6F2S1923 (0.03)

-1-

1 Introduction

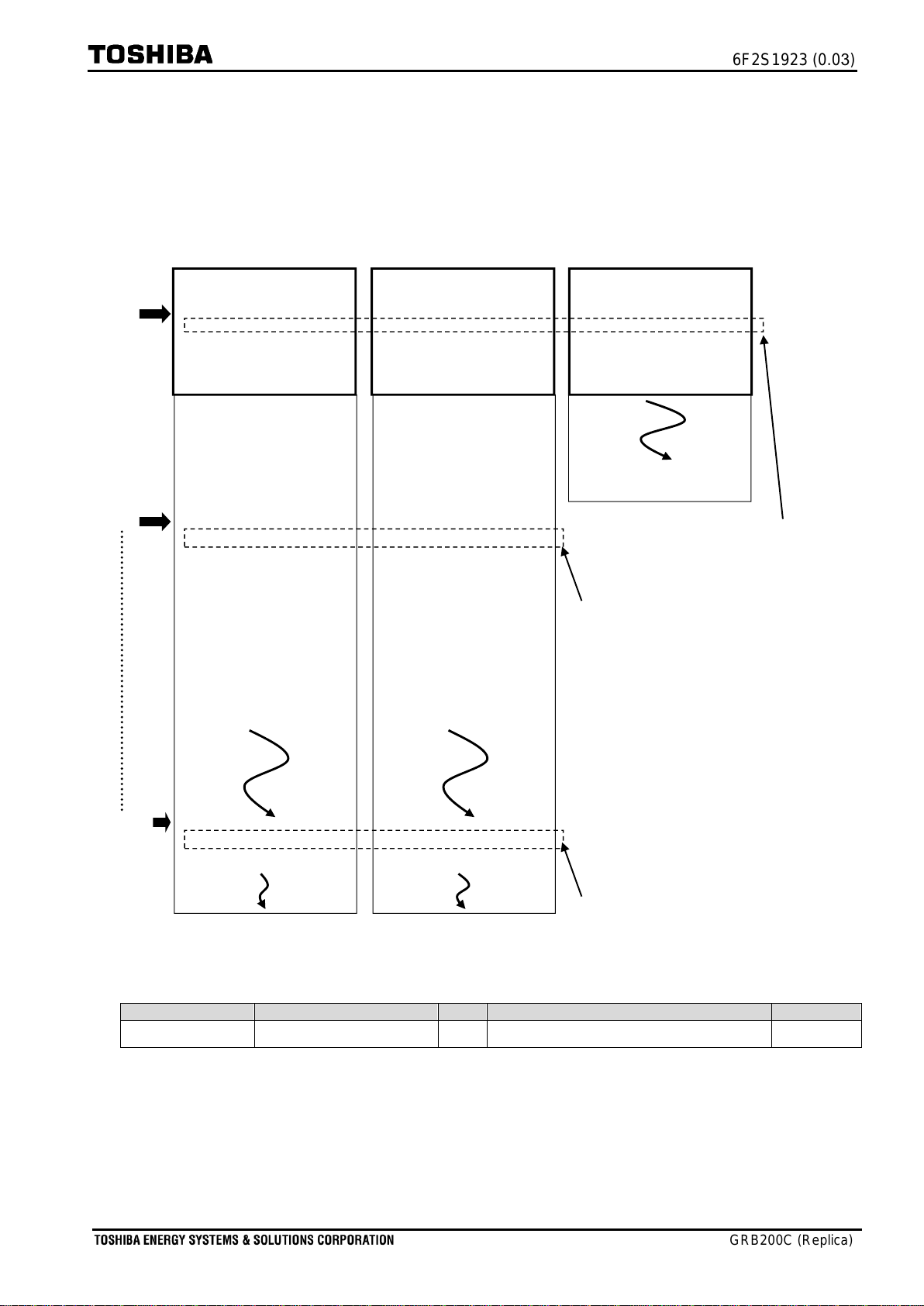

In order that a busbar is protected, the user must implement within it the busbar topology of

the substation to which it is to be applied. GRB200 relay operates using a check-zone-

protection zone (DIFCH) and discriminating-zone-protection zones (DIFZA, DIFZB etc.). The

DIFCH zone provides an overall protection for the entire busbar, whilst the DIFZA, DIFZB etc.

zones provide individual protection zones for discrete busbar sections. The zones are protected

based on the differential protection principle (DIF; derived from Kirchhoff’s law).

Busbar transformation does not affect the DIFCH zone protection because the sum of all

of the currents flowing in the busbar is zero regardless of the transformation. On the other

hand, busbar transformation may affect DIFZA, DIFZB etc. zone protections because they

operation for individual one. The zone could vary through busbar transition. The replica

feature is able to follow the busbar transition when the ‘Open’or ‘Closed’position signals are

given with the substation circuit breakers (CBs) and disconnectors (DSs). Thus, the DIFZA,

DIFZB etc. zones are able to follow the busbar transition so that the protection can work

correctly.

The replica feature duplicates the currents flowing in respective discriminating-zone-

protection zones; it is required for the user to have settings for respective channels (CHs).

Busbar topology and operation can be duplicated by Replica with 24 CHs.

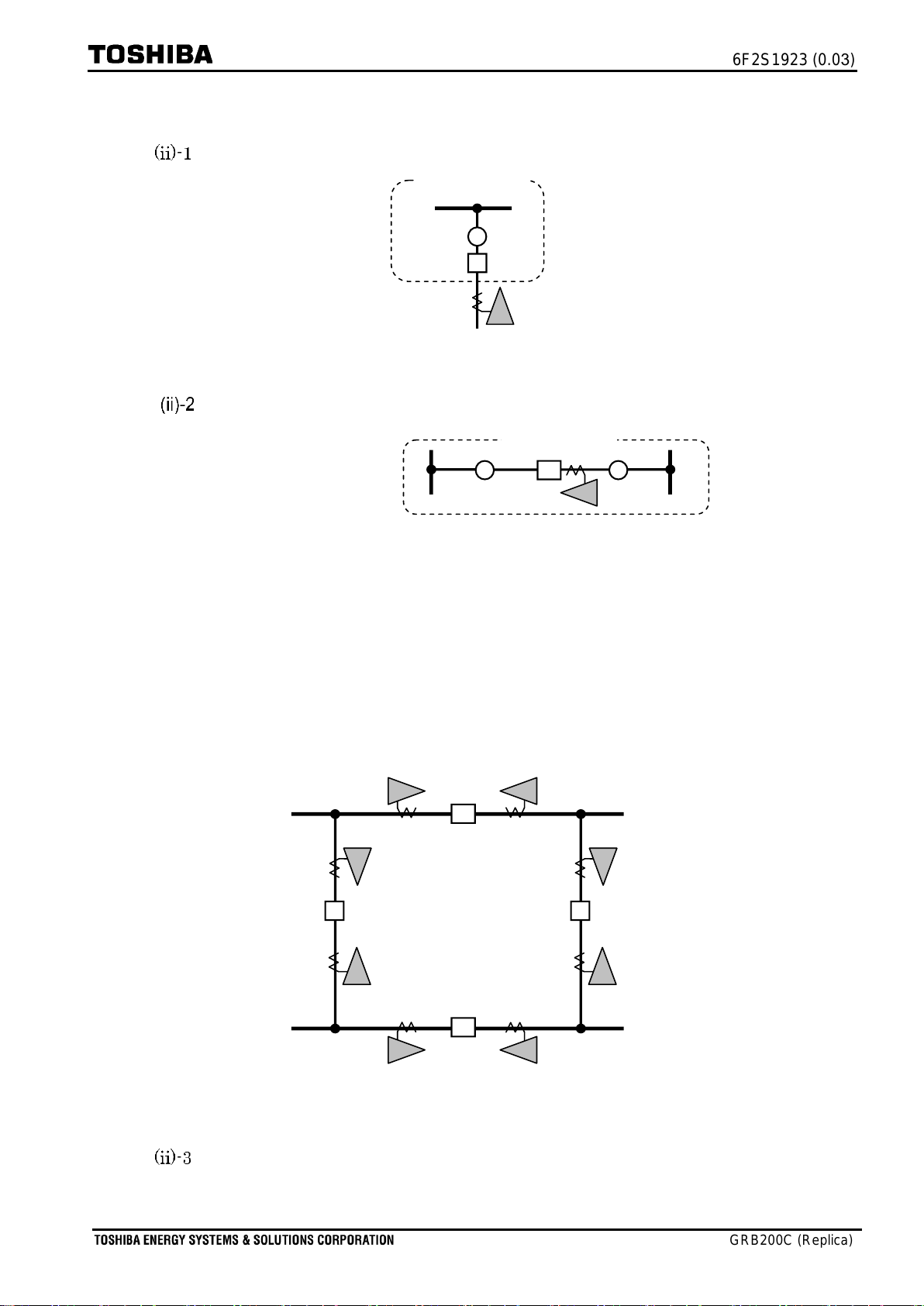

A CH can correspond with a feeder. The CH can have three protection zones or less:

Zone1, Zone2, and Zone3. A protection zone (DIFZ*) corresponds with a protection

zone (Zone*) on one-to-one basis.

A CH can correspond with a bus coupler. Forward Zone1/Zone2/Zone3 and Reverse

ZoneR1 are ready to protection. A protection zone (DIFZ*) is assigned to a protection

zone (Zone*) on one-to-one basis.

CT inputs are for current information about flowing-in and flowing-out in each zone.

During a particular operational condition such that a bus-coupler circuit breaker is

opened, if the protection zone does not require current information, Zero ampere

control is invoked so that the current is not relevant to the differential calculation

─────────────────────────────────────────────────────────────────

Note: The contents discussed herein are based on an understanding of the principle of

operation of the GRB200 relay that are described in a separate Instruction

manual entitled “

Centralized Busbar Protection IED GR200 series (GRB200).”