Operation Manual / TPL76-C

Page 7

© Copyright 2016 ABB. All rights res

erved.

February 2016HZTL2485_ENRevision C

The turbocharger is a turbomachine and consists of the following main

components:

Turbine

Compressor

These are both mounted on a common shaft.

The exhaust gases from the diesel engine flow through the gas inlet

casing (07) and nozzle ring (08) to the turbine wheel.

The turbine wheel (09) uses the energy contained in the exhaust gas to

drive the compressor wheel (12). The compressor then draws in fresh air,

compresses it and then forces it into the cylinders.

The exhaust gases escape to free air through an exhaust gas pipe which

is connected to the gas outlet casing (06).

The air which is necessary for operation of the diesel engine and is

compressed in the turbocharger is drawn through the suction branch or

the filter silencer (01) into the compressor wheel (12). This air then passes

through the diffuser (11) and leaves the turbocharger through the

compressor casing (13).

The rotor runs in two radial plain bearings (02/05). One plain bearing is in

the bearing bush (04), and the second one is in the axial thrust bearing

(03) at the compressor end.

The plain bearings are connected to a central lubricating oil duct which is

fed with oil from the engine's lubricating oil circuit. The oil outlet is always

at the lowest point of the bearing casing (10).

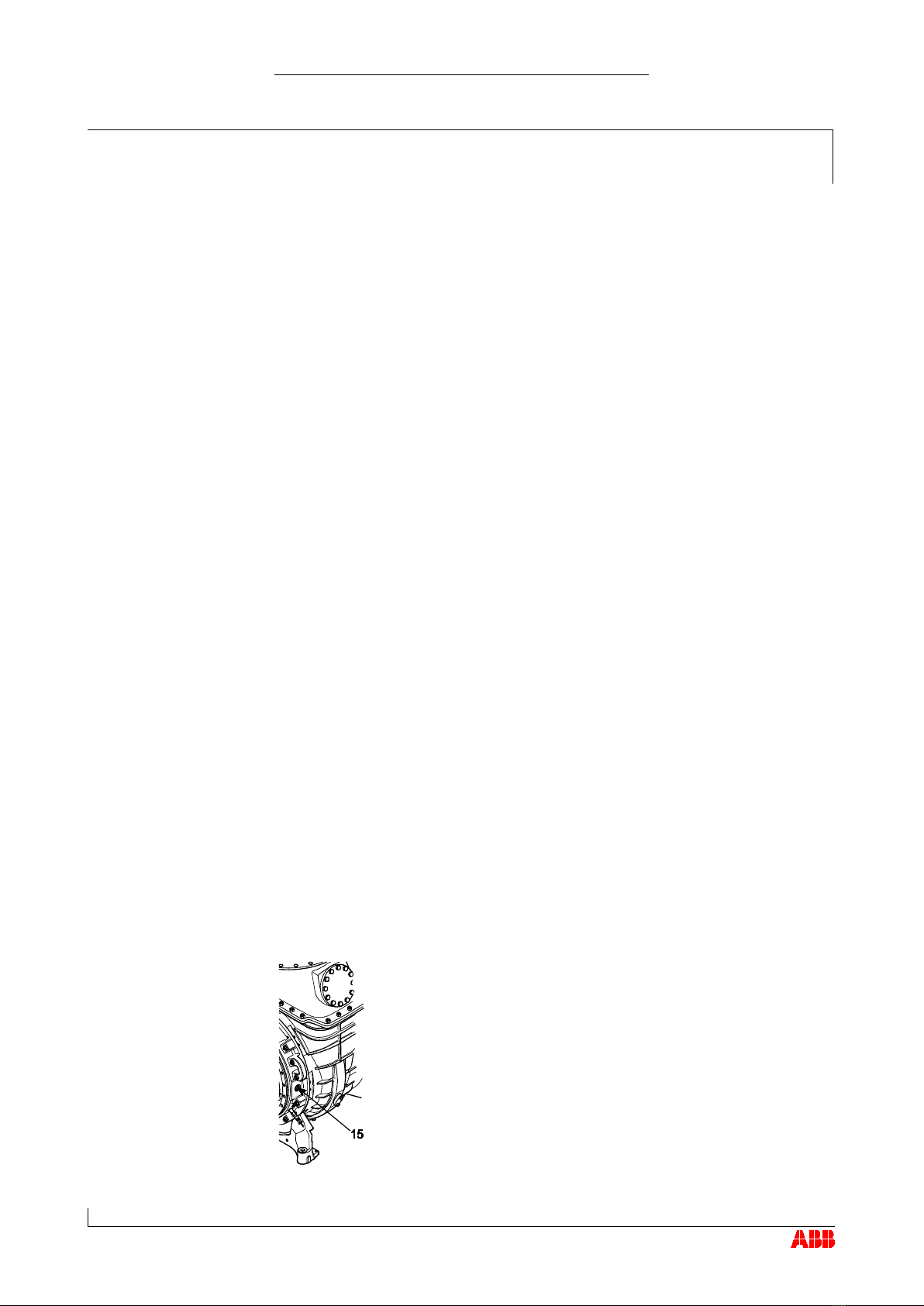

Turbocharger version with compressor wheel cooling system

Depending on its range of use, the turbocharger is

provided with a compressor wheel cooling system.

Compressor wheel cooling means that, after the charge air

cooler at the engine end, cooled compressor air is

delivered to the turbocharger to cool the compressor

wheel.

Depending on the respective operating conditions, it is

absolutely essential that the compressor wheel is cooled in

order to guarantee its reliability and the replacement

intervals. In the case of the turbocharger version with

compressor wheel cooling, the cooling air is supplied

through the side connection (15) in the bearing casing.