Toss PIREG-D2 User manual

Operating Instructions

Temperature Controller PIREG-D2

With kind regards

GmbH & Co. KG

-Verpackungssysteme-

Danziger Straße 15

D-35418 Alten-Buseck

Tel.: +49 (0) 64 08 -90 91- 0

Fax: +49 (0) 64 08 -43 55

E-Mail: [email protected]

Internet: www.toss-gmbh.de

2

Applications:

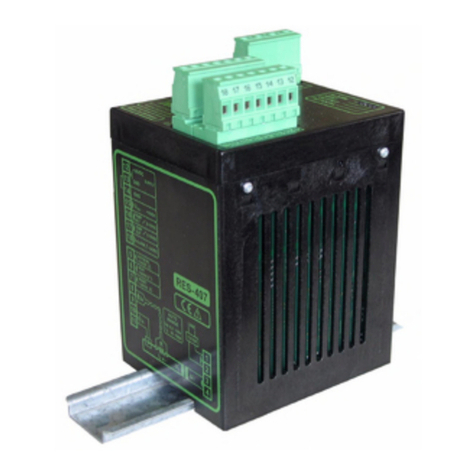

Current transformer

Contents:

1. Safety instructions and warnings

3

3.8.1. Temperature function

12

1.1. General safety instructions

3

3.8.2. Sequence function

12

1.2. Application

3

3.8.3. Time pulse function

12

1.3. Note on the heating conductor

3

3.9. Display functions

12

1.4. Note on the sealing transformer

3

3.9.1. Languages

12

1.5. Note on the current transformer

4

3.9.2. Brightness

12

1.6. General assembly instructions

4

3.9.3. Hold mode

12

1.7. Maintenance

4

3.9.4. Cycle counter

12

1.8. Validity

4

3.9.5. Saving

12

2. Short description

4

3.9.6. Releases

12

3. Functions

5

3.9.7. Temperature unit

13

3.1. Control

5

4. Operation

13

3.1.1. Heating ramp

5

4.1. Keys

13

3.1.2. Setting the temperature coefficient

5

4.1.1. Cursor

13

3.1.3. Calibration reference time

5

4.1.2. Setting numerical values

13

3.1.4. Temperature range

5

4.1.3. Selecting functions

13

3.1.5. Calibration mode

5

4.1.4. Acceptance of the settings

13

3.1.6. Transformer type

6

4.1.5. Menu change

13

3.1.7. Reference temperature

6

4.1.6. Menu return

13

3.1.8. Temperature coefficient correction

6

4.1.7. Locking

13

3.2. Calibration:

6

4.1.8. Execution prevention

13

3.2.1. Initialisation

6

4.2. LEDs

13

3.2.2. Calibrating the input amplifier

6

4.2.1. Power

13

3.2.3. Determining the phase shift

6

4.2.2. Heat

13

3.2.4. Determining the reference resistance

6

4.2.4. Alarm

13

3.2.5. Temperature reference time

7

4.3. Inputs

13

3.2.6. Checking the reference resistance

7

4.3.1. Start inputs

13

3.2.7. Determining the P-factor

7

4.3.2. Preheat inputs

14

3.2.8. Setting an initializing remanence

7

4.3.3. Calibration Start input

14

3.2.9. Temperature coefficient correction

7

4.3.4. Reset input

14

3.2.10. Single-point tc correction

8

4.3.5. Target value input

14

3.2.11. P-factor correction

9

4.4. Outputs

14

3.3. Off-State

9

4.4.1. Actual value output

14

3.4. On-State

10

4.4.2. Message relay output

14

3.5. Sequence control

10

4.4.3. Control relay outputs

14

3.5.1. Preheating

10

4.4.4. Alarm output

14

3.5.2. Start delay

10

4.4.5. ELR output

14

3.5.3. Sealing time

10

4.5. Interfaces

14

3.5.4. Cooling phase

10

5. Menu structure

15

3.6. Monitoring

10

5.1. Switching on

15

3.6.1. Temperature monitoring

10

5.2. Working menu

15

3.6.2. Monitoring of heating

10

5.2.1. Working menu without sequence contr.

15

3.6.3. Monitoring of starting

10

5.2.2. Working menu with sequence control

15

3.6.4. Monitoring of communication

10

5.2.3. Symbols for the operating status

16

Device description: PIREG-D2

Resistance Temperature Controller

Packaging machine for sealing plastic films

3

3.7. Error state

10

5.2.4. Error menu

16

3.7.1. Error causes

11

5.2.5. Calibration Selection menu

16

3.8. Relay functions

12

5.2.5.1. Calibration information menu

17

5.3. Selection menu

17

5.8.2. Hold Mode menu

24

5.4. Sequence Control menu

17

5.8.3. Operating menu

24

5.4.1. Preheat menu

18

5.8.4. Releases menu

24

5.4.2. Start Function menu

18

5.9. Save menu

25

5.4.3. Start Delay menu

18

5.9.1. Parameter Sets menu

25

5.4.4. Sealing Time menu

18

5.9.2. Factory Settings menu

25

5.4.5. Cooling Phase menu

18

5.10. Information menu

26

5.5. Monitoring menu

19

6. Commissioning

26

5.5.1. Temperature Monitoring menu

19

6.1. Configuring the settings

26

5.5.2. Heating Monitoring menu

19

6.2. Connecting the PIREG-D2

26

5.6. Relay settings menu

19

6.3. Control inputs

26

5.6.1. Message Relay settings menu

20

6.4. Connecting to the mains voltage

26

5.6.1.1. Message Relay Temp. function m.

20

6.5. Burning in the heating conductor

26

5.6.1.2. Message Relay Sequence func. m.

20

6.6. When the contr. does not work corr.

26

5.6.1.3. Message Relay Time Pulse func. m.

20

7. The heating conductor

27

5.6.2. Control relay settings menu

21

8. Technical data

27

5.6.2.1. Control Relay Temp. function menu

21

8.1. Controller

27

5.6.2.2. Control Relay Sequence func. m.

21

8.2. Current transformer

29

5.6.2.3. Control Relay Time Pulse func. m.

21

8.3. Sealing transformer

29

5.6.3. Alarm Relay settings menu

21

8.4. TM6 thermometer

29

5.6.4. Relay Outputs status menu

22

8.5. Ordering codes

29

5.7. Regulator settings menu

22

8.6. Housing

30

5.7.1. Tc settings menu

22

8.6.1. PIREG-D housing

30

5.7.1.1. Variable Tc settings menu

22

8.6.2. Current transformer housing

30

5.7.2. Temperature settings menu

22

9. Connection diagrams

31

5.7.3. Time settings menu

23

9.1. PIREG-D2with ext. solid-state relay -

31

5.7.4. Calibration settings menu

23

9.2. PIREG-D2with int. thyristors

31

5.7.5. Target Value settings menu

23

9.3. RS232 interface connection

31

5.8. Display settings menu

23

10. Application note

32

5.8.1. Language and Brightness settings m.

24

10.1. Application instructions

32

1. Safety instructions and warnings

1.1. General safety instructions

The safety instructions and warnings given in this description must be followed to guarantee

safe operation of the equipment. The equipment can be operated without impairing the operational

reliability if the conditions stated in the technical specifications are observed.

The equipment may only be installed and started-up by suitably trained personnel.

Maintenance and repair of the equipment may only be carried out by trained personnel, who are

familiar with the dangers and guarantee conditions.

1.2. Application

The PIREG-D2resistance temperature controller may only be used for the heating and temperature control

of heating conductors as specified in accordance with the safety instructions, rules and regulations for

such applications.

Non-observance of the instructions or incorrect use of the equipment can result in impairment of the safety

or overheating of the heating conductor, the electrical wiring or the transformer.

1.3. Note on the heating conductor

A basic precondition for the function and safe operation of the complete heating system is the application

of suitable heating conductors.

The positive temperature coefficient of the heating conductor used must be equal or greater than the positive

temperature coefficient set at the PIREG-D2. The appropriate temperature coefficient of the heating conductor

must be set on the display unit of the PIREG-D2or via the interface. The temperature coefficient of the heating

conductor must be positive over the entire temperature range.

Caution: Using heating conductors with too low a temperature coefficient, or adjusting the

controller to a temperature coefficient that is too high, can result in uncontrolled overheating or

melting of the heating conductor.

Temperature regulation of heating conductors connected in parallel must be more precise than of heating

conductors connected in series. However, the wiring must be strictly symmetrical and performed in such a

way that no overcurrent arises when two heating conductors on opposite sides contact each other.

If series-connected heating conductors have to be used, the effect on the overcurrent reaction should be

taken into consideration if two opposite sealing bands touch each other.

4

1.4. Note on the sealing transformer

The sealing transformer must be configured according to EN 60742 (VDE 0551) (isolating transformer with

reinforced isolation). All types and designs that comply with the standards can be used as sealing

transformers. The induction in the transformer's iron core must not be reduced as is normally the case with

primary side thyristor operation. Transformers with low losses are disrupted less on the secondary side than

transformers that have low energizing currents. Thus in applications with short heating and sealing times, stiff

and generally larger transformers should be used. Where a great deal of sealing is to be performed, a

transformer with a primary voltage of 400 V is advantageous, because this way, the PIREG-D2's internal

actuator is more likely to be sufficient and an external actuator with solid-state relay will not have to be used.

Caution: There must be sufficient protection against accidental contact if the transformer is

installed in a machine frame. Furthermore, ensure that water, cleaning liquids or conducting liquids

do not come into contact with the transformer. The conductor wiring cross sections should be

designed to match the actual currents. Non-observance of these notes may result in impairment

of the electrical safety.

For best results, the transformer's performance and the secondary voltage must be suited to the heating

conductor. A short heat-up period is reached with of a high transformer output voltage. However, the voltage

selected should not be too large so that not less than 12 controller measurements are needed for a target

temperature increase of 300°C when heating up (heat-up period (>240 ms). For smaller heat-up curves,

correspondingly fewer measurements are necessary. (The PIREG-D2takes a measurement every 20 ms while

heating).

The larger the transformer's secondary voltage for a given heating conductor, the more energy is fed into the

heating conductor, even in the "off" state. This is done by means of temperature measuring pulses, which the

controller regularly sends to the heating conductor. Therefore, the higher the secondary voltage of the

transformer the greater is the difference between the resting temperature and the ambient temperature in the

"off" state.

1.5. Note on the current transformer

The current transformer is an essential part of the control system. Only Toss current transformers may be

used. The current transformer mayonly be operated with ballast resistance. The ballast resistance is integrated

into the PIREG-D2. The current transformer must be mounted in such a way that magnetic leakage fields from

the sealing transformer or other leakage fields do not affect the measurement.

1.6. General assembly instructions

The PIREG-D2resistance temperature controller is only suited for use in a switch cabinet. Open operation is

not permitted.

The controller is designed for installation into the switch panel and the current transformer is fitted on a 35 mm

mounting rail according to DIN EN 50022. When installing the controller in the switch panel, there must be a

distance of at least 20 mm from the neighbouring device. Heat dissipation from neighbouring devices must be

taken into account (note the ambient temperature specifications).

1.7. Maintenance

The PIREG-D2resistance temperature controller does not require any special maintenance. However, an

occasional check or tightening of the connection terminals is recommended. Dust deposits on the controller

can be removed with dry compressed air once the power has been switched off.

1.8. Validity

The first device version (v.vv) shipped was the version 1.00 with program versions 1.13 for the display unit

(d.dd), 1.16 for the electrically isolated side (g.gg) and 1.10 for the instrumentation side (m.mm).

Supplements in this description which are only valid from a later version include the version, the notation

Vv.vv/d.dd/g.gg/m.mm, e.g. V1.00/1.13/1.16/1.10 from which they are valid. The device and program versions

are read from the Information menu or by a command (LVERS) via the interface.

2. Short description

The PIREG-D2resistance temperature controller is a controller with integrated sequence control used for

temperature control of heating conductors for heat-impulse sealing of foils and for the control of film sealing

machines.

The sealing transformer is switched by the PIREG-D2on the primary side. The heating conductor is fed from

the secondary side of the transformer. The measuring signals are received directly at the heating conductor

and are made available to the controller.

The PIREG-D2resistance temperature controller has four control inputs and three relay outputs for control of

the film sealing machine. The PIREG-D2resistance temperature controller can control a film sealing machine

independently via these inputs/outputs and the integrated sequence control. The three relay outputs are

divided into one message output and two control outputs with different capacities. In addition there is an alarm

output.

The temperature coefficient of the heating conductor must be positive. Its resistance increases when it is

heated. This effect is used for temperature control. The temperature controller measures and regulates the

resistance of the heating conductor. The temperature coefficient is a material constant that depends on the

5

alloy used for the heating conductor. The actual temperature is determined by measuring the voltage and

current.

The PIREG-D2operates as a proportional control unit that independently determines the P-factor (the control

amplification) for the controlled system of a process during calibration. The controlled system consists

of a sealing transformer and a heating conductor. The P-factor determined during calibration can afterwards

still be corrected by a command or an adjustment in the display unit ( 5.2.5. and 4.9.).

The PIREG-D2is operated via the integrated display unit ( 5.) with 5 keys ( 4.1.) or via the RS232- or

USB interface ( 4.5. –4.9.) fitted at the PIREG-D. Combinations of both types of operation are possible.

An LCD-module with eight lines with twenty-one digits each is used as display.

The PIREG-D2is set to the temperature coefficients of the heating conductor ( 5.7.1. and 4.9.). The

PIREG-D2can also determine the actual temperature coefficient of a heating conductor itself by means of a

temperature coefficient correction ( 5.7.4. and 4.9.). Connect the PIREG-D via the RS232 interface to an

external TM6 thermometer which measures the actual temperature of the heating conductor ( 4.5.2.) to

simplify the temperature coefficient correction. Depending on the setting, the PIREG-D2can operate up to a

temperature range of 500 °C.

During calibration, the controller sets itself to the secondary voltage of the transformer and the current through

the heating conductor. The secondary voltage of the transformer maybe within a range of 1...80 V. The current

measured with a current transformer can range from 20 to 400A. The calibration values can be stored in the

PIREG-D2, so that there is no need for renewed calibration and start-up time after switching on the power

when conditions have not changed.

The PIREG-D2carries out calibration in a variable room temperature range of 0…50 °C. The actual reference

temperature must be set in the display unit of the controller ( 5.7.2.). This is advantageous in the case of

constant sealing temperatures with different environmental conditions.

High quality sealing transformers, such as toroidal core transformers, are switched on by the PIREG-D2on the

primary side. A smooth switching procedure is employed that compensates for the remanence of the sealing

transformer. An initialising remanence setting is made automatically after switching on the power and following

calibration. Only a short remanence setting lasting 40 ms for El core transformers and 80

ms for toroidal core transformers is needed before each sealing process. If, with toroidal core transformers,

the pause between two sealing processes is longer than 10 minutes, the remanence setting takes

160 ms. The remanence is the residual magnetization in the transformer's iron core. During the initial

remanence setting procedure, the heating conductor has to be heated for a short time to approx. 40 to 70°C.

The PIREG-D2itself uses a phase angle controller for temperature control.

3. Functions

3.1. Control

The following settings which must be carried out prior to calibration are available for the PIREG-D2controller.

The PIREG-D2automatically adapts to the Vr voltage and the Ir current of the heating conductor and to the P-

factor (control amplification).

3.1.1. Heating ramp: The heating ramp is used to set the time value during which the controller adjusts the

actual temperature to the target temperature in a linear ramp ( 5.7.3.). This allows the heating conductor to

be heated gradually.

3.1.2. Setting the temperature coefficient: The temperature coefficient of the heating conductor which must

be positive must be set on the PIREG-D2( 5.7.1.). The temperature coefficient is a material constant that

depends on the alloy used for the heating conductor.

Caution: Using heating conductors with too low a temperature coefficient, or adjusting the controller

to a temperature coefficient that is too high, can result in uncontrolled overheating or melting of the

heating conductor.

The actual value can then not reach the target value and the controller continues to heat continuously.

The variable temperature coefficient setting must be used for heating conductors with a temperature coefficient

that differs from the four possible coefficients.

3.1.3. Calibration reference time: The heating conductor resistance is determined at the reference

temperature during calibration ( 3.2.). To ensure that the reference resistance value determined is correct,

the resistance of the heating conductor is measured again after the calibration reference time has expired, and

compared with the determined reference resistance measured previously. If the difference between both

measurements is greater than 1.2% a new calibration process is started. This ensures that calibration of the

PIREG-D2does not take place during cooling of the heating conductor. By extending the calibration reference

time, changes in the resistance of the heating conductor during cooling can be detected more quickly.

3.1.4. Temperature range: The PIREG-D2controller has four fixed working temperature ranges 200, 300,

400 and 500 °C to be selected and a variable temperature range of 100…500°C. The limits for the overand

undertemperatures are chosen accordingly (nominal value +20% or -10 °C respectively).

6

3.1.5. Calibration mode:

- New calibration: If the calibration mode “new-calibration“ is chosen, the PIREG-D2performs a calibration

after every power-on or the signal “Reset”. The calibration values are not saved. Calibration can also be started

in the Off- or error state with the signal “Calibration Start”.

- Save calibration: Calibration is only started with the signal “Calibration Start”. The signal “Calibration

Start” can be applied in the Off- or error state or before power-on. The calibration values are stored in a

non-volatile memory and cannot be deleted by a power on or the signal “Reset”. This means that a new

calibration must be performed after the heating conductor configuration was changed or modifications were

carried out on the transformer. The saved values are then overwritten with the newly determined values.

3.1.6. Transformer type: The PIREG-D2must be adapted to the sealing transformer type (El or toroidal iron

core). For the first power on several unipolar phase controls are applied to the transformer and the remanence

in the iron core of the transformer is set in a defined position. The angle of current flow of the phase angle

control for remanence setting must be matched to the transformer type. The quick switch-on procedure is used

for every sealing during which only a few remanence-pulses are applied to the transformer before it is switched

on. If the pause between two sealing processes is longer than 10 minutes for toroidal core transformers the

number of the remanence pulses of the quick switch-on procedure is doubled.

The soft switch-on procedure is used for switching on high-quality transformers without power surges.

3.1.7. Reference temperature: The reference temperature is the ambient temperature for determining the

reference resistance RBez of the heating conductor during calibration. The reference temperature for the

PIREG-D2can be set from 0 to 50 °C.

3.1.8. Temperature coefficient correction: The PIREG-D2has two temperature coefficient corrections which

can correct alloy-dependent dispersions of the heating conductor materials.

- Temperature coefficient correction: With the standard temperature coefficient correction the heating

conductor is heated in eight temperature increments. Upon each step the value is compared with the actual

temperature of the heating conductor dependent on the actual value correction. The standard temperature

coefficient correction is an essential part of the calibration ( 3.2.) and is carried out during calibration.

- Single-point temperature coefficient correction: With single-point temperature coefficient correction only

one single operating point is corrected. The single-point temperature coefficient correction is carried out

outside the calibration and is started from the Off-state.

3.2. Calibration:

During calibration, the PIREG-D2independently adjusts to the combination of sealing transformer and heating

conductor. At the same time, the voltage "Vr" at the heating conductor and the current "Ir" through the heating

conductor are measured every second. This status is indicated by the corresponding operating status symbols

in the symbol field of the Working menu on the display unit (_ 5.3.). The three relay outputs of the PIREG-D2

can output a ‘Calibration Ok’ message with a corresponding setting which is reset during calibration. Additional

information about the individual calibration steps are displayed on the actual value display or output. The actual

value is updated every second.

The calibration process will undergo the following steps:

3.2.1. Initialisation: During initialisation, the PIREG-D2determines the data necessary for calibration. In

addition, it checks the selected temperature coefficient for dynamics and continuity in the selected temperature

range. Should the dynamics and continuity exceed the permitted limits, the PIREG-D2will stop the calibration

procedure with error 133 (parameter error).

3.2.2. Calibrating the input amplifier: The input amplifiers for Vr and Ir are adjusted in steps to the voltage

and current at the heating conductor. During this calibration step the actual value display shows different

values every second and various voltages are applied to the actual value output every second. The measured

current or voltage value is displayed or output alternately.

The actual value display shows the current within 0 to 50% of the set temperature range of the controller and

the voltage within 50 to 100%. The zero point of the measured values is set at 50 %. At the beginning of the

calibration, the amplifiers (for Vr and Ir) are initialised with minimum amplification. At the end of the calibration

procedure, if the adjustment has been made successfully, the range for the displayed current value is from 16

- 33 % and the range for the displayed voltage value is from 66 - 83 %.

The current displayed at the actual value output is in the 0 - 5 V range, the voltage in the 5 - 10 V range.

The zero point of the measured values is 5 V. At the beginning of the calibration, the amplifiers (for Vr and

Ir) are initialised with minimum amplification. At the end of the calibration procedure, if the adjustment has

been made successfully, the range for the displayed current value is from 1.66 - 3.33 V and the range for the

displayed voltage value is from 6.66 - 8.33 V.

3.2.3. Determining the phase shift: During this step, the transformer-dependent phase shift between Vr and

Ir is measured and corrected. The controller automatically sets the optimum scan times for Vr and Ir.

The actual value display and the actual value output are adjusted to the phase shift. 50% of the set temperature

range of the controller or a signal of ca. 5 V correspond to the optimum value.

7

3.2.4. Determining the reference resistance: (5.7.2.) The reference resistance of the heating conductor

(Rref) is determined in this step. A reference temperature of 0...50 °C must be set in the controller for

calibration. During calibration, the heating conductor must be at the reference temperature to ensure that

regulation is exact. By standardizing the voltage signal (Vr) and the current signal (Ir), the reference resistance

for the different temperature coefficients is always within the same resistance range. If 20 °C has been selected

as the reference temperature, then heating conductor's R20 is directly determined as the reference resistance.

If a heating conductor temperature other than 20 °C has been selected for calibration, then the determined

reference resistance corresponds to the temperature coefficient above or below the value for the R20. The

reference resistance is displayed for one second at calibration step 4 as the actual value and at the actual

value output. With a reference temperature of 20 °C an actual value of

70…80 % of the set temperature range of the controller is displayed or the voltage at the actual value output

is 7 –8 V. The actual value display is between 60 to 100% for the whole reference temperature range of 0 to

50 °C and the voltage at the actual value output is between 6 and 10 V.

3.2.5. Temperature reference time: ( 5.7.3.) The aim of the temperature reference time is to ensure that the

reference resistance can only be determined when the heating conductor has completely cooled down. The

actual value display is counted down during the reference time from 100 % to 0 % of the set temperature range

of the controller. During this reference time, the signal at the actual value output declines from 10 V to 0 V.

Times of 15 or 30 s can be chosen for the temperature reference time.

3.2.6. Checking the reference resistance: The reference resistance is checked after the temperature

reference time is finished. If calibration takes place on a heating conductor that has cooled down still further

during the temperature reference time, the entire calibration will be discarded and the procedure automatically

restarted. Once the reference resistance has been successfully checked, the PIREG-D2calculates the R20

(resistance at 20°C) of the heating conductor from the reference temperature set, the temperature coefficients

selected and the reference resistance (Rbez.) determined.

The reference resistance measured is displayed for one second as the actual value and at the actual value

output. The same value must be shown on the display or the same value must be set at the actual value output

as when the reference resistance was determined ( 3.2.4).

3.2.7. Determining the P-factor: The P-factor of the sealing transformer/heating conductor combination is

determined by heating with a constant correction variable. The heating conductor is either warmed by a

maximum of approx. 60 K or charged for a maximum of 120 network periods with a defined control value.

The total amplification of the control system is calculated from the measurement of the power fed into the

heating conductor and the measurement of the temperature increase of the heating conductor. The P-factor

for the PIREG-D2is calculated from this.

In the case of adverse conditions of the sealing transformer and heating conductor combinations or the public

supply the P-factor of the PIREG-D2can be corrected manually within a range of 30…110 % ( 5.2.5. and

4.9.).

3.2.8. Setting an initializing remanence: Soft switch-on procedure is carried out by setting an initializing

remanence to switch on the sealing transformer without current surge following a calibration. Setting an

initializing remanence takes 80 ms for the El- and 300 ms for toroidal core transformers (with 50 Hz mains

frequency).

3.2.9. Temperature coefficient correction: Differences of temperature coefficients can be corrected using

this function. These result from the dispersion of the metallurgical composition of the heating conductors.

In calibration stage 9, the PIREG-D2gradually heats up the heating conductor in eight temperature increments

or stages. The PIREG-D2compares its actual value temperature with the actual temperature of the heating

conductor, which it receives as a target value or directly as a measured temperature value from the TM6

thermometer.

The size of each increment is a result of the selected temperature range. The first temperature increment is

always 50 °C. The temperature of the eighth temperature increment falls 20% below the final value of the

selected temperature range. The six other temperature increments are equidistant between these points. For

the 300 °C temperature range, this gives the temperatures 50, 77, 104, 131, 159, 186, 213 and 240 °C. For

the 500 °C temperature range, this gives the temperatures 50, 100, 150, 200, 250, 300, 350 and 400 °C.

The actual temperature of the heating conductor must be set as target value in the display unit or reported

back directly to the PIREG-D2as a measured value of the TM6 thermometer via the RS232 interface.

Deviations of up to ±20 % between the calculated actual value temperature and the actual temperature of the

heating conductor can be corrected ( 5.7.4. und 4.9.). The correction process is controlled with the

“Start”/”Heat” option from the Working menu, the Start signal or via the “SSTST” command. The correction

process can also run automatically when the TC correction heating time was correspondingly set.

After a corresponding setting the TC temperature coefficient correction can be saved so that it doesn’t need

to be repeated after a new calibration but only when the heating conductor is replaced ( 5.2.5.).

Performing the temperature coefficient correction:

8

- manual operation: The actual temperature of the heating conductor is reported back as target value to the

PIREG-D2. The next temperature step is switched to with the rising edge of the “Start” signal. After the heating

conductor has reached a uniform temperature the temperature set as the target value is taken

over as the actual temperature of the heating conductor with the falling edge of the “Start” signal. Operation

can also be executed with the “Start”/”Heat” option from the Working menu ( 5.2.).

After heating to the next temperature stage, only accept the temperature once the heating conductor itself

has reached the specified temperature. The displayed actual value and the actual value output will still

indicate the uncorrected actual value temperature of the PIREG-D2.

- manual operation with the TM6 thermometer: The temperature coefficient correction is controlled with the

“Start” signal or the “Start”/”Heat” option as described above. The actual temperature of the heating conductor

is measured with the TM6 thermometer which is connected to the RS232 interface of the PIREG-D2. The

PIREG-D2automatically tries to establish a connection with the TM6 thermometer at the beginning of the

temperature coefficient correction. As soon as a connection to the TM6 thermometer has been established the

measured value is displayed ( 5.2.). Ensure that the same temperature unit is set on the TM6 thermometer

and on the PIREG-D2display unit ( 5.8.).

- automatic temperature coefficient correction: The PIREG-D2must be connected to the TM6 thermometer

and the set value for the TC correction heating time must be greater zero for the automatic temperature

coefficient correction. The heating time is the period until the heating conductor has reached a uniform

temperature at a temperature stage. The heating time is set in the display unit or by the SKTKZ command

(5.7.3. and 4.9.). The PIREG-D2undergoes the automatic temperature coefficient correction independently

and remains at each temperature stage for the preset heating time.

The controller must undergo calibration steps one to eight for each calibration. Step nine is a selectable

calibration function ( 5.7.4.). If an error occurs during the individual calibration steps, the PIREG-D2stops the

calibration process and then restarts the calibration. Calibration is stopped with an error message after attempt

five was not successful ( 3.7.).

After a successful calibration the PIREG-D2returns to the Off-state.

Calibration must be carried out when the heating conductor has reached the determined reference temperature

to ensure that the R20 reference resistance of the heating conductor is calculated correctly. The time required

for a calibration process depends on various factors. The calibration duration is determined by the voltage at

the heating conductor, the current flowing through the conductor, the phase shift from Vr and Ir and the P-

factor of the sealing transformer/heating conductor combination. The controller needs maximum 43 or 58

seconds for one calibration process.

If the calibration process is not successful, e.g. because the P-factor has been determined incorrectly, the

controller makes another four attempts before reporting an error. In this case, the maximum calibration time

can amount to 215 or 290 s, depending of the temperature reference time.

If the calibration mode “new calibration” is chosen, the controller always switches to calibration immediately

after a power-on or after a reset and carries out a new calibration. Calibration can also be started in the Off-

or error state with the signal “Calibration Start” or from the Calibration selection menu of the display unit.

If the calibration mode “Save” is chosen, the controller switches to calibration when in an Off- or error state or

before power-on only when the “Calibration Start” signal is applied. Calibration can also be started in the Off-

or error state from the Calibration selection menu on the display unit ( 5.2.5.). In this type of calibration, the

calibration values are saved in a non-volatile memory and are loaded immediately after a power-on or the

“Reset" signal.

3.2.10. Single-point temperature coefficient correction: With the single-point temperature coefficient

correction the tolerances of the temperature coefficient of the heating conductor can be corrected for just one

operating point. For this operating point the actual temperature of the heating conductor is reported back to

9

the PIREG-D2as target value or directly as measured value of the TM6 thermometer. The singlepoint

temperature coefficient correction is carried out outside the standard calibration and is started from the Off-

state. Single-point temperature coefficient correction has an Off and an On state. After singlepoint temperature

coefficient correction was started, the PIREG-D2is in the Off-state. When the PIREG-D2is in the On-state,

the heating conductor is heated to the temperature which was set as target value in the Off-state.

After heating, only accept the temperature once the heating conductor itself has reached the specified

temperature. The displayed actual value and the actual value output will still indicate the uncorrected actual

value temperature of the PIREG-D2. The single-point temperature coefficient correction finishes upon exiting

the On state. The correction process is controlled with the “Start”/”Heat” option from the Working menu, with

the “Start” signal or via the “SSTST” command. The single-point TC correction can also run automatically when

the TC correction heating time was correspondingly set.

Deviations of up to ±20 % between the calculated actual value temperature and the actual temperature of the

heating conductor can be corrected. Single-point temperature coefficient correction can only be performed if

no standard temperature coefficient correction via eight points ( 3.2.9.) was carried out during calibration.

The single-point temperature coefficient correction is reset at each calibration. After a corresponding setting

the single-point temperature coefficient correction can be saved so that it doesn’t need to be repeated after a

new calibration but only when the heating conductor is replaced ( 5.2.5.).

Performing the single-point temperature coefficient correction:

- manual operation: Single-point temperature coefficient correction is started from the Calibration selection

menu on the display unit ( 5.2.5.) of the PIREG-D2or by the SSTKA command when the PIREG-D2is in the

Off-state. The PIREG-D2retains the temperature set as target value as the temperature of the operating point

as long as a low-signal is applied as “Start” signal. When a high-signal is applied as “Start” signal the

PIREG-D2heats the heating conductor to the temperature of the operating point. Now the actual temperature

of the heating conductor is set as target value. When a low-signal is applied again as "Start” signal, the

PIREG-D2calculates the correction factors for the single-point temperature coefficient correction and saves

these values if "Save" was selected as calibration mode. The single-point temperature coefficient correction

using the “Start”/”Heat” option from the Working menu is controlled as described above.

The status of the single-point temperature coefficient correction is indicated by the corresponding operating

status symbols in the symbol field of the Working menu on the display unit ( 5.2.).

- manual operation with the TM6 thermometer: The single-point temperature coefficient correction is started

and controlled as described above. The actual temperature of the heating conductor is measured with the TM6

thermometer which is connected to the RS232 interface of the PIREG-D2. The PIREG-D2automatically tries

to establish a connection with the TM6 thermometer at the beginning of the singlepoint temperature coefficient

correction. As soon as a connection to the TM6 thermometer has been established the measured value is

displayed ( 5.2.).

- automatic single-point temperature coefficient correction: The PIREG-D2must be connected to the

TM6 thermometer and the set value for the TC correction heating time must be greater zero for the automatic

single-point temperature coefficient correction. The heating time is the period until the heating conductor has

reached a uniform temperature in the On-state of the single-point TC correction. The heating time is set in the

display unit or by the SKTKZ command ( 5.7.3. and 4.9.). Automatic single-point temperature coefficient

correction is started as described above for manual operation. The PIREG-D2undergoes the automatic single-

point temperature coefficient correction independently and remains in the Onstate for the preset heating time.

3.2.11. P-factor correction: The P-factor correction is used for subsequent manual correction of the calibrated

P-factor ( 3.2.7.) in the case of very unfavourable conditions of the sealing transformer/heating conductor

combinations or the public supply. The correction range is 30…110 %.

The P-factor correction is set in the display unit or by the SKPFK command ( 5.2.5. and 4.9.). The P-factor

correction value will not be reset during a calibration as it is system dependent.

3.3. Off-State

The PIREG-D2measures continuously the heating conductor resistance when in the Off-state, determines its

temperature and displays or outputs the temperature as actual value.

For each resistance measurement a positive and negative power line half-wave of the same fixed angle of

current flow (1.8 ms at 50 Hz mains frequency) is applied to the transformer. The time intervals of the

measurements depend on the temperature of the heating conductor. When the heating conductor has reached

a temperature of 20 °C, the measuring interval is 1.5 s. At a temperature of 300 °C, the measuring interval is

only 100 ms.

The heating conductor is heated in the Off-state and dependent on the voltage by the energy introduced when

measuring the resistance.

The controller switches from the Off-state to the On-state as soon as the “Start” signal is applied. When the

“Calibration Start” signal is applied the PIREG-D2returns to calibration and to the off state after the end of a

successful calibration. The PIREG-D2then stays in the Off-state even when the “Calibration Start” signal is

still applied (evaluation of the rising edge). A corresponding control is also possible with the “Start”/”Heat”

10

options from the Working menu ( 5.2.). Single-point temperature coefficient correction can be started from the

Calibration selection menu of the display unit of the PIREG-D2when in the Off-state ( 5.2.5.).

3.4. On-State

In the On-state, the PIREG-D2controls the temperature of the heating conductor in accordance with the target

value. A phase angle controller is used. The controller returns to the Off-state when the “Start” signal is

removed. A corresponding control is also possible with the “Start”/”Heat” options from the Working menu

( 5.2.).

When sequence control is activated the On-state additionally consists of the Start delay and the cooling

phase ( 5.4.).

3.5. Sequence control

The sequence control can be switched on and off (_ 5.4.). If the sequence control is switched off, then a sealing

process with the set target temperature is activated and deactivated after the “Start” signal. If the

sequence control is switched on, a sealing cycle with subsequent start delay, sealing time and cooling time

will be started automatically after the “Start” signal.

3.5.1. Preheating: With “Preheating” the heating element is preheated when the sealing process or a sealing

cycle is paused. Preheating is controlled with the “Preheat” signal. When the “Preheat” signal is

applied the connected PIREG-D2controller adjusts the temperature of the heating conductor to the preset

preheating temperature. The preheating temperature can be set irrespective of the target temperature.

Preheating is also possible when the sequence control is switched off.

3.5.2. Start delay: Start delay is the delay time after the “Start” signal was applied and until sealing time

starts. During the start delay the heating conductor will not be heated by the PIREG-D2. Preheating (if set)

continues to run.

3.5.3. Sealing time: During the sealing time the PIREG-D2adjusts the temperature of the heating conductor

according to the set target value. Depending on the settings the sealing time starts when this sequence

phase is reached or after the actual temperature has exceeded 95% of the target value.

3.5.4. Cooling phase: The sealing time is followed by the cooling phase. Depending on the setting the

heating conductor is to cool down for a set time or to the preset temperature during the cooling phase.

The cooling temperature can either be set as an absolute value or as percentage of the target value.

3.6. Monitoring

3.6.1. Temperature monitoring: Temperature monitoring is a monitoring function which is activated and set

on the display unit (_ 5.5.1.) or by the STUEE command. The actual temperature is monitored during the

sealing process whether it is in the temperature OK-range. If the actual value leaves the temperature OK-

range during the sealing process after the stabilisation time has ended the PIREG-D2will go to error state with

error 83 or 84. The stabilisation time will be restarted if the target value is changed by more than 2 °C.

3.6.2. Monitoring of heating: The heating monitoring is a monitoring function which is activated and set on

the display unit (_ 5.5.2.) or by the SAHUE command. With this function the temperature rise is monitored after

the “Start" signal was applied. If the actual temperature does not reach the temperature OKrange

within the set heating time the PIREG-D2will go to error state with error 85. Preheating monitoring is restarted

if the target value increases by more than 5 °C.

3.6.3. Monitoring of starting: A sealing cycle can be interrupted with the “Start” monitoring function. The

sealing cycle is interrupted when the “Start” signal is no longer applied during the running sealing cycle.

An Emergency Stop function will then be executed. (_ 5.5.)

3.6.4. Monitoring of communication: The monitoring of the communication is an additional monitoring

function for the two interfaces of the PIREG-D2controller and is activated and set with a command (SKOUE)

for each interface individually. This function monitors the communication via the interfaces. If the

communication is interrupted for a longer time than the set downtime, then the PIREG-D2switches to error

state.

3.7. Error state

The error state is indicated on the PIREG-D2only when an error occurs. The controller monitors the line

voltage, the temperature of the heating conductor, the values of the voltage and current measurements at

the heating conductor, the calibration parameters and the monitoring functions.

The Alarm output and the Alarm LED are switched in the error state. The actual value output is also cycled

in some error cases. The voltage at the actual value output then changes every second between the

voltages applicable to the different errors (_ table 1). The error state can only be cancelled by switching off the

power supply, the „Reset“ signal and „Calibration Start“. With errors 10…33 the error state cannot be cancelled

with the “Calibration Start” signal.

In the error state the Error menu can be called from the display unit (_ 5.2.4.). Here, the error number, an error

description and possible corrective actions are displayed.

11

12

3.8. Relay functions

The same functions can be set independently for each of the message- and the two control relay outputs.

3.8.1. Temperature function: The relay is actuated if the actual temperature is in the “Temperature ok”

range. A delay during which the actual temperature has stabilized can be set with the stabilization time.

The holding function is an additional function during which the relay remains activated after the sealing

cycle and until start of the following sealing cycle.

3.8.2. Sequence function: This relay function is used to set the conditions when the relay is actuated:

- Active upon “Start” signal: The relay is actuated as soon as the “Start” signal is applied and is released

when the cooling phase has ended.

- Active when temperature is reached: The relay is actuated when the actual temperature has exceeded

95% of the target value and is released when the cooling phase has ended.

- Active during heating phase: The relay is actuated while the sealing time is running off.

- Active during cooling phase: The relay is actuated during the cooling phase.

- Calibration Ok: The relay is not actuated during calibration. It is actuated again after a successful

calibration.

End of calibration is indicated with the “Calibration Ok” function.

3.8.3. Time pulse function: The following switching pulses can be generated with the relays using the

“Time pulse” function:

- Heating phase: The relay is actuated for the set pulse time when sealing time starts, i.e. during heating

of the heating conductor.

- Cooling phase: The relay is actuated for the set pulse time at the start of the cooling phase.

- Pulse end: The relay is actuated for 500 ms at the end of the cooling phase.

3.9. Display functions

3.9.1. Languages: The following languages can be set for the PIREG-D2display unit:

German English French Italian Dutch Russian

3.9.2. Brightness: The brightness of the background lighting is set as a percentage value.

3.9.3. Hold mode: If the “Hold” mode is activated the actual temperature value which was measured at the

end of the sealing process or the sealing time will also displayed. You can select whether the measured

actual value is only displayed for 2 seconds or until the following sealing process or sealing cycle is started.

3.9.4. Cycle counter: The PIREG-D2display unit has a cycle counter (0…9999999) for counting the sealing

cycles. The cycle counter can be reset. In the case of an overflow the counter restarts with zero.

In addition the PIREG-D2display unit has a total cycle counter (0…999999999) which is used as „service life

counter“, and can therefore not be reset.

3.9.5. Saving: With the PIREG-D2display unit settings can be saved and restored. One distinguishes

between parameter sets ( 5.9.1.) and factory settings ( 5.9.2.). The settings for different applications of the

sealing machine are saved using the five parameter sets so that the machine can be adjusted quickly when

the application was changed. One basic setting of the machine can be saved and restored with the factory

settings. In addition the PIREG-D2can be reset to its factory settings.

3.9.6. Releases: The PIREG-D2display unit has three release levels ( 5.8.4.) with which different

userdependent operating levels can be realized. Each release level has its own release number. All release

numbers are factory-set to “0000”. All release levels are thus activated after the controller was switched on

so that the controller can be set. After switching off or resetting the controller, all levels are locked, for which

the release number is not "0000". To unlock a release level permanently, the release number of this release

level should be "0000". An unlocked release level can be locked again by entering the release number

"0000", without having to switch off the controller.

The following settings are assigned to the individual release levels.

- Level 0: Control via the inputs and buttons of the display unit (unprotected).

- Level 1: - Setting of level 0

- Target value

- Sealing time and cooling time

- Reference temperature for calibration

- Reading parameter sets 1…5

- Level 2: - Setting of level 1

- All controller settings

(settings of the TC temperature, time, calibration and target value)

- Saving parameter sets 1…5

- Level 3: - Setting of level 2

- All settings of the PIREG-D2

13

3.9.7. Temperature unit: With the PIREG-D2display unit the temperature values can be indicated in [°C]

or [°F] ( 5.8.). The temperature unit is only used for display of the temperature values. The display unit

continues to operate internally with the unit [°C] even when [°F] is displayed which results in temperature

leaps of 2 °F when the unit [°F] is set as temperature value.

When working with the TM6 thermometer the same temperature unit must be set on the thermometer and

on the PIREG-D2display unit.

4. Operation

4.1. Keys

The following five keys are used for operating the PIREG-D2display unit:

4.1.1. Cursor: The cursor is moved to the possible setting items using the arrow keys in the display.

There are numerical values which can be set, options which can be selected and menu items for calling

another menu. An empty triangle is used as symbol for the cursor. The cursor remains on the menu

item which was selected last after the menu was changed.

4.1.2. Setting numerical values: Move the cursor to the numerical value to be set and confirm with the

Ok button. As soon as the value is changed using the and buttons the value starts flashing at a frequency

of 1 Hz indicating that the value was changed. The value is accepted after the Ok button was

pressed and stops flashing. Press the key to cancel the changes and to restore the original value.

If the and buttons are pressed for more than 1 second the numerical value starts to run at a rate of

change of 10 dig/sec.. If the button is pressed more than 3 seconds the rate of change increases to 100

dig/sec..

4.1.3. Selecting functions: Move the cursor to the item to be selected. Press the Ok button to select the

item. A filled triangle is used as selection cursor. If the cursor and the selection cursor are on the same

function, the display changes between the selection cursor and the cursor at a frequency of 1Hz.

4.1.4. Acceptance of the settings: The set numerical values are accepted by pressing the Ok button. If

the setting is not accepted within 3 seconds after it was changed with the Ok button, then the setting will

be discarded and the old value will be further used.

The numerical values can also be accepted automatically, i.e. the setting will be accepted if it was not

changed for more than 3 seconds. The automatic acceptance is activated and deactivated in the Operating

menu ( 5.8.3.).

4.1.5. Menu change: Move the cursor to the menu item if you want to change the menu. If the menu

item is also an option, you should use the button to change the menu. Press the Ok button if it is a

mere menu item. Exit the menu with the button .

Switch to the last changed setting in a menu by pressing the +simultaneously in the Working menu.

4.1.6. Menu return: If no changes were made, the program will return from all menus to the Working

menu after 20 seconds at the latest. Press the key combination +to jump to the position in the menu

where the program returned to the Working menu. The menu return can be activated and deactivated in

the Operating menu ( 5.8.3.).

4.1.7. Locking: A locking which prevents unintentional changes of the settings is provided which can be

activated and deactivated by pressing the key combination + + Ok . First, however, the locking must be

activated in the Operating menu ( 5.8.3.).

4.1.8. Execution prevention: If a setting or menu change is not possible, the cursor changes to a diagonal

cross for one second to indicate this status.

Please note: Most settings cannot be changed during calibration process and in ON-condition.

4.2. LEDs

4.2.1. Power: The green Power LED indicates that the PIREG-D2controller is connected to the line voltage.

4.2.2. Heat: The yellow LED “Heat” indicates that a sealing cycle is executed if the sequence control is

switched on. If the sequence control is switched off, this LED only signalizes the sealing process itself.

4.2.4. Alarm: The red LED “Alarm” indicates that an error is present and that the PIREG-D2controller is in

an error state. The error is shown in plain text in the Error menu on the display unit ( 5.2.4.).

4.3. Inputs

4.3.1. Start inputs: The PIREG has two Start inputs: one Start input (X3) which is controlled by an external

voltage, and the Start contact input (X7) which is controlled when the input is connected to AGND (X2) for

example with a switch.

A sealing process or a sealing cycle is started by applying the high-signal to the Start input (X3) or

connecting the Start contact input (X7) with AGND (X2). If the sequence control is switched on and the

“Start” monitoring function is deactivated, a sealing cycle will only be started with rising edge.

14

If standard TC correction via eight points was selected the correction process is also controlled by the

Start inputs for manual operation. The single-point TC correction is also controlled by the Start inputs.

4.3.2. Preheat inputs: The PIREG has two Preheat inputs: one Preheat input (X22) which is controlled by an

external voltage, and the Preheat contact input (X19) which is controlled when the input is connected

to AGND (X2) for example with a switch.

If a high-signal is applied to the Preheat input (X22) in the pause between two sealing processes or sealing

cycles or the Preheat contact input (X19) is connected to AGND (X2), the PIREG-D2will regulate the

temperature of the heating conductor to the set preheating temperature (_ 5.4.1.).

4.3.3. Calibration Start input: When a high-signal is applied to the Calibration Start input (X25) in the

Off- or error state the PIREG-D2changes in the calibration state. Normally the controller is adapted to the

sealing transformer and heating conductor combination. During calibration of the controller the signal can

be switched back to Low.

4.3.4. Reset input: When a high-signal is applied to the Reset input (X26) the PIREG-D2is reset to the

status after power-on in case of a malfunction. This is possible without switching the line voltage off.

4.3.5. Target value input: Beside setting the target value on the PIREG-D2display unit, the target temperature

can also be set on the target value input (X23). The target value is set with an analogue voltage.

The option for setting the target temperature is selected on the display unit (_ 5.7.5.) or by a command.

- Internal: The target value is set on the PIREG-D2display unit (_ 5.2.).

- Target value U: The temperature target value is set with an analogue voltage. The voltage range of the

target value is 0 - 10 V. The selected temperature range applies to the maximum target voltage i.e. 10 V at the

target value input correspond to 300 °C if the selected temperature range is 300 °C.

- Target value R: The temperature target value is set with a potentiometer. For the potentiometer the

wiper is connected to the target value input (X23), the CW connection to the actual value output (X24) and the

CCW connection to the GND connection (X20). The actual value output then works as reference voltage

source with an output voltage of 10 V. Pay attention to the correct phase sequence when connecting the

potentiometer. The voltage at the target value input should increase for clockwise rotation (CW) on the

potentiometer. The selected temperature range is adjusted to the target value voltage as described above.

4.4. Outputs

4.4.1. Actual value output: The actual value output (X24) supplies a voltage in the range 0 - 10 V,

proportional to the temperature of the heating conductor. The voltage range refers to the selected

temperature range, i.e. 10 V at the actual value output correspond to 300 °C if the selected temperature

range is 300 °C. The actual value output can supply a maximum current of 5 mA.

When the target value input is used with a potentiometer (setting “target value R”) the actual value output

operates as a constant voltage source with an output voltage of 10 V.

4.4.2. Message relay output: The message relay output 1 (X21) has an NO contact which operates against

the GND connection (X20). It can be set whether the contact is open or closed when the relay is actuated.

The switching capacity of the relay contact is only designed for message functions. The relay contact was

set at the factory to be closed when the relay is actuated.

4.4.3. Control relay outputs: The control relay outputs 1 (X16/X17/X18) and 2 (X27/X28/X29) provide a

change-over contact. The switching capacity is only designed for control functions.

4.4.4. Alarm output: The alarm output (X5/X6) is a relay switching contact. It can be set whether the alarm

output is opened or closed in the case of a fault. The factory setting of the relay contact is “closed” when a

fault occurs.

4.4.5. ELR output: The ELR output (X1/X2) controls an external solid-state relay which is used as actuator

instead of the internal actuator of the controller. Combinations of heating conductor and sealing transformer

with capacities exceeding the permissible capacity of the internal actuator can be switched with the external

solid-state relay.

4.5. Interfaces

We will provide you with the detailed interface description of the control system with integrated PIREG-D2

resistance temperature controller for packaging machines if required.

15

5. Menu structure

5.1. Switching on

Line 1 After switching the PIREG-D2controller on, the initial screen

Line 2 will be displayed for 2 seconds before the Working menu is

Line 3 called automatically ( 5.2.).

Line 4

Line 5 Line 1…4: Logo of the Toss company

Line 6 Line 6: Legal form of the Toss company

Line 7 Line 7: Seat of the company incl. zip code and town

Line 8 Line 8: Telephone number of the Toss company

5.2. Working menu

5.2.1. Working menu without sequence control

Line 1 Line 1…2: Display and adjustment of the target value as

Line 2 numerical value. The adjustable target value range is shown

Line 3 in line 2.

Line 4 Line 3…4: Actual value display; when the Hold mode is

Line 5 activated “Hold” is displayed in line 4 as long as the actual

Line 6 value is maintained.

Line 7 When the TM6 thermometer is connected the measured

Line 8 value of the TM6 thermometer “888.8°C” is displayed in line

4 during standard and single-point temperature coefficient

correction.

Line 1…4: Four items for selection are displayed on the

right half. Click the “Menu” menu item to call the Selection

menu ( 5.3.). If the locking was activated then the text

„####“ will be shown instead of the text “Menu”.

The following option “Heat.” or “Start” is only available if the

Start function ( 5.4.2.) was activated.

- without sequence control: Select the “Heat” option to

execute a manual sealing process and keep the Ok button

pressed.

5.2.2. Working menu with sequence - with sequence control: If the Start function “Start sealing

Control cycle” is selected for the sequence control, a sealing cycle

Line 1 will be started manually with the “Start” option. If “Heating

Line 2 only” is selected for the Start function a sealing process will

Line 3 be executed manually with the “Heat” option as long as the

Line 4 Ok button is pressed.

Line 5 The “Cal.” menu item calls up the Calibration selection

Line 6 menu ( 5.2.5.).

Line 7 Line 5: Bar chart of the actual value.

Line 8 Line 6: Display of the cycle time, i.e. the duration (0…999.s)

of the last sealing process or sealing cycle. During automatic

temperature coefficient correction with the TM6 thermometer

the decreasing Tc correction heating time will be

displayed instead of the cycle time.

Line 6…8: A symbol field for the operating status is shown

on the right half. This symbol field can be selected in the

case of an alarm and an Error menu ( 5.2.4.) with an error

description and possible corrective actions will be displayed.

- with sequence control:

Line 7: Sealing time of the sequence control; the value can

be changed either in the Working menu or in the Sealing

Time menu ( 5.4.4.). The value of the ending sealing time

which –depending on the setting - is counted up or down

can be displayed here during the sealing process.

Line 8: Cooling phase of the sequence control; the value

can be changed either in the Working menu or in the Cooling

Phase menu ( 5.4.5.).

The value of the ending cooling time which –depending on

the setting - is counted up or down during the cooling process

is displayed here. This requires that the cooling time

was selected for the cooling phase.

16

5.2.3. Symbols for the operating status

17

18

5.4. Sequence Control menu

5.3. Selection menu

19

20

5.5. Monitoring menu

5.6. Relay settings menu

Other manuals for PIREG-D2

1

Table of contents

Other Toss Controllers manuals

Popular Controllers manuals by other brands

Illinois Tool Works

Illinois Tool Works SIMCO PulseFlow PFC instructions

Siemens

Siemens SINUMERIK 840DE user manual

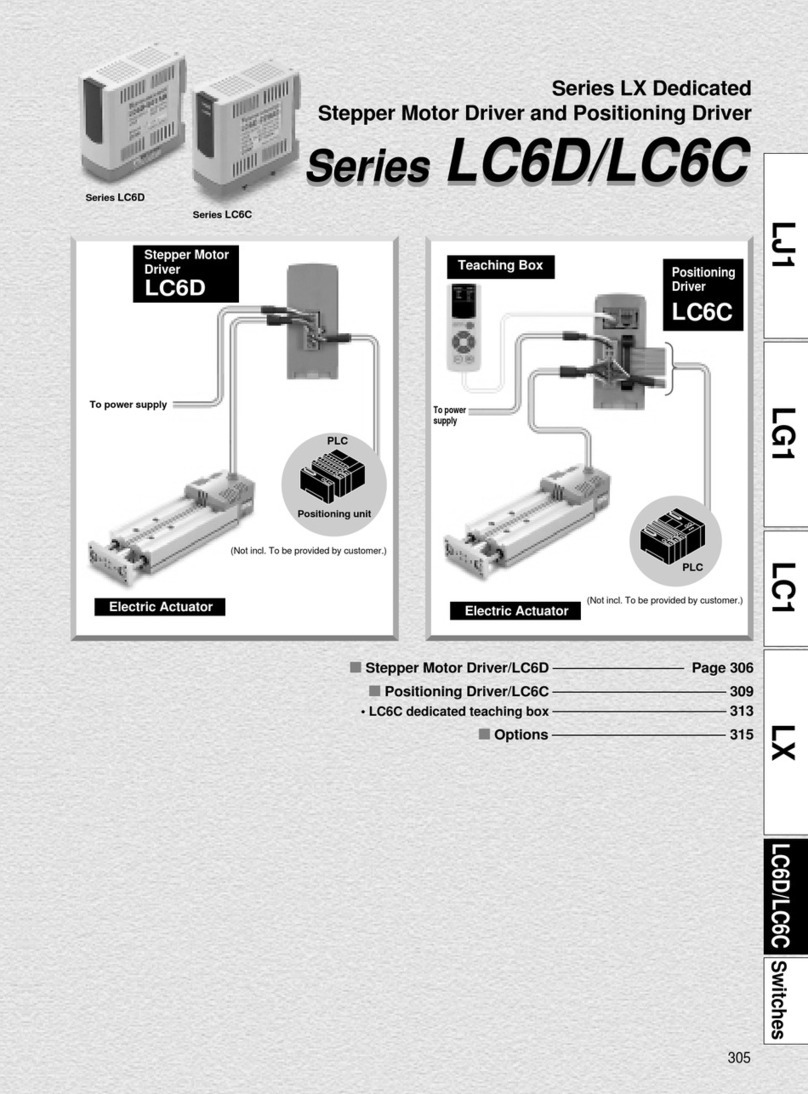

SMC Networks

SMC Networks LX Dedicated Series manual

Delta Electronics

Delta Electronics DVP15MC11T Operation manual

Ss Brewtech

Ss Brewtech FTSs Pro Touch Product guide

LG

LG PRCKA0 installation manual