TORXUN AUTOPED 10 User manual

Autoped/ M10 APPENDIX rev 0 (09221 DRAFT) A-1

AUTOPED(TM)/ MODEL-10 OPERATOR

APPENDIX

©2021

Autoped/ M10 APPENDIX rev 0 (09221 DRAFT) A-2

TORXUN reserves the right to make changes in the products described in this manual without notice and without obligation of TORXUN to notify any

persons of any such revisions or changes. Additionally, TORXUN makes no representations or warranties with respect to this manual.

This manual is copyrighted 2021 TORXUN Vehicle Access Systems, all rights reserved.

No portion of this manual may be copied, reproduced, translated, or reduced to any electronic medium without prior written consent from TORXUN.

Autoped/ M10 APPENDIX rev 0 (09221 DRAFT) A-3

TABLE OF CONTENTS

AUTOPED OPERATOR PARTS AND COMPONENTS ……………………………….………………………………………….

A-5

SECTION I INSTALLING AUTOPED OPERATOR ON HEADERS LESS THAN 4”

...……………………………………………….

A-6

IMPORTANT INSTALLATION NOTE ………………………………………………………………………………………….

A-7

I.1 DOOR HANDING ……………………………………………………………………………………………………...…….

A-8

I.2INSTALLATION: LEFTHAND OPERATOR FOR HEADERS LESS THAN 4” IN HEIGHT …………………………

A-9

I.3 INSTALLATION: RIGHTHAND OPERATOR FOR HEADERS LESS THAN 4” IN HEIGHT ……………………….

A-10

SECTION II INSTALLING THE AUTOPED OPTIONAL POSITIVE STOP

…..………....................................................................

A-11

II.1 OPTIONAL POSITIVE STOP KIT ……………………………………........................................................................

A-12

II.2 INSTALLATION: POSITIVE STOP ASSEMBLY ………………………………………………………………………..

A-12

II.3 ADJUSTING THE POSITIVE STOP POSITION ………………………………………………………………………...

A-14

SECTION III ADJUSTING CLOSING SPRING PRELOAD ………………………………………………………………………

A-15

III. ADJUSTING THE CLOSING SPRING PRELOAD ……………………………...……………………………………….

A-16

SECTION IV MENUS AND PROGRAMMING ...…………………………………………………………………………………...

A-17

IV.1 PROGRAMMING FLOW: GUIDE CHART ………………………………………………………………………………

A-18

IV.2 MENU GLOSSARY ………………………………………………………………………………………………………..

A-18

IV.3 CONTROL UNIT LED LIGHTS …………………………………………………………………………………………..

A-19

IV.4 LCD SCREEN GLOSSARY ………………………………………………………………………………………………

A-19

IV.5 CHART FOR MENUS AND WHAT THEY DO ………………………………………………………………………….

A-19

IV.6 CHART FOR OPTIONS IN THE PARAMETER MENU: SETTINGS FOR DOOR/GATE MOVEMENT …………

A-20

IV.7 CONFIGURATION MENU OPTIONS AND DEFINITIONS ……………………………………………………………

A-22

IV.8 DOUBLE DOOR MENU CHART …………………………………………………………………………………………

A-24

IV.9 DIAGNOSTIC TABLE ……………………………………………………………………………………………………..

A-24

IV.10 CHART FOR THE REINIT MENU (DERSET BACK TO FACTORY DEFAULT) ………………………………….

A-25

IV.11 BLOCK/UNBLOCK MENU: LOCK KEYS ……………………………………………………………………………...

A-25

IV.12 TEACH MENU ……………………………………………………………………………………………………………

A-25

SECTION V TROUBLE SHOOTING AND ERROR CHARTS …………………………………………………………………...

A-26

V.1 ERROR CODE DEFINITIONS …………………………………………………………………………………………….

A-27

SECTION VI TERMINAL CONNECTIONS AND WIRING SCHEMATICS ……………………………………………………..

A-32

VI.1 TERMINAL CONNECTION CHART ……………………………………………………………………………………..

A-33

Autoped/ M10 APPENDIX rev 0 (09221 DRAFT) A-4

VI.2 WIRING SCHEMATIC DIAGRAMS ……………………………………………………………………………………...

A-35

SECTION VII SERVICE PARTS ……………………………………………………………………………………………………..

A-41

VII.1 SERVICE PARTS/COMPONENTS VISUAL GUIDE ………………………………………………………………….

A-42

VII.2 STANDARD PARTS LIST ………………………………………………………………………………………………..

A-43

VII.3 OPTIONAL PARTS LIST …………………………………………………………………………………………………

A-43

Autoped/ M10 APPENDIX rev 0 (09221 DRAFT) A-5

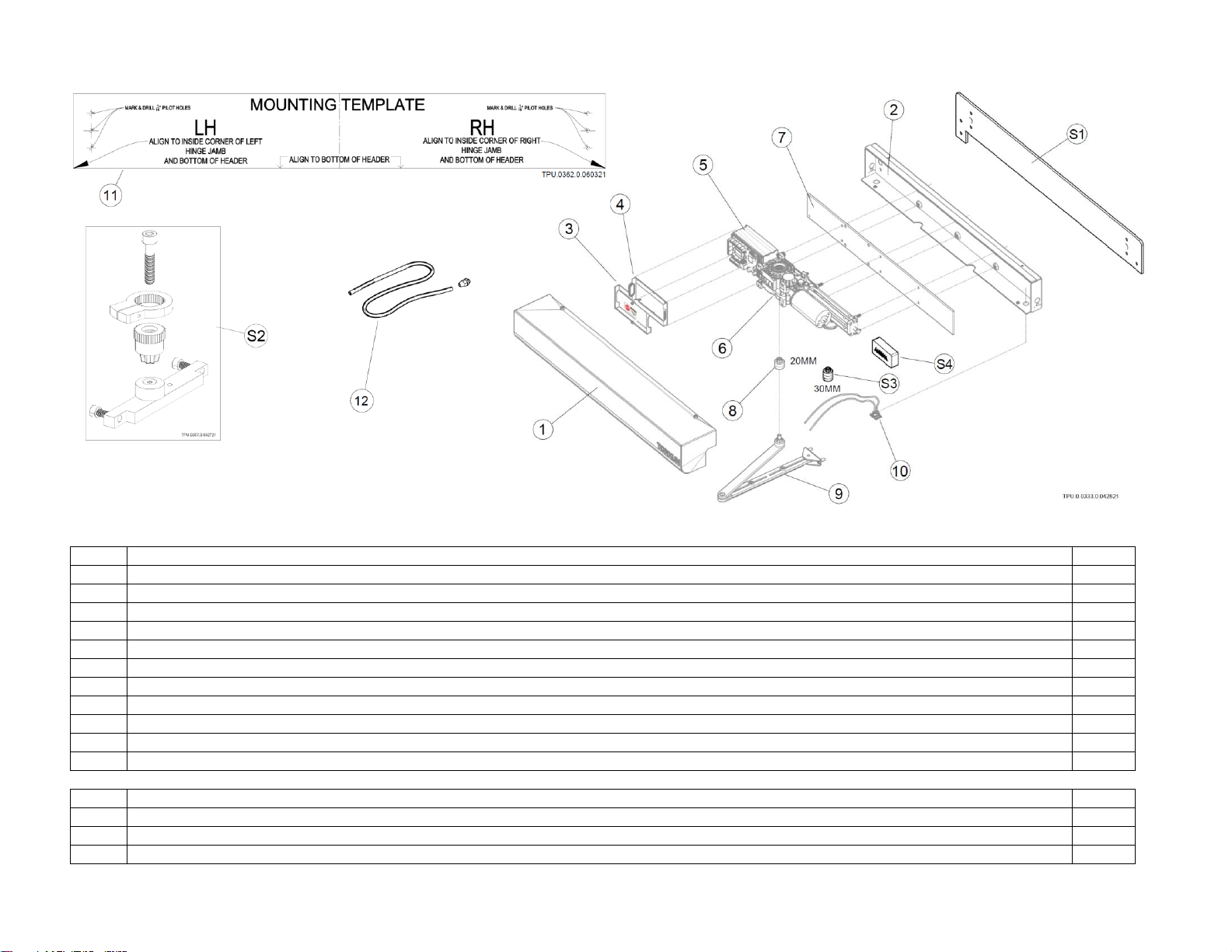

AUTOPED OPERATOR PARTS AND COMPONENTS

Item

Standard Parts Description

Qty

1

Enclosure Assembly - Front Cover

1

2

Enclosure Assembly - Rear Cover (Chassis)

1

3

Push Arm Assembly –factory assembled Lever Arm, Push Arm and Arm Shoe

1

4

Spindle Extension, 20mm

1

5

Rocker Switch

1

6

Control Unit Cover - Front and Rear

1 set

7

Drive Assembly–factory assembled motor-gearbox-controller on mounting plate

1 set

8

Drive Assembly Mounting Plate

1

9

Paper Mounting Template –for use on headers 4” or more in height or on door eaves

1

10

Rocker Switch Kit

1 set

11

Paper Mounting Template

1

12

Conduit Adapter Kit

1 set

Optional Parts Description

S1

Stiffener Plate (Optional)

(1)

S2

Positive Stop Kit (Optional)

(1)

S3

Spindle Extension, 30mm (Optional)

(1 set)

S4

Radio Frequency Activation Kit

(1)

Autoped/ M10 APPENDIX rev 0 (09221 DRAFT) A-6

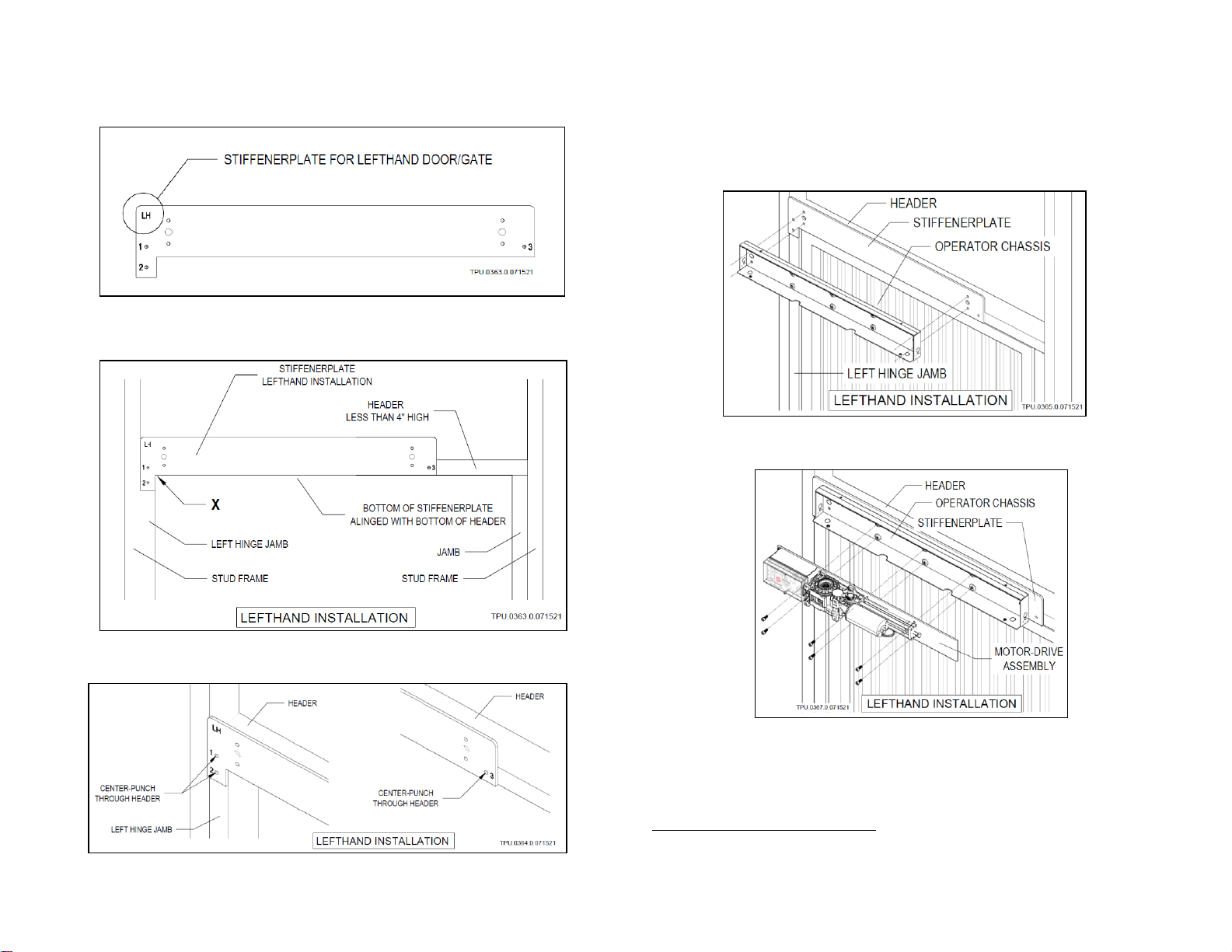

SECTION I

INSTALLING AUTOPED

ON

DOOR/GATE HEADERS LESS THAN FOUR INCHES (4”)

For installation of AUTOPED Operator on headers less than four inches (4”)

in height, TORXUN requires the use of the AUTOPED StiffenerPlate or its

equivalent to add rigidity to the installation of the operator

Autoped/ M10 APPENDIX rev 0 (09221 DRAFT) A-7

IMPORTANT INSTALLATION NOTE

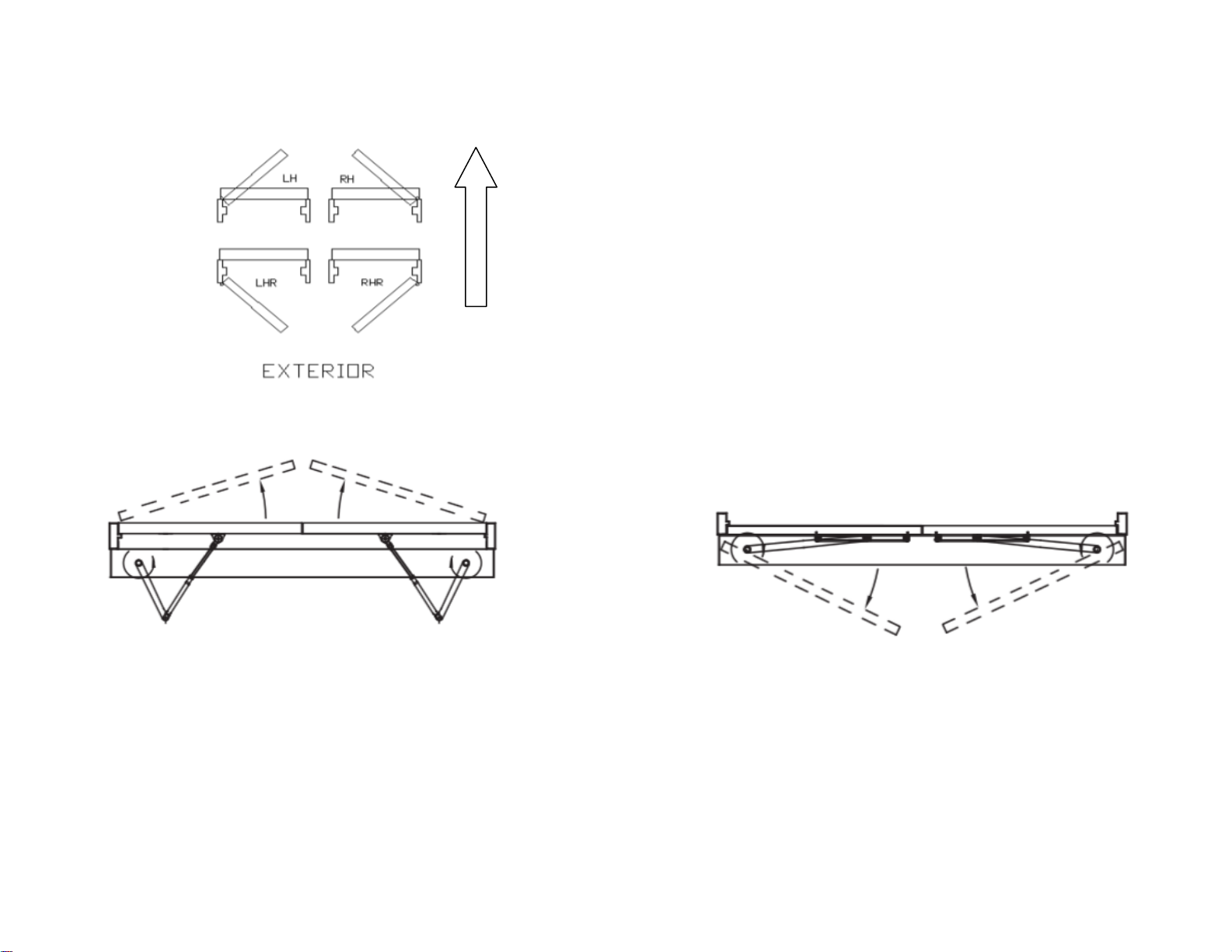

THE AUTOPED CAN BE USED FOR BOTH LEFTHAND OR RIGHTHAND DOOR/GATE SYSTEM WITHOUT

NEED FOR ADAPTER OR MODIFICATION

TO CHANGE HAND OF OPERATOR INSTALLATION:

FLIP THE MOTOR-DRIVE ASSEMBLY CLOCKWISE OR COUNTER-CLOCKWISE BEFORE

MOUNTING TO CHASSIS; Fig 1

CHASSIS IS NEUTRAL, ORIENTATION IS THE SAME FOR LEFT OR RIGHT HAND INSTALLATION

LEFTHAND OPERATOR INSTALLATION: CONTROL BOX UNIT IS AT LEFT OF GEAR BOX

RIGHTHAND OPERATOR INSTALLATION: CONTROL BOX UNIT IS AT RIGHT OF GEAR BOX

Fig I.1 CHANGING OPERATOR INSTALLATION: LEFTHAND TO RIGHTHAND OR VICE VERSA

Autoped/ M10 APPENDIX rev 0 (09221 DRAFT) A-8

I.1 DOOR HANDING

I.1aDefinition Door Handing

LH: Left Hand -> typically with a pull arm

RH: Right Hand -> typically with a pull arm

LHR: Left Hand Reverse -> typically with a push arm

RHR: Right Hand Reverse -> typically with a push arm

I.1bPush Application –Same Drive Unit for LHR and RHR

I.1c Pull Application –Same Drive Unit for LH and RH

Autoped/ M10 APPENDIX rev 0 (09221 DRAFT) A-9

I.2 INSTALLATION: LEFTHAND OPERATOR FOR HEADERS LESS THAN 4” IN HEIGHT

STEP 1 Use StiffenerPlate for Lefthand (LH) installation

STEP 2 Align “X”to corner of left hinge jamb and bottom of

header

STEP 3 Center-punch pilot holes 1,2,3

STEP 4 Drill 1/16” pilot holes 1,2,3

STEP 5 Fasten1StiffenerPlate through holes 1,2,3

STEP 6 Mount2operator Chassis to StiffenerPlate

STEP 7 Mount3Motor-Drive assembly to operator Chassis

STEP 8 Refer back to AUTOPED Installation Manual, Section I.5

to continue installation of the Swing Arm assembly

1Type, size and material of fasteners by installer

2Use screws NF 7/16 x 20 x 3/4 included in kit to mount

3Use screws M6 x 1.0 x 12 included in kit to mount

Autoped/ M10 APPENDIX rev 0 (09221 DRAFT) A-10

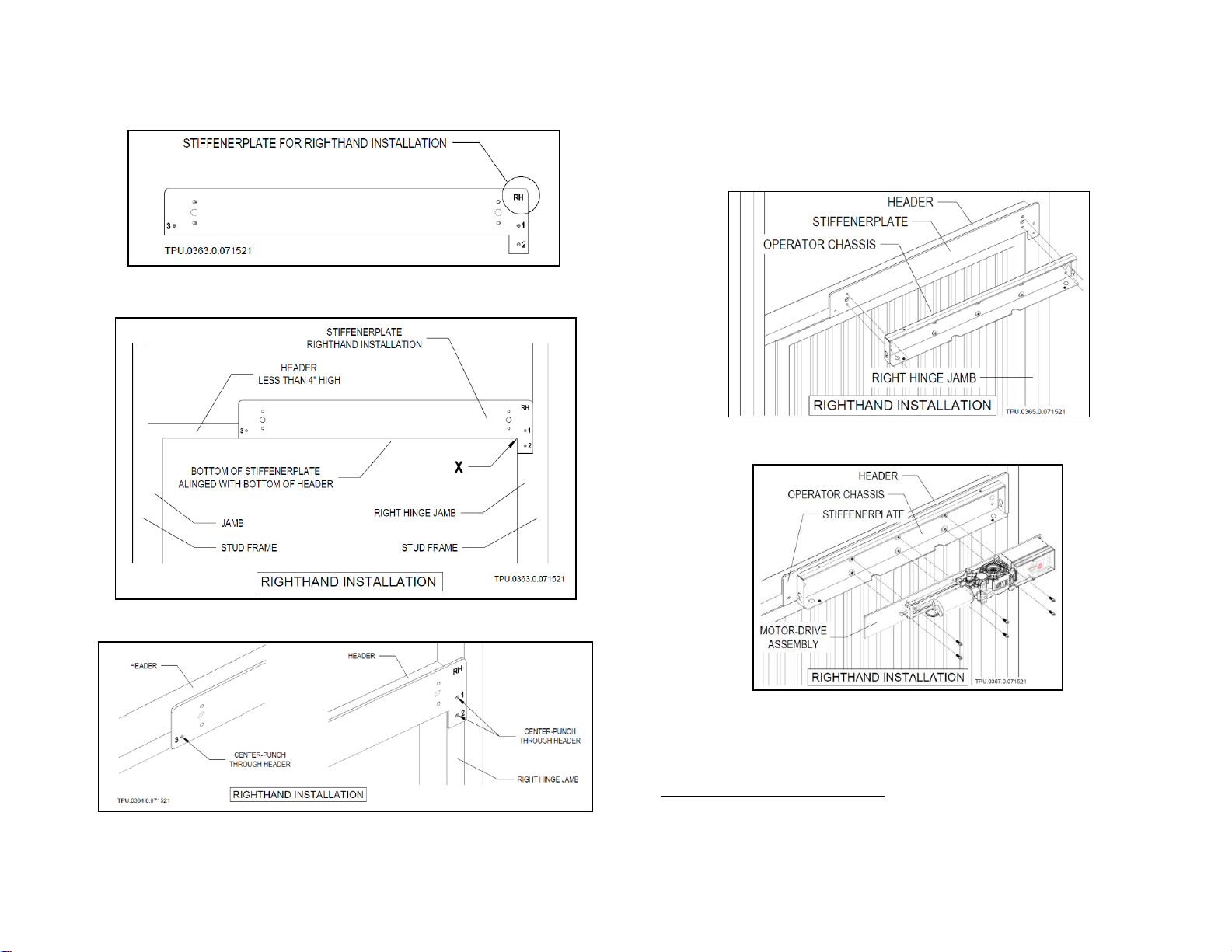

I.3 INSTALLATION: RIGHTHAND OPERATOR FOR HEADERS LESS THAN 4” IN HEIGHT

STEP 1 Use StiffenerPlate for Righthand (RH) installation

STEP 2 Align “X”to corner of right hinge jamb and bottom of

header

STEP 3 Center-punch pilot holes 1,2,3

STEP 4 Drill 1/16” pilot holes 1,2,3

STEP 5 Fasten4StiffenerPlate through holes 1,2,3

STEP 6 Mount5operator Chassis to StiffenerPlate

STEP 7 Mount6Motor-Drive assembly to operator Chassis

STEP 8 Refer back to AUTOPED Installation Manual, Section I.5

to continue installation of the Swing Arm assembly

4Type, size and material of fasteners by installer

5Use screws NF 7/16 x 20 x 3/4 included in kit to mount

6Use screws M6 x 1.0 x 12 included in kit to mount

Autoped/ M10 APPENDIX rev 0 (09221 DRAFT) A-11

SECTION II

INSTALLING THE AUTOPED

OPTIONAL POSITIVE STOP

TORXUN recommends use of the optional Positive Stop Kit when a physical stop

such as a wall, bollard, floor stop or similar items are not in place to limit the gate

or door from opening past safe limits 105º

Autoped/ M10 APPENDIX rev 0 (09221 DRAFT) A-12

II.1 OPTIONAL POSITIVE STOP KIT (P/N M10S.0040)

II.2 INSTALLING THE POSITIVE STOP

STEP 1 Swing door/gate to max opening; keep in open position.

STEP 2 Remove top two bolts on the Gear Box mounting plate

STEP 3 Install the Positive Stop Cam Bracket and Cam; use the

two stainless steel M6x3 bolts included in the kit

Autoped/ M10 APPENDIX rev 0 (09221 DRAFT) A-13

STEP 4 Gather the Spindle bolt, Positive Stop Clamp & Spindle

STEP 5 Assemble the Stop Clamp and Spindle together

STEP 6 Insert Clamp and Spindle assembly to the Gearbox

IMPORTANT NOTE ON STEP 6

Make sure that the Stop Clamp* and Stop Spindle*

are flush with each other when assembled (see

diagram*)

When placing the Stop Clamp* over the Stop

Spindle*, the door must be in the open position no

more than 105° from closed position. Place the Stop

Clamp so that its rounded vertical face (contact point)

is a hairline from making contact with the Positive

Stop Cam.

STEP 7 Insert the Spindle Bolt to the Positive Stop Clamp and

Spindle assembly; tighten to fasten the assembly to the

Gearbox

STEP 8 Go to section II.3 for Adjustment of Stop position

Autoped/ M10 APPENDIX rev 0 (09221 DRAFT) A-14

II.3 ADJUSTING THE STOP POSITION

Note: Maximum swing open position is 105º

STEP 1 Clamp the end of the Motor Shaft with a Vice Grip to

keep shaft from rotating

STEP 2 Loosen the set screw of the Positive Stop Clamp

STEP 3 Pull the Positive Stop Clamp off from the Spindle

STEP 4 Rotate the Positive Stop Clamp clockwise or

counterclockwise as needed (1~2 teeth at a time)

STEP 5 Reset the Positive Stop Clamp back on to the Spindle

STEP 6 Tighten the set screw

STEP 7 Remove grip from motor shaft, turn operator on to test

the open position of Door/Gate panel

STEP 8 If needed, repeat the preceding steps to test again

Fine adjustments of the stop position may be necessary and is

done by adjusting the Stop Cam position

STEP 9 Loosen the Positive Stop Cam Retaining Bolt

STEP 10 Rotate the Positive Stop Cam clockwise or

counterclockwise as needed

STEP 11 Tighten the Positive Stop Cam Retaining Bolt

STEP 12 Run the Operator to test the open position of Door/Gate

panel

STEP 13 If needed, repeat the preceding steps and test again

Autoped/ M10 APPENDIX rev 0 (09221 DRAFT) A-15

SECTION III

ADJUSTING

CLOSING-SPRING PRELOAD

In the process of installing the AUTOPED, the spring tension may need to be

adjusted to regulate the closing pressure of the door or gate panel. Make these

adjustments when the door or gate panel does not fully close or slams when

closing.

Autoped/ M10 APPENDIX rev 0 (09221 DRAFT) A-16

III. ADJUSTING CLOSING SPRING PRELOAD

The AUTOPED operator is equipped with a closing spring that

aids in the closure of the gate/door and to maintain closing speeds

while the gate/door is in manual mode. When power to the

operator is cut or turned off, the closing spring will allow the

Door/Gate to close in a controlled manner, fully latching the door

lock system.

The tension of the spring is responsible for regulating the amount

of pressure the door requires to be pushed open before the “Push

and Go”assist takes over.

Preload adjustment is done by turning the Adjusting Screw. By

default, distance Xbetween top of head of Adjusting Screw and

spring bracket is:

X= 1-1/32 inch (26 mm)

To adjust the Closing Spring Preload:

STEP 1 Swing Door/Gate panel open to about 60º

STEP 2 Allow panel to close on its own

STEP 3 Check to see if Door/Gate latches on full lock

STEP 4 Adjust distance Xaccording to Table II.3 (below)

STEP 5 Repeat the above steps if needed

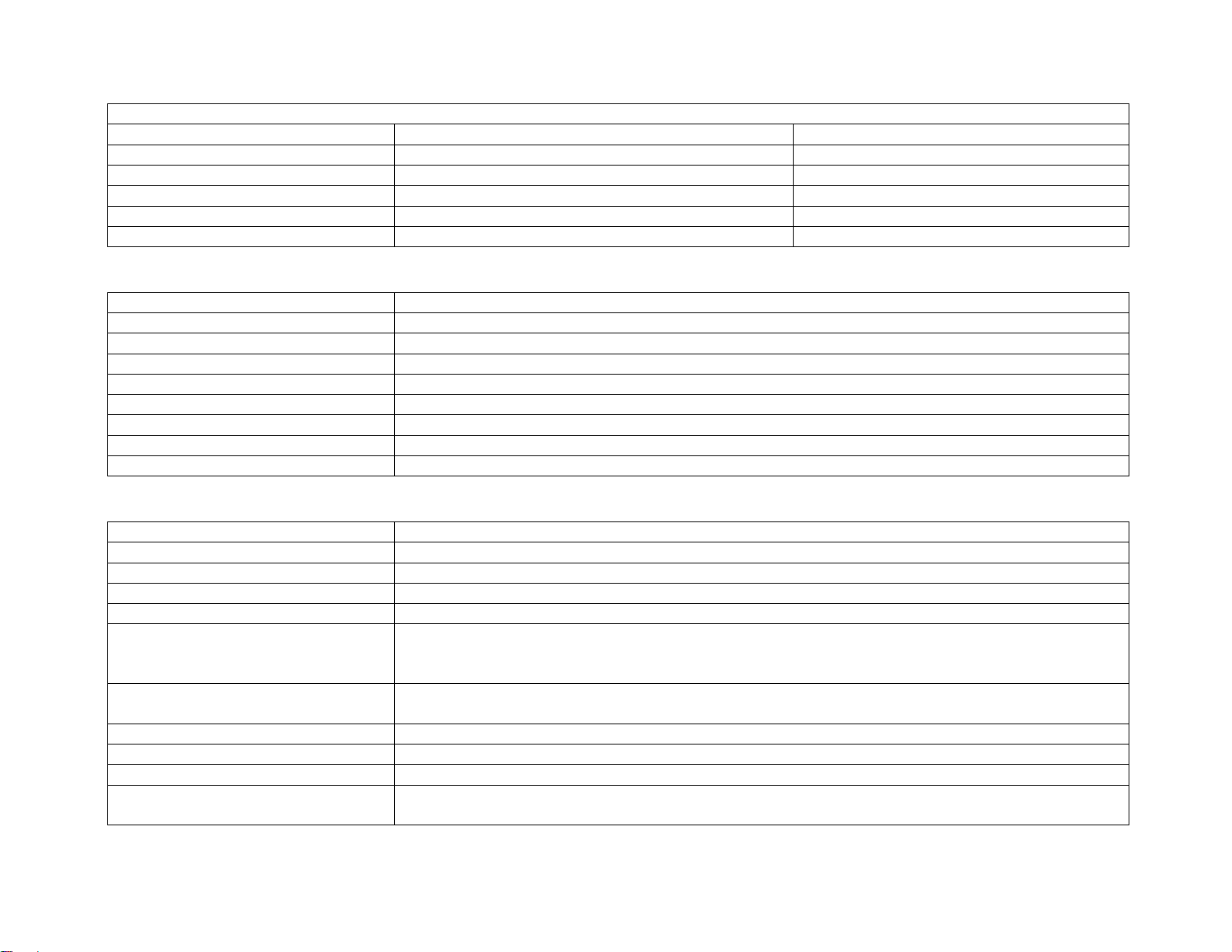

Table II.3 Preload XValues

Door/Gate

panel width

37”

43”

49”

55”

63”

Standard push arm

Measure “X”

1-9/16”

1-7/16”

1-1/4”

1-1/16”

7/8”

Optional slide arm

Measure “X”

1-7/16”

1-5/16”

1-1/16”

3/4”

11/16”

Autoped/ M10 APPENDIX rev 0 (09221 DRAFT) A-17

SECTION IV

MENUS AND PROGRAMMING

Autoped/ M10 APPENDIX rev 0 (09221 DRAFT) A-18

IV.1 PROGRAMMING FLOW: GUIDE CHART

IV.2 MENU GLOSSARY

Display

Description

OEO

Exterior activation sensor (exterior activation signal)

OEI

Interior activation sensor (interior activation signal)

KEY

Activation device (external switch activation signal, key switch, card reader, etc.)

SES

swing side Door/Gate mounted sensor (swing side safety signal)

PRE

Header mounted sensor on swing side

SER

Push side door mounted sensor (approach side safety signal)

SEF

Door mounted sensor for obstacle detection (recycle sensitivity)

EMY-IN

Emergency open input (emergency input signal)

PUGO

Push and go

Autoped/ M10 APPENDIX rev 0 (09221 DRAFT) A-19

IV.3CONTROL UNIT LED LIGHTS

LED description and color indications

LED

Description

Indicator

SOK

System ok

Green flashing

OE active

Opening devise

Blue=active

SE active

Safety devise

Yellow=active

Error

Error

Red

E-lock relay

E-lock relay

White

IV.4 LCD SCREEN GLOSSARY

Display

Description

<REF?>

Waits for reference switch

< ?? >

Unknown

><

Closed

>##<

Closed and locked

<<>>

Opening

<>

Open

>><<

Closing

==

Stopping

IV.5 CHART FOR MENUS AND WHAT THEY DO

Menu Title

Description

Parameter

Sets the parameters for swing Door/Gate movements

CONFIG

Configuration: sets the parameters of the AUTOPED control features and functions

DOUBLE DOOR

Sets the closing sequence and interlock function

DIAGNOSTICS

Diagnostic tools that display the status of various inputs

ERROR ACTIVE

Displays pending active errors

Activate error list is updated with the latest addictions appearing at the end

A0 indicates the latest active error

HISTORY ERROR

Displays all active errors that were detected and then corrected or not corrected.

H0 indicates the latest active error

REINT

Reinitialization resets settings back to factory default

BLOCK?

Locks/unlocks joystick

UPDATE SW

Start the upgrade process from the USB stick

TEACH

Programs the initial setup, finds errors (if any)

Programs a new setup procedure when deemed necessary

Autoped/ M10 APPENDIX rev 0 (09221 DRAFT) A-20

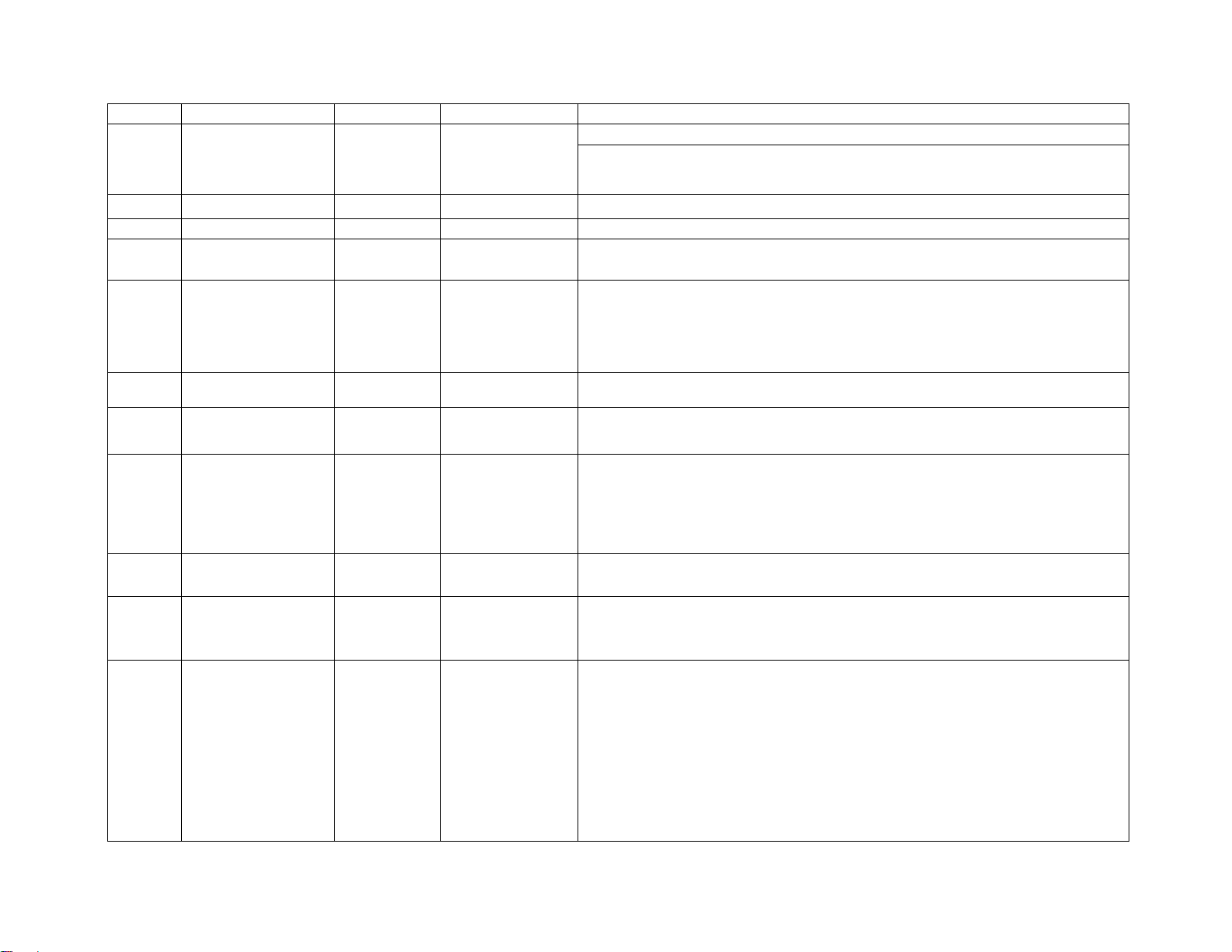

IV.6 CHART FOR OPTIONS IN THE PARAMETER MENU: SETTINGS FOR DOOR/GATE MOVEMENT

Device

Unit type

Default

Value

Description

Region

Both

Eu

Eu or us

EU- Europe; US- united states

Software version determined by UL standards. Must be changed to

US

Vo

Low energy

9

0-9

Vc

Low energy

9

0-9

TOEx

Low energy

5s

3-60s

ANSI 156.19 for low energy: TOEx must be no less than 5 seconds

TKey

Low energy

5s

3-180s

TKey sets the hold open time resulting from an activation signal

from a device (referred to as KEY) on terminals 2+3

With TOEx and TKey, you can set a different hold open time for

different activation devices by using different terminals

TPuGo

Low energy

3s

3-180s

Determines how long the Door/Gate stays open

TDelay

Low energy

.2s

0.0-4.0s

Tdelay sets the amount of time the door hesitates to allow the lock to

release before opening.

FDelay

Low energy

Off

Off-7.0A

Fdelay is a temporary “hold closed” force applied to the door to keep it

closed while the electric lock is being released. This parameter sets

the amount of force that is applied. FDelay is only active if TDelay

setting is greater than 0.

TLock

Low energy

0.5s

0.0-4.0s

Sets amount of time Door/Gate panel will press against lock to engage

it.

Flock

Low energy

2.0A

Off-7.0A

Sets amount of force that is applied to the Door/Gate panel to engage

the lock at the closed position. It is only active if TLock setting is

greater than 0.

FSlam

Low energy

Off

Off-10

Accelerating function (Force Slam). For example: when a Door/Gate

panel needs to be forced shut due to a latch or heavy seals.

Table of contents

Popular Industrial Equipment manuals by other brands

CRH

CRH Leviat HALFEN HDB-Z Assembly instructions

ABB

ABB HT842293 Operation manual

Danfoss

Danfoss AFPA 2 / VFG 2 DN 15-250 operating guide

RINGSPANN

RINGSPANN DV 025 PFM Installation and operating instructions

Starview

Starview SSB2-1418 Original instruction manual

Siemens

Siemens SIRIUS 3RV1923 operating instructions