TORQUE SAFE TORQUE SAFE User manual

1 | Page

Operations Manual

TORQUE SAFE TM

2015

PLEASE READ CAREFULLY BEFORE USE

www.ogoncontracting.com.au

2 | Page

Operations Manual

Torque Safe

Torque Safe is a handle operated safety device designed to fit Hydraulic Torque

Wrench’s and give operators greater control and prevent hand injuries.

To operate Torque Safe correctly, operators must squeeze the handle down by

placing both hands on the Hydraulic Torque Wrench.

This includes when positioning the Hydraulic Torque Wrench, removing the

tool from a bolt or any other task requiring hands to be on the tooling.

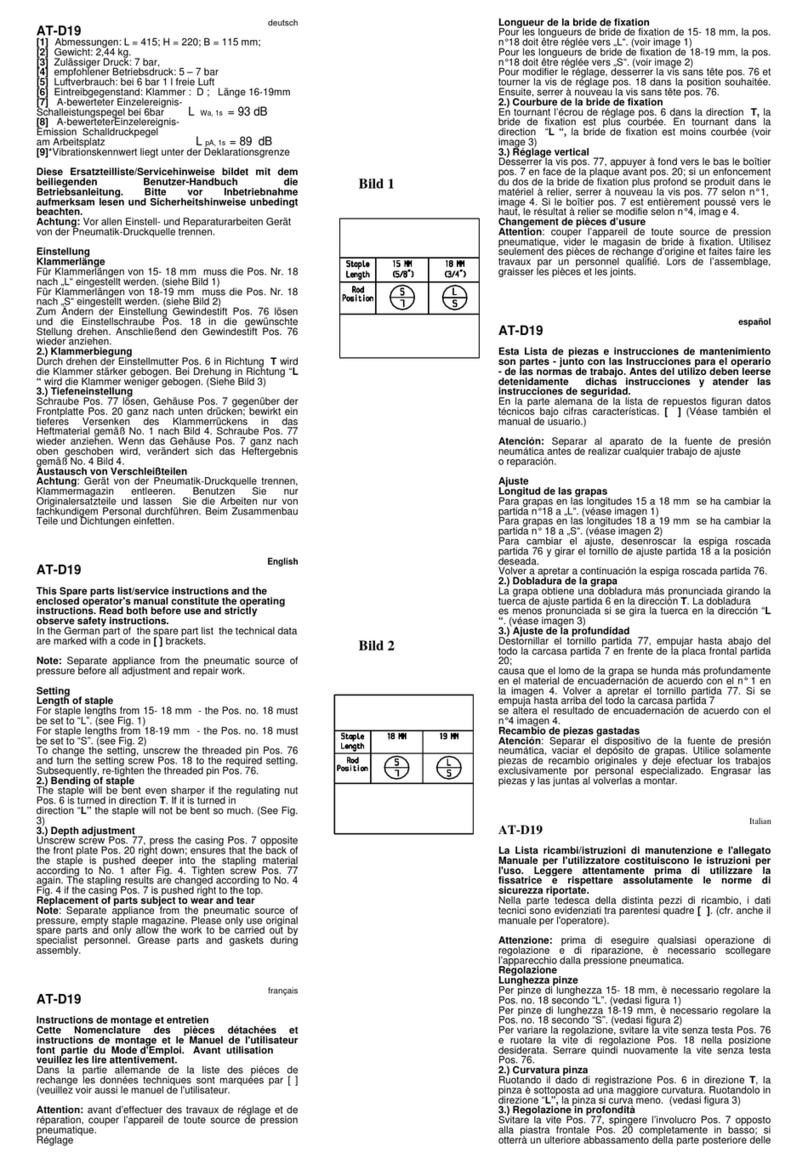

(Diagram handle depressed)

The Blue in the above diagram shows the oil flow being looped between the two

hose ports and returned back to the oil tank under low pressure.

Depressing the handle closes ports which supply oil to the Hydraulic Torque

Wrench, and loops the oil flow back through the hoses to the tank. By closing

this off with Torque Safe, the button which activates the Hydraulic Torque

Wrench will be inactive, which stops the tool driving, thus eliminating any

possible hand crushing injuries.

General Operating Instructions

The purpose of this manual is to provide basic instructions to safely operate a

Hydraulic Torque Wrench equipped with Torque Safe.

Please read this manual carefully and follow instructions provided herein.

When selecting a socket for a Hydraulic Torque Wrench use only approved

impact sockets. Failure to do so may result in the socket breaking under

pressure and causing personal injury.

3 | Page

Operations Manual

General Operating Instructions (continued)

The recommended PPE requirements to be used are safety glasses, gloves,

steel cap boots, long pants and a long sleeve shirt.

If a Job requires two operators, before commencing work, a clear work plan

should be established between the two.

Working Pressure

A Hydraulic Torque Wrench has a maximum working pressure of 10,000 psi.

Check that all hydraulic equipment (pumps, hoses, couplers) are rated for

10,000 psi working pressure and are free of any damage and are in good

working condition.

Review the hydraulic pump documentation to ensure maximum working

pressure does not exceed 10,000 psi.

Hydraulic Torque Wrench Connection

When using hydraulic hoses for a Hydraulic Torque Wrench and pump ensure

they are at the correct pressure rating of 10,000 psi. Also ensure they have

safety couplers which prevents the hoses from accidently coming loose.

Connect the twin line hose by connecting the male couplers to the female

couplers. Ensure the connections are fully engaged and tightened to the final

thread.

Loose or improperly threaded couplers will prevent the tool from operating

correctly and can be potentially dangerous if pressurised.

Couplers are to be hand tightened only, DO NOT USE PLIERS. Over tightening

of couplers could cause thread failure. To loosen the couplers, push the

couplers together, which pushes the spring loaded part inside the coupler, and

turn clockwise. A small amount of oil will drip from the couplers on

disconnection, this is normal.

4 | Page

Operations Manual

Electrical Connections

Ensure there is correct power availability and use recommended amperage

listed on the motor nameplate. Failure to do this could result in motor failure

from electrical overloading.

Ensure correct electrical tagging and testing has been performed. Minimise

length of any extension cords, ensuring all power outlets and extension cords

have ground outlets. As electrical motors may spark, do not operate in the

area of combustible liquids.

Air Connections

Ensure you have sufficient airflow and pressure. You will require 60-100 psi to

operate the pneumatic pump. Check manufactures recommended air pressure

ratings on the pump.

Ensure correct rated pressure air hoses are used and have an internal diameter

of 19mm. A filter regulator, lubricator and water trap is recommended.

Functional (Operational) Check

Before using any Hydraulic Torque Wrench a function check must be carried

out.

Ensure the Hydraulic Torque Wrench is connected correctly.

Turn on the pump operating the Hydraulic Torque Wrench ensuring there are

no oil leaks. This is best checked at maximum working pressure 10,000 psi.

After ensuring there is no oil leaks, repeat this process with the Torque Safe

handle depressed, ensuring that the Hydraulic Torque Wrench does not drive.

Changing Drive Direction

To remove the square drive out of the Hydraulic Torque Wrench, press the

button in on the drive retainer, gently pull on the square drive removing it

from the spline in the head of the tool.

5 | Page

Operations Manual

Changing Drive Direction (continued)

To change direction insert the drive to the opposite side of the tool end

removed. Gently turn the square drive until it can be engaged in the spline and

pushed in. Depress the drive retainer button, engage the button with the drive

retainer and release the button locking the square drive into position.

Reaction Arm

All Hydraulic Torque Wrenches are equipped with universal reaction arms.

The reaction arm is designed to absorb and counteract forces created as the

Hydraulic Torque Wrench operates. The reaction arm should extend in the

same direction as the square drive, however slight adjustments can be made to

suit each particular application. Reaction arms rotate 360 degrees.

Setting the Torque

Ensure the Hydraulic Torque Wrench being used has been calibrated and

checked within the manufactures guidelines.

Once the Hydraulic Torque Wrench is fully connected and power or air supply

confirmed, the operator may now adjust the pressure to the required torque

setting.

When tightening, refer to the manufactures torque setting and bolt tightening

sequence requirements. Bolt pattern and tightening sequence can vary

between different manufactures or gasket materials.

Torque settings vary between different manufactured Hydraulic Torque

Wrenches. Refer to the relevant manufacturer Hydraulic Torque Wrench

Tension Chart. Different sized Hydraulic Torque Wrench’s, for example ¾ drive,

1 drive, 1 ½ drive and 2 ½ inch drive, all have different torque charts. Ensure

you use the correct chart for the Hydraulic Wrench being used.

6 | Page

Operations Manual

Once the required torque settings for the Hydraulic Torque Wrench have been

established, set the pump to the correct pressure by loosening the lock nut

counter clockwise and turning the pressure regulator, then start the pump by

pushing down and holding the on button.

To adjust the pressure, turn the regulator clock wise, the pressure will be

visible on the gauge at all times. Adjust the regulator until the correct pressure

reached. Re-press and hold the on button to re-check the pressure is correct.

Always refer to the operations manual of your brand

and model of hydraulic torque wrench.

Table of contents

Popular Tools manuals by other brands

BEA

BEA AT-D19 Spare parts list/service instructions

TORQTECH

TORQTECH CA-10RC-ENDO operating instructions

NIPPON POP RIVETS AND FASTENERS

NIPPON POP RIVETS AND FASTENERS PNT600 instruction manual

Southland

Southland S-HLT-3017-SBEZ-E Operator's manual

Skil

Skil 1743 Original instructions

Wera

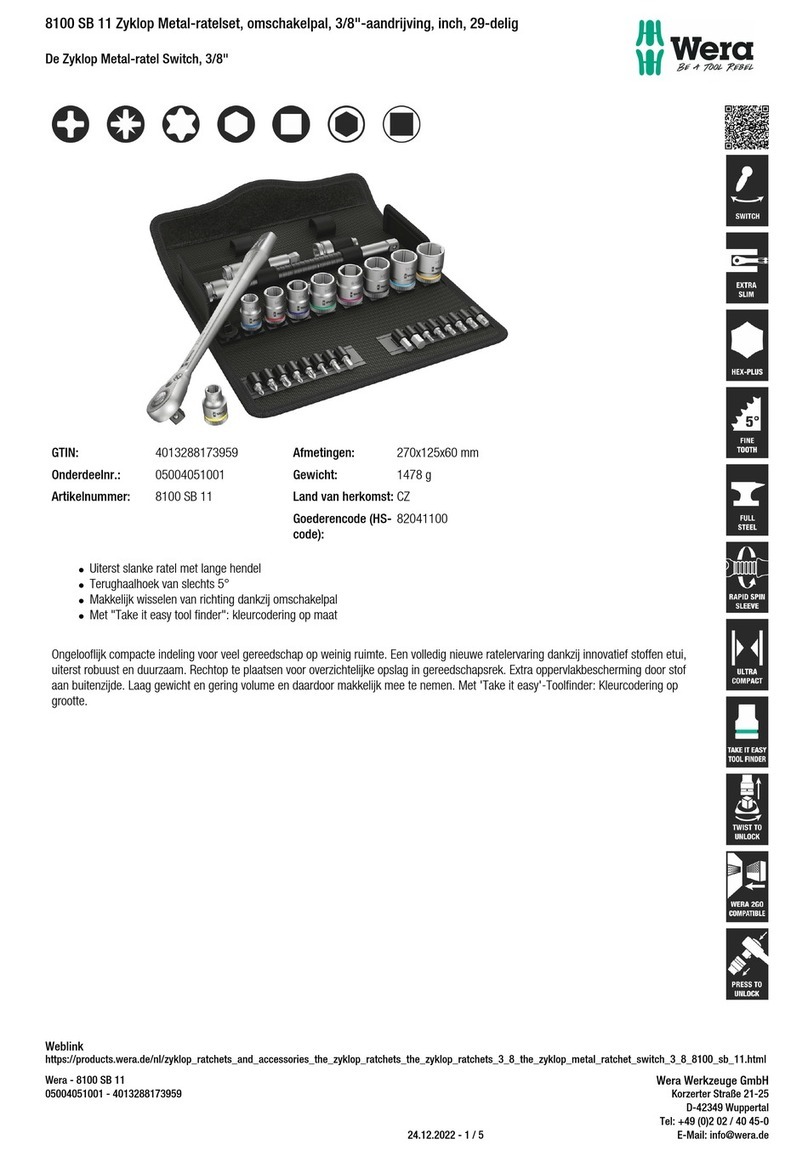

Wera 8100 SB 11 manual