer at any person or animal.

•Make sure all fluid hoses and lines are in good

condition and all connections and fittings are

tight before applying pressure to the system.

•Use cardboard or paper to find leaks.

•Safely relieve all pressure in the system before

performing any work on it.

•Get immediate medical help if fluid is injected

into skin.

•Hot liquids and chemicals can cause burns or

other harm.

Warning

Switching from Boom Spray

Mode to Hand Spray Mode

1. Stop the machine and set the parking brake.

Driving while using the hand sprayer can cause

loss of control, resulting in injury or death. Do not

operate the hand sprayer while driving.

Warning

2. Ensure that the pump switch is on and the pro control

(if applicable) is set in the manual position.

3. Set the throttle to the hand spray position.

4. Ensure that the trigger lock on the spray gun is locked.

5. Set the spray selection switch to the hand spray position

(Fig. 31).

m–6404

1

2

34

Figure 31

1. Spray selection switch

2. Rate control switch 3. Valve control lever

4. Pressure gauge

6. Move the valve control lever forward to the hand spray

position (Fig. 31).

7. Adjust the rate control switch to increase or decrease

the pressure, as read on the pressure gauge, to the

desired setting (Fig. 31).

Note: The maximum pressure is 150 psi.

Spraying with the Hand

Sprayer

1. Pull out the desired amount of hose from the reel.

2. Release the trigger lock.

3. Direct the spray gun nozzle at the area to be sprayed

and pull the trigger.

4. Release the trigger and set the trigger lock when

finished.

Switching from Hand Spray

Mode to Boom Spray Mode

1. Press the rewind button on the hose reel until only a few

feet of hose is out of the reel.

14

Hands, loose clothing, long hair, and jewelry could

get caught in the hose and reel while rewinding

and cause injury.

•Keep your hands clear of the reel and hose while

it is rewinding.

•Do not wear loose clothing or jewelry and tie up

long hair.

Caution

2. Press the rate control switch to reduce the pressure until

the pump stops.

3. Move the valve lever rearward to the boom spray

position.

4. Direct the spray gun nozzle at an area where it is safe to

spray, release the trigger lock, and pull the trigger until

all remaining fluid is out of the hose, then set the trigger

lock.

5. Set the spray selection switch to the boom spray

position.

6. Return the spray gun to the holder on the back of the

reel.

15

Table of contents

Other Toro Tools manuals