Toro 08120 User manual

Form No. 3465-437 Rev A

Heater Kit

W orkman

®

UTX Utility V ehicle

Model No. 08120

Installation Instructions

Safety

Cooling System Safety

•Swallowing engine coolant can cause poisoning;

keep out of reach from children and pets.

•Discharge of hot, pressurized coolant or touching

a hot radiator and surrounding parts can cause

severe burns.

– Always allow the engine to cool at least 15

minutes before removing the radiator cap.

– Use a rag when opening the radiator cap, and

open the cap slowly to allow steam to escape.

•Do not operate the machine without the covers

in place.

•Keep your ngers, hands and clothing clear of

rotating fan and drive belt.

•Shut of f the engine and remove the key before

performing maintenance.

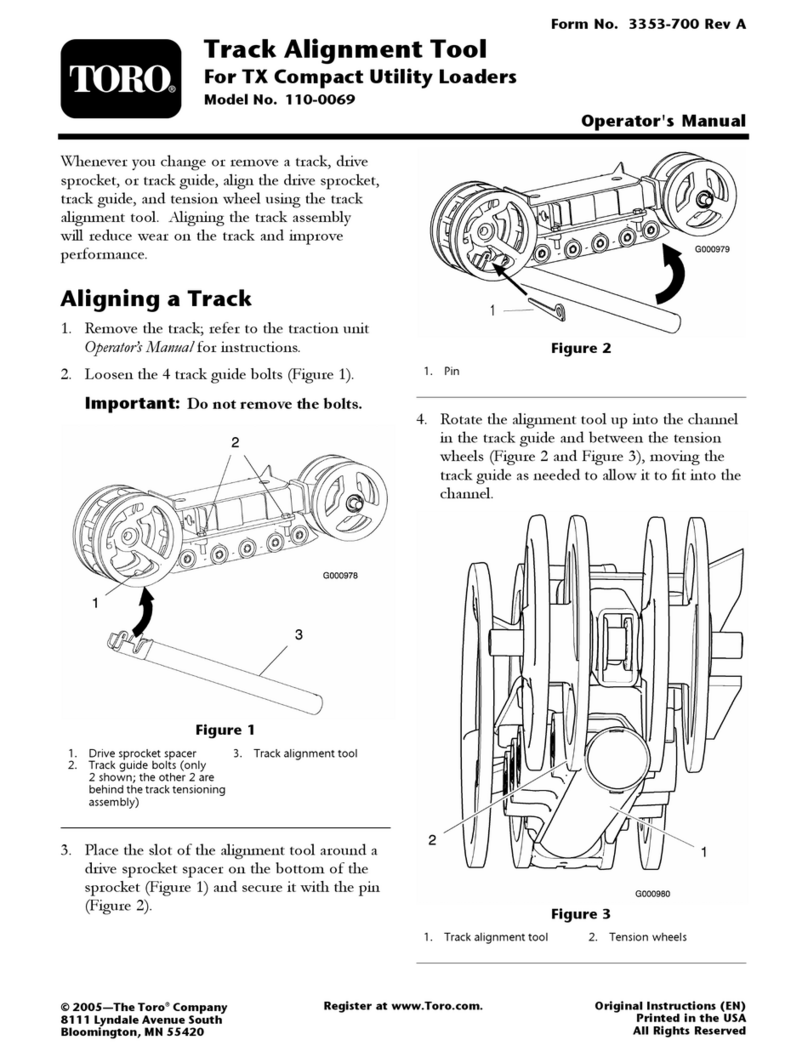

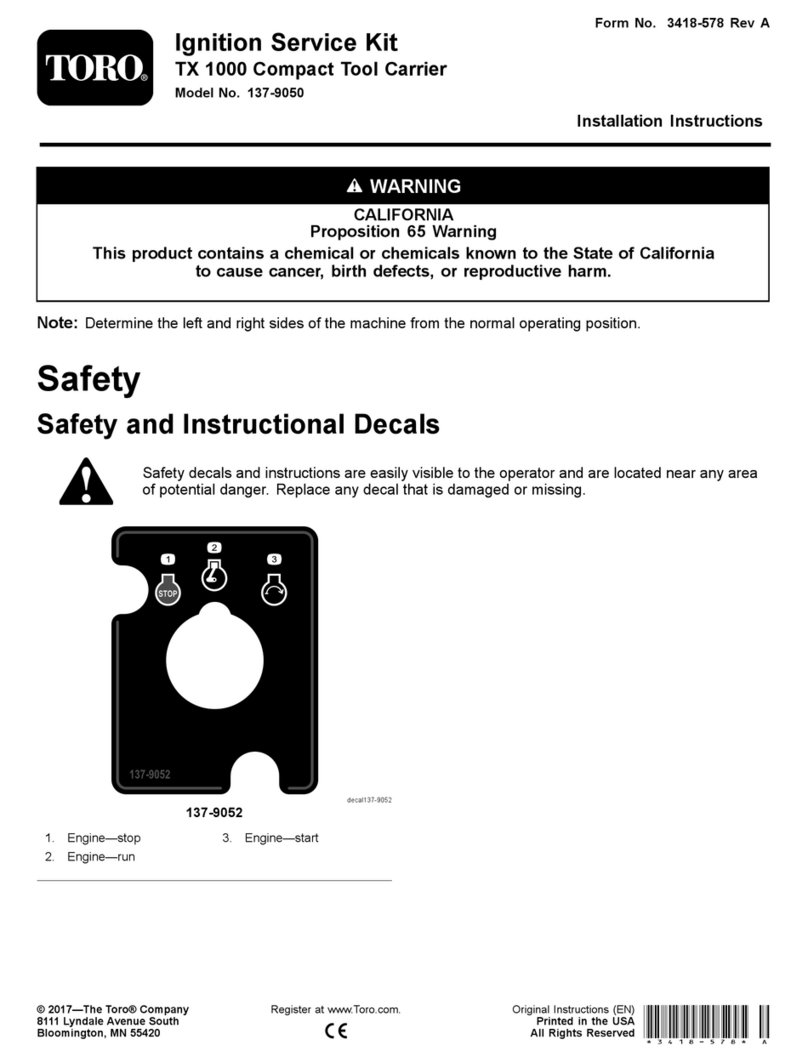

Safety and Instructional Decals

Safety decals and instructions are easily visible to the operator and are located near any area

of potential danger . Replace any decal that is damaged or missing.

decal145-2229

145-2229

1. Fan—of f

3. Heat—low

2. Fan—on full

4. Heat—high

© 2023—The T oro® Company

81 1 1 L yndale A venue South

Bloomington, MN 55420

Register at www .T oro.com.

Original Instructions (EN)

Printed in the USA

All Rights Reserved

*3465-437*

Installation

Loose Parts

Use the chart below to verify that all parts have been shipped.

Procedure Description

Qty .

Use

1

No parts required

–

Prepare the machine.

Heater control panel 1

Rotary switch 1

Rotary linear switch 1

Switch nut (7/16 inch)

2

Knob 2

Button-head bolt (5/8 inch)

4

Locknut (#10-24)

4

Control cable

1

2

Wire harness 1

Install the heater control panel.

3

No parts required

–

Cut the holes for the vents.

Heater box assembly 1

Heater mount bracket 1

Carriage bolt (1/4 x 3/4 inch)

6

Locknut (1/4 inch)

6

Coolant hose (5/8 x 13 inches)

1

Coolant hose (5/8 x 26 inches)

1

V ent hose (2 x 18 inches)

8

Y -adapter 2

Band clamp 2

Cable tie

16

4

V ent 6

Assemble the heater box assembly .

Hex bolt (5/16 x 3/4 inch)

2

Carriage bolt (1/4 x 3/4 inch)

25

Locknut (1/4 inch)

2

Install the heater box assembly .

Cable tie

6

Band clamp 2

W ater valve 16

Hose 3

Route the hoses.

7

Pan-head bolt (#10-24 x 3/8 inch)

1 Install the wire harness.

8

No parts required

–

Connect the battery .

9

No parts required

–

Burp the cooling system.

2

1

Preparing the Machine

No Parts Required

Procedure

1. Park the machine on a level surface.

2. Shift the transmission lever to the P (P ARK )

position.

3. Shut of f the engine and remove the key .

4. W ait for the engine to cool completely .

g364252

Figure 1

5. Disconnect the negative (-) battery cable from

the battery post.

g365494

Figure 2

1. Negative (-) battery cable

2. Battery post

6. Raise the hood; refer to the machine Operator ’ s

Manual .

7. Drain approximately 2 L (1/2 US gallon) of

engine coolant (or until coolant stops owing out

of the rubber hoses) from the cooling system;

refer to the Operator ’ s Manual .

Note: Retain coolant for reuse after installation

of the kit.

3

2

Installing the Heater Control

Panel

Parts needed for this procedure:

1 Heater control panel

1 Rotary switch

1 Rotary linear switch

2

Switch nut (7/16 inch)

2 Knob

4

Button-head bolt (5/8 inch)

4

Locknut (#10-24)

1

Control cable

1 Wire harness

Procedure

1. On the dashboard, remove the 4 switch plugs

and cut out the material between the switch

cutouts ( Figure 3 ).

g398819

Figure 3

2. Locate the 2 drill pilot dimples ( Figure 4 ) and

drill 2 pilot holes (3/16 inch) directly over the

pilot dimples.

g398820

Figure 4

1. Drill pilot dimples

W ARNING

Using a drill without wearing eye

protection may allow debris to enter the

eye, causing personal injury .

When drilling, always wear eye

protection.

3. Using the heater control panel as a template,

drill the other 2 holes located on the right side.

4. Install the 2 switches onto the control panel with

2 switch nuts (7/16 inch) as shown in A of Figure

5.

5. Install a knob over each switch (B of Figure 5 ).

g430408

Figure 5

4

6. Move the control knobs to the middle position

as shown in Figure 6 .

g430155

Figure 6

1. Move the knobs to the middle position.

7. Ensure that the heater switch is in the middle

position and connect one end of the control

cable to the back of the heater switch ( Figure 7 ).

g430382

Figure 7

8. Ensure that the water valve is in the middle

position and connect it onto the other end of the

control cable ( Figure 8 ).

9. Ensure that the heater switch can sweep from

low heat to high heat and that the water valve

fully opens and closes. Adjust the cable if

necessary .

g460374

Figure 8

5

10. Plug the 5-terminal connector on the kit wire

harness into the back of the airow switch

(Figure 9 ).

g430409

Figure 9

1 1. Route the control cable, water valve, and wire

harness through the dashboard and secure the

control panel assembly onto the dashboard with

4 button-head bolts (5/8 inch) and 4 locknuts

(#10-24); refer to Figure 10 . T orque the bolts to

3 N∙m (30 in-lb).

g430435

Figure 10

6

3

Cutting the Holes for the

V ents

No Parts Required

Procedure

1. Locate the 4 drill pilot dimples on the top of the

dashboard ( Figure 1 1 ) and drill 4 holes (76 mm

or 3 inches) directly over the pilot dimples.

Note: Use a 76 mm (3 inch) hole saw to drill

the vent holes.

g398901

Figure 1 1

1. Drill pilot dimples

2. Locate the 2 drill pilot dimples on the oorboard

(Figure 12 ) and drill 2 holes (76 mm or 3 inches)

directly over the pilot dimples.

Note: It is recommended to use a 76 mm (3

inch) hole saw to drill the vent holes.

3. Remove the burrs from the holes.

g398912

Figure 12

1. Drill pilot dimples

7

4

Assembling the Heater Box

Assembly

Parts needed for this procedure:

1 Heater box assembly

1 Heater mount bracket

6

Carriage bolt (1/4 x 3/4 inch)

6

Locknut (1/4 inch)

1

Coolant hose (5/8 x 13 inches)

1

Coolant hose (5/8 x 26 inches)

8

V ent hose (2 x 18 inches)

2 Y -adapter

2 Band clamp

16

Cable tie

6 V ent

Procedure

Important: Do not interfere with the shifter

linkage or steering column when installing the

hoses.

1. Connect 6 vent hoses to the adjustable vents

using 6 large cable ties ( Figure 13 ).

Note: Ensure that the vents are orientated to

blow air toward the operator on the operator ’ s

side of the machine and toward the passenger

on the passenger ’ s side.

2. Route the hoses and install the 4 adjustable

vents into the 4 top holes ( Figure 13 ).

3. Route the hoses and install the 2 adjustable

vents into the lower 2 holes ( Figure 13 ).

4. Connect the 2 outer vent hoses to the 2 lower

hoses using the 2 Y -adapters and 4 cable ties

(Figure 13 and Figure 14 ).

Connect 2 additional vent hoses to the

assembled outer vent hoses and secure them

using 2 cable ties ( Figure 13 and Figure 14 ).

5. Connect the 4 vent hoses to the heater box

using 4 cable ties ( Figure 13 and Figure 14 ).

g460891

Figure 13

1. V ent

3. Cable tie

2. Y -adapters

g460561

Figure 14

1. Outer hose assemblies

8

6. Attach the heater box assembly to the heater

mount bracket with 6 carriage bolts (1/4 x 3/4

inch) and 6 locknuts (1/4 inch); refer to Figure

15 . T orque the bolts to 1 1 N∙m (100 in-lb).

g460444

Figure 15

1. Heater box assembly 3. Heater mount bracket

2. Locknut (1/4 inch) 4. Carriage bolt (1/4 x 3/4

inch)

7. Connect the 2 coolant hoses onto the front of

the heater box with 2 band clamps as shown in

Figure 16 .

g460443

Figure 16

9

5

Installing the Heater Box

Assembly

Parts needed for this procedure:

2

Hex bolt (5/16 x 3/4 inch)

2

Carriage bolt (1/4 x 3/4 inch)

2

Locknut (1/4 inch)

Procedure

Note: If the machine has the glass windshield and

wiper kit installed, remove the washer bottle from the

frame of the machine. Install it onto the side of the

heater box assembly after the heater box is installed

on the machine (see step 3).

1. Attach the front of the heater box assembly to

the frame of the machine with 2 hex bolts (5/16

x 3/4 inch).

g399053

Figure 17

1. Hex bolt (5/16 x 3/4 inch)

3. Heater box assembly

2. Machine frame

2. Attach the back of the heater box assembly

to the dash brackets on the machine with 2

carriage bolts (1/4 x 3/4 inch) and 2 locknuts

(1/4 inch); refer to Figure 18 .

g460678

Figure 18

1. Locknuts (1/4 inch) 2. Carriage bolts (1/4 x 3/4

inch)

3. If the machine has the glass windshield and

wiper kit installed, install the washer bottle onto

the side of the heater box assembly as shown

in Figure 19 .

g429465

Figure 19

10

6

Routing the Hoses

Parts needed for this procedure:

6

Cable tie

2 Band clamp

1 W ater valve

3 Hose

Procedure

1. Disconnect the existing coolant hose from the

side of the coolant tank ( Figure 20 ) and shorten

the hose by 23 cm (9 inches).

Retain the band clamp for reuse.

g409844

Figure 20

1. Coolant tank

2. Existing coolant hose

1 1

2. Connect the 2 coolant hoses that were

previously installed to the heater box to their

appropriate ports on the water valve with 2 band

clamps ( Figure 21 ).

Note: If a BOSS snowplow is installed on the

machine, route the heater core lower hose

(Figure 21 ) around the plow solenoid.

3. Connect the previously shortened thermostat

bypass hose to the water valve with a band

clamp ( Figure 21 and Figure 22 ).

4. Connect the remaining hose to the water valve

with a band clamp, then connect the other end of

the hose to the large port on the upper reservoir

with a band clamp ( Figure 21 and Figure 22 ).

g460521

Figure 21

1. T o the heater core lower

hose

3. T o the upper reservoir

large port

2. From the thermostat

bypass hose

4. T o the heater core upper

hose

g460460

Figure 22

1. Coolant tank

3. W ater valve

2. Coolant hoses (3)

4. Existing coolant hose

(previously removed

from coolant tank and

shortened)

12

7

Installing the W ire Harness

Parts needed for this procedure:

1

Pan-head bolt (#10-24 x 3/8 inch)

Procedure

1. Install the fuse cover (supplied with kit wire harness) onto the left side of the heater box with the pan-head

bolt (#10-24 x 3/8 inch) as shown in Figure 23 .

2. Route the kit wire harness as shown in Figure 23 .

g460700

Figure 23

1. T o airow switch (previously installed)

4. T o machine wire harness

2. Fuse cover—connected to the heater box with a pan-head

bolt (#10-24 x 3/8 inch)

5. T o heater box

3. T o fuse cover

13

8

Connecting the Battery

No Parts Required

Procedure

Connect the negative (-) battery cable to the battery

post.

g365493

Figure 24

1. Negative (-) battery cable

2. Battery post

9

Burping the Cooling

System

No Parts Required

Procedure

W ARNING

If the engine has been running, the

pressurized, hot coolant can escape and

cause burns.

• Do not open the radiator cap when the

engine is running.

• Use a rag when opening the radiator cap,

and open the cap slowly to allow steam to

escape.

Coolant type: 50% ethylene-glycol with organic

additive technology (OA T) 50% distiller water

1. Remove the cap from the cooling system

reservoir .

2. Fill the cooling system reservoir until coolant

reaches the lower line within the reservoir .

3. Rotate the temperature-control knob to full heat.

4. Start and run the engine until the cooling fan

cycles.

When the machine is at operating temperature,

the coolant level within the reservoir should be

at the upper line.

5. Add coolant as necessary to replace air that has

been purged from the cooling system.

6. Install the cooling system reservoir cap.

14

Operation

Operating the Fan

The fan has 4 speeds ( O FF , L OW , M EDIUM , and H IGH ).

Rotate the fan-control knob to regulate the speed of

the fan.

Rotate the temperature-control knob to regulate the

air temperature in the cab.

Maintenance

Servicing the Heater Air

Filter

Service Interval : Every 250 hours —Change the

heater air lter (more frequently in

dusty or dirty conditions).

Note: The heater air lter is designed to keep the

cabin air clean.

1. Remove the lter access cover from the heater

box assembly ( Figure 25 ).

g41 1877

Figure 25

1. Filter access cover

2. Gently remove the lter from the heater box

assembly .

Note: Do not attempt to clean the lter .

3. Inspect the new lter for damage by looking

into the lter while shining a bright light on the

outside of the lter .

Note: Holes in the lter appear as bright

spots. Inspect the element for tears, an oily

lm, or damage to the rubber seal. If the lter is

damaged, do not use it.

Note: Use care when handling the lter to avoid

damaging or deforming it.

4. Carefully install the lter .

5. Install the lter access cover on the heater box

assembly with the corresponding hardware.

Cleaning the Heater

Important: Do not get the heater box or heater

components wet.

15

Table of contents

Other Toro Tools manuals