© Danfoss | 2021.03 | 7AQ372053646406en-000101

AFPA 2 / VFG 2 (21) DN 15-250, VFG 22 (221) DN 65-250

ENGLISH

Safety Notes

Prior to assembly and commissioning

to avoid injury of persons and damages

of the devices, it is absolutely necessary

to carefully read and observe these instructions.

Necessary assembly, start-up, and maintenance

work must be performed only by qualified,

trained and authorized personnel.

Prior to assembly and maintenance work on the

controller, the system must be:

- depressurized,

- cooled down,

- emptied and

- cleaned.

Please comply with the instructions of the

system manufacturer or system operator.

Disposal instructions

This product should be dismantled

and its components sorted, if possible,

in various groups before recycling or

disposal.

Always follow the local disposal regulations.

Definition of Application

The controller is used for differential pressure

control in bypass lines of water and water glycol

mixtures for heating, district heating and cooling

systems.

The technical data on the label plates determine

the use.

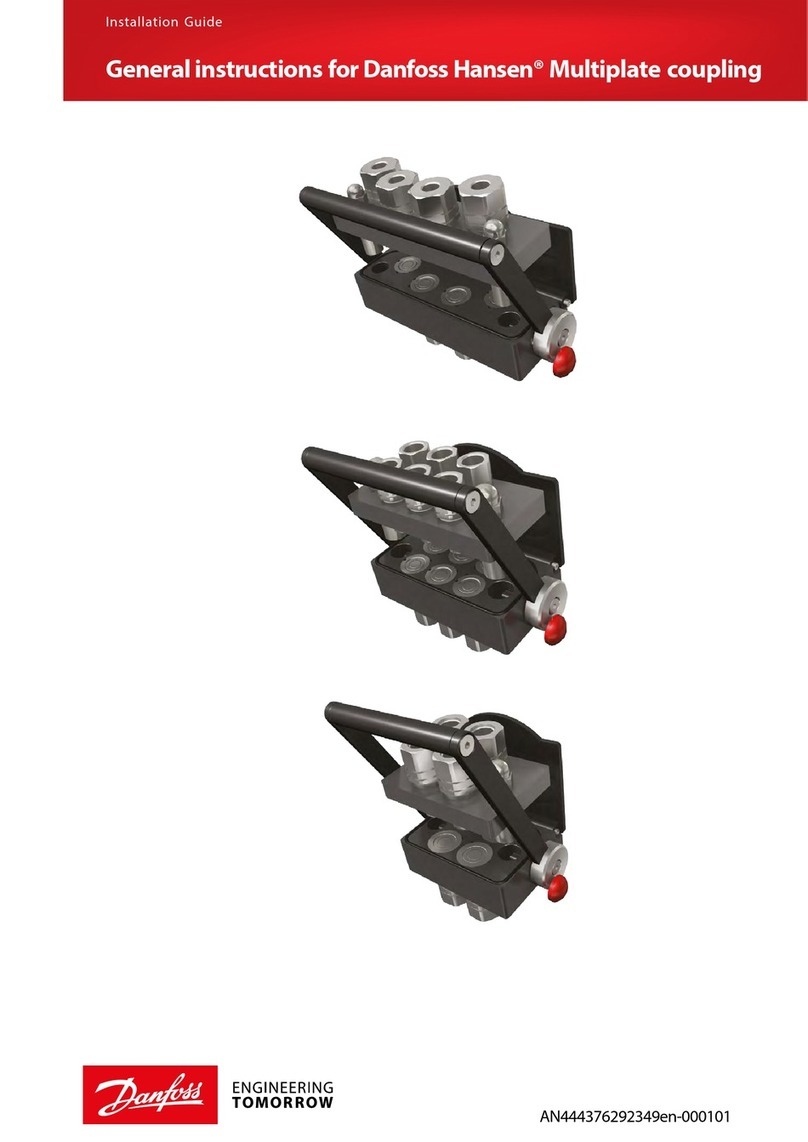

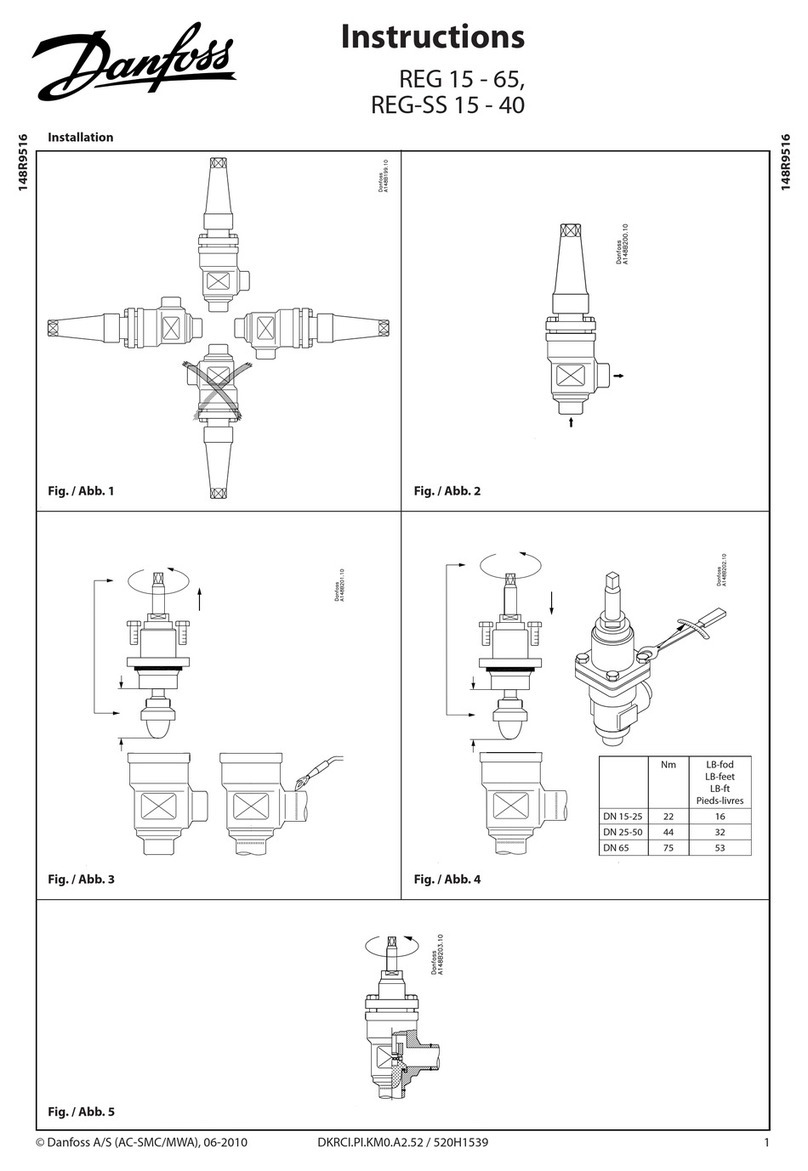

Scope of Delivery ❶

*) adapter 003G1780, accessory sold separately,

**) Impulse tube AF, accessory sold separately

Assembly

Admissible Installation Positions ❷

①media temperatures up to 150 °C:

Can be installed in any position.

②media temperatures > 150 °C.

Installation permitted only in horizontal

pipelines with the actuator oriented

downwards.

Installation Location and Installation

Scheme ❸

Bypass installation

The valve is closed without pressure

and is opening on rising differential

pressure ①.

Valve Installation ❹

1. Install strainer ①before the controller.

2. Rinse system prior to installing the valve.

3. Observe flow direction ②on valve body.

Flanges ③in the pipeline must be in

parallel position and sealing surfaces

must be clean and without any damage.

4. Install valve.

5. Tighten screws crosswise in 3 steps up to the

max. torque.

Actuator Installation ❺

The actuator stem must be screwed into

the valve stem. Spring on the pressure

actuator is factory adjusted (stressed).

For proper installation spring has to be

released (unstressed) first.

1. Remove the spindle protection cup and

release the valve spindle by removing the

nut, washer and cardboard tube.

2. Align the actuator stem with the valve stem,

connect both stems and turn gently the

whole pressure actuator clockwise with both

hands, until the stems are fully connected

(valve stem fully screwed into the actuator

stem).

3. Release the uninon nut by pulling out the

blocking spring.

4. Tight the union nut by hand or with wrench

key using minimal force

5. Release the pressure actuator by turning it

counter clockwise for approximately half a

turn.

6. Observe the position of impulse tubes

connection to the valve and align the

actuator accordingly.

7. Hold the actuator in the position and tight

the union nut to the valve with 100- 120 Nm

torque.

Impulse Tube mounting ❻

• Which impulse tubes to use?

The impulse tube set AF (2×) ❻① can be

used: Order No.: 003G1391

or use the following pipes:

Steel /

Stainless steel Ø 10×1 ISO 1127 D3/T3

Copper Ø 10×1 Cu-DHP R200

EN124 49

• The impulse tube ③ can be connected

directly to the valve ④

or

to the pipeline ⑤.

Connection to the valve ❼

1. Remove plug ①at the valve.

2. Screw in threaded joint G 1/4 ②with copper

seal, Torque 40 Nm.

- or -

Connection to the Pipeline ❽①

No connection downwards/upwards ②, could

bring dirt/air into an impulse tube.

1. Cut pipe in rectangular sections ③and

deburr.

2. For copper pipe:

insert sockets ④on both sides.

3. Verify the correct position of the cutting

ring ⑤.

4. Press impulse tube ⑥into the threaded joint

up to its stop.

5. Tighten union nut ⑦Torque 40 Nm.

When installing seal pots ❽⑧, please

observe the Installation Instructions

for the seal pots.

Insulation ❾

For media temperatures up to 120 °C the

pressure actuator may be insulated ①.

Dismounting ❿

Danger

Danger of injury by hot water

Prior to dismounting depressurize system or

use shut off valves on the impulse tubes! ①

Carry out dismounting in following steps: ②

1. Fasten pressure actuator with the safety

bands to the fixed points in surroundings

2. Before releasing the actuator, fully release

the union nut

3. Hold the pressure actuator with both

hands, and release it by turning it counter

clockwise ~30 turns. During turning, control

the actuator weight all the time to prevent

unexpected fall of detached actuator.

4.

Carefully remove the actuator from the valve.

Before installing actuator back to the valve,

setting spring must be fully released again.

Leak and Pressure Test ⓫

Observemax.

permitted pressure, see below.

The pressure behind the valve ②must not

exceed the pressure before the valve ①.

Observe nominal pressure ⑤of the valve.

Caution:

The valve is closed without pressure and it

opens on rising pressure before the valve.

Prior to pressure tests, it is absolutely necessary

to remove the impulse tube at the valve ④.

Close connections with plugs G ¼ ISO 228.

Max. pressure [bar] with connected impulse tube:

AFPA 2

cm232 80 160 320 640

bar 16 52.5 1.3 0.35

Max. test pressure with disconnected impulse

tube must not exceed the plant testing pressure

and must always be lower than 1.5 × PN.

Non-compliance may cause damages at the

controller ③.

Filling the System, Start-up ⓬

The pressure ②behind the valve

must not exceed the pressure ①before

the valve.

Non-compliance may cause damages at the

controller ③.

1. Open shut-off devices that are possibly

available at the impulse tubes ④.

2. Slowly open valves in the system.

3. Slowly open shut-off device ⑤.

4. Slowly open shut-off device ⑥.

Putting out of Operation

1. Slowly close shut-off device ⑤.

2. Slowly close shut-off device ⑥.

Setpoint Adjustment ⓭

1. Set-point range see rating plate ①

2. Start-up of system, see section ⓬.

3. Start pump ②

4. Observe pressure indicator ③

5.

Slightly close fitting ④behind the pump (in

flow direction) so that the pressure

③

is rising.

6. Adjustment of the differential pressure over

the valve:

•

Turning to the right ⑥reduces the set-point

(unstressing the spring - tension spring)

•

Turning to the left ⑦increases the set-point

(stressing the spring)

7. If the required pressure ③cannot be set,

further close the fitting ④.

8. The set-point adjuster ⑧may be sealed.

9. Release the not yet used pointer ⑨, move it

to the set position and fix it with the screw to

mark setting position

Dimensions ⓮

Flanges: connection dimensions acc. to

DIN 2501, seal form C