Toro 5 User manual

Operator’s Manual

Domestic English (EN)

Form No. 3323-831 Rev A

5, 7 and 11 Blade Reels

for Reelmaster5500 & 6000 Series

03860—200000001 & Up

03861—200000001 & Up

03862—200000001 & Up

The Toro Company – 1999

Printed in USA All Rights Reserved

Introduction

Thank you for purchasing a Toro product.

All of us at Toro want you to be completely satisfied

with your new product, so feel free to contact your

local Authorized Service Dealer for help with service,

genuine Toro replacement parts, or other information

you may require.

Whenever you contact your Authorized Service

Dealer or the factory, always know the model and

serial numbers of your product. These numbers will

help the Service Dealer or Service Representative

provide exact information about your specific

product. You will find the model and serial number

plate located in a unique place on the product as

shown below.

1

1. Modeland Serial Number Plate

For your convenience, write the product model and

serial numbers in the space below.

Model No:

Serial No.

Read this manual carefully to learn how to operate

and maintain your product correctly. Reading this

manual will help you and others avoid personal injury

and damage to the product. Although Toro designs,

produces and markets safe, state-of-the-art products,

you are responsible for using the product properly

and safely. You are also responsible for training

persons who you allow to use the product about safe

operation.

The Toro warning system in this manual identifies

potential hazards and has special safety messages that

help you and others avoid personal injury, even death.

DANGER, WARNING and CAUTION are signal

words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

DANGER signals an extreme hazard that will cause

serious injury or death if the recommended

precautions are not followed.

WARNING signals a hazard that may cause serious

injury or death if the recommended precautions are

not followed.

CAUTION signals a hazard that may cause minor or

moderate injury if the recommended precautions are

not followed.

Two other words are also used to highlight

information. “Important” calls attention to special

mechanical information and “Note” emphasizes

general information worthy of special attention.

The left and right side of the cutting unit is

determined by standing with the rear roller nearest

you.

1

Contents

Page

Safety 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safe Operating Practices 2. . . . . . . . . . . . . .

Safety and Instruction Decals 3. . . . . . . . . . .

Specifications 4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Set–Up 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loose Parts 5. . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 5. . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting Front Shield 5. . . . . . . . . . . . . . . .

Adjusting Rear Shield 5. . . . . . . . . . . . . . . .

Adjusting Turf Compensation Spring 6. . . .

Setting Height-of-Cut 7. . . . . . . . . . . . . . . . . . . .

A. Adjusting (Parallel) Bedknife to Reel 7. .

B. Setting Cutting Unit Attitude 9. . . . . . . .

C. Leveling Front Roller 13. . . . . . . . . . . . . .

D. Finalizing Height-of-Cut 14. . . . . . . . . . . .

Page

Maintenance 15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Backlapping Reelmaster 5500

Traction Units 15. . . . . . . . . . . . . . . . . . . . .

Backlapping Reelmaster 6000

Traction Units 17. . . . . . . . . . . . . . . . . . . . .

Lubrication 19. . . . . . . . . . . . . . . . . . . . . . . . .

SPA (Single Point Adjustment) Spring

Adjustment 20. . . . . . . . . . . . . . . . . . . . . . .

2

Safety

Safe Operating Practices

•Read, understand, and follow all instructions in

the traction unit operator’s manual before

operating the cutting unit.

•Read, understand, and follow all instructions in

this operator’s manual before operating the

cutting unit.

•Never allow children to operate the cutting units.

Do not allow adults to operate traction unit or

cutting units without proper instruction. Only

trained operators who have read this manual

should operate the cutting units.

•Never operate the cutting units when under the

influence of drugs or alcohol.

•Keep all shields and safety devices in place. If a

shield, safety device or decal is illegible or

damaged, repair or replace it before operation is

commenced. Also tighten any loose nuts, bolts,

and screws to ensure cutting unit is in safe

operating condition.

•Always wear substantial shoes. Do not operate

cutting unit while wearing sandals, tennis shoes,

sneakers or shorts. Also, do not wear loose

fitting clothing which could get caught in

moving parts. Always wear long pants and

substantial shoes. Wearing safety glasses, safety

shoes and a helmet is advisable and required by

some local ordinances and insurance regulations.

•Remove all debris or other objects that might be

picked up and thrown by the cutting unit reel

blades. Keep all bystanders away from the

mowing area.

•If the cutting blades strike a solid object or the

cutting unit vibrates abnormally, stop and shut

the engine off. Check cutting unit for damaged

parts. Repair any damage before restarting and

operating the cutting unit.

•Lower the cutting units to the ground and

remove key from ignition switch whenever

machine is left unattended.

•Be sure cutting units are in safe operating

condition by keeping nuts, bolts and screws

tight.

•Remove key from ignition switch to prevent

accidental starting of the engine when servicing,

adjusting or storing the machine.

•Perform only those maintenance instructions

described in this manual. If major repairs are

ever needed or assistance is desired, contact an

Authorized Toro Distributor.

•To ensure optimum performance and safety,

always purchase genuine Toro replacement parts

and accessories to keep the Toro all TORO.

Never use “will-fit” replacement parts and

accessories made by other manufacturers.

Look for the Toro logo to assure genuineness.

Using unapproved replacement parts and

accessories could void the warranty of The Toro

Company.

Safety

3

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near

any area of potential danger. Replace any decal that is damaged or lost.

ON FRONT SHIELD OF CUTTING UNIT

(Part No. 93–6688)

4

Specifications

Reel Construction: Fairway reels. All welded. 5, 7

or 11 blades.

Recommended Height Of Cut Range:

5 Blade – 1” to 1-3/4” (25–44 mm)

7 Blade – 1/2” to 1” (13–25 mm)

11 Blade – 3/8” to 3/4” (10–19 mm)

Note: Use bedknife Part No. 93-9774 for

heights-of-cut below 1/2” (13 mm).

Reel Diameter: 7 in. (178 mm)

Power Attachment: Reel motors feature quick

disconnect for removal or installation onto cutting

unit. Cutting units can be driven from either end.

Height–of–cut & Roller Adjustment: Height-of-cut

adjustment is made at the rear roller with quick

locating pin and/or threaded micro–adjustment. Front

roller position is adjustable to set cutting unit attitude.

Bedknife And Bedbar Adjustment: Single point

adjustment (SPA) mechanism.

Selected Clip Control: The Reelmaster 5500

Traction Unit is equipped with manually adjustable

reel speeds which control selected clip.

Note: Refer to Traction Unit Operator’s

Manual for proper set–up procedure.

Automatic Clip Control: The Reelmaster 6000

Series Traction Unit is equipped with an electronic

controller which is programmed to achieve automatic

clip control. As the traction unit speed varies, the

controller will automatically adjust the hydraulic flow

to the reel motors to vary reel speed and maintain

proper clip. For proper clip, the controller needs to

know what cutting units are installed (5, 7 or 11

blade) and the height-of-cut.

Note: Refer to Traction Unit Operator’s

Manual for proper set–up procedure.

Rollers: Front roller is a 3” (76 mm) diameter cast

Wiehle roller. Rear roller is a 3” (76 mm) diameter

steel full roller. Both rollers use heavy duty ball

bearings with two conventional single lip seals and a

Toro labyrinth seal to provide four sealing surfaces to

protect the bearings.

Optional Equipment

Dethatching Cutting Unit Model No. 03871

Grass Basket Kit Model No. 03882

High Torque Reel Motor Part No. 98-2448

Wiehle Roller Scraper Part No. 100-9908

Rear Roller Scraper Kit Part No. 100-9920

RM6000 Shoulder Wiehle Roller Part No. 99-8675

RM5500 Shoulder Wiehle Roller Part No. 100-9911

RM6000 Shoulder Wiehle Scraper Part No. 99-8670

RM5500 Shoulder Wiehle Scraper Part No. 100-9913

Low Height-of-Cut Bedknife*Part No. 93-9774

Gauge Bar AssemblyPart No. 98-1852

Angle Indicator Part No. 99-3503

Backlapping Brush Assembly Part No. TOR299100

Bedknife Screw Tool Part No. TOR510880

Cutting Unit Tool Kit Part No. TOR4070

Reel Drive Tool Part No. TOR4074

* For height-of-cut below 1/2” (13 mm)

Supplied with tractor

5

Set–Up

Loose Parts

Note: Use the chart below to verify all parts have been shipped.

DESCRIPTION QTY. USE

Operator’s Manual 1Read before operating machine.

Parts Catalog 1Use for ordering replacement parts.

Registration Card 1Fill out and return to Toro.

Inspection

After the cutting unit is unboxed, inspect the

following:

1. Check each end of the reel for grease. Grease

should be visibly evident in the reel bearings and

internal splines of reel shaft.

2. Ensure that all nuts and bolts are securely

fastened.

3. Make sure carrier frame suspension operates

freely and does not bind when moved back and

forth.

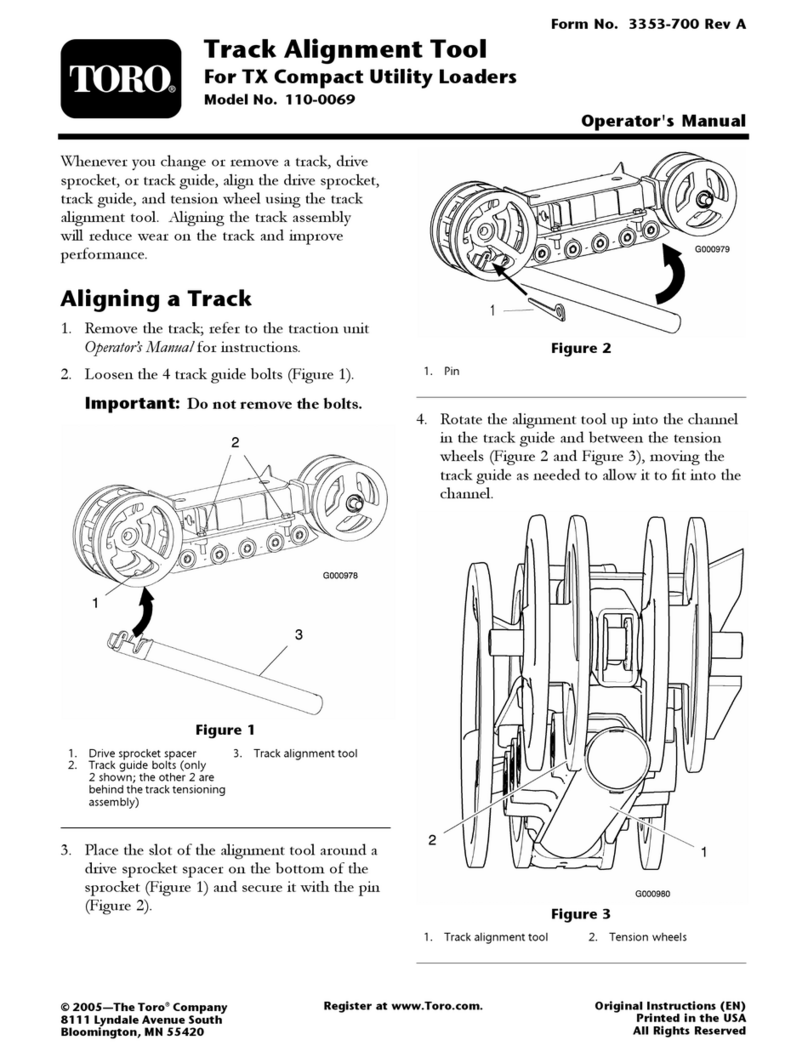

Adjusting Front Shield

Adjust front shield for desired grass clippings

dispersion.

1. Position cutting unit on a flat level surface.

2. Loosen flange head capscrew securing shield to

right side plate. Move shield to desired angle and

tighten screw (Fig. 1).

1

2

3

4

Figure 1

1. Front grass shield

2. Front capscrew 3. Rear grass shield

4. Rear capscrew

Adjusting Rear Shield

Under most conditions, best dispersion is attained

when rear shield is closed (front discharge). When

conditions are heavy or wet, rear shield may be

opened.

1. To open rear shield (Fig. 1), loosen flange head

capscrew securing shield to right side plate,

rotate shield to open position and tighten

capscrew.

Set–Up

6

Adjusting Turf Compensation

Spring

The Turf Compensation Spring (Fig. 2), connecting

carrier frame to cutting unit, controls the amount of

fore-aft rotation available, as well as the amount of

ground clearance in transport and turn around.

The Turf Compensation Spring also transfers weight

from the front to rear roller. This helps to reduce a

wave pattern in the turf, also known as bobbing.

IMPORTANT: Make spring adjustments with

cutting unit mounted to traction unit and

lowered to shop floor. Refer to Traction Unit

Operator’s Manual for mounting

instructions.

1. Tighten lock nut on rear of spring rod until the

gap (C) between rear of spring bracket and front

of washer is 1” (26 mm) (Fig. 2).

2. Tighten hex nuts on front end of spring rod until

the compressed length (A) of spring is 8” (203

mm) (Fig. 2).

Note: When cutting rough or undulating turf,

increase compressed length (A) of

spring to 8-1/2” (216 mm) and gap (C)

between rear of spring bracket and

front of washer to 1-1/2” (39 mm)

(Fig. 2).

Note: As compressed spring length (A)

decreases, weight transfer from front

roller to rear roller increases and

carrier frame/cutting unit rotation angle

(B) decreases.

Note: As gap (C) between spring bracket and

washer increases, cutting unit ground

clearance decreases and carrier

frame/cutting unit rotation angle (B)

increases.

“C”

“A”

“B”

Figure 2

7

Setting Height-of-Cut

IMPORTANT: To insure proper setting of

height-of-cut, these procedures must be

followed in this order:

A. Adjusting (Parallel) Bedknife To Reel

B. Setting Cutting Unit Attitude

C. Leveling Front Roller

D. Finalizing Height-of-Cut

IMPORTANT: Each cutting unit must be set

consistently. Minor differences in

either height-of-cut, attitude, bedknife wear,

or reel blade wear, among cutting units, may

result in negative after cut appearance.

Note: The cutting unit has been set at the

factory at 5/8” (16 mm) height-of-cut

and with a cutting unit attitude of 2

degrees. Also, the bedknife has been

backed off from the reel to prevent

shipping damage. Verify setting to

ensure changes did not occur during

shipment.

A. Adjusting (Parallel) Bedknife

to Reel

IMPORTANT: The reel and bedknife must be

parallel to insure the cutting unit cuts grass

across the bedknife, and the reel and bedknife

wear evenly.

Note: Toro recommends light contact

between the reel and bedknife.

However, for dry and/or sparse

conditions a .001–.002” (.03–.05 mm)

clearance may be required to prevent

heat buildup which can cause uneven

wear in the reel and bedknife.

Note: A 3/4 inch (19 mm) wrench is needed

to rotate bedknife adjustment knob.

Each notch on the knob will move the

bedknife 0.0005 inches (.013 mm)

closer to the reel (Fig. 3).

1

Figure 3

1. Bedknifeadjusting knob

1. Rotate cutting unit backward to gain access to

reel and bedknife (Fig. 4).

2. While slowly rotating the reel in the mowing

direction, turn the bedknife adjusting knob

clockwise until you hear light contact between

the reel and bedknife.

3. Insert a 1” (25 mm) wide piece of newspaper

perpendicular to the bedknife, and then rotate the

reel slowly in the mowing direction to see if the

reel cuts the paper - do this on both ends of the

bedknife (Fig. 4).

Setting Height-of-Cut

8

RIGHT

LEFT

Figure 4

4. If paper is cut on both ends, the bedknife is

parallel to the reel. If not proceed to step 5.

Note: If reel makes contact on both sides of

bedknife but still does not cut paper,

cutting unit may need to be backlapped

(refer to Backlapping) and/or reel and

bedknife may need to be reground

(refer to Toro manual for Sharpening

Reel and Rotary Mowers, Form No.

80–300PT).

1

2

3

4

Figure 5

1. Pivot hub casting

2. Pivot hub locknuts 3. Top adjusting nut

4. Bottom adjusting nut

5. Loosen the pivot hub lock nuts to allow

movement of the pivot hub casting (Fig. 5).

6. If paper was not cut on the left side: loosen the

bottom adjusting nut on the pivot hub, then turn

the top adjusting nut clockwise to pull the pivot

hub up. OR If paper was not cut on the right

side: loosen the top adjusting nut on the pivot

hub, then turn the bottom adjusting nut

counterclockwise to push the pivot hub down

(Fig. 5).

Note: To reduce thread play, always tighten

the bottom adjusting nut last.

7. Recheck reel to bedknife contact on both ends of

the bedknife, and repeat step 6 as necessary.

Note: Reel to bedknife contact may become

too tight or too loose after previous

adjustment; therefore, turn bedknife

adjustment knob, accordingly, for light

contact.

8. Retighten pivot hub lock nuts.

Note: Recheck if paper cuts on both ends, to

insure the bedknife did not move when

re–tightening the pivot hub lock nuts.

Setting Height-of-Cut

9

B. Setting Cutting Unit Attitude

IMPORTANT: Cutting unit “attitude” has a

significant impact on the performance of the

cutting unit. Attitude refers to the angle of the

bedknife relative to the ground (Fig. 6).

Adjustable front and rear brackets allow for

variable adjustment of cutting unit attitude

within the height-of-cut range. All cutting

units on a given machine must be set to the

same attitude, otherwise after-cut appearance

could be negatively affected.

ATTITUDE

Figure 6

The best cutting unit attitude is dependent on your

turf conditions and desired results. Experience with

the cutting unit on your turf will determine the best

setting to use. Cutting unit attitude can be adjusted

throughout the cutting season to allow for various turf

conditions.

In general, less aggressive attitudes (example: 2

degrees) are more appropriate for warm season

grasses (Bermuda, Zoysia) while cool season grasses

(Bluegrass, Rye) may require more aggressive

attitudes (example: 6 degrees). More aggressive

attitudes cut more grass off by allowing the spinning

reel to pull more grass up into the bedknife. An angle

that is too flat (attitude less than 1 degree) may allow

the bedbar or other parts of the cutting unit to drag in

the turf causing tufting. Therefore, minimum

recommended attitude is 1 degree.

For setting consistent cutting unit attitude, Toro

strongly recommends using a two-screw gauge bar,

Toro part no. 98-1852 (Fig. 7). The first screw is set

for height-of-cut, and the second screw is set for

cutting unit attitude. The second screw setting is an

easy method of transferring cutting unit attitude to all

cutting units on a machine.

HOC SETTING

ATTITUDE 2.00”

(51 mm)

“A”

First Screw

Second Screw

Figure 7

Setting Attitude for New Cutting Units

Table 1 lists starting dimensions for setting up a new

cutting unit with attitudes of 2, 4, 6 and 8 degrees.

Note: The second screw setting will change

throughout the life of the bedknife and

reel due to wear, even if the

height-of-cut is not changed.

Therefore, after initial set up use

Checking and Adjusting Attitude for

Used Cutting Unit procedure.

1. Using a two-screw gauge bar, Toro Part No.

98-1852, set first screw to desired height-of-cut.

This setting is from the bar face to the underside

of the screw head (Fig. 7).

2. Using Table 1, set the attitude, “A,” for the

second screw on the gauge bar. This setting is

from the bar face to the end of the screw (Fig. 7).

Setting Height-of-Cut

10

Table 1—New Cutting Unit Set Up Guide

Desired Height-of-Cut

(HOC) Desired

Attitude Second Screw “A”

(Fig. 7) Front Height-of-Cut

Rod “B” (Fig. 8) Rear Height-of-Cut

Rod “C” (Fig. 8) Rear Support

Bracket (Fig. 8)

(in) (mm) (degrees) (in) (mm) (in) (mm) (in) (mm) (location)

0.375 (10) 2* 0.180 4.6 1.625 41.3 1.866 47.4 top

4* 0.231 5.9 1.825 46.4 1.625 41.3 top

6* – – 2.026 54.5 1.387 35.2 top

8* – ––––– top

0.500 (13) 2* 0.299 7.6 1.499 38.1 1.740 44.2 top

4* 0.356 9.0 1.700 43.2 1.500 38.1 top

6* 0.414 10.5 1.901 48.3 1.262 32.1 top

8* – ––––– top

2 0.228 5.8 1.360 34.5 1.910 48.5 top

4 0.285 7.2 1.561 39.6 1.668 42.4 top

6 0.342 8.7 1.762 39.6 1.429 26.3 top

8 – – 1.963 49.9 1.191 30.3 top

0.625 (16) 2 0.353 9.0 1.234 31.3 1.784 45.3 top

4 0.410 10.4 1.435 36.4 1.543 29.2 top

6 0.467 11.9 1.636 41.6 1.304 24.6 top

8 – – 1.838 46.7 1.066 27.1 top

0.750 (19) 2 0.478 12.1 1.109 28.2 1.659 42.1 top

4 0.535 13.6 1.310 33.3 1.418 36.0 top

6 0.592 15.0 1.511 38.4 1.179 29.9 top

8 0.650 16.5 1.713 43.5 0.94123.9 top

0.875 (22) 2 0.603 15.3 0.98325.0 1.533 38.9 top

4 0.660 16.8 1.185 30.1 1.292 45.5 top

6 0.717 18.2 1.386 35.2 1.054 26.8 top

8 0.775 19.7 1.588 40.3 0.81620.7 top

1.000 (25) 2 0.728 18.5 0.85721.8 1.407 35.7 top

4 0.785 19.9 1.060 26.9 1.167 29.6 top

6 0.842 21.4 1.261 32.0 0.92923.6 top

8 0.900 22.9 1.463 37.2 0.69117.6 top

1.125 (29) 2 0.853 21.7 0.73218.6 1.282 32.6 top

4 0.910 23.1 0.93423.7 1.042 26.5 top

6 0.967 24.6 1.136 28.9 0.80420.4 top

8 1.025 26.0 1.388 35.3 0.56614.4 top

1.250 (32) 2 0.978 24.8 0.60615.4 1.156 29.4 top

4 1.035 26.3 0.80920.5 0.91623.3 top

6 1.092 27.7 1.011 25.7 0.67917.2 top

8 1.150 29.2 1.213 30.8 0.44111.2 top

1.375 (35) 2 1.103 28.0 0.48012.2 1.030 26.2 top

4 1.160 29.5 0.68417.4 0.79120.1 top

6 1.217 30.9 0.88622.5 0.55314.0 top

8 1.275 32.4 1.088 27.6 0.3168.0 top

1.500 (38) 2 1.228 31.2 0.3559.0 0.90523.0 top

4 1.285 32.6 0.55814.2 0.66616.9 top

6 1.342 34.1 0.76119.3 0.42810.9 top

8 1.400 35.6 0.96324.5 0.1914.9 top

1.625 (41) 2 – – 0.2295.8 1.404 35.7 bottom

4 1.410 35.8 0.43311.0 1.166 29.6 bottom

6 1.427 36.2 0.63616.2 0.92823.6 bottom

8 1.525 38.7 0.83821.3 0.69117.6 bottom

1.750 (45) 2 – – 0.1032.6 1.278 32.5 bottom

4 1.535 39.0 0.3087.8 1.040 26.4 bottom

6 1.592 40.4 0.51113.0 0.80320.4 bottom

8 1.650 41.9 0.71318.1 0.56614.4 bottom

* Optional Low Cut Bedknife, Toro part no. 93-9774, is required for height-of-cut below 0.500” (13 mm).

For front (”B”) or rear roller distances (“C”) less than 1” (25 mm) order long cone nut (Part No. 95-2790) to

replace bottom cone nut for improved support.

Setting Height-of-Cut

11

3. Rotate the cutting unit backward to gain access

to reel and bedknife.

4. Set the front height-of-cut rod height,“B,” using

the dimension given in Table 1. This

measurement is between the top surface of the

height-of-cut rod and top cone nut (Fig. 8).

5. Set the rear support casting in either the top or

bottom location as indicated in Table 1. Set the

rear height-of-cut rod height .100” (3 mm) less

than the dimension given in Table 1 which will

create a gap between the rear roller and the

gauge bar (Fig. 8).

1

2

“B”

3

4

“C”

3

4

Figure 8

1. First screw

2. Second screw 3. Height-of-cut rod

4. Cone nut

6. Place gauge bar across front and rear rollers. The

first screw head should fit snugly over edge of

bedknife and the end of second screw should

contact bottom of bedknife (Fig. 8). If there is a

gap between the front roller and the gauge bar or

you can not put the gauge bar on, adjust the front

roller until: (1) first (height-of-cut) screw fits

snugly over bedknife, (2) second screw just

contacts bedknife, and (3) gauge bar touches

front roller. Verify front roller (attitude) at each

end of the bedknife.

Note: At this time, there should be a small

gap between the rear roller and gauge

bar.

Setting Height-of-Cut

12

Checking or Adjusting Attitude for Used

Cutting Units

Note: As a starting point for adjusting cutting

unit attitude, the cutting unit may be

set up using the dimensions from

Table 1. However, because of wear on

the bedknife and reel, the following

procedure must be used to ensure the

correct attitude setting.

1. Rotate cutting unit backward to gain access to

reel and bedknife.

2. Place an angle indicator, Toro Part No. 99–3503,

on the bedknife and record the bedknife angle

(Fig. 9).

1

Figure 9

1. Bedknifeangle

3. Using a two-screw gauge bar, Toro Part No.

98-1852, set first screw to desired height-of-cut.

4. Place the gauge bar across front and rear rollers.

The first screw head needs to fit snugly over

edge of the bedknife,while the gauge bar

contacts the front roller (Fig. 10).

Note: The rear roller does not have to contact

the gauge bar.

5. Adjust second screw to contact bedknife. Move

rear roller up, if needed.

6. Place an angle indicator on the gauge bar and

record the gauge bar angle (Fig. 10).

1

2

34

increase

attitude

decrease

attitude

Figure 10

1. First screw

2. Second screw 3. Gauge bar angle

4. Front Roller

Setting Height-of-Cut

13

7. Adjust the front roller to your desired cutting

unit attitude:

Bedknife Angle (step 2)

– Gauge Bar Angle (step 6)

= Cutting Unit Attitude (degrees)

Note: Moving the front roller down will

decrease your cutting unit attitude,

while moving the front roller up will

increase cutting unit attitude (Fig. 10).

C. Leveling Front Roller

IMPORTANT: Toro strongly recommends the

use of a leveling plate when setting–up or

adjusting any reel type cutting unit. The

leveling plate will help to ensure accurate and

consistent adjustments. Contact your local

Toro Distributor for ordering a leveling plate.

1. Position cutting unit on a flat surface.

2. Position a 1” (25 mm) or thicker bar (for higher

heights-of-cut) under the reel blades and against

the front edge of the bedknife (Fig. 11). Make

sure bar covers the full length of the reel

blades.

3. Rock cutting unit forward (on reel blades and

steel bar) until front roller contacts flat surface.

Reel blades and bedknife must maintain contact

with bar. Rear roller should not contact surface

(Fig. 11).

Contact along full length of front roller and reel blade

levels front roller to reel.

Bar stock (1” x 3/4”

stock suggested)

Ref. flat surface

(1” x 20 x 30” flat

stock suggested)

Figure 11

4. Use a piece of newspaper or visually check to

see if any gap exists between front roller ends

and flat surface (Fig. 12). If needed, adjust

front height-of-cut rods until both ends of

roller are in contact with level surface.

Setting Height-of-Cut

14

Note: If leveling the front roller causes the

cutting unit attitude to be different

from side to side by more than one

degree, you may need to regrind the

reel and/or bedknife to eliminate

uneven wear.

Figure 12

D. Finalizing Height-of-Cut

1. Rotate the cutting unit vertical and place the

gauge bar across front and rear rollers (Fig. 13).

2. Adjust rear roller until it contacts the gauge bar

on both sides (Fig. 13).

1

2

3

Figure 13

1. First screw

2. Second screw 3. Adjust rear roller

Note: Make sure gauge bar is in contact with

the front roller at all times to keep

desired height-of-cut.

3. Slide gauge bar toward the end of the cutting

unit to remove. Gauge bar can now be utilized to

set remaining cutting units on machine.

15

Maintenance

Backlapping Reelmaster 5500

Traction Units

POTENTIAL HAZARD

•Reels may stall when backlapping.

WHAT CAN HAPPEN

•Reels may restart. Contact with rotating

reels will cause serious injury.

HOW TO AVOID THE HAZARD

•Do not attempt to restart reels by hand or

touch reels while backlapping.

•Stop engine and turn height-of-cut knob

one position toward “1.”

Note: When backlapping, the front units

all operate together, and the rear

units operate together.

1. Position the machine on a level surface, lower

the cutting units, stop the engine, engage the

parking brake, and move the Enable/Disable

switch to disable position.

2. Unlock and raise the seat to expose controls.

3. Locate the reel speed selector knobs and backlap

knobs (Fig. 14). Rotate the desired backlap

knob(s) to the backlap position and the desired

reel speed selector knob(s) to position “1.”

1

12

2

Figure 14

1. Reel speed selector knob 2. Backlap knob

Note: Backlapping speed may be increased

by moving the reel speed selector knob

toward “13”. Each position will

increase speed approximately 100 rpm.

After changing selector, wait 30

seconds for the system to stabilize at

the new speed.

4. Make initial reel to bedknife adjustments

appropriate for backlapping on all cutting units

which are to be backlapped.

5. Start engine and run at idle speed.

Maintenance

16

POTENTIAL HAZARD

•Changing engine speed while backlapping

may cause reels to stall.

WHAT CAN HAPPEN

•Reels may restart. Contact with rotating

reels will cause serious injury.

HOW TO AVOID THE HAZARD

•Never place hands or feet in reel area while

engine is running.

•Never change engine speed while

backlapping.

•Only backlap at idle engine speed.

•Never attempt to turn reels by hand or foot

while engine is running.

6. Select either front, rear, or both backlap knobs to

determine which reels will be backlapped.

7. Move Enable/Disable switch to Enable position.

Move Lower Mow/Lift control forward to start

backlapping operation on designated reels.

8. Apply lapping compound with a long handle

brush (Toro Part No. 29–9100). Never use a

short handled brush (Fig. 15).

1

Figure 15

1. Longhandle brush

9. If reels stall or become erratic while

backlapping, stop backlapping by moving the

Lower Mow/Lift control lever rearward. Once

the reels have stopped, move the desired reel

speed selector knob(s) one position closer to

“13.” Resume backlapping by moving the

Lower Mow/Lift control lever forward.

10. To make an adjustment to the cutting units while

backlapping, turn reels OFF by moving the

Lower Mow/Raise lever rearward; move the

Enable/Disable switch to Disable and turn the

engine OFF. After adjustments have been

completed, repeat steps 5–9.

11. Backlap until the reels can cut paper.

Note: When the cutting unit is adequately

sharpened, a burr will form on the

front edge of the knife. Using a file,

carefully remove the burr without

dulling the cutting edge (Fig. 16).

Figure 16

12. Repeat procedure for all cutting units to be

backlapped.

13. When backlap operation has been completed,

return the backlap knobs to the forward flow

position, lower seat and wash all lapping

compound off cutting units. Adjust cutting unit

reel to bedknife as needed.

IMPORTANT: If the backlap knobs are not

returned to the forward flow position after

backlapping, the cutting units will not raise

or function properly.

Maintenance

17

Backlapping Reelmaster 6000

Traction Units

POTENTIAL HAZARD

•Reels may stall when backlapping.

WHAT CAN HAPPEN

•Reels may restart. Contact with rotating

reels will cause serious injury.

HOW TO AVOID THE HAZARD

•Do not attempt to restart reels by hand or

touch reels while backlapping.

•Stop engine and turn height-of-cut knob

one position toward “A.”

Note: When backlapping, the front units

all operate together, and the rear

units operate together.

1. Position the machine on a level surface, lower

the cutting units, stop the engine, engage the

parking brake, and move the Enable/Disable

switch to disable position.

2. Unlock and raise the seat to expose controls.

3. Open control cover and turn the H.O.C. selection

knob to position “P” (Fig. 17).

1

Figure 17

1. Height-of-cutselection

knob

Note: Backlapping speed may be increased

by moving the H.O.C. selection knob

toward “A”. Each position will

increase speed approximately 60 rpm.

After changing selector, wait 30

seconds for the system to respond to

the new speed target.

4. Make initial reel to bedknife adjustments

appropriate for backlapping on all cutting units

which are to be backlapped.

5. Start engine and run at idle speed.

Maintenance

18

POTENTIAL HAZARD

•Changing engine speed while backlapping

may cause reels to stall.

WHAT CAN HAPPEN

•Reels may restart. Contact with rotating

reels will cause serious injury.

HOW TO AVOID THE HAZARD

•Never place hands or feet in reel area while

engine is running.

•Never change engine speed while

backlapping.

•Only backlap at idle engine speed.

•Never attempt to turn reels by hand or foot

while engine is running.

6. Select either front or rear on the backlap switch

to determine whether front or rear reels will be

backlapped.

7. Move Enable/Disable switch to Enable position.

Move Lower Mow/Lift control forward to start

backlapping operation on designated reels.

8. Apply lapping compound with a long handle

brush (Toro Part No. 29–9100). Never use a

short handled brush (Fig. 18).

1

Figure 18

1. Longhandle brush

9. If reels stall or become erratic while

backlapping, the reel control light will begin to

blink and the reels will turn off. If this occurs,

turn the H.O.C. selection knob one position

closer to “A”. Then, toggle the Enable/Disable

switch to the disable position followed by the

enable position. To resume backlapping, move

the Lower Mow/Lift control lever forward.

10. To make an adjustment to the cutting units while

backlapping, turn reels OFF by moving the

Lower Mow/Raise lever rearward; move the

Enable/Disable switch to Disable and turn the

engine OFF. After adjustments have been

completed, repeat steps 5–9.

11. Backlap until the reels can cut paper.

Note: When the cutting unit is adequately

sharpened, a burr will form on the

front edge of the knife. Using a file,

carefully remove the burr without

dulling the cutting edge (Fig. 19).

Figure 19

12. Repeat procedure for all cutting units to be

backlapped.

This manual suits for next models

2

Table of contents

Other Toro Tools manuals