Toss ROPEX RESISTRON RES-407 User manual

19.11.07

RESISTRON

RES-407 GB

Important features

• Microprocessor technology

• Automatic zero calibration (AUTOCAL)

• Automatic optimization (AUTOTUNE)

• Automatic configuration of the secondary voltage and current ranges

(AUTORANGE, as of April 2005)

• Automatic phase angle compensation (AUTOCOMP, as of April 2005)

• Automatic frequency adjustment

• Large current and voltage range

• Electrically isolated analog input for set point selection with potentiometer or 0…10VDC

• Electrically isolated 0…10VDC analog output for ACTUAL temperature

• 24VDC control signals for START, AUTOCAL and RESET with electrical isolation

• Alarm function with fault diagnosis

• Heatsealing band alloy and temperature range selectable as standard (as of June 2003)

Operating

Instructions

Exclusive Sales and Service:

www.tossheatseal.com

Toss Machine Components, Inc.

539 S. Main Street, Nazareth. PA 18064

Phone 610-759-8883 Fax 610-759-1766

E-Mail: [email protected]

Exclusive Sales and Service:

www.tossheatseal.com

Toss Machine Components, Inc.

539 S. Main Street, Nazareth. PA 18064

Phone 610-759-8883 Fax 610-759-1766

E-Mail: [email protected]

Page 2 RES-407

Contents

1 Safety and warning notes . . . . . . . . . . . . . . 3

1.1 Use . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Heatsealing band . . . . . . . . . . . . . . . . 3

1.3 Impulse transformer . . . . . . . . . . . . . . 3

1.4 Current transformer PEX-W2/-W3 . . . . 3

1.5 Line filter . . . . . . . . . . . . . . . . . . . . . . . 4

1.6 Warranty provisions . . . . . . . . . . . . . . . 4

1.7 Standards / CE marking . . . . . . . . . . . 4

2 Application . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Principle of operation . . . . . . . . . . . . . . . . . 5

4 Description of the controller . . . . . . . . . . . 6

5 Accessories and modifications . . . . . . . . . 6

5.1 Accessories . . . . . . . . . . . . . . . . . . . . . 6

5.2 Modifications (MODs) . . . . . . . . . . . . . 7

6 Technical data . . . . . . . . . . . . . . . . . . . . . . 10

7 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . 12

8 Installation . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.1 Installation procedure . . . . . . . . . . . . 12

8.2 Installation steps . . . . . . . . . . . . . . . . 13

8.3 Power supply . . . . . . . . . . . . . . . . . . . 14

8.4 Line filter . . . . . . . . . . . . . . . . . . . . . . 15

8.5 Current transformer PEX-W3 . . . . . . 15

8.6 Auxiliary voltage . . . . . . . . . . . . . . . . 16

8.7 Wiring diagram (standard) . . . . . . . . . 16

8.8 Wiring diagram with booster

connection (MOD 26) . . . . . . . . . . . . 17

8.9 Wiring diagram with "Temp-

erature reached" signal (MOD 40)

or „Temp. OK“ signal (MOD 46) . . . . 18

9 Startup and operation . . . . . . . . . . . . . . . . 19

9.1 View of the controller . . . . . . . . . . . . . 19

9.2 Controller configuration . . . . . . . . . . . 19

9.3 Heatsealing band . . . . . . . . . . . . . . . . 21

9.4 Startup procedure . . . . . . . . . . . . . . . 22

10 Controller functions . . . . . . . . . . . . . . . . . 24

10.1 Indicators and controls . . . . . . . . . . . 24

10.2 Temperature setting

(set point selection) . . . . . . . . . . . . . . 25

10.3 Temperature indication (actual value

output) . . . . . . . . . . . . . . . . . . . . . . . . 26

10.4 Automatic zero calibration

(AUTOCAL) . . . . . . . . . . . . . . . . . . . . 27

10.5 "START" signal (HEAT) . . . . . . . . . . . 28

10.6 "RESET" signal . . . . . . . . . . . . . . . . . 28

10.7 Measuring impulse duration

(as of April 2005) . . . . . . . . . . . . . . . . 29

10.8 Automatic phase angle

compensation (AUTOCOMP)

(as of April 2005) . . . . . . . . . . . . . . . . 29

10.9 Temperature diagnosis

(as of April 2005) . . . . . . . . . . . . . . . . 30

10.10 Heatup timeout

(as of April 2005) . . . . . . . . . . . . . . . . 31

10.11 Diagnostic interface/visualization software

(as of April 2005) . . . . . . . . . . . . . . . . 31

10.12 System monitoring/alarm output . . . . 31

10.13 Error messages . . . . . . . . . . . . . . . . . 32

10.14 Fault areas and causes . . . . . . . . . . . 37

11 Factory settings . . . . . . . . . . . . . . . . . . . . . 38

12 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 39

13 How to order . . . . . . . . . . . . . . . . . . . . . . . . 40

14 Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Safety and warning notes

RES-407 Page 3

1 Safety and warning notes

This RESISTRON temperature controller is

manufactured according to DIN EN 61010-1. In the

course of its manufacture it passed through quality

assurance, whereby it was subjected to extensive

inspections and tests.

It left the factory in perfect condition.

The recommendations and warning notes contained in

these operating instructions must be complied with, in

order to guarantee safe operation.

The device can be operated within the limits indicated

in the "Technical Data" without impairing its operational

safety. Installation and maintenance may only be

performed by technically trained, skilled persons who

are familiar with the associated risks and warranty

provisions.

1.1 Use

RESISTRON temperature controllers may only be used

for heating and temperature control of heatsealing

bands which are expressly suitable for them, and

providing the regulations, notes and warnings

contained in these instructions are complied with.

In case of non-compliance or use contrary to

the intended purpose, there is a risk that

safety will be impaired or that the heatsealing band,

electrical wiring, transformer etc. will overheat.

Ensuring such compliance is the personal

responsibility of the user.

1.2 Heatsealing band

A basic prerequisite for reliable and safe operation of

the system is the use of suitable heatsealing bands.

The resistance of the heatsealing band which

is used must have a positive minimum

temperature coefficient in order to guarantee

trouble-free operation of the RESISTRON

temperature controller.

The temperature coefficient must be specified as

follows:

e.g. Alloy-20: TCR = 1100 ppm/K

NOREX: TCR = 3500 ppm/K

The RESISTRON temperature controller must be set

and coded according to the temperature coefficient of

the heatsealing band.

The use of incorrect alloys with a too low

temperature coefficient and incorrect coding

of the RESISTRON temperature controller lead to

uncontrolled heating and ultimately to burn-out of

the heatsealing band!

The heatsealing bands that were originally supplied

must be identified by detail specification, part number

or some other means that will assure that replacement

bands are identical.

1.3 Impulse transformer

A suitable impulse transformer is necessary to ensure

that the control loop functions perfectly. This

transformer must be designed according to VDE 0570/

EN 61558 (isolating transformer with reinforced

insulation) and have a one section bobbin. When the

impulse transformer is installed, suitable shock

protection must be provided in accordance with the

national installation regulations for electrical

equipment. In addition, water, cleaning solutions and

conductive fluids must be prevented from seeping into

the transformer.

Incorrect installation of the impulse

transformer impairs electrical safety.

1.4 Current transformer PEX-W2/-W3

The current transformer supplied with the RESISTRON

temperature controller is an integral part of the control

system.

Only the original ROPEX PEX-W2 or PEX-W3

current transformer may be used. Other

transformers may cause the equipment to

malfunction.

The current transformer may only be operated if it is

connected to the RESISTRON temperature controller

correctly (see section 9, "Startup and operation"). The

relevant safety instructions contained in section 8.3,

"Power supply", must be obeyed. External monitoring

modules can be used in order to additionally increase

!

!

TCR 10 4–

×10 K 1–

≥

!

!

!

Application

Page 4 RES-407

operating safety. They are not included in the scope of

supply of the standard control system and are

described in a separate document.

1.5 Line filter

The use of an original ROPEX line filter is mandatory in

order to comply with the standards and provisions

mentioned in section 1.7 "Standards / CE marking" on

page 4. This device must be installed and connected

according to the instructions contained in section 8.3,

"Power supply" as well as the separate documentation

enclosed with the line filter.

1.6 Warranty provisions

The statutory provisions for warranties apply for a

period of 12 months following the delivery date.

All devices are tested and calibrated in the factory.

Devices that have been damaged due to faulty

connections, dropping, electrical overloading, natural

wear, incorrect or negligent handling, chemical

influences or mechanical overloading as well as

devices that have been modified, relabeled or

otherwise altered by the customer, for example in an

attempt to repair them or install additional components,

are excluded from the warranty.

Warranty claims must be examined in the factory and

approved by ROPEX.

1.7 Standards / CE marking

The controller described here complies with the

following standards, provisions and directives:

Compliance with these standards and provisions is only

guaranteed if original accessories and/or peripheral

components approved by ROPEX are used. If not, then

the equipment is operated on the user's own

responsibility.

The CE marking on the controller confirms that the

device itself complies with the above-mentioned

standards.

It does not imply, however, that the overall system also

fulfils these standards.

It is the responsibility of the machine manufacturer and

of the user to verify the completely installed, wired and

operationally ready system in the machine with regard

to its conformity with the safety provisions and the EMC

directive (see also section 8.3, "Power supply"). If

peripheral components (e.g. the transformer or the line

filter) from other manufacturers are used, no functional

guarantee can be provided by ROPEX.

2 Application

This RESISTRON temperature controller is an integral

part of the "series 400", the outstanding feature of

which is its microprocessor technology. All

RESISTRON temperature controllers are used to

control the temperature of heating elements

(heatsealing bands, beaded bands, cutting wires,

heatsealing blades, solder elements etc.), as required

in a variety of heatsealing processes.

The controller is most commonly used for impulse-

heatsealing PE and PP films in:

• Vertical and horizontal f/f/s machines

• Pouch, filling and sealing machines

• Film wrapping machines

• Pouch-making machines

• Group packaging machines

•L-sealers

DIN EN 61010-1

(VDE 0411-1)

Safety provisions for electrical

measuring, control and laboratory

devices (low voltage directive).

Overvoltage category III, pollution

severity 2, safety class II.

DIN EN 60204-1 Electrical equipment of machines

(machinery directive)

EN 50081-1 EMC interference emissions

according to EN 55011, group 1,

class B

EN 50082-2 EMC interference immunity:

ESDs, RF radiation, bursts, surges.

Principle of operation

RES-407 Page 5

•etc.

The use of RESISTRON temperature controllers

results in:

• Repeatable quality of the heatseals under any

conditions

• Increased machine capacity

• Extended life of the heatsealing bands and teflon

coatings

• Simple operation and control of the sealing process

3 Principle of operation

The resistance of the heatsealing band, which is

temperature-sensitive, is monitored 50x per second

(60x at 60Hz) by measuring the current and voltage.

The temperature calculated with the help of these

measurements is displayed and compared with the set

point.

The primary voltage of the impulse transformer is

adjusted by phase-angle control if the measured values

deviate from the set point. The resulting change in the

current through the heatsealing band leads to a change

in the band temperature and thus also its resistance.

This change is measured and evaluated by the

RESISTRON temperature controller.

The control loop is closed: ACTUAL temperature = SET

temperature. Even minute thermal loads on the

heatsealing band are detected and can be corrected

quickly and precisely.

The thermoelectric control loop which is formed has a

highly dynamic response because purely electrical

variables are measured at a high sampling rate. A very

wide secondary current range can be controlled with

only minimal power loss - a considerable advantage -

because power is controlled on the primary side of the

transformer. This allows optimum adaptation to the

load and to the required dynamic range despite the

exceptionally compact dimensions of the controller.

PLEASE NOTE!

RESISTRON temperature controller play a significant

role in enhancing the performance of modern

machines. However, the full benefit can only be

obtained from the advanced technology offered by this

control system if all the system components, in other

words the heatsealing band, the impulse transformer,

the wiring, the timing signals and the controller itself,

are compatible with one another.

We will be pleased to

contribute our many

years of experience

towards optimizing your

heatsealing system.

R=f(T)

+

_

Set point

Start

Indicators

and

controls

or

bus interface

Actual value

LINE

RESISTRON controller

Heatsealing band R = f (T)

Current

transformer

Impulse transformer

UR

IR

prim.

U1

sec.

U2

Description of the controller

Page 6 RES-407

4 Description of the controller

The microprocessor technology endows the

RESISTRON temperature controller RES-407 with

previously unattainable capabilities:

• Very simple operation thanks to AUTOCAL, the

automatic zero calibration function.

• Good dynamic response of the control system

thanks to AUTOTUNE, which adapts automatically

to the controlled system.

• High precision thanks to further improved control

accuracy and linearization of the heatsealing band

characteristic.

• High flexibility: The AUTORANGE function (as of

April 2005) covers a secondary voltage range from

0.4V to 120V and a current range from 30A to

500A.

• Automatic adjustment to the line frequency in the

range from 47Hz to 63Hz.

• Increased protection against dangerous conditions,

such as overheating of the heatsealing band.

The electrically isolated analog interfaces for the

temperature set point and the actual temperature

(0-10VDC) allow the temperature to be set either

directly on the machine PLC or by means of an external

potentiometer (PD-x).

Similarly, the real heatsealing band temperature can be

visualized either on the display of the machine PLC or

on an external temperature meter (ATR-x).

The RESISTRON temperature controller RES-407

features an integrated fault diagnosis function, which

tests both the external system (heatsealing band,

wiring etc.) and the internal electronics and outputs a

selective error message in case of a fault.

To increase operational safety and interference

immunity, all 24VDC logic signals are electrically

isolated from the controller and the heating circuit.

Coding switches on the temperature controller itself

can be used to adapt to different heatsealing band

alloys (Alloy A20, NOREX etc.) and set the required

temperature range (0...300°C, 0...500°C etc.) on all

controllers manufactured as of June 2003.

An external 24VDC auxiliary voltage is required to

supply the isolating amplifiers and optocouplers. The

compact design of the RESISTRON temperature

controller RES-407 and the plug-in connections make

this controller easy to install.

5 Accessories and modifications

A wide range of compatible accessories and peripheral

devices are available for the RESISTRON temperature

controller RES-407. They allow it to be optimally

adapted to your specific heatsealing application and to

your plant's design and operating philosophy.

5.1 Accessories

The products described below are only a few of the

wide range of accessories available for RESISTRON

temperature controllers (ª"Accessories" leaflet).

Analog temperature meter ATR-x

For front panel mounting or mounting on a top hat rail (DIN TS35 rail).

Analog indication of the ACTUAL temperature of the heatsealing band in °C. The

meter damping of the unit is optimized for the abrupt temperature changes that occur

in impulse mode.

Digital temperature meter DTR-x

For front panel mounting or mounting on a top hat rail (DIN TS35 rail).

Digital indication of the ACTUAL temperature of the heatsealing band in °C, with

HOLD function.

Accessories and modifications

RES-407 Page 7

5.2 Modifications (MODs)

Owing to its universal design, the RESISTRON

temperature controller RES-407 is suitable for a very

wide range of heatsealing applications.

Various modifications (MODs) are offered for the

RESISTRON temperature controller RES-407 for

implementing special applications.

The modifications described here are just a few of the

large number available. Separate documents are

supplied for all modifications.

MOD 01

Amplifier for low secondary voltages

(UR= 0.25…16VAC). This modification is necessary,

for example, for very short or low-resistance

heatsealing bands.

Set point potentiometer PD-x

Front panel-mounting version for setting the required SET heatsealing temperature

of the RESISTRON temperature controller. The number which appears on the

display corresponds to the SET heatsealing temperature in °C.

Line filter

Essential in order to ensure CE conformity.

Optimized for the RESISTRON temperature controller.

Impulse transformer

Designed according to VDE 0570/EN 61558 with a one-section bobbin.

Optimized for impulse operation with RESISTRON temperature controllers.

Specified according to the heatsealing application

(ªROPEX Application Report).

Communication interface CI-USB-1

Interface for connecting a RESISTRON temperature controller with diagnostic inter-

face (DIAG) to the PC (USB port). Associated PC visualization software for dis-

playing setting and configuration data, and for recording SET and ACTUAL tempe-

ratures in real time.

Booster

External switching amplifier, necessary for high primary currents

(continuous current > 5A, pulsed current > 25A).

Monitoring current transformer

For detecting frame short-circuits on the heatsealing band.

Used as an alternative to the standard PEX-W2/-W3 current transformer.

Accessories and modifications

Page 8 RES-407

MOD 21

Inverts the alarm signal (terminal 18). If an alarm is

signaled, the alarm output is switched to open condition

(LOW). If the controller does not report an alarm, a

24VDC voltage level (HIGH) is output at terminal 18.

MOD 26

Additional terminal for connecting an external switching

amplifier (booster). This modification is necessary for

high primary currents (continuous current > 5A, pulsed

current > 25A).

MOD 37 (until May 2003)

Additional rotary coding switch for the heatsealing band

alloy and the temperature range. Various heatsealing

band alloys (e.g. Alloy-20, NOREX) and temperature

ranges (e.g. 300°C, 500°C) can be selected.

This modification is supplied as standard

with all controllers manufactured as of June

2003 (ª

ªª

ªsection 9.2.2 "Configuration of the rotary

coding switch for the temperature range and alloy

(as of June 2003)" on page 20).

MOD 40

Additional terminal for "Temperature reached" signal.

This output signal is activated when the ACTUAL

temperature of the heatsealing band exceeds 95% of

the SET heatsealing temperature. It can be used to

monitor the process, for example, or to control the

closure of the heatsealing bars.

MOD 40 cannot be used in combination with

MOD 26 (booster connection) manufactured

prior to March 2005.

!

Switch

position

Temp.

range

Temp.

coefficient

Band

alloy

0

5

1

2

3

4

6

7

8

9

0

5

1

2

3

4

6

7

8

9

0

1

4

5

8

300°C

300°C

500°C

500°C

300°C

1100ppm/K

780ppm/K

1100ppm/K

780ppm/K

3500ppm/K

e.g. Alloy-20

e.g. Alloy L

e.g. Alloy-20

e.g. Alloy L

e.g. NOREX

0 = Factory settings

SWITCH POS.

1

0

4

5

8

TEMP. RANGE

300°C

300°C

500°C

500°C

300°C

ALLOY

780ppm/K

1100ppm/K

(L)

(A20)

1100ppm/K (A20)

780ppm/K

3500ppm/K

(L)

(NOREX)

!

Accessories and modifications

RES-407 Page 9

MOD 46 (as of April 2005)

Additional terminal for "Temperature OK" signal. If this

modification is installed, the RES-407 checks whether

the ACTUAL temperature is within a settable tolerance

band ("OK" window) on either side of the SET

temperature. The lower ( ) and upper

( ) tolerance band limits are configured in the

factory to -10K and +10K. These values can be set

independently of one another in the ROPEX

visualization software (ªsection 10.11 "Diagnostic

interface/visualization software (as of April 2005)" on

page 31).

If the actual temperature is inside the specified

tolerance band when the "START" signal is activated,

the output signal is activated as well (see graph below):

If the actual temperature leaves the tolerance band, the

output signal is deactivated again. The output signal

then remains deactivated, even if the actual tempera-

ture subsequently returns to the tolerance band.

It is thus possible to check - as part of the monitoring

concept, for instance - whether the output signal is still

active at the end of the heatsealing process, in other

words whether the actual temperature has remained

within the defined tolerance band throughout the entire

process.

The output signal is not deactivated again until the next

"START" signal is activated or until an alarm is

signaled.

MOD 46 ("Temperature OK" signal) cannot be

used in combination with MOD 40

("Temperature reached" signal).

∆ϑlower

∆ϑupper

Set

Signal

Set+∆ϑlower

Set+∆ϑupper

Actual value

Time

Time

Not conduct.

Conductive

„Temp. OK“

!

Technical data

Page 10 RES-407

6 Technical data

Type of construction Housing for installation in the electrical cabinet

Snaps onto a standard top hat rail (DIN TS35 rail, 35mm) acc. to DIN EN 50022

Dimensions: 90 x 75mm; height: 135mm (incl. terminals)

Line voltage All controllers manufactured as of April 2005:

115VAC version: 110VAC -15 %…120VAC +10% (equivalent to 94…132VAC)

230VAC version: 220VAC -15 %…240VAC +10% (equivalent to 187…264VAC)

400VAC version: 380VAC -15 %…415VAC +10% (equivalent to 323…456VAC)

All controllers manufactured as of January 2004 up to March 2005:

115VAC version: 115VAC -15 %…120VAC +10% (equivalent to 98…132VAC)

230VAC version: 230VAC -15 %…240VAC +10% (equivalent to 196…264VAC)

400VAC version: 400VAC -15 %…415VAC +10% (equivalent to 340…456VAC)

All controllers manufactured up to December 2003:

115VAC, 230VAC or 400VAC, tolerance: +10% / -15%

Depending on the controller version (ªsection 13 "How to order" on page 40)

Line frequency 47…63Hz, automatic adjustment to frequencies in this range

Auxiliary voltage

Terminals 12+13

24VDC, +20%, -10%, reverse polarity-protected

Current input (up to March 2005): max. 50mA

(as of April 2005): max. 1.0A

Heatsealing band

type and temperature

range

All controllers manufactured as of April 2005:

The temperature range and temperature coefficient settings can also be specified

by means of the ROPEX visualization software (ªsection 10.11 "Diagnostic

interface/visualization software (as of April 2005)" on page 31) in addition to the

rotary coding switch (see below):

Temperature range: 200°C, 300°C, 400°C or 500°C

Temperature coefficient: 400…4000ppm (variable setting range)

All controllers manufactured as of June 2003:

Five different ranges can be set on the controller with a rotary coding switch:

Temperature coefficient 1100ppm, 0…300°C (e.g. Alloy A20), default

Temperature coefficient 780ppm, 0…300°C (e.g. Alloy L)

Temperature coefficient 1100ppm, 0…500°C (e.g. Alloy A20)

Temperature coefficient 780ppm, 0…500°C (e.g. Alloy L)

Temperature coefficient 3500ppm, 0…300°C (e.g. NOREX)

All controllers manufactured up to May 2003:

Default value 300°C, Alloy-20

The temperature range and alloy are selectable with MOD 37.

Analog input

(set point)

Terminals 16+14

0…10VDC, Imax = 5mA, electrically isolated

Equivalent to 0…300°C or 0…500°C

or with an external PD-3 or PD-5 precision potentiometer (R = 2kohms)

0…2kohms equivalent to 0…300°C or 0…500°C

Analog output

(actual value)

Terminals 17+14

0…10VDC, Imax = 5mA, electrically isolated

Equivalent to 0…300°C or 0…500°C

Accuracy: ±1% add. 50mV

Technical data

RES-407 Page 11

Reference voltage +10VDC / ±5%, Imax =5mA

Digital logic levels

Terminals 5, 6, 7

LOW (0V): 0…2VDC, electrically isolated

HIGH (24VDC): 12…30VDC (max. current input 6mA)

Reverse polarity-protected

Switching output for

"Temp. OK" signal

(MOD 40)

Umax =30VDC

Imax =50mA

UON < 2V (saturation voltage)

Alarm output UON < 3V (saturation voltage), electrically isolated,

short-circuit proof

Up to March 2005: Imax =40mA

As of April 2005: Imax =200mA

As of April 2005, the output can also be inverted by means of a plug-in jumper.

Maximum load

(primary current of

impulse transformer)

Imax = 5A (duty cycle = 100%)

Imax = 25A (duty cycle = 20%)

Power dissipation max. 20W

Ambient

temperature

+5…+45°C

Degree of protection IP20

Installation If several controllers are installed on one top hat rail

(DIN TS35 rail), a clearance of at least 20mm should

be allowed between them.

The moving clip required for fastening must be facing

down for mounting on a horizontal top hat rail.

End holders to mechanical fix the controller must be fitted at both ends for

mounting on a vertical top hat rail.

Weight Approx. 0.7kg (incl. connector plug-in parts)

Housing material Plastic, polycarbonate, UL-90-V0

Connecting cables

Type / cross-sections

Rigid or flexible; 0.2…2.5 mm² (AWG 24…12)

Plug-in connectors

If ferrules are used, they must be crimped in accordance

with DIN 46228 and IEC/EN 60947-1.

This is essential for proper electrical contact in the terminals.

!

Dimensions

Page 12 RES-407

7 Dimensions

8 Installation

ªSee also section 1 "Safety and warning notes" on

page 3.

Installation and startup may only be

performed by technically trained, skilled

persons who are familiar with the associated risks

and warranty provisions.

8.1 Installation procedure

Proceed as follows to install the RESISTRON

temperature controller RES-407:

1. Switch off the line voltage and verify that all circuits

are deenergized.

2. The supply voltage specified on the nameplate of

the RESISTRON temperature controller must be

identical to the line voltage that is present in the

plant or machine. The line frequency is

automatically detected by the temperature controller

in the range from 47Hz to 63 Hz.

3. Install the RESISTRON temperature controller in

the electrical cabinet on a standard top hat rail (DIN

TS35 rail, according to DIN EN 50022). If several

controllers are installed on one top hat rail, the

minimum clearance specified in section 6 "Technical

data" on page 10 must be allowed between them.

4. Wire the system in accordance with the instructions

in section 8.3 "Power supply" on page 14,

section 8.6 "Auxiliary voltage" on page 16 and the

ROPEX Application Report. The information

provided in section 8.2 "Installation steps" on

page 13 must be heeded additionally.

Check the tightness of all the system

connections, including the terminals for the

impulse transformer windings.

5. Make sure that the wiring conforms to the relevant

national and international installation regulations.

75.0 90.0

113.0

135.0

!

!

Installation

RES-407 Page 13

8.2 Installation steps

Line

Impulse

transformer

Current transformer

PEX-W2/-W3

U (prim.)

1

Heatsealing band R= f (T)

U (sec.)

2

A

F

Controller

Temperature

meter

ATR-x

Digital

potentiometer

PD-x

Avoid long

cables

Heatseal element

with coppered ends

Use heatseal bands with

suitable temperature coefficient

20mm clearance if several

controllers installed on

one top hat rail

Note

polarity

No additional

resistance

in secondary

circuit

Dimension

transformer correctly

- Secondary voltage

- Power

- Duty cycle

Configure

DIP switches

correctly

Sufficient wire

cross-section

No

push-on

connectors

Twisted

Current measuring

wires IR

R

Connect U measuring

wires directly to

heatsealing band ends

Line filter

LF-xx480

Note

direction

of rotation

Note

number

of turns

(up to March 2005)

Installation

Page 14 RES-407

8.3 Power supply

ROPEX

temperature

controller

UR

IR

R

PRIM.

U1

Kb

Ka

SEC.

U2

LINE

I

>

I

>

GND/

Earth

N(L2)

L1 (L1)

LINE

FILTER

ON

OFF

K1

3

3

3

1

Short wires

2

2

Line

115VAC, 230VAC, 400VAC

50/60Hz

Circuit breaker

Double-pole, C characteristic

(ªROPEX Application Report)

Short-circuit protection only.

RESISTRON temperature controller not protected.

!

Relay Ka

For "HEAT ON - OFF" function (all-pole) or

"EMERGENCY STOP".

Line filter

The filter type and size must be determined according to

the load, the transformer and the machine wiring

(ªROPEX Application Report).

Do not run the filter supply wires (line side) parallel

to the filter output wires (load side).

!

RESISTRON temperature controller belonging to the

4xx Series.

Relay Kb

Load break (all-pole), e.g. in combination with the alarm

output of the temperature controller.

When using a series resistor RV-....-1 the relay Kb

shall be installed.

!

Impulse Transformer

Designed according to VDE 0570/EN 61558 (isolating

transformer with reinforced insulation). Connect core to

ground.

Use transformers with a one section bobbin. The

power, duty cycle and voltage values must be

determined individually according to the application

(ªROPEX Application Report and "Accessories" leaflet

for impulse transformers).

!

Wiring

The wire cross-sections depend on the application

(ªROPEX Application Report).

Guide values:

Primary circuit: min. 1.5mm², max. 2.5mm²

Secondary circuit: min. 4.0mm², max. 25mm²

cThese wires must always be twisted (>20/m)

dThese wires must be twisted (>20/m) if several control

loops are laid together ("crosstalk").

eTwisting (>20/m) is recommended to improve EMC.

Installation

RES-407 Page 15

8.4 Line filter

To comply with EMC directives – corresponding to

EN 50081-1 and EN 50082-2 – RESISTRON control

loops must be operated with line filters.

These filters damp the reaction of the phase-angle

control on the line and protect the controller against line

disturbances.

The use of a suitable line filter is part of the

standards conformity and a prerequisite of

the CE mark.

ROPEX line filters are specially optimized for use in

RESISTRON control loops. Providing that they are

installed and wired correctly, they guarantee

compliance with the EMC limit values.

You can find the exact specification of the line filter in

the ROPEX Application Report calculated for your

particular heatsealing application.

For more technical information: ª"Line filter"

documentation.

It is permissible to supply several

RESISTRON control loops with a single line

filter, providing the total current does not exceed

the maximum current of the filter.

The wiring instructions contained in section 8.3 "Power

supply" on page 14 must be observed.

8.5 Current transformer PEX-W3

The PEX-W3 current transformer supplied with the

RESISTRON temperature controller is an integral part

of the control system. The current transformer may only

be operated if it is connected to the temperature

controller correctly (ªsection 8.3 "Power supply" on

page 14).

!!

LINE

PE

Large cross-section

wire to ground

Large cross-section

wire to ground

Large frame contact surface

Do not lay parallel Mounting plate (galvanized)

max. 1m

ROPEX

temperature

controller

Snap-on for DIN-rail 35 x 7,5mm or 35 x 15mm (DIN EN 50022)

terminal

block

terminal

wires

14

60

24 75 14

23 28

26

39

12

Installation

Page 16 RES-407

8.6 Auxiliary voltage

Since the inputs and outputs of the RES-407 are

electrically isolated, a 24VDC auxiliary voltage must be

applied to terminals 12+13. The auxiliary voltage has a

maximum current input of 1,0A and it is also protected

against reverse polarity.

8.7 Wiring diagram (standard)

GND

GND

+24VDC

14

12

7

6

5

4

3

2

1

U

REF

+10VDC

16

17

15

13

18

=

=

Auxiliary

supply

16

15

14

cw

2K

OPTION:

SET POINT

POTENTIOMETER

PD-3 or PD-5

RES-407

(also with MOD 01)

Impulse

transformer

LINE

Line filter LF-xx480

prim.

U1

RESET

with 24VDC signal

START (HEAT)

with 24VDC signal

AUTOCAL

with 24VDC signal

ALARM

OUTPUT

+24VDC

ANALOG

OUTPUT

(real temperatur)

+0...10VDC

ANALOG

INPUT

(set point)

+0...10VDC

Ground

for 24VDC signals.

Must be grounded

externally to prevent

electrostatic

charging!

R

9

8

UR

Current transformer

PEX-W2/-W3

Heat-

sealing

band

sec.

Twisted

0V

(Internal ground)

No external

grounding allowed!

0V

(Internal ground)

No external

grounding allowed!

U2

up to

production

date

March 2005

11

10

IR

Installation

RES-407 Page 17

8.8 Wiring diagram with booster

connection (MOD 26)

RESET

with 24VDC signal

START (HEAT)

with 24VDC signal

AUTOCAL

with 24VDC signal

ALARM

OUTPUT

+24VDC

GND

GND

+24VDC

14

12

7

6

5

U

REF

+10VDC

16

17

15

13

18

ANALOG

OUTPUT

(real temperature)

+0...10VDC

ANALOG

INPUT

(set point)

+0...10VDC

=

=

Auxiliary

supply

R

9

8

UR

Booster

NC

NC

2

24

IN OUT

1

13

4

3

16

15

14

cw

2K

OPTION:

SET POINT

POTENTIOMETER

PD-3 or PD-5

Current transformer

PEX-W2/-W3

Impulse

transformer

Heat-

sealing

band

LINE

Line filter LF-xx480

sec.

Twisted

0V

(Internal ground)

No external

grounding allowed!

0V

(Internal ground)

No external

grounding allowed!

U2

prim.

U1

RES-407

(also with MOD 01)

Ground

for 24VDC signals.

Must be grounded

externally to prevent

electrostatic

charging!

up tol

production

date

March 2005

20

19

11

10

IR

Installation

Page 18 RES-407

MOD 26 cannot be used in combination with

MOD 40 ("Temperature OK" signal)

manufactured up to March 2005.

8.9 Wiring diagram with "Temp-

erature reached" signal (MOD 40)

or „Temp. OK“ signal (MOD 46)

MOD 40 cannot be used in combination with

MOD 26 (booster connection) manufactured

prior to March 2005.

MOD 46 cannot be used in combination with

MOD 40.

BOOSTER

19 20

4

3

2

1

Additional terminals

in housing cover

for MOD 26 (booster connection)

AUTOCAL

OUTPUT

HEAT

ALARM

!

+

RES- 407

I

max. 50mA

+24VDC

GND GND

+24VDC

4

3

2

1

Additional terminals

in housing cover

for MOD 40 (”Temp. reached” signal)

or MOD 46 (”Temp. OK” signal)

AUTOCAL

OUTPUT

HEAT

ALARM

! !

Startup and operation

RES-407 Page 19

9 Startup and operation

9.1 View of the controller

9.2 Controller configuration

The controller must be switched off in order

to configure the coding switches and the

plug-in jumpers.

9.2.1 Configuration of the DIP switches

for secondary voltage and current

Automatic configuration (AUTORANGE)

(as of April 2005)

The secondary voltage and current ranges are

automatically configured by the automatic calibration

function (AUTOCAL). The voltage is configured in the

range from 0.4VAC to 120VAC and the current in the

range from 30A to 500A. If the voltage and/or the

current is outside the permissible range, a detailed

error message appears on the controller (ªsee

section 10.13 "Error messages" on page 32).

Configuration with coding switches

(up to March 2005)

Set the DIP switches for matching the secondary

voltage U2and the secondary current I2to the correct

position for your application.

You can find the exact configuration of the

DIP switches in the ROPEX Application

Report calculated for your particular application.

Te r m in a l s

Wiring diagram

LEDs

Coding switches and

plug-in jumpers

Nameplate

!

!

Startup and operation

Page 20 RES-407

If the secondary current I2is less than 30 A, the

PEX-W2 or PEX-W3 current transformer must have

two turns (ªROPEX Application Report).

9.2.2 Configuration of the rotary coding

switch for the temperature range

and alloy (as of June 2003)

This configuration is supplied as standard

with all controllers manufactured as of June

2003. The settings are only possible on older

controllers in conjunction with MOD 37 (ª

ªª

ªsection

"MOD 37 (until May 2003)" on page 8).

If the switch is set to "9" (as of April 2005), more

temperature ranges and alloys can be selected by

means of the ROPEX visualization software (ªsee

section 10.11 "Diagnostic interface/visualization

software (as of April 2005)" on page 31).

3

2

145

ON

OFF

1...10V

6...60V

20...120V

ON

OFF

OFF

OFF

ON

OFF

OFF

OFF

ON

30...100A

60...200A

120...400A

OFF

ON

ON

OFF

OFF

ON

DIP switch DIP switch

12

U

2

I

2

345

3

2

145

4

3

ON

OFF

U (V)

2

1-10

SWITCH

ON

Factory settings

2x

0

5

1

2

3

4

6

7

8

9

0

5

1

2

3

4

6

7

8

9

Switch

position

0

1

4

5

8

300°C

300°C

500°C

500°C

300°C

1100ppm/K

780ppm/K

1100ppm/K

780ppm/K

3500ppm/K

e.g. Alloy-20

e.g. Alloy L

e.g. Alloy-20

e.g. Alloy L

e.g. NOREX

Temp.

range

Temp.

coefficient

Band

alloy

0 = Factory settings

SWITCH POS.

1

0

4

5

8

9

TEMP. RANGE

300°C

300°C

500°C

500°C

300°C

PC CONFIGURATION

ALLOY

780ppm/K

1100ppm/K

(L)

(A20)

1100ppm/K (A20)

780ppm/K

3500ppm/K

(L)

(NOREX)

9 PC-CONFIGURATION

!

Table of contents

Other Toss Controllers manuals

Popular Controllers manuals by other brands

iNels

iNels RF KEY - 40 quick start guide

DAB

DAB ES 1 M Instruction for installation and maintenance

Toro

Toro TEMPUS 53828 user guide

Samson

Samson TROVIS 5431 Mounting and operating instructions

DEUTSCHMANN AUTOMATION

DEUTSCHMANN AUTOMATION LOCON 7 instruction manual

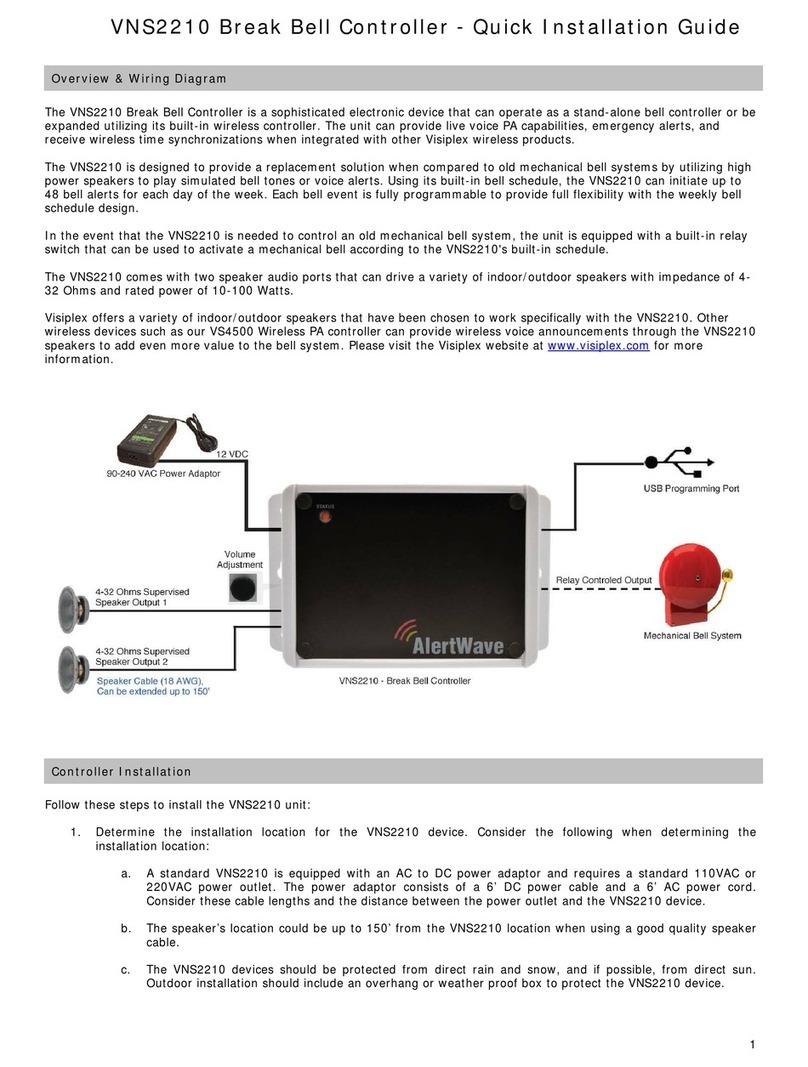

visiplex

visiplex VNS2210 Quick installation guide

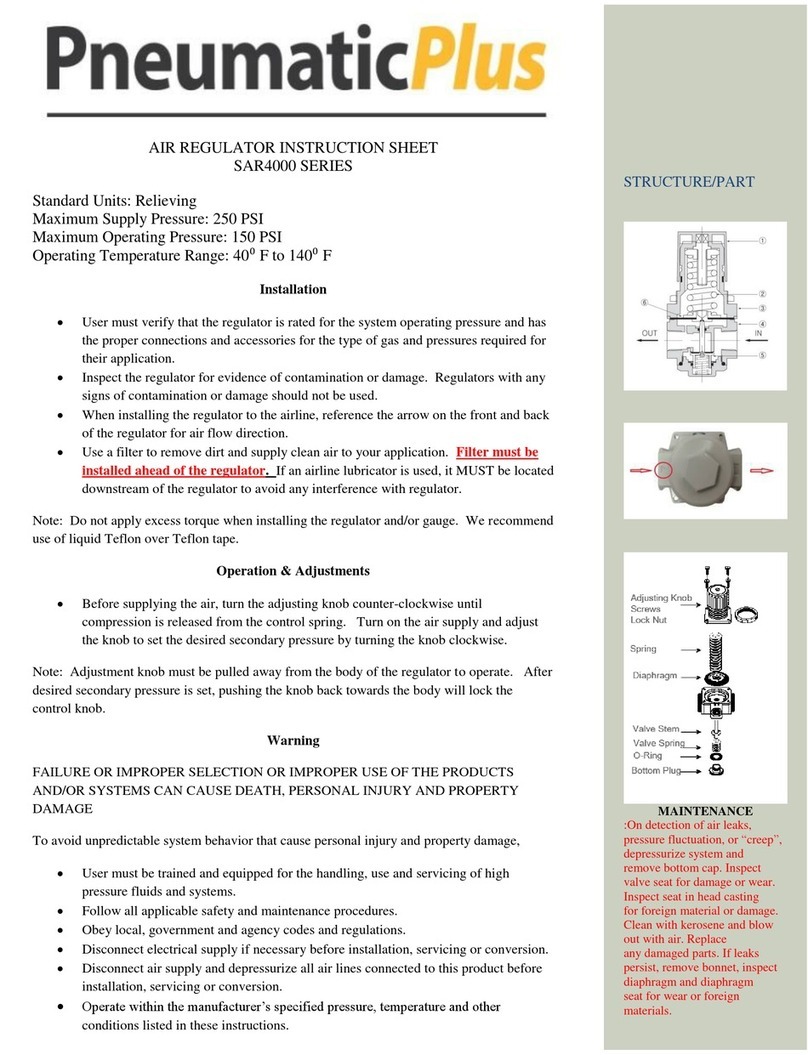

PneumaticPlus

PneumaticPlus SAR4000 Series instruction sheet

Zaber Technologies Inc.

Zaber Technologies Inc. NA Series user manual

esera

esera ECO 100 PRO quick guide

Lenze

Lenze L-force HighLine C 8400 Series Reference manual

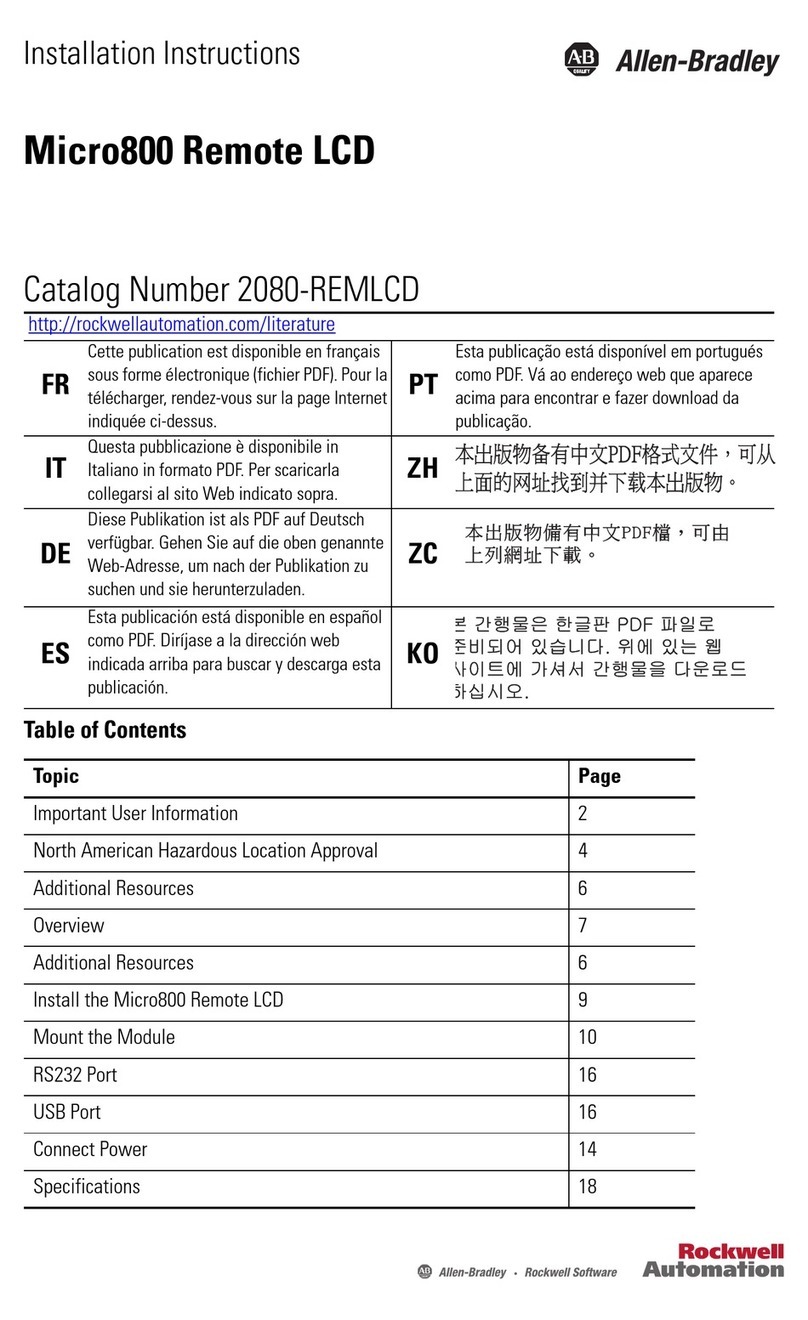

Allen-Bradley

Allen-Bradley Micro800 installation instructions

Pego

Pego Vision Touch Wellness User and maintenance manual