TABLE OF CONTENTS 1__________________________________________

INTRODUCTION 3_______________________________________________

INTENDED USE 3________________________________________________

SAFETY GUIDELINES 4__________________________________________

ROTATING DRIVELINES 5_______________________________________________

PERSONAL SAFETY 6__________________________________________________

WORK AREA 7________________________________________________________

TOOL USE AND CARE 8________________________________________________

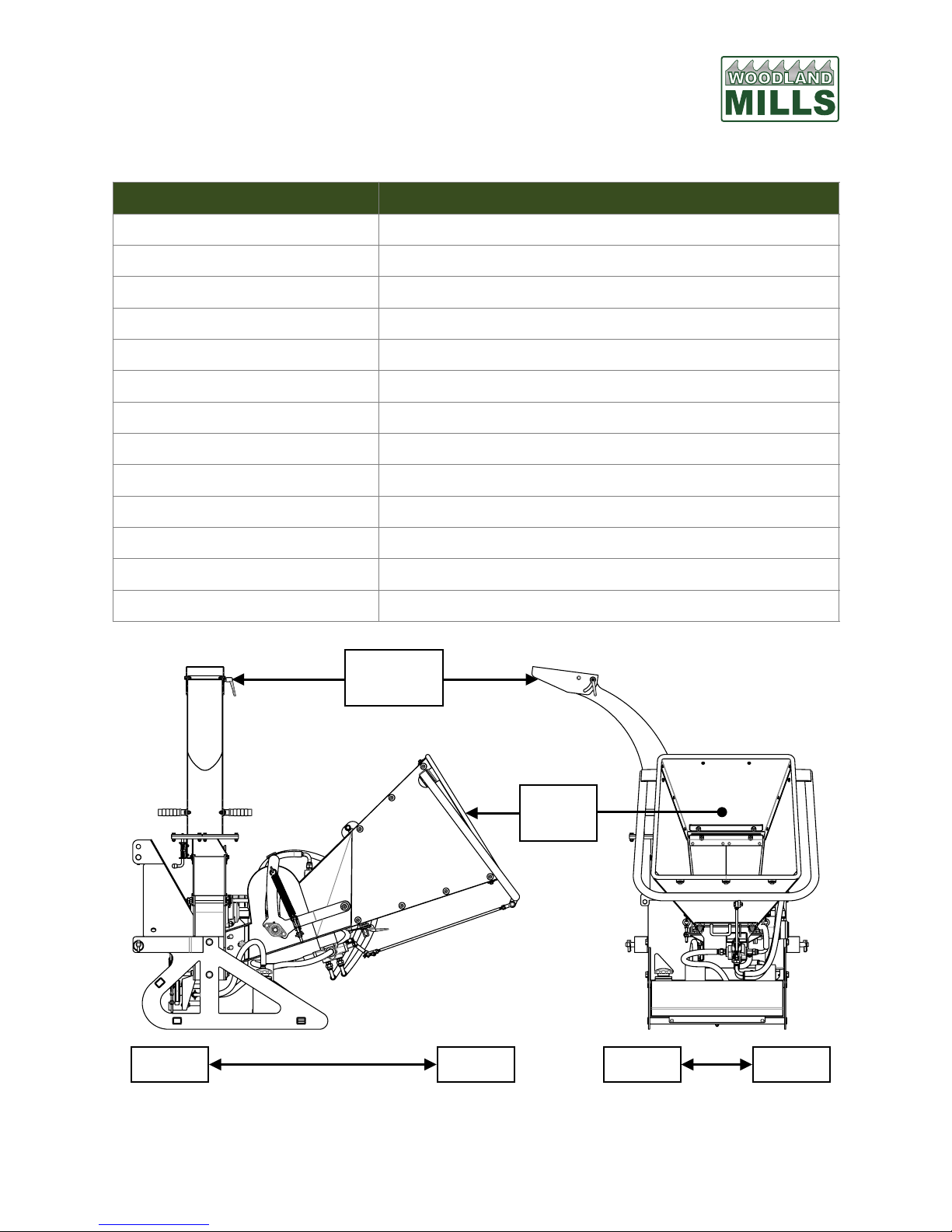

TECHNICAL SPECIFICATIONS 9___________________________________

i. OVERALL DIMENSIONS—OPERATING STATE 10________________________

ii. OVERALL DIMENSIONS—STORED STATE 11____________________________

iii. 3-POINT HITCH DIMENSIONS 12______________________________________

ASSEMBLY 13__________________________________________________

1. TOOLS REQUIRED 13_______________________________________________

2. UNPACKING 14____________________________________________________

A. UNBOXING THE CRATE 14___________________________________________

3. INFEED CHUTE 15__________________________________________________

A. TOP PANEL 15______________________________________________________

B. SIDE PANELS AND BOTTOM PANEL 16________________________________

C. EDGE BAR 17_______________________________________________________

D. CONTROL ARM 19__________________________________________________

E. CONTROL ARM LINKAGE 20_________________________________________

4. DISCHARGE CHUTE 22______________________________________________

TRIMMING THE PTO SHAFT 23____________________________________

OPERATION 25_________________________________________________

1. START UP 25______________________________________________________

2. INFEED ROLLER CONTROL 26_______________________________________

3. DISCHARGE CHUTE 27______________________________________________

4. CHIPPING 28______________________________________________________

5. STOPPING 28______________________________________________________