6 SKF LAGM 1000E

This mode is for permanent installation on a pipe to check amount passing through the

pipe. This mode is very battery efficient. The batteries can last several years.

6.1 Menu functionality

To enter the menu press the and buttons at the same time.

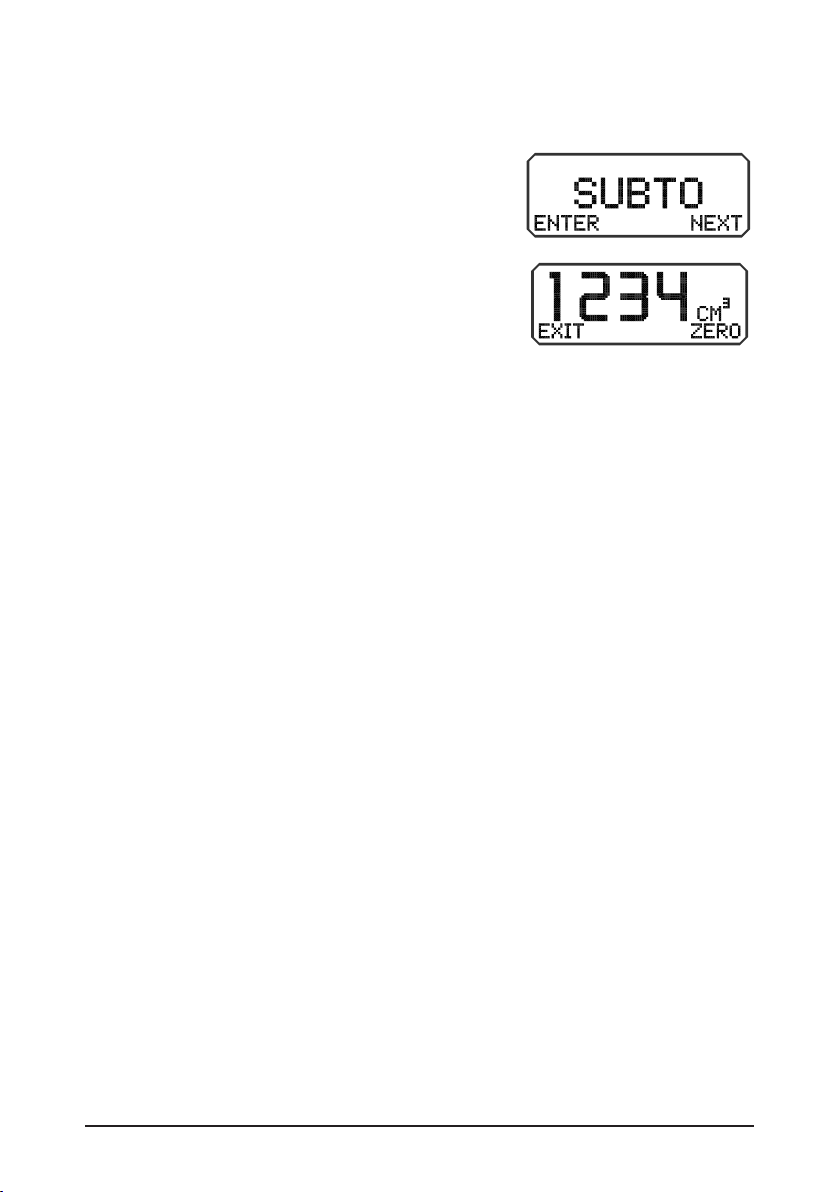

The first option in the menu is the sub total counter.

Press ENTER (left button) to display this value and

reset it if required or press NEXT (right button) for the

following option in the menu.

The second option in the menu is total counter. Press

ENTER (left button) to display this value and reset it if

required or press NEXT (right button) for the following

option in the menu.

The third option in the menu is for calibration of the

grease meter. Press ENTER (left button) to display

the calibration value and adjust it if required or press

NEXT (right button) for the following option in the

menu.

The fourth option in the menu is for displayed units.

Press ENTER (left button) to display or change the

used unit or press NEXT (right button) for the following

option in the menu.

The fifth option in the menu is the auto shut off time.

Press ENTER (left button) to display or change the

auto shut off time or NEXT (right button) for the

following option in the menu.

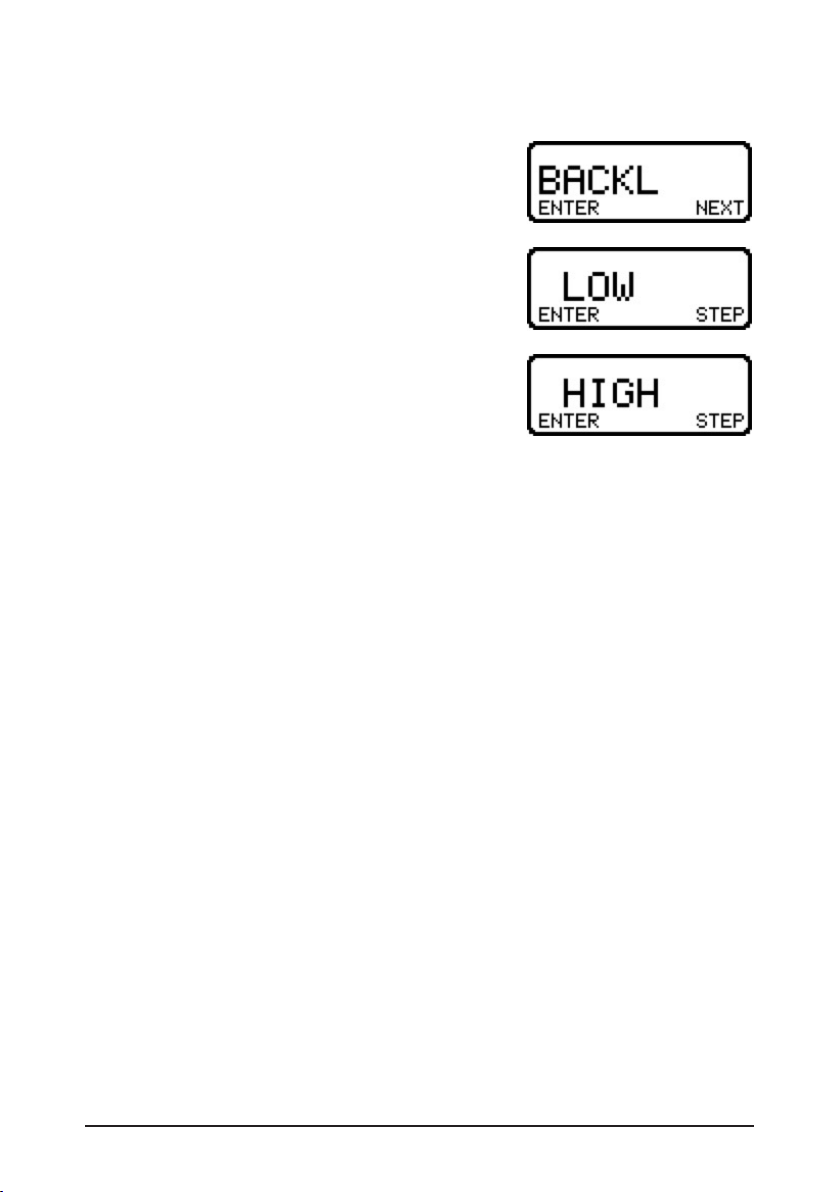

The last option in the menu is to set the light level

of backlight. Press ENTER (left button) to display

or change the light level of backlight or NEXT

(right button) for the first option in the menu.

It is always possible to exit the menus and return to normal measuring state by pressing

the and buttons at the same time.