Toss PIREG 545 User manual

PIREG 545 cUL Operators Guide 2021

1

PIREG®-545

Operator’s Guide

539 South Main Street Phone: (610) 759-8883 E-Mail: info@tossheatseal.com

Nazareth, PA 18064 Fax: (610) 759-1766 Web: www.tossheatseal.com

PIREG 545 cUL Operators Guide 2021

2

Table of Contents:

1. GENERAL, SAFETY AND WARNING INSTRUCTIONS ............................................................................................ 6

1.1. NOTE ON THE OPERATOR’S GUIDE ............................................................................................................................. 6

1.2. ICONS AND SYMBOLS ............................................................................................................................................... 6

1.3. GENERAL SAFETY INSTRUCTIONS ................................................................................................................................ 6

1.4. APPLICATION ......................................................................................................................................................... 6

1.5. HEAT SEAL BANDS AND GENUINE TOSS ALLOY 20® ..................................................................................................... 6

1.6. IMPULSE TRANSFORMER .......................................................................................................................................... 7

1.7. CURRENT TRANSFORMER ......................................................................................................................................... 7

1.8. LINE FILTER ............................................................................................................................................................ 7

1.9. GENERAL ASSEMBLY INSTRUCTIONS AND DIMENSIONS .................................................................................................... 7

1.10. CE CONFORMITY & CUL LISTING ............................................................................................................................. 8

1.11. MAINTENANCE..................................................................................................................................................... 9

1.12. DISPOSAL ............................................................................................................................................................ 9

2. CONTROLLER DESCRIPTION AND INSTALLATION OVERVIEW ............................................................................. 9

2.1. INSTALLATION OVERVIEW ....................................................................................................................................... 10

2.2. PIREG®-545 REAR ELECTRICAL PIN-OUT ................................................................................................................... 10

2.3. WIRING DIAGRAM FOR THE PIREG®-545 .................................................................................................................. 11

2.4. WIRING DIAGRAM FOR THE PIREG®-545 WITH EXTERNAL SOLID-STATE RELAY (BOOSTER) ................................................ 11

3. INSTALLATION AND COMMISSIONING .............................................................................................................12

3.1. INSTALLATION ...................................................................................................................................................... 12

3.2. CONFIGURING THE SECONDARY VOLTAGE AND CURRENT ............................................................................................... 12

3.3. CONFIGURING THE SETTINGS ................................................................................................................................... 12

3.4. CONNECTING THE PIREG®-545 .............................................................................................................................. 12

3.5. EXTERNAL SOLID STATE RELAY (BOOSTER) ................................................................................................................. 13

3.6. CONTROL INPUTS .................................................................................................................................................. 13

3.7. CONNECTING TO THE MAINS VOLTAGE ...................................................................................................................... 13

3.8. THE TOSS ALLOY 20 & SUITABLE HEAT SEAL BAND MATERIALS ................................................................................... 13

3.9. BURNING IN THE GENUINE TOSS ALLOY 20 HEAT SEAL BAND ........................................................................................ 13

3.10. CURRENT TRANSFORMER ..................................................................................................................................... 13

3.11. WHEN THE CONTROLLER DOES NOT WORK CORRECTLY ............................................................................................... 14

4. OPERATION ......................................................................................................................................................14

4.1. BUTTONS ............................................................................................................................................................ 14

4.1.1. Changing between menu levels: .............................................................................................................. 14

4.1.2. Setting of numeric values: ....................................................................................................................... 14

4.1.3. Setting of functions: ................................................................................................................................. 14

4.1.4. Accepting numeric values or functions: ................................................................................................... 14

4.1.5. Menu return: ............................................................................................................................................ 15

4.1.6. Brightness: ............................................................................................................................................... 15

4.1.7. Edit Prevention: ....................................................................................................................................... 15

4.1.8. Locking: .................................................................................................................................................... 15

5. FUNCTIONS ......................................................................................................................................................15

5.1. CONTROL ............................................................................................................................................................ 15

5.1.1. Setting temperature coefficients: ............................................................................................................ 15

5.1.2. Temperature range: ................................................................................................................................. 15

5.1.3. Transformer type: .................................................................................................................................... 15

5.1.4. Reference temperature: ........................................................................................................................... 15

5.2. AUTO CALIBRATION AND TEMP. COEFFICIENT CORRECTION: ......................................................................................... 15

5.2.1. Establishing the ambient temperature’s reference resistance (Rref): ..................................................... 15

5.2.2. Single-point temperature coefficient correction: ..................................................................................... 15

5.2.3. 8-Point Temperature-coefficient correction: ........................................................................................... 16

5.3. OFF-STATE .......................................................................................................................................................... 16

5.4. ON STATE............................................................................................................................................................ 16

5.5. TIME CONTROL ..................................................................................................................................................... 16

5.5.1. Preheating: .............................................................................................................................................. 16

5.5.2. Start delay: .............................................................................................................................................. 17

PIREG 545 cUL Operators Guide 2021

3

5.5.3. Sealing time: ............................................................................................................................................ 17

5.5.4. Cooling phase: ......................................................................................................................................... 17

5.6. MONITORING ...................................................................................................................................................... 17

5.6.1 Temperature diagnostic: .......................................................................................................................... 17

5.6.2. Temperature rise monitor: ....................................................................................................................... 17

5.6.3. Start signal monitor: ................................................................................................................................ 17

5.7. ALARM STATE ...................................................................................................................................................... 18

5.7.1. Possible Alarms: ....................................................................................................................................... 18

5.7.2. Fault Area Diagram: ................................................................................................................................ 19

5.8. INPUTS ............................................................................................................................................................... 21

5.8.1. Start inputs: ............................................................................................................................................. 21

5.8.2. Preheat inputs: ........................................................................................................................................ 21

5.8.3. Autocal Start Input: ................................................................................................................................. 22

5.8.4. Reset Input: .............................................................................................................................................. 22

5.8.5. “Set” Temperature Input: ........................................................................................................................ 23

5.9. OUTPUTS ............................................................................................................................................................ 24

5.9.1. Actual Temperature Output: ................................................................................................................... 24

5.9.2. Alarm output: .......................................................................................................................................... 24

5.9.3. Booster output: ........................................................................................................................................ 24

5.9.4. K1 and K2 - Control relay outputs: ........................................................................................................... 24

5.9.5. Output 1 - Message relay: ....................................................................................................................... 24

5.10. RELAY AND OUTPUT FUNCTIONS - K1 RELAY, K2 RELAY, OUTPUT 1 ............................................................................. 25

5.10.1. Timing Charts for Relay and Output Functions ...................................................................................... 26

5.10.1. Timing Charts Continued: ...................................................................................................................... 27

5.11. DISPLAY FUNCTIONS ............................................................................................................................................ 27

5.11.1. Languages: ............................................................................................................................................ 27

5.11.2. Brightness: ............................................................................................................................................. 27

5.11.3. Hold mode: ............................................................................................................................................ 27

5.11.4. Batch and Cycle Counters: ..................................................................................................................... 27

5.11.5. Recipe Storage: ...................................................................................................................................... 27

5.11.6. Security Protection: ................................................................................................................................ 27

5.11.7. Temperature unit: .................................................................................................................................. 28

6. MENU STRUCTURE ...........................................................................................................................................28

6.1. START ................................................................................................................................................................ 28

6.2. HOME SCREEN ..................................................................................................................................................... 28

6.2.1. Home Screen with time control ON ......................................................................................................... 28

6.2.2. Home Screen with time control OFF ........................................................................................................ 29

6.2.3. Alarm Screen ............................................................................................................................................ 30

6.3. SETTING-MENU .................................................................................................................................................... 30

Settings Menu 101 – Seal Temperature............................................................................................................. 30

Settings Menu 102 – Preheat Temperature....................................................................................................... 30

Settings Menu 103 – Start Delay ....................................................................................................................... 31

Settings Menu 104 – Sealing Time ..................................................................................................................... 31

Settings Menu 105 – Cooling Mode ................................................................................................................... 31

Settings Menu 106 – Hold Mode ....................................................................................................................... 31

Settings Menu 107 - AutoCal ............................................................................................................................. 31

Settings Menu 107 – AutoCal CONTINUED ........................................................................................................ 32

Settings Menu 108 - AutoComp ......................................................................................................................... 32

Settings Menu 109 - Single Point Calibration .................................................................................................... 32

Settings Menu 110 – 8-Point Calibration ........................................................................................................... 33

Settings Menu 111 – Recall Recipe .................................................................................................................... 33

Settings Menu 112 – Save Recipe ...................................................................................................................... 33

Settings Menu 113 – Batch Counter Reset ........................................................................................................ 34

6.4. CONFIGURATION-MENU ......................................................................................................................................... 34

Configuration Menu 201 - Language ................................................................................................................. 34

Configuration Menu 202 – Recall / Save Settings .............................................................................................. 34

Configuration Menu 203 – Alloy Tc Selection / ppm.......................................................................................... 34

Configuration Menu 204 – Variable Tc Setting .................................................................................................. 35

Configuration Menu 204 a-d – Variable Tc Settings .......................................................................................... 35

Configuration Menu 205 – Temperature Range ................................................................................................ 35

Configuration Menu 206 – Maximum Temp. Setting ....................................................................................... 35

PIREG 545 cUL Operators Guide 2021

4

Configuration Menu 207 – Low Temperature Deviation ................................................................................... 36

Configuration Menu 208 – High Temperature Deviation .................................................................................. 36

Configuration Menu 209 – Time Control ........................................................................................................... 36

Configuration Menu 210 – Cool Mode Selection ............................................................................................... 36

Configuration Menu 211 – Start of Sealing Timer ............................................................................................. 36

Configuration Menu 212 – K1 Relay Function ................................................................................................... 36

Configuration Menu 212a – K1 Impulse Duration ............................................................................................. 37

Configuration Menu 213 – “Hand” Button Function ......................................................................................... 37

Configuration Menu 214 – Seal Cycles (Resettable) .......................................................................................... 37

Configuration Menu 215 – Alarm Relay Switch Mode ....................................................................................... 37

Configuration Menu 216 – Output 0-10 VDC / Ref. ........................................................................................... 37

Configuration Menu 217 – Temperature Diagnosis .......................................................................................... 37

Configuration Menu 218 – Temp. Diagnosis Time Delay ................................................................................... 38

Configuration Menu 219 – Heat-Up Time Out ................................................................................................... 38

Configuration Menu 222 – Output 1 Function ................................................................................................... 38

Configuration Menu 222a – Output 1 Impulse Duration ................................................................................... 38

Configuration Menu 223 – Output 1 Switching Mode ....................................................................................... 38

Configuration Menu 225 – Temperature Unit C° or F°....................................................................................... 38

Configuration Menu 226 – Batch Counter-Home Screen ................................................................................... 39

Configuration Menu 227 – Advance PIREG Features ......................................................................................... 39

6.5. ADVANCED CONFIGURATION MENU .......................................................................................................................... 39

Advance Config. Menu 301 – Tc Correction ....................................................................................................... 39

Advance Config. Menu 302a – Single Point Correction Reset ............................................................................ 39

Advance Config. Menu 302b – 8-Point Correction Reset ................................................................................... 39

Advance Config. Menu 303 – Tc Correction Heating Time ................................................................................ 40

Advance Config. Menu 304 – P-Factor Correction ............................................................................................. 40

Advance Config. Menu 305 – Calibration Compare Time .................................................................................. 40

Advance Config. Menu 307 – K2 Relay Function ............................................................................................... 40

Advance Config. Menu 307a – K2 Impulse Duration ......................................................................................... 40

Advance Config. Menu 308 – Seal Time Count Direction ................................................................................... 40

Advance Config. Menu 309 – Cool Time Count Direction .................................................................................. 41

Advance Config. Menu 310 – Heating Ramp-Up ............................................................................................... 41

Advance Config. Menu 311 – Transformer Type Selection ................................................................................ 41

Advance Config. Menu 312 – Menu Return to Home Screen ............................................................................. 41

Advance Config. Menu 313 – Locking Function (ON/OFF) ................................................................................. 41

Advance Config. Menu 314 – Auto Accept Value Changes ................................................................................ 41

Advance Config. Menu 315 – Total Life Cycles .................................................................................................. 42

Advance Config. Menu 316 – PIREG 545 Software Version ............................................................................... 42

Advance Config. Menu 317 – Reset Input Function ........................................................................................... 42

Advance Config. Menu 317a – Reset Input Time Delay ..................................................................................... 42

Advance Config. Menu 318 – AutoCal Input Function ....................................................................................... 43

Advance Config. Menu 318a – AutoCal Input Time Delay ................................................................................. 43

7. SECURITY PROTECTION.....................................................................................................................................44

7.1. SECURITY PROTECTION LEVELS ................................................................................................................................ 44

7.2. SECURITY PROTECTION MENUS ............................................................................................................................... 44

7.2.1 Security Protection menu 401: Security level selection ............................................................................. 44

7.2.2. Security Protection menu 402: Settings Level, function selection ............................................................ 45

7.2.3. Security Protection menu 403: Settings Level, locking function .............................................................. 45

7.2.4. Security Protection menu 404: Settings Level, unlocking function .......................................................... 45

7.2.5. Security Protection menu 405: Settings Level, changing password function ........................................... 46

7.2.6. Security Protection menu 406: Settings Level, set new password function ............................................. 46

7.2.7. Security Protection menu 407: Level 1, function selection ...................................................................... 46

7.2.8. Security Protection menu 408: Level 1, locking function ......................................................................... 47

7.2.9. Security Protection menu 409: Level 1, unlocking function ..................................................................... 47

7.2.10. Security Protection menu 410: Level 1, changing password function ................................................... 47

7.2.11. Security Protection menu 411: Level 1, set new password function ..................................................... 48

7.2.12. Security Protection menu 412: Level 2, function selection .................................................................... 48

7.2.13. Security Protection menu 413: Level 2, locking function ....................................................................... 48

7.2.14. Security Protection menu 414: Level 2, unlocking function ................................................................... 49

7.2.15. Security Protection menu 415: Level 2, changing password function ................................................... 49

7.2.16. Security Protection menu 416: Level 2, set new password function ...................................................... 49

PIREG 545 cUL Operators Guide 2021

5

8. TECHNICAL DATA ..............................................................................................................................................50

8.1. SCREEN SYMBOLS ................................................................................................................................................. 50

8.2. CONTROLLER ....................................................................................................................................................... 50

8.1.1. Standards - CE marking ........................................................................................................................... 53

8.3. CURRENT TRANSFORMER........................................................................................................................................ 53

8.4. SEALING TRANSFORMER ......................................................................................................................................... 53

8.5. EXTERNAL THERMOMETER DTM3000 ..................................................................................................................... 53

8.6. ORDERING CODES ................................................................................................................................................. 54

8.7. SPARE PARTS ....................................................................................................................................................... 54

9. APPLICATION NOTE ..........................................................................................................................................54

9.1. APPLICATION INSTRUCTIONS ................................................................................................................................... 54

PIREG 545 cUL Operators Guide 2021

6

1. General, safety and warning instructions

1.1. Note on the Operator’s Guide

The purpose of this Operator’s Guide is to ensure optimum installation, commissioning, operation and

maintenance of the PIREG

®

-545 and must be read prior to carrying out any of the actions described.

Keep the operator’s guide handy and accessible to all users for possible referencing. Pass this guide on

to future users of the PIREG

®

-545.

All necessary settings are described in this operator’s guide. Should difficulties nevertheless arise during

commissioning or operation, please do not carry out any unauthorised manipulations. You could put your-

self and others at risk as well as jeopardize your warranty claim. In such cases, please contact us immedi-

ately:

Phone: 610-759-8883

TOSS Machine Components, Inc.

539 South Main Street

Nazareth, PA 18064 USA

Fax: 610-759-1766

Email: info@tossheatseal.com

Internet: www.tossheatseal.com

1.2. Icons and symbols

Danger:

Indicates a hazard that could result in personal injury. Whenever this symbol is used,

the device description must be consulted,

and the accompanying instructions must be observed

and followed in order to avoid hazards.

Danger:

Indicates a hazard due to electrical current. Failure to observe the safety instructions

may result in serious or fatal injuries.

Danger: Indicates a hazard due to hot surfaces or burn up that could result in personal injury.

Note:

Indicates particularly important information which, if ignored, can lead to material damage,

for example.

1.3. General safety instructions

The safety instructions and warnings given in this description must be followed to guarantee safe

operation of the equipment. The equipment can be operated without impairing the operational

reliability if the conditions stated in the technical specifications are observed.

The equipment may only be installed and started-up by suitably trained personnel.

Maintenance and repair of the equipment may only be carried out by trained personnel, who are

familiar with the dangers and guarantee conditions.

1.4. Application

The PIREG

®

-545 resistance temperature controller may only be used for the heating and tem-

perature control of TOSS approved heat seal bands

as via isolating transformers in accordance

with the regulations, notes and warnings contained in this description.

Non-observance

of the instructions or incorrect use of the equipment can result in impairment of

the safety or overheating of the heat seal band, the electrical wiring or the transformer.

1.5. Heat Seal Bands and Genuine TOSS Alloy 20®

A basic precaution for the functioning and safe operation of the complete heat sealing system is the use of

suitable heat seal bands such as genuine TOSS Alloy 20 heat seal bands.

The positive temperature coefficient of the heat seal band must be equal or greater than the positive tem-

perature coefficient set on the PIREG

®

-545. This appropriate temperature coefficient of the heat seal band

must be set on the PIREG

®

-545 by means of the built-in display. The temperature coefficient of the heat

seal band must be positive over the entire temperature range.

Caution: Using heat seal bands with too low a temperature coefficient or

adjusting the controller

to a temperature coefficient that is too high, can result in uncontrolled overheating or

the burning

out of the heat seal band.

Heat seal bands connected in parallel must be strictly symmetrical and performed in such a way that no

over-current arises if two heat seal bands on opposite sides should touch.

PIREG 545 cUL Operators Guide 2021

7

If series-connected heat seal bands must be used, the effect on the over-current reaction if two sealing

bands on opposite side should touch needs to be taken into consideration.

1.6. Impulse Transformer

The sealing transformer must be configured according to EN 61558 (VDE 0570) resp. UL 5085 (isolating

transformer with reinforced isolation) and in a single-chamber design

Caution: There must be sufficient protection against accidental contact if the transformer is in-

stalled in a machine frame. Furthermore, ensure that water, cleaning liquids or conducting liquids

do not come into contact with the transformer. The conductor wiring c

ross sections should be

designed to match the actual currents. Non-

observance of these notes may result in impairment

of the electrical safety.

For best results, the transformer's performance and the secondary voltage must be properly designed for

the given heat seal band (refer to the TOSS Application Report). The rate of the heat-up time is determined

by the secondary voltage being supplied. The proper selection of the secondary voltage for a target tem-

perature increase of 300°C should only allow for a heat-up period of 240 ms.

Measuring impulses continue while the PIREG

®

-545 is in the OFF state. Therefore, the higher the second-

ary voltage for a given heat seal band the greater the difference may be between the actual resting tem-

perature and the ambient temperature.

1.7. Current Transformer

The current transformer is an essential part of the control system. Only the Toss CT-50

current

transformers may be used. The current transformer may only be operated with ballast resistance.

The ballast resistance is integrated into the PIREG

®

-545. The cu

rrent transformer must be

mounted in such a way that magnetic leakage fields from the sealing transformer or other leakage

fields do not affect the measurement.

Caution: The used cable to the heating conductor can heat up the current transformer.

1.8. Line filter

A suitable line filter must be used to comply with the EMC directives listed in section 1.10. This guaran-

tees compliance with the limit value for interference emission and are an essential component to the CE

mark. The correct specification of the line filter is determined by the current load of the specific heat seal-

ing application.

This information can be found on the TOSS application report. It is important that the filter’s supply wires

not be run parallel with the filter’s output wires.

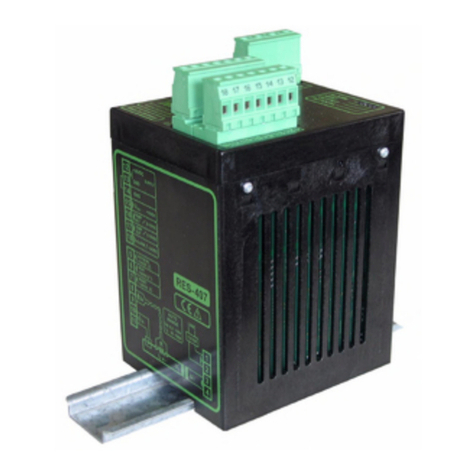

1.9. General assembly instructions and dimensions

The PIREG

®

-545 resistance temperature controller is only suited for use in an electrical cabinet. Open

operation is not permitted. The controller is designed for mounting in a control panel and the current trans-

former is mounted on a 35mm mounting rail as per EN 60715 (EN 50022). When assembling the controller

on the control panel, there must be a distance of at least 20mm away from any adjacent devices. Heat

dissipation from neighboring devices must be taken into account (note the ambient temperature specifica-

tions).

PIREG 545 cUL Operators Guide 2021

8

PIREG

®

-545 Temperature Controller

Current Transformer CT -50 (Section 1.7.)

1.10. CE Conformity & cUL listing

2014/35/EU, Low voltage Directive

- EN 61010-1:2011-07,

Safety requirements for electrical equipment, control, and laboratory use.

2014/30/EU, Electromagnetic compatibility Directive

- EN 61000-6-2:2016-05,

Electromagnetic compatibility (EMC) – Part 6-2: Generic standards - Immunity for industrial environ-

ments

- EN 61000-6-3:2011-09,

Electromagnetic compatibility (EMC) – Part 6-3: Generic standards - Emission standard for residential,

commercial and light-industrial environments

A suitable line filter is required for packaging machinery so that the machinery is compliant with

the electromagnetic compatibility directive.

2011/65/EU, RoHS directive

PIREG 545 cUL Operators Guide 2021

9

cUL certification:

- UL61010-1 and CAN/CSA C22.2 No. 61010-1-12:

Electrical Equipment For Measurement, Control, and Laboratory Use; Part 1: General Requirements

- UL61010-2-030 and CAN/CSA C22.2 No. 61010-2-030-18:

Electrical Equipment For Measurement, Control, and Laboratory Use; Part 2-030 Particular requirements

for equipment having testing or measuring circuits

1.11. Maintenance

The PIREG

®

-545 resistance temperature controller does not require any special maintenance. However,

an occasional check or tightening of the connection terminals is recommended. Dust deposits on the con-

troller can be removed with dry compressed air once the power has been switched off.

1.12. Disposal

Do not dispose of the device with household waste! The PIREG

®

-545

and its components must

be disposed of via the local collection points for electronic waste in accordance with the WEEE

Directive 2012/19/EU on waste electrical and electronic equipment.

Incorrect disposal can pose a risk to the environment. The PIREG

®

-545

, its components and

packaging materials must be disposed of in accordance with national waste treatment and dis-

posal regulations.

2. Controller Description and Installation Overview

The PIREG

®

-545 resistance temperature-controller is a temperature controller with a built-in time control,

which is used to control the temperature of genuine TOSS Alloy 20 heat seal band material, or suitable

heat seal bands, for impulse heat sealing of polymeric films, laminate films, and non-woven materials, and

for controlling some basic functions of heat sealing machines.

NOTE: Some examples of heat sealing application include, bag/pouch sealing, vertical or horizontal

form/fill/seal, film splicing, custom port sealing, tube sealing, and seaming non-woven materials.

The impulse transformer is used by the PIREG

®

-545 on the primary side. The heat seal band is fed from

the secondary side of the transformer. As the heat seal band resistance changes with temperature, the

measuring signals are received directly from the heat seal band and are made available to the controller at

rate of 50 times per second when operated at 50Hz or at a rate of 60 times a second when operated at

60Hz.

The PIREG

®

-545 temperature controller has four control inputs and three relay outputs that can control

various functions of the heat sealing machine. In addition, there is an alarm output.

The temperature coefficient of genuine TOSS Alloy 20 heat seal band material, or suitable heat seal band

material must be positive. Its resistance increases when it is heated. This change in resistance is used for

temperature control. The temperature controller measures and regulates the resistance of the heat seal

band. The actual temperature is determined by measuring the voltage and current to calculate its temper-

ature reference resistance (Rref).

NOTE: TOSS Alloy-20 heat seal bands can be straight or contoured shaped to provide flat, uniform

sealing or they can be round, beaded, or T-profiled to perform a seal and cut operation. Seal and

cut can also be performed in contoured shapes. Ask your TOSS applications engineer for more

information.

The PIREG

®

-545 can be easily operated with the built-in display unit. An OLED module with five lines

containing twenty-one digits each is used for the display. The PIREG

®

-545 can operate up to a temperature

range as high as 500°C.

During auto-calibration, the controller sets itself to the secondary voltage of the transformer and the current

through the heat seal band. The secondary voltage of the transformer may be within a range of 1...80 V.

Higher secondary voltage ranges are possible with the use of TOSS series resistor. The current measured

with a current transformer can range from 20 to 400A.

The PIREG

®

-545 performs the auto-calibration process within a variable ambient temperature range of 0-

50°C. During this process, the actual ambient temperature must be set in the controller.

The PIREG

®

-545 provides a measurement pause function. During the measurement pause, the PIREG

®

-

545 stops the resistance measurement making it possible to interrupt the heat seal band circuit without

generating an alarm. The measurement pause is controlled using either the reset or calibration-start inputs.

PIREG 545 cUL Operators Guide 2021 10

2.1. Installation Overview

2.2. PIREG®-545 rear electrical pin-out

PIREG 545 cUL Operators Guide 2021 11

2.3. Wiring diagram for the PIREG®-545

2.4. Wiring diagram for the PIREG®-545 WITH external solid-state relay (Booster)

PIREG 545 cUL Operators Guide 2021

12

3. Installation and commissioning

First, check that the voltage stated on the PIREG

®

-545 resistance temperature controller matches the mains

voltage, and that the transformer primary current matches the controller's load current capability.

For safe operation, the PIREG

®

-545

resistance temperature controller may only operate in sym-

metrical TN and TT networks.

During installation, an overcurrent protection device must be provided in front of the mains input

of the PIREG

®

-545.

The PIREG

®

-545

must be connected to the mains voltage via an easily accessible and marked

isolating device (e.g., switch or circuit breaker).

3.1. Installation

The PIREG

®

-545 resistance temperature controller is only suited for use in a switch cabinet. Open operation

is not permitted.

The PIREG

®

-545 is intended to be used in a safety enclosure which should conform with requirements for

protection against the spread of fire, against electrical shock, against mechanical hazards and should have

adequate rigidity according to UL 61010-1.

The controller is designed for mounting in a control panel and the current transformer is mounted on 35mm

mounting rails as per EN 60715 (EN 50022). When mounting the controller, observe a minimum distance

of at least 20 mm to adjacent devices and cabling on all sides.

Heat dissipation from neighbouring devices must be considered (note the ambient temperature specifica-

tions).

3.2. Configuring the secondary voltage and current

The secondary voltage of the transformer may be within a range of 1...80V while the current measured

with a current transformer can range from 20 to 400 A. During AUTOCAL, the secondary voltage and

current are configured automatically. If during AUTOCAL it is found that the voltage and/or current is out-

side of the permissible range an Error signal will be displayed on the screen.

If the secondary current falls below 20A, the secondary voltage wire must be looped through the CT-50

current transformer a second time (or multiple times). Refer to the TOSS application report.

3.3. Configuring the settings

Prior to initial operation, the correct temperature coefficient must be set for the genuine TOSS Alloy 20 heat

seal band material, or the suitable heat seal band material being used. Setting too high a temperature

coefficient may lead to overheating of the heat seal band. If necessary, the variable reference temperature

must be set.

In addition, the temperature range, and the transformer type must be set. The heating ramp can be adjusted

before or after auto-calibration.

Then the PIREG

®

-545 controller can be auto-calibrated. The settings for the sequence control, monitoring,

relays etc. can be specified before or after auto-calibration.

3.4. Connecting the PIREG

®

-545

The PIREG

®

-545 must be connected according to the wiring diagrams in Section 2.3. or Section 2.4. when

using an external solid-state relay (Booster). It is not necessary to pay attention to the polarity of the current

Ir and voltage Ur measurement cables to the heat seal band, nor to the connection of the sealing trans-

former on the primary or secondary side.

When connecting a target value potentiometer, it is vital to pay attention to the correct phase sequence. In

the 0 °C setting, the resistance between terminals X20 and X23 must be 0 . See Section 5.8.5.

The measurement cables for voltage measurement (Ur) must be connected directly to the heat seal band

and have to be twisted. (50 turns per meter). The cables from the sealing transformer should be connected

to the heat seal band with cable lugs and not with plug-type connections. Ensure that the conductors are

of adequate cross-section. No additional components, such as fuses, switches or resistance-loaded am-

meters should be integrated in the secondary circuit of the sealing transformer.

PIREG 545 cUL Operators Guide 2021

13

3.5. External Solid State Relay (booster)

Based on the specific heat sealing application, when high primary currents are to be expected (continuous

current > 5A or peak current > 25A) an external solid state relay (booster) is required. The connections are

to be made at terminals 1 & 2. A wiring diagram with an external solid state relay can be found in Section

2.4 of this manual. Installation of the external solid state relay does not require special settings.

3.6. Control inputs

The control inputs for Start (pins 7+2) and Preheating (pins 19+2) may not be actuated before the PIREG

®

-

545 controller is switched on for the first time. (If auto-calibration is not suitable any more after the heat seal

band was changed, the heat seal band may overheat).

3.7. Connecting to the mains voltage

Following connection to the mains, the PIREG

®

-545 controller will switch to the error state with the error

message “Data error, saved calibration values do not match the setting” as settings were not yet made.

The necessary settings via the menus or interfaces and calibration must now be carried out. The icon

“Pause” should be displayed following a successful calibration.

3.8. The TOSS Alloy 20 & Suitable Heat Seal Band Materials

The TOSS Alloy 20 heat seal band is an important component of the control circuit because it functions

both as a temperature sensor and heating element at the same time.

The measurement principle of the resistance temperature controller requires that the TOSS Alloy 20 or

suitable heat seal band has a positive temperature coefficient, which is set at the PIREG

®

-545. The con-

troller offers a selection of the four fixed Tc-settings, 1.) Alloy L-746ppm, 2.) Alloy A20K-862ppm 3.) Alloy

A20C-1235ppm, and 4.) Norex-4830ppm. The four fixed Tc-settings relate to heat seal bands that are

available at TOSS. A “variable” Tc-settings selective is also available. This allows for the use of heat seal

bands that do not match any of the ppm values available from the four fixed Tc-settings. With “variable”

selected, a ppm range of 400…2200ppm is programmable. The use of a heat seal band with a smaller

temperature coefficient than can be set within “variable” range on the controller can result in the heating

element getting overheated or burning up. Despite full heating capacity, the actual value cannot reach the

target value.

The “variable” selection is also used when an NIST validated temperature is required. Adjusting the “vari-

able” ppm allows the operator to calibrate the bands temperature to an independent, NIST calibrated, tem-

perature measuring device.

During initial heating of the heat seal band to between 250° and 300°C, the cold resistance of the heat seal

band can vary by 2 - 3 % (burn-in effect). This resistance variation results in a zero-point error of 20° - 30°C.

After a few heating cycles, this zero-point error needs to be corrected by a new auto-calibration.

Overheated or burnt-out heat seal bands should not be used because of irreversible changes in the tem-

perature coefficients.

A constructional measure to improve the exact temperature control and to increase the life of the heat seal

band and the Teflon (PTFE) coating is to copper-plate or silver-plate the heat seal band’s contacts. This

measure ensures that the TOSS Alloy 20 heat seal band contacts remain cold and allows the controller to

measure only where sealing is taking place. The temperature of the heat seal band can only be determined

by the PIREG

®

-545 as the mean of all parts of the heat seal band. If any individual parts of the heat seal

bands that are exposed or otherwise not in contact with any heat dissipating areas, they will heat up faster

than those sections of the heat seal band that are able to dissipate their heat. In this case, the temperature

reached at these sections will be lower than the temperature displayed by the controller and the sealing

performance will be worse.

Auto-Calibration of the PIREG

®

-545 is recommended every time the heat seal band is installed/replaced,

in order to correct any tolerances of the heat seal band arising during manufacture. When TOSS Alloy 20

heat seal bands are used, burn-in will again be necessary.

3.9. Burning in the genuine TOSS Alloy 20 heat seal band

With the sealing tool held open, the genuine TOSS Alloy 20 heat seal band should be "burnt in" in such a

way that the "Start" signal is applied and a target temperature is slowly increased from zero. The final burn-

in temperature should be at least 50°C above the determined application sealing temperature. The genuine

TOSS Alloy 20 heat seal band should be monitored (initial colors, hot spots). Auto-Calibration should be

carried out again following burn-in and complete cool down of the heat seal band.

3.10. Current Transformer

To reduce the risk of electric shock, always open or disconnect circuit from power distribution

system (or service) or building before installing or servicing current transformers.

The following must be observed when installing the current transformer:

PIREG 545 cUL Operators Guide 2021

14

- The current transformers may not be installed in equipment where they exceed 75 percent of

the wiring space of any cross-sectional area within the equipment.

-

Restrict installation of current transformer in an area where it would block ventilation openings.

- Restrict installation of current transformer in an area of breaker arc venting.

- Not suitable for Class 2 wiring methods and Not intended for connect

ion to Class 2 equipment.

-

Secure current transformer and route conductors so that the conductors do not directly contact

live terminals or bus.

3.11. When the controller does not work correctly

See Section 5.7. - Alarm State

4. Operation

4.1. Buttons

The operation of the PIREG

®

-545 controller is executed by four buttons indicated as follows:

Menu Scroll

up

down

Enter / Hand / Reset

≡

4.1.1. Changing between menu levels:

The PIREG

®

-545 has four menu levels: 1) Settings, 2) Configuration, 3) Advance Configuration, and 4)

Security Protection.

Note: Levels 3 and 4 are only available when the “Advance PIREG

®

Features” in Configuration

menu 227 is set to ON.

Setting Menu: The start point for all menu levels is the Home Screen and Settings menu. From the

Home Screen, press the Menu Scroll button

to advance through the various Settings menus.

Configuration menus: From the Home Screen, hold the Menu Scroll button

for longer than 2s to

change to the Configuration menus. Then press the Menu Scroll button

to advance through the

various Configuration menus.

Advanced Configuration menus: From the Home Screen, simultaneously hold the Menu Scroll button

and

button for longer than 2s to change to the Advanced Configuration menus. Then press the

Menu Scroll

button to advance through the various Advanced Configuration menus.

Security Protection menus: From the Home Screen, simultaneously hold the Menu Scroll button

and

button for longer than 2s to change to the Security Protection menus. Then press the Menu

Scroll button

to advance through the various Security Protection menus.

4.1.2. Setting of numeric values:

Numeric values are altered by pressing the

or

buttons. Once altered, it starts to blink indicating it has

been altered. To select the altered numeric value, press the Enter button

≡

, and the blinking stops. Pressing

the Menu Scroll button

will advance the controller to the next menu without altering the accepted value.

4.1.3. Setting of functions:

Functions are altered by pressing the

or

buttons. Once altered, it starts to blink indicating it has been

altered. To select the altered function, press the Enter button

≡

, and the blinking stops. Pressing the Menu

Scroll button

will advance the controller to the next menu without altering the accepted function.

4.1.4. Accepting numeric values or functions:

Accepting numeric values or functions is executed by pressing the Enter button

≡

. If the altered setting is

not accepted within 15 seconds by pressing the Enter button

≡

, it will not be altered, and the previously

accepted value is kept. Auto Accept can be programmed in Advance Configuration 314. With Auto Accept

set to ON, the altered setting will flash for 2 seconds and then automatically accepted.

PIREG 545 cUL Operators Guide 2021

15

4.1.5. Menu return:

Returning from all menus back to the Home Screen can be achieved three ways:

1) Holding the Enter button

≡

for 2 seconds.

2) Repeatedly pressing the Menu Scroll button

≡

to advance through the entire set of menus

found in the menu level currently in.

3) Automatic return from all menus back to Home Screen will happen after 20s of inactivity.

This can be activated in Advance Configuration menu 312.

4.1.6. Brightness:

Setting the brightness of the display-lighting can be altered by pressing the

buttons while in the Home

Screen. The setting will be saved when the setting has not been altered for 3 seconds.

4.1.7. Edit Prevention:

If a value or function cannot be altered an ““ will appear in front of the value/function for 1s to indicate that

the alteration is not allowed.

4.1.8. Locking:

To prevent inadvertent altering of settings two locking feature exists. The first method for locking and

unlocking is done from the Home Screen by simultaneously pressing the

+

+

≡

buttons. Before using

this feature, it must be turned ON in Advance Configuration menu 313. The second method for locking and

unlocking is to hold the Menu Scroll button

while the controller is being powered ON or while the start

menu is displayed after reset. See Section 6.2 for Locking Symbols.

5. Functions

5.1. Control

With the PIREG

®

-545, there are the following control settings which must be performed before start-up.

5.1.1. Setting temperature coefficients:

The heat seal band's temperature coefficient must be set on the PIREG

®

-545. The temperature coefficient

is a material constant specific to the heat seal band material being used for the heat seal band.

Using heat seal bands with too low a temperature coefficient or adjusting the controller to a tem-

perature coefficient that is too high, can result in uncontrolled overheating or burning out

of the

heat seal band.

There are four selectable temperature coefficients, Alloy A20C, Alloy A20K, Alloy L, and Norex. A Variable

temperature coefficient exists allowing for the precise calibration of a specific heat sealing system.

5.1.2. Temperature range:

The PIREG

®

-545 offers a choice between four fixed temperature ranges of 200, 300, 400 and 500°C and

a variable maximum temperature dependent on the selected range.

5.1.3. Transformer type:

The PIREG

®

-545 must be adapted to the type of sealing transformer, EI core (commonly preferred) or

toroidal core.

5.1.4. Reference temperature:

The reference temperature is the environmental (ambient) temperature at which the heat seal band re-

sistance, called reference resistance (Rref), is determined during the auto-calibration process. With the

PIREG

®

545, the reference temperature may be set between 0 and 50°C.

5.2. Auto Calibration and Temp. Coefficient Correction:

During auto-calibration, the PIREG

®

-545 ambient temperature reading independently adapts to the combi-

nation of sealing transformer and the heat seal band material being used.

5.2.1. Establishing the ambient temperature’s reference resistance (Rref):

The ambient temperature of 0-50°C must be set in the controller before the auto-calibration process can

begin (Settings Menu 107). Before the auto-calibration begins, it is important the heat seal band is at the

ambient temperature to ensure accuracy throughout the entire temperature range. At the conclusion of the

auto-calibration process the “ACT” temperature on the Home Screen will reflect that of the reference tem-

perature.

5.2.2. Single-point temperature coefficient correction:

With the single-point temperature coefficient correction, the actual measured temperature difference for

one selected operating temperature (preferably the optimal sealing temperature in which the machine will

be operated at) can be corrected. The PIREG

®

-545 allows the user to compare the selected operating

temperature to the actual measured temperature of the heat seal band. The user can then store the actual

measured temperature, thus correcting the reference resistance (Rref) for the chosen operating

PIREG 545 cUL Operators Guide 2021

16

temperature. At the conclusion of the single point calibration, when the Rref has been corrected, the tem-

perature correction is saved until it is requested to be performed again.

N

ote

:

During Single Point calibration, it is i

mportant to relieve the sealing force from the heat seal

band while it is heating to the Single Point set temperature. This will allow for the heat seal band

to expand freely during heat-

up without risk of damaging the heat seal band. The K1 relay, K2

re

lay, or Output1 can all be programmed to provide a control message to open and close the heat

seal jaw bar, while the temperature-

coefficient correction is in process. When programmed, the

chosen relay is actuated after a delay of 250 ms and when the actua

l temperature has exceeded

95% of the desired temperature. The chosen relay is released when the heat seal band's actual

temperature is reported back to the PIREG

®

-545. (from V1.00/1.07/1.29/1.23)

5.2.3. 8-Point Temperature-coefficient correction:

Actual measured temperature differences can be corrected by this feature. When requested, at the con-

clusion of the initial auto-calibration stage, the heat seal band is heated to eight temperature stages by the

PIREG

®

-545. When the PIREG

®

-545 is programmed to operate at a temperature range of 300°C, the eight

temperature stages are 50, 77, 104, 131, 159, 186, 213 and 240°C. When programmed for a range of

500°C, the eight temperature stages are 50, 100, 150, 200, 250, 300, 350 and 400°C. At each stage, the

PIREG

®

-545 allows the user to compare the stage temperature to the actual measured temperature of the

heat seal band. The user can then store the actual measured temperature, thus correcting the reference

resistance (Rref) for that temperature stage. At the conclusion of the 8-point calibration, when the Rref for

each temperature stage has been corrected, the entire temperature correction is saved until it is requested

to be performed again.

Note: During 8-

Point calibration, it is important to relieve the sealing force from the heat seal

band while it is heating to the various pre-

set temperature points. This will allow for the heat seal

band to expand freely during heat-up without risk of damagi

ng the heat seal band. The K1 relay,

K2 relay, or Output1 can all be programmed to provide a control message to open and close the

heat seal jaw bar, while the temperature-

coefficient correction is in process. When programmed,

the chosen relay is actuated after a delay of 250 ms and when the actual temperature has ex-

ceeded 95% of the desired temperature. The chosen relay is released when the heat seal band's

actual temperature is reported back to the PIREG

®

-545. (from V1.00/1.07/1.29/1.23)

5.3. Off-state

In the Off state, and with measurement pause inactive, the PIREG

®

-545 continually measures the heat seal

band's resistance, calculates its temperature, and it is displayed as the actual value (“Act”) on the Home

Screen. Since power is introduced to the heat seal band for measuring the resistance, it heats up slightly

in the Off state, depending on the heat seal band voltage.

The controller switches from the Off state to the On state when the “Start” signal is applied. If the “Autocal

Start” signal is applied at pins 25 + 20, the PIREG

®

-545 switches to calibration mode then returns to the

Off state when calibration has been successful. See Section 5.8.3.

In the Off state it is possible to activate a measurement pause (from V1.00/1.07/1.29/1.23). During the

measurement pause, the PIREG

®

-545 stops the resistance measurement making it possible to interrupt

the heat seal band circuit without generating an alarm. The measurement pause is automatically stop, if

the On state or the calibration state is activated.

5.4. On state

In the On state, the PIREG

®

-545 regulates the heat seal band temperature in accordance with the set value.

As soon as the “Start” signal is removed, the controller returns to the Off state. The controller can also be

programmed in Configuration menu 213 to switch to the ON state by holding down the Enter button

≡

from

the Home Screen.

5.5. Time control

The time control can be switched On and Off in Configuration menu 209. If the time control is switched Off,

then a sealing process with the set desired temperature is only activate when a “Start” signal is present. If

the time control is switched On, a sealing cycle with subsequent start delay, sealing time and cooling time

will be started automatically after the “Start” signal is applied. If the time control is switched On w/ start

supervising, a sealing cycle with subsequent start delay, sealing time and cooling time is only activate when

a “Start” signal is present.

5.5.1. Preheating:

“Preheating” can be used to preheat the heat seal band during a pause in the sealing cycle. The PIREG

®

-

545 adjusts the heat seal band temperature to the programmed preheating temperature. This feature re-

duces the time it takes for the heat seal band to reach the “Set” sealing temperature. Preheating can be

activated two ways, 1) it can be controlled by using a 24VDC signal at pins 22 + 20 or 2) via a controlled

contact at pins 2 and 19. The preheating temperature can be set irrespective of the desired temperature.

The minimum Preheat temperature is 40°C. See Section 5.8.2

PIREG 545 cUL Operators Guide 2021 17

5.5.2. Start delay:

Start delay is the delay time after the “Start” signal has been applied and until sealing time starts. During

the start delay the heat seal band is not heated by the PIREG®-545. If preheating has been switched on, it

continues through the start delay.

5.5.3. Sealing time:

During the sealing time the PIREG®-545 adjusts the heat seal band temperature according to the set target

value. Depending on the setting for Start of Sealing Time, the sealing time can start with the “Start” signal

or after the “Set” temperature has been reached.

5.5.4. Cooling phase:

The sealing time is followed by the cooling phase. Depending on the setting for the Cooling Mode, the heat

seal band is cooled down for either a set time or to a preset temperature. The cooling temperature can

either be set as an absolute temperature or as a percentage of the programmed “Set” temperature.

5.6. Monitoring

5.6.1 Temperature diagnostic:

Temperature diagnostic is a temperature monitoring feature enabled and set in the PIREG®-545. During

the sealing process, the actual temperature is monitored to ensure that it is within an OK temperature

control limits. If the actual temperature falls out of the OK temperature control limits for longer than the

programmed diagnostic delay, the PIREG®-545 enters the alarm state.

5.6.2. Temperature rise monitor:

The temperature rise monitor is a monitoring feature enabled and set in the PIREG®-545. With this feature,

the temperature rise is monitored after the “Start" signal has been applied. If the “Set” temperature value

does not reach the set OK temperature range within the set heating period, the PIREG®-545 enters the

alarm state.

5.6.3. Start signal monitor:

With time control set to “ON / w. start supervising”, a sealing cycle can be interrupted when the “Start” signal

is no longer applied during the running sealing cycle. This monitor can be linked to various machine func-

tions deemed important to achieving a quality heat sealing cycle.

PIREG 545 cUL Operators Guide 2021 18

5.7. Alarm state

The PIREG®-545 enters the Alarm state only when it detects an error. The controller monitors the mains

voltage, the heat seal band temperature, the current and voltage measurements on the heat seal band, the

calibration parameters and the monitor functions.

Here the error’s number, its description and a possible remedy are given.

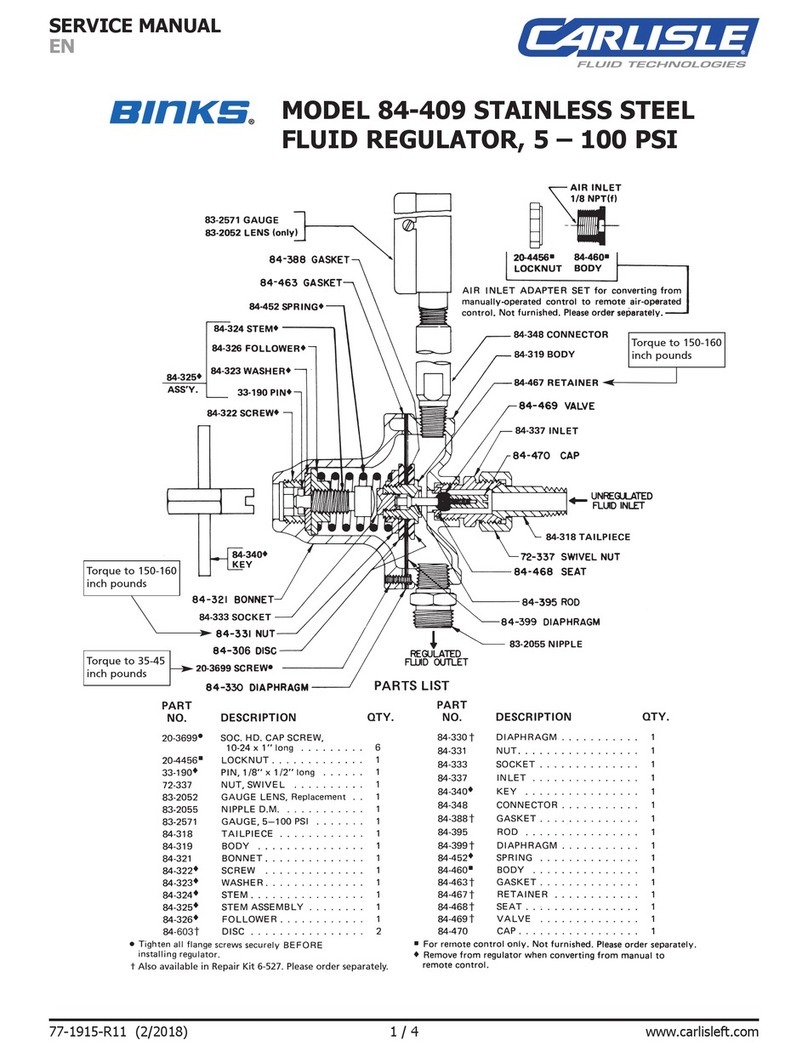

5.7.1. Possible Alarms:

Alarm

Code

Alarm Cause Analog

(Between

Pins 20 & 24) Fault Area

101 Current signal Ir missing 0.66 1

102 Voltage signal Ur missing 1.33 3

103 Current Ir and voltage Ur signal missing 2.00 2 or 9

104 Current signal Ir too high

6.33 <> 10

Run Autocal

7 or 8

or

Loose Contact

4, 5, or 6

105 Voltage signal Ur to high

106 Current signal Ir and voltage signal Ur too high

107 Temperature step, down

2.66 Loose Contact

4, 5, or 6

108 Temperature step, up

111

Calibration Error: Current signal Ir too low

6.66 <> 10 8

Calibration Error: Current signal Ir too high

112

Calibration Error: Voltage signal Ur too low

7.33 <> 10 7 Calibration Error: Voltage signal Ur too high

Calibration Error: Voltage signal Ur unstable

113

Calibration Error: Current signal Ir and voltage signal Ur

too high

8.00 <> 10 7 or 8

Calibration Error: Current signal Ir and voltage signal Ur

too low

Calibration Error: Current signal Ir too low, Voltage sig-

nal Ur too high

Calibration Error: Current signal Ir too high, Voltage sig-

nal Ur too low

Calibration Error: R20 cannot be determined

Calibration Error: P-factor could not be determined

121 Calibration Error: Reference temperature to high

122 Calibration Error: Range of Tc correction exceeded

123 Calibration Error: Temperature for steadiness and dy-

namic to low

PIREG 545 cUL Operators Guide 2021 19

Alarm

Code

Alarm Cause Analog

(Between

Pins 20 & 24)

Fault

Area

201 Line frequency missing

3.33 Check Power

Supply

204 Line voltage too low

205 Line voltage too high

211 Calibration values do not fit setting

6.00 <> 10 Run Autocal

221

Communication control RS232 connection

Communication control USB connection

Communication control TM6 thermometer

222 Communication control internal connection 1

Communication control internal connection 2

302 Temperature too low

6.33 <> 10

Run Autocal

or

Loose Contact

4,

5,

or 6

303 Temperature too high

304 Heatup timeout, Heatup time exceeded 4.00

Run Reset

(Check Config

Menu 219)

307 Temperature diagnosis activated, temperature too low

2.66 4, 5, or 6

308 Temperature diagnosis activated, temperature too high

901 Device error

4.66 Check

Controller

902 Internal error

903 Write/read error of memory

5.7.2. Fault Area Diagram:

PIREG 545 cUL Operators Guide 2021 20

Fault

Area

Reason

Possible Causes

1

Current signal missing between

Ur measurement connection

point and heat seal band.

Wire break (check crimp connectors), heat seal band break

Loose/defective contacting to heat seal band

CT-50 current transformer sig-

nal missing

Ir measuring wire from current transformer to temperature con-

troller is loose or not connected.

2

Primary circuit disconnect

Wire break, triac in controller defective

Primary winding of isolation transformer disconnected

Secondary circuit disconnect

before Ur pickoff point

Wire break

Secondary winding of isolation transformer disconnected

3

Ur signal missing

Ur measuring wire loose or disconnected

4

Resistance shift, partial short-

circuit

Heat Seal band intermittently in contact with conductive parts

(clamp, opposite heat sealing bar, etc.)

5

Parallel circuit disconnect

Wire break, heat sealing band break

Loose or defective contacting to heat seal band

6

Full short-circuit

Heat Seal band installed incorrectly, insulation at the ends of

the heat sealing bar is missing or incorrectly installed

Heat seal band in full contact of conductive part(s)

7

Ur signal incorrect

Ur signal outside tolerable range of 0.4…80 VAC

8

Ir signal incorrect

Ir signal outside tolerable range of 20…500 A

Turns thru CT-50 current trans-

former incorrect

Check number of turns (two or more turns required for current

signal less than 20 A)

9

Internal controller fault

Hardware fault (replace controller)

Table of contents

Other Toss Controllers manuals

Popular Controllers manuals by other brands

Allen-Bradley

Allen-Bradley MicroLogix 1400 instruction manual

Bosch

Bosch Worcester Digital Twin Channel Programmer Installation & operating instructions

Synergy Global Technology

Synergy Global Technology RAC281 user manual

Resol

Resol DeltaSol BS Plus manual

BENSON

BENSON CP4 User instruction manual

MDT

MDT Glass Push Button II Smart Series Technical manual