6

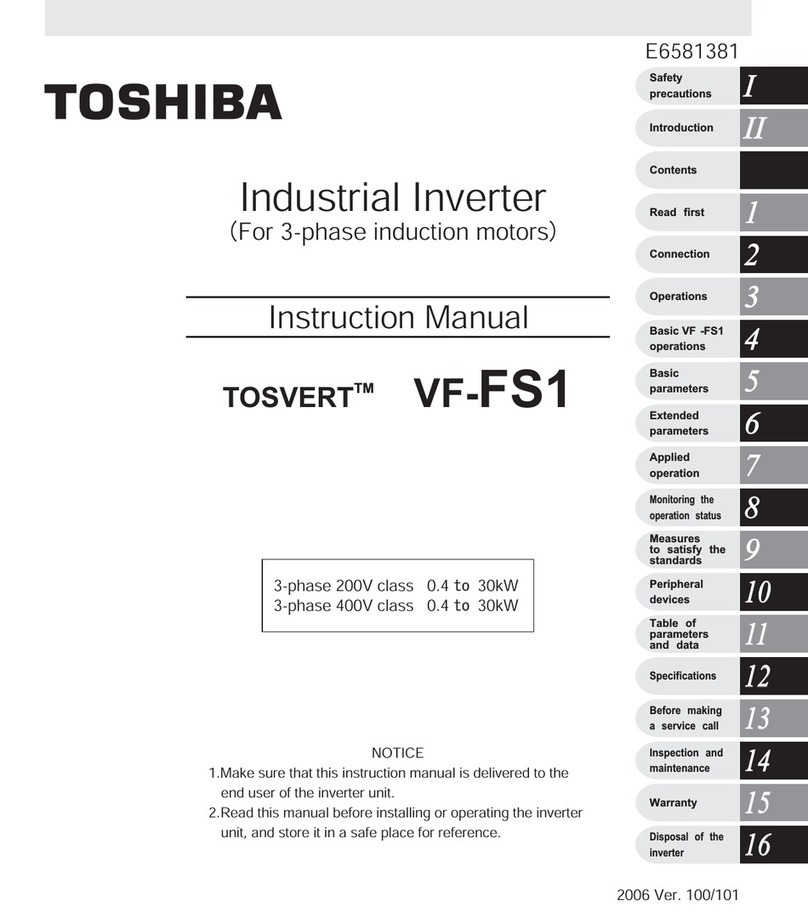

2. Component names and functions (continued)

SHC

OS

0

0

0

000

12341234 1234 12

312 4

RST

COM

NONC65L2L1

Printed circuit

board

1. Error determinations

2. Special settings

3. Remote communication

4. Oil-back settings

Operation control

selection

Operational speed

selection

Cut-off pressure setting

Setting pressure

(low-pressure constant control)

Cut-in pressure setting

Cut-off pressure difference

(low-pressure constant control)

Pipe connection port (liquid)

Pipe connection port (gas)

Analog signal selection switch

This switch sets the type of analog signal.

Maximum operating speed setting switch

This switch sets the maximum operating speed for the

inverter.

Sets the operating speed for low-pressure differential

control and test operation mode.

Operating control setting switch

Sets the operating control method for the inverter.

(Set this switch before switching the power supply

ON. Cannot be switched during operation.)

Auxiliary control switch

Can set the number of retries until error determination,

special settings, external device communication, and

whether or not to use oil-back operation.

System setting switch

This switch sets the control system. This switch is pre-set upon leaving

the factory. Do not change the factory default.

Display setting switch

This switch can set and change LED display functions.

Cut-in pressure setting switch

This switch sets the cut-in pressure for low-pressure differential control.

When low-pressure constant control is used, this switch sets the

pressure difference with respect to the stopping pressure.

Operating pressure and cut-off pressure

setting switch

This switch sets the operating low-pressure value for low-pressure

constant control. Also sets the cut-off pressure when low-pressure

differential control is used.

Compressor delay duration reduction switch

This switch reduces the duration of the compressor restart delay by

causing a short. Should not be used during normal operation. (Use

only during checks, such as test operation)

Power supply terminals (L1, L2, L3, N)

Connect to a 380-415 V 3N~ (50 Hz) power supply.

Analog input terminals (7, 8)

Connect analog input signals (4 mA to 20 mA, 1 mA to 5 mA, 1 V to

5 V DC) if used for control.

Error reset terminals (9, 10)

These terminals can perform an error reset when shorted.

(may not always succeed in resetting, depending on the error type)

Remote operation / stop terminals (11, 12)

Start when shorted, stop when released. (can be used for emergency

stops, pump-out stops, and analog signal control stops)

Communication terminals (S1, S2, SG)

Connect a dedicated Toshiba controller, if used.

(Use a shielded wire of at least 0.3 mm2)

Solenoid valve power terminals (L, N)

Power supply (220-240 V AC) for a solenoid valve.

(Maximum capacity: 4 A or less)

Error output terminal (NC, NO, COM)

Used for no-voltage contact output during a condensing unit error.

(Maximum capacity: 220-240V AC, 4 A or less)

Defrost heater control terminals (5, 6)

Can provide a voltage-less connection if switched ON while the

compressor is stopped.

(Maximum capacity: 220-240 V AC, 4 A or less)

Display LEDs

Normally displays the discharge pressure (MPa) and intake pressure

(MPa).

Also displays error codes when errors occur.

Changing the display mode enables the operating frequency, various

operational data, and past error history to be displayed.

Controller selection switch

This switch is pre-set to the right-hand side upon leaving the factory.

Do not change the factory default.

*This model does not allow refrigerant selection setting.

Power switch

Can be switched OFF to force-stop the condensing unit.

*Note: The original power source is not interrupted. Exercise caution.

Operation switch

Can force-close the line solenoid valve via pump-down stop.

Grounding screw

Frontal cabinet removed