TOTALINE TTL-RECO250S User manual

USERMANUAL EN

TTL‐RECO250S

REFRIGERANTRECOVERYUNIT

1 EN

TABLEOFCONTENTS

GENERALSAFETYGUIDELINES 2EN

SPECIFICATIONS 4EN

STANDARDLIQUID/VAPORRECOVERYPROCEDURE 5EN

SELF‐PURGEPROCEDURE 7EN

LIQUIDPUSH/PULLPROCEDURE 8EN

TANKCOOLINGPROCEDURE9EN

ALTERNATIVECOOLINGPROCEDURE 10EN

OILSEPARATINGPROCEDURE 11EN

TROUBLESHOOTING12EN

WIRINGDIAGRAM13EN

PARTSDIAGRAM14EN

2 EN

GENERALSAFETYGUIDELINES

1. Readallsafety,operatingguidelinesandinstructionsbeforeoperating

thisrecoverymachine.

2. Alwaysthinkbeforeacting,familiaritybreedscarelessness,and

carelessnesscanbeharmfultoyourhealth,orworse,resultindeath.

3. OnlyaqualifiedtechnicianshouldoperatethisRecoverymachine.

4. Readallsafetyinformationregardingthesafehandlingofrefrigerant

andrefrigerantoil,includingtheMaterialSafetyDataSheet.

MSDSsheetscanbeobtainedfromyourrefrigerantsupplier..

5. Alwayswearsafetygogglesandprotectivegloveswhenworkingwith

refrigerantstoprotectyourskinsandeyesfromrefrigerantgasesand

refrigerantliquid.Avoidgettingintouchwithcausticityliquidorgas.

6. Besurethatanyroomwhereyouareworkingisthoroughlyventilated.

7. UseONLYauthorizedrefillablerefrigeranttanks.Itrequirestheuseof

recoveringtankswithaminimumof27.6barworkingpressure.

8. Donotoverfillthestoragetank.Tankisfullat80%volume.Thereshould

beenoughspaceforliquidexpansion‐overfillingofthetankmaycausea

violentexplosion.

9. DonotexceedtheworkingpressureofRecoveringTankcylinder.

10. Donotmixdifferentrefrigerantstogetherinonetank,ortheycould

notbeseparatedorused.

11. Beforerecoveringtherefrigerant,thetankshouldachievethevacuum

level:‐0.1mpa,whichisforpurgingnon‐condensablegases.

Eachtankwasfullofnitrogenwhenitwasmanufacturedinthefactory,thus

thenitrogenshouldbeevacuatedbeforethefirstuse.

12. Whentherecoverymachineisnotused,allthevalvesshouldbeclosed.

Becausetheairorthemoistureoftheairmayharmtherecoveryresultand

shortentheservicelifeoftherecoverymachine.

13. Whenusinganextensioncord,itshouldbea14AWGminimumandno

longerthan7.62meters(25feet),oritmaymakethevoltagedropanddamage

thecompressor.

14. Adryfiltermustalwaysbeusedandshouldreplacedfrequently.

Andeachtypeofrefrigerantmusthaveitsownfilter.Forthesakeofassuring

thenormaloperationoftheunit,pleaseusethefilterspecifiedbyour

company.Highqualitydryfilterswillbringhighqualityservices

15. Specialcareshouldbetakenwhenrecoveringfromaburned‐out

3 EN

system.Usetwohighacidcapacityfilters,inseries.Whenyouhave

finishedrecoveringfromthesystem,flushtherecoverymachinewithasmall

amountofcleanrefrigerantandrefrigerantoiltopurgeoffanyforeign

substancesleftinthemachine.

16. ThisrecoverymachinehasaPressureShutOffSwitch.Ifthepressure

insidethesystemshouldgoabove38bars,thesystemwillautomaticallyshut

itselfoff.Theshutoffswitchmustbemanuallyreset.

17. Ifthetankpressureexceeds20.7bar,usetheTANKCOOLING

PROCEDUREtoreducethetankpressure.

18. Tomaximizerecoveryrates,usetheshortestpossiblelengthof3/8”or

largerhose.Ahosenolongerthan0.9meterisrecommended

19. Whenrecoveringlargeamountsofliquid,usetheLIQUIDPUSH

/PULLPROCEDURE.

20. Afterrecovering,makesurethere'snorefrigerantleftinthemachine.

ReadtheSELF‐PURGINGPROCEDUREcarefully.Liquidrefrigerantremained

maybeexpandedanddestroythecomponents.

21. Ifthisrecoverymachineistobestoredornotusedforanylengthof

time,werecommendthatitbecompletelyevacuatedofanyresidual

refrigerantandpurgedwithdrynitrogen.

22. Toreducetheriskofinjury,careshouldbetakenwhenmovingthis

machine.

4 EN

SPECIFICATIONS

Models TTL-RECO250S

Refrigerants

Cat.III: R-12,R-134a,R-401C,R-406A,R-500

Cat.IV: R-22, R-401A, R-401B, R-402B, R-407C,

R-407D, R-408A, R-409A, R-411A,

R -411B, R-412A, R-502, R-509

Cat.V: R-402A, R-404A, R-407A, R-407B, R-407F

R-410A,

R-507

Voltage 220-240VAC 50/60Hz

Compressor 1/2HP Oil-less

Max current 4A @ 50Hz 8A @ 60Hz

HP Shut-off 38bar/550psi

Recovery

Rate

Cat. III Cat. IV Cat. V

Vapor 13.8kg/h 15.0kg/h 15.6kg/h

Liquid 94.2kg/h 108.6kg/h 111.0kg/h

Push/Pull 278.4kg/h 334.2kg/h 373.2kg/h

LP Shut-off OFF:8inHg;ON:6psi

Operating Temp 0-40°C

Case Blow Molded High Impact Polyethylene

Dimensions L= 485mm x B= 220mm x H=365mm

Net Weight 15kg

5 EN

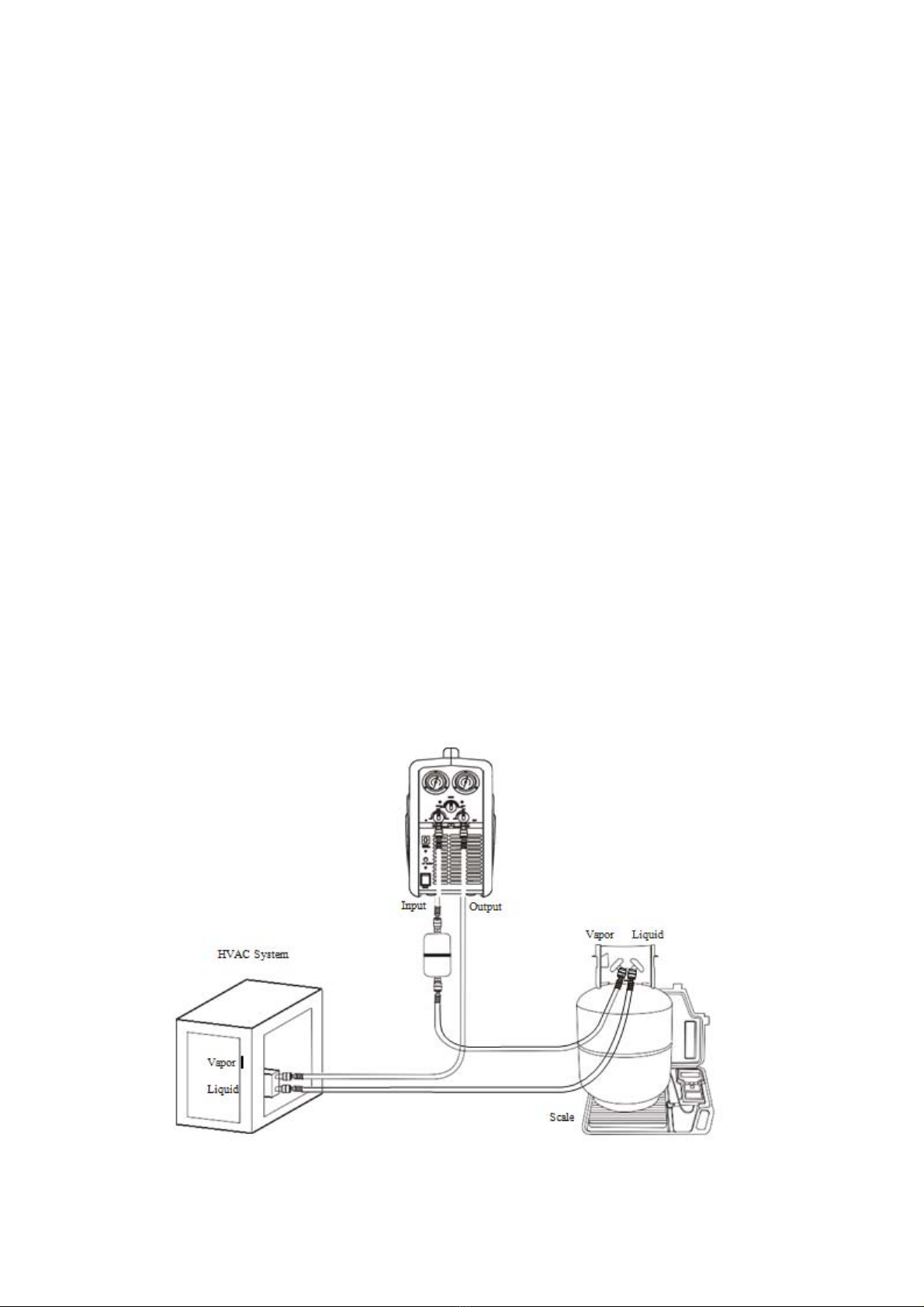

STANDARDLIQUID/VAPORRECOVERYPROCEDURE

1. Makesurethisrecoverymachineisingoodoperatingcondition.

2. Makesureallconnectionsarecorrectandtight.

3. Opentheliquidportofthestoragetank.

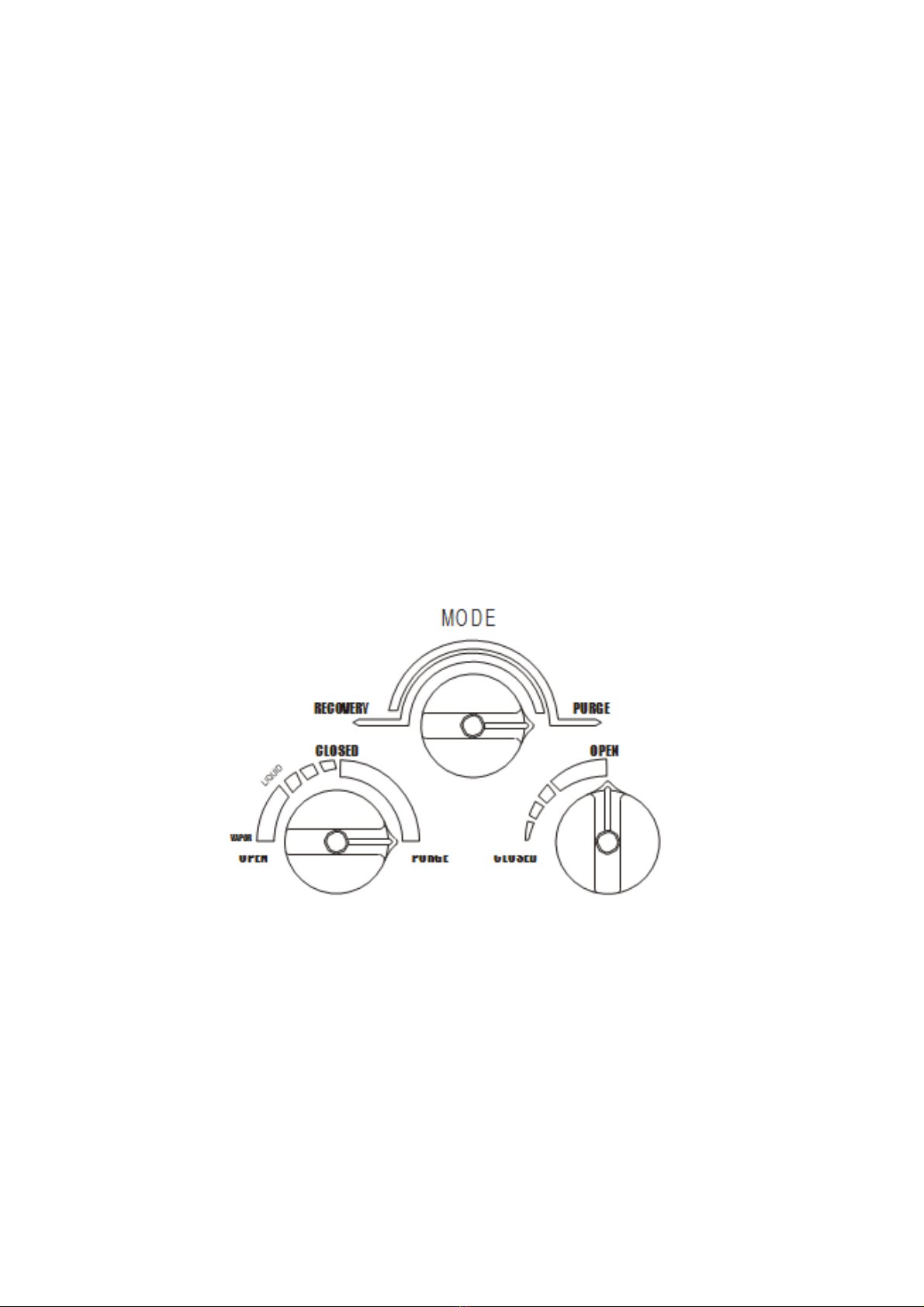

4. MakesuretheMODEvalveissetonRECOVER.

5. Opentheoutputportoftherecoverymachine.

6. Opentheliquidportonyourmanifoldgaugeset;openingtheliquidport

willremovetheliquidfromthesystemfirst.Aftertheliquidhasbeen

removed,openthemanifoldvaporporttofinishevacuatingthesystem.

6 EN

STANDARDLIQUID/VAPORRECOVERYPROCEDURE

7. Connecttherecoveryunittoarightoutlet.(Seethenameplateonthe

machine)SwitchthepowerswitchtotheONposition,tostartthe

compressor.

8. Slowlyopentheinputportonthemachine.

1)Ifthecompressorstartstoknock,slowlythrottlebacktheinputvalve

untiltheknockingstops.

2) Iftheinputvalvewasthrottledback,itshouldbefullyopenedoncethe

liquidhasbeenremovedfromthesystem(themanifoldgaugesetvapor

portshouldalsobeopenedatthistime).

9. Rununtildesiredvacuumisachieved.

1) Closethemanifoldgaugesetsvaporandliquidports.

2) Turnoffthemachine.

3) Closetheunit'sinputportandproceedwiththeSELF–PURGE

PROCEDUREonthenextpage.

Note:

Iftherecoverymachinefailstostart,rotatetheINPUTvalveandthe

MODEvalvetopurgeposition.ThenrotatetheMODEvalveback

torecoveryposition,andopentheINPUTvalve.

Caution:

Alwayspurgetheunitaftereachuse.Failuretopurgetheremaining

refrigerantfromtheunitcouldresultintheacidicdegradationof

internalcomponents,ultimatelycausingpremature.

.

7 EN

SELF‐PURGEPROCEDURE

Procedureforpurgingremainingrefrigerantfromthismachine.

1. Closetheportsofthesystembeingservicedthatareconnectedtothe

inputportofthemachine.

2. Turnofftherecoverymachine.

3. TurntheInputvalvetothePURGEposition.

4. TurntheMODEvalvetothePURGEposition.

5. Restartthemachine.

6. Rununtildesiredvacuumisachieved.

7. Closetheportsontherecoverytankandthemachine.

8. Turnthemachineoff.

9. ReturntheMODEvalvetotheRECOVERposition.

10. Disconnectandstoreallhosesanddryfilter

8 EN

LIQUIDPUSH/PULLPROCEDURE

Push/pullprocedureonlyworkswithlargesystemswheretheliquid

refrigerantisnolessthan6.8kg(15lbs).

1.PutMODEvalveknobonRECOVER

2.OpenOUTPUTvalve.

3. OpenINPUTvalve.

4. Whenthescalestopsrisingcloseallports

5. Switchoffthemachine.

CAUTION:

WhenusingthePush/pullmethod,ascalemustbeusedtoavoidover

fillingthestoragetank,oncethesiphonisstarted,itcancontinueand

overfillthestoragetankevenifthetankisequippedwithafloat

levelsensor.Thesiphoncancontinueevenwhenthemachineis

turnedoff.Youmustmanuallyclosethevalvesonthetankandthe

unittopreventoverfillingoftherecoverytank.

9 EN

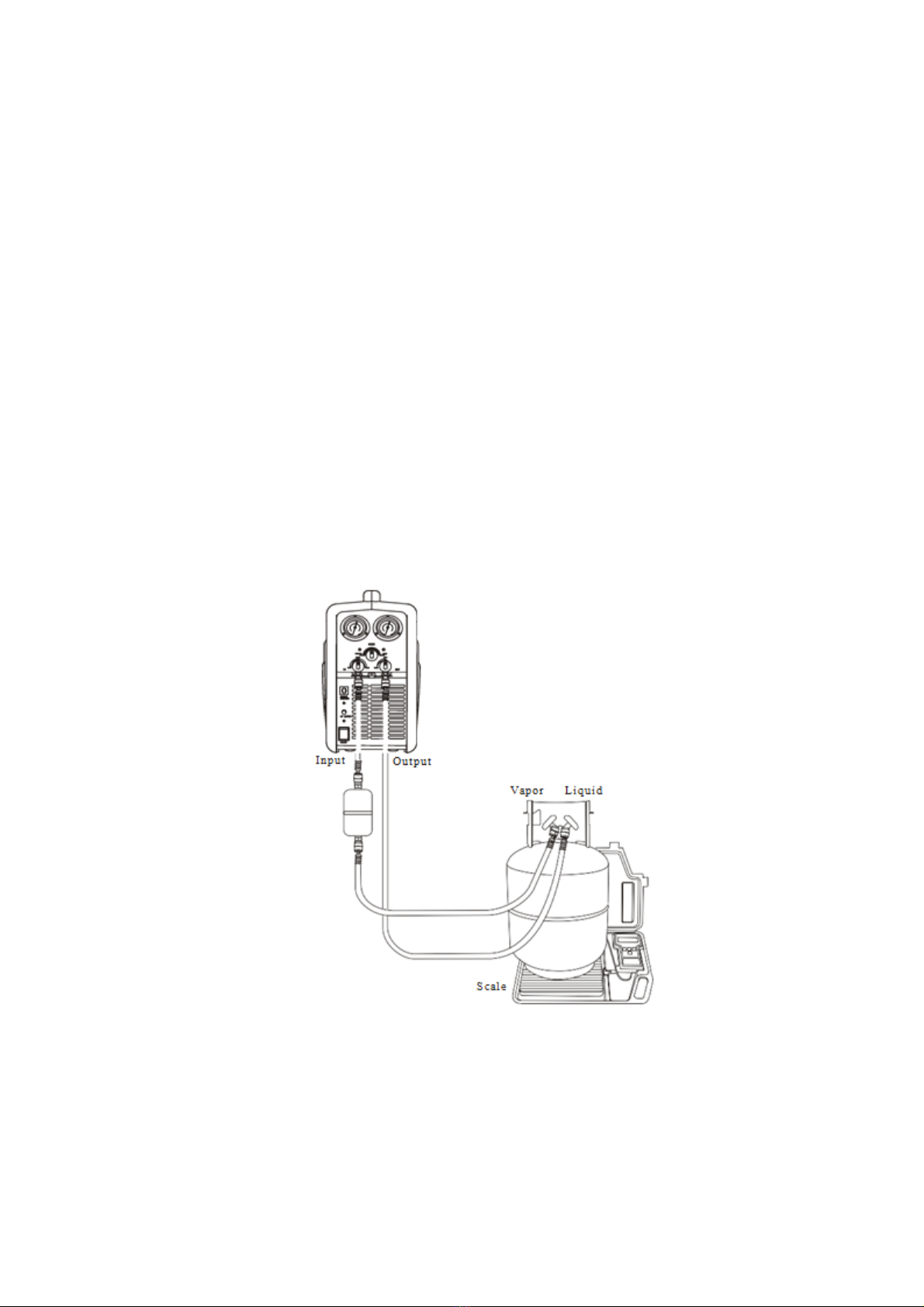

TANKCOOLINGPROCEDURE

Inorderforthisprocedure,youmusthaveaminimumof5lbs.(2.3kg)of

liquidrefrigerantinthestoragetank.

1. Connectthehosesasshown.

2. TurntheMODEvalvetotheRecoverposition.

3. OpentheVaporandLiquidvalveofthestoragetank.

4. Poweron,andstartthecompressor.

5. OpentheINPUTvalveandOUTPUTvalveofthemachine.

6. ThrottletheOUTPUTvalveofthemachinesothattheoutputpressure

is100psigreaterthantheinputpressure,butnevermorethan300psi.

7. Rununtiltankiscold.

10 EN

ALTERNATIVECOOLINGPROCEDURE

Setupyourequipmentasshown,itispossibletocoolthestoragetank

duringtherecoveryprocedureifnecessary.

1. Openthevaporvalveofthestoragetank(itisclosedwhile

recovering)

2. Closethetwovalvesofthemanifoldgaugeset

3. FollowthesixthandseventhitemsofthetankCoolingProcedure.

11 EN

OILSEPARATINGPROCEDURE

1) Makesureallconnectionsarecorrectandtight.

2) Makesuretheportofdrainvalveisclosed.

3) MakesuretheMODEvalveonRECOVERYposition

4) Opentheliquidportofthestoragetank.

5) Opentheoutputportoftheunitandliquidportonthemanifold

gaugeset.

6) TurnthepowerswitchtoON.Opentheinputvalveslowlytoliquid

position.Rununtiltherecoveryisachieved.

7) TurnthepowerswitchtoOFF.Opentheportofoildrainvalve,

anddraintheoilintoasuitablecontainer,thencloseTheoil

drainport.

8) Disconnectallhoses

12 EN

TROUBLESHOOTING

13 EN

WIRINGDIAGRAM

14 EN

PARTSDIAGRAM

TTL‐RECO250S

ISTRUZIONID’USO IT

TTL‐RECO250S

UNITA’DIRECUPEROREFRIGERANTE

1 IT

SOMMARIO

NORMEDISICUREZZAELINEEGUIDAPERL’UTILIZZO 2IT

SPECIFICHETECNICHE 4IT

PROCEDURASTANDARDRECUPEROLIQUIDO/VAPORE 5IT

PROCEDURASELF‐PURGING 7IT

PROCEDURAPUSH/PULL 8IT

PROCEDURADIRAFFREDDAMENTODELLABOMBOLA 9IT

PROCEDURAALTERNATIVADIRAFFREDDAMENTO 10IT

PROCEDURAPERLASEPARAZIONEDELL’OLIO11IT

RISOLUZIONEPROBLEMI12IT

SCHEMAELETTRICO13IT

VISTAESPLOSO14IT

2 IT

NORMEDISICUREZZAELINEEGUIDAPERL’UTILIZZO

1. Leggereattentamenteilpresentemanualeprimadiutilizzarel’unitàdi

recupero.

2. Pensareprimadiagire,lafamiliaritàgeneraincuriaedisattenzione;può

esseredannosoperlasalute,opeggio,causarelamorte.

3. L’utilizzodell’unitàdirecuperoèdestinatoesclusivamentead

operatoriqualificati.

4. Leggeretutteleinformazionidisicurezzariguardantilamanipolazione

delrefrigeranteel'oliorefrigerante,compresalaSchedadiSicurezza.

Leschededisicurezzapossonoessereottenutepressoilfornitore.

5. Indossaresempreadeguateprotezioni,qualiguantiedocchiali;il

contattoconilrefrigerantepuòprovocarececitàedaltridannifisici.

Evitaredientrareincontattoconliquidoogascaustici.

6. Assicurarsidifarfunzionareilrecuperatoreinambientiadeguatamente

ventilatieconunbuonricambiod’aria.

7. UtilizzareSOLOdellebomboledirefrigerantericaricabiliautorizzatecon

pressionedilavorominimadi27.6bar.

8. Nonriempiretroppolebomboledirecupero.Lebombolesonopiene

all’80%dellalorocapacitàmassima.Unriempimentoeccessivopotrebbe

causareviolentiesplosioni.

9. Nonsuperarelapressionedilavorodellabomboladirecupero.

10. Nonmischiarerefrigerantidiversinellastessabombola.

11. Primadirecuperareilrefrigerate,labomboladeveraggiungereungrado

divuotodi‐0.1mPa,perpoterrimuovereigasnoncondensabiliedeventuale

umidità.

12. Quandol’unitànonvieneutilizzatatuttelevalvoledevonoesserechiuse.

L’ariael’umiditàpossonodanneggiareleprestazionidirecuperoeridurrela

duratadelrecuperatore.

13. Sesiusaunaprolungaelettrica,lasezionedeicavideveesserealmeno

2.0mm2edilcavonondeveesserepiùlungodi7.62m(25feet);ciòpotrebbe

causarel’abbassamentoditensioneedanneggiareilcompressore.

14. Utilizzaresempreunfiltrodeidratoreesostituirlofrequentemente.Ogni

tipodirefrigerantedeveavereilpropriofiltro.Alfinediassicurareinbuon

funzionamentodell’unitàdirecupero,siconsigliadiutilizzarefiltridialta

qualità.

15. Prestaremoltaattenzionequandosirecuperadaunsistemabruciato:

3 IT

utilizzareduefiltriperacidodialtacapacitàinserie.Arecuperoultimato

lavarel’unitàconunapiccolaquantitàdirefrigerantepulitoeconolio

refrigeranteperripuliredasostanzeestraneerimasteall’interno.

16. L’unitàhaundispositivodiarrestoautomaticodialtapressione.Sela

pressioneall’internodelsistemasaleoltre38.5barl’unitàsispegnerà

automaticamente.L’interruttoredovràessereresettatomanualmente.

17. Selapressionedellabombolasuperai20.7bar,seguirelaPROCEDURADI

RAFFREDDAMENTOperridurnelapressione

18. Perottimizzarelavelocitàdirecupero,fareusodiuntuboflessibilepiù

cortopossibile.Lunghezzaraccomandatainferiore0.9m

19. Duranteilrecuperodigradiquantitàdirefrigeranteliquidousarela

proceduraPUSH/PULL.

20. Dopoilrecuperoassicurarsichenoncisiapiùrefrigerantenell’unità.

Leggereattentamentelaproceduradi“SELF‐PURGE”.Sedelrefrigerante

liquidorimanenell’unità,sipuòespandereedanneggiareicomponenti.

21. Inprevisionediunlungoperiododiinattivitàosel’unitàdeveessere

riposta,evacuarel’unitàdaogniresiduodirefrigeranteeripulirlaconazoto

secco.

22. Perridurreilrischiodilesioni,occorreprestareattenzionequandosi

movimentalamacchina.

Table of contents

Languages: