Tradinco TRAQC-8 User manual

User Manual

TRAQC-8

TRAQC-8

Portable Calibrator

User Manual

User Manual

TRAQC-8

TRAQC-8 04/2017 EN Rev.4 page : 2

Content

1. General ...............................................................................................5

1.1 Warranty .........................................................................................5

1.2 TRAQC-8 Description.........................................................................6

1.2.1 CE Pressure Equipment Directive 2014/68/EU ..................................6

1.2.2 CE EMC Directive 2014/30/EU ........................................................6

1.2.3 CE Electrical Safety Directive 2014/35/EU........................................7

1.3 Symbols Used ..................................................................................7

1.4 Scope of this manual ........................................................................7

1.5 Calibrator Interface...........................................................................8

1.6 Navigation .......................................................................................9

1.7 Electrical Connections .....................................................................10

2. Operating Instructions ........................................................................11

2.1 Set up...........................................................................................11

2.2 Operating Instructions ....................................................................11

2.2.1 Measurement of external test pressures ........................................12

2.3 Instructions for the refilling of the gas bottles ....................................12

2.4 End of use .....................................................................................12

2.5 Storage .........................................................................................12

2.6 Power Supply.................................................................................13

2.6.1 Battery status display .................................................................13

2.6.2 Operating time indication.............................................................13

2.6.3 Instrument charging before storage ..............................................13

2.6.4 Battery Replacement...................................................................13

2.7 Power On/Off .................................................................................14

2.8 Menu ............................................................................................14

2.9 Zeroing .........................................................................................15

2.10 Selecting Pressure Units ..................................................................15

2.11 Pressure Range ..............................................................................16

2.11.1 Electric in- or output active.........................................................16

2.11.2 Electric in- or output not active ...................................................16

2.11.3 Selecting Pressure sensor Auto ranging .........................................16

2.12 Instrument Status ..........................................................................17

3. User Configuration..............................................................................18

3.1 Pressure Setup...............................................................................18

3.1.1 Pressure range ...........................................................................18

3.1.2 Pressure unit..............................................................................18

3.1.3 Averaging on/off.........................................................................18

3.1.4 Averaging setup .........................................................................18

3.1.5 Resolution Setup ........................................................................19

3.1.6 Conversion Table ........................................................................19

3.1.7 Set customer unit .......................................................................19

3.1.8 Absolute mode ...........................................................................20

3.2 Electrical Input A Setup...................................................................20

3.2.1 mA Input...................................................................................20

3.2.2 mA + Xmtr Supply (optional) .......................................................21

3.2.3 Xmtr Power Setup (optional)........................................................21

3.2.4 Resistance input (optional) ..........................................................21

3.2.5 RTD input (optional) ...................................................................21

3.2.6 Switch Test................................................................................22

3.2.7 Switch Test Setup.......................................................................22

3.2.8 V Input......................................................................................22

3.2.9 Hart Resistor..............................................................................22

3.2.10 mA/V Scaling .............................................................................22

3.2.11 Set mA/V Scaling.......................................................................23

23

3.3 Electrical Output A Setup (optional) ..................................................24

User Manual

TRAQC-8

TRAQC-8 04/2017 EN Rev.4 page : 3

3.3.1 Pressure xmtr mode (Pressure transmitter mode)...........................24

3.3.2 Xmtr mode settings (Parameter Mode Settings)..............................25

3.3.3 Current Output...........................................................................25

3.3.4 Current Output Settings ..............................................................25

3.3.5 Voltage Output...........................................................................26

3.3.6 Voltage Output Settings ..............................................................26

3.3.7 Auto Span Check Mode................................................................26

3.3.8 Ramp Mode ...............................................................................26

3.4 Electrical input B setup (optional) .....................................................26

3.5 Electrical output B setup (optional) ...................................................26

3.6 Instrument Configuration ................................................................27

3.7 Using the Memory Mode ..................................................................29

3.8 Memory Functions ..........................................................................29

3.8.1 List by tag number .....................................................................29

3.8.2 List by serialnumber ...................................................................29

3.8.3 View definitions ..........................................................................29

3.9 Advanced Options...........................................................................30

3.9.1 Set rtc time ...............................................................................30

3.9.2 Set rtc date ...............................................................................30

3.9.3 Set recal Date ............................................................................30

3.9.4 Erase data memory.....................................................................30

3.9.5 Show Product Data .....................................................................31

3.10 Calibration of TRAQC-8....................................................................32

3.10.1 Adjust instrument inputs. ............................................................32

3.10.1.1 Current input ....................................................................... 33

3.10.1.2 Current in + Loop supply (optional) ....................................... 33

3.10.1.3 Voltage input ....................................................................... 33

3.10.1.4 Adjust Vbat A/D ................................................................... 34

3.10.1.5 P1: XX-YY BARG (Pressure Sensor Adjustment)........................ 34

3.10.1.6 Clear user adjustments ......................................................... 34

3.10.1.7 Resistance input ................................................................... 34

3.10.2 Adjust instruments outputs (optional) ...........................................35

3.10.2.1 Current source ..................................................................... 35

3.10.2.2 Current simulator ................................................................. 35

3.10.2.3 Voltage output ..................................................................... 36

3.10.3 Show calibration factors ..............................................................36

4. Data transfer .....................................................................................37

5. Computer Interface (Optional) .............................................................37

5.1 General Description ........................................................................37

5.2 Connections...................................................................................37

5.3 RS232 Settings ..............................................................................37

6. Maintenance instructions .....................................................................38

6.1.1 Main power supply cable..............................................................38

6.1.2 Housing.....................................................................................38

6.1.3 Test connections.........................................................................38

6.1.4 Regulating valves .......................................................................38

6.2 Pressure gauges .............................................................................38

6.3 Battery maintenance.......................................................................39

6.4 High pressure gas bottles ................................................................39

7. Product Specifications .........................................................................40

7.1 General .........................................................................................40

7.2 Measurement .................................................................................40

7.3 Generation and control....................................................................40

7.4 Data storage..................................................................................40

7.5 Options & Accessories .....................................................................41

User Manual

TRAQC-8

TRAQC-8 04/2017 EN Rev.4 page : 5

1. General

1.1 Warranty

During the design and manufacturing of this instrument the at most attention has been given to

quality and durability.

This manual contains information needed for the safe and effective use of the

capabilities of the instrument.

Please read the manual carefully before operating the instrument. By doing so possible

damage to the instrument or damage caused by the incorrect use of the instrument can

be avoided.

TRADINCO INSTRUMENTS warrantees the instrument in accordance with the Standard Terms and

Conditions of the Instrument Trade as issued by the Association bearing the name "Federation

Het Instrument" (The Instrument Federation, (filed with the Clerk of Utrecht District Court on 13

January 1993 under number 16/93 and with the Chamber of Commerce and Industry in

Amersfoort on 18 January 1993. A copy is available on request.

TRADINCO INSTRUMENTS warrantees that this product will be free from defects in materials and

workmanship for a period of 5 years from the date of shipment. If any such product proves

defective during this warranty period, TRADINCO INSTRUMENTS, at its option, will either repair

the defective product without charge for parts or labour, or will provide a replacement in exchange

for the defective product.

In order to obtain service under this warranty, Customer must notify TRADINCO INSTRUMENTS

of the defect before the expiration of the warranty period and make suitable arrangements for

the performance of the service.

Customer shall be responsible for packaging and shipping of the defective product to the service

centre designated by TRADINCO INSTRUMENTS, with shipping charges prepaid.

If no defect can be found Customer may be charged for costs of the investigation.

This warranty does not apply to any defect, failure or damage caused by:

a. Improper use of the instrument.

b. Battery leakage.

c. Normal wear of the product.

d. Modification or repair carried out by or on behalf of the owner or by a third party.

e. Implementation of modifications to the product that are not supplied or implemented by

TRADINCO INSTRUMENTS.

TRADINCO INSTRUMENTS and its vendors will not be liable for any indirect, special, incidental or

consequential damages irrespective of whether TRADINCO INSTRUMENTS or the vendor has

advance notice of the possibility of such damages.

The type number of the product, as listed on the instrument tag plate, should always be

mentioned in any correspondence concerning the product.

Tradinco Instrumenten-Apparaten b.v.

Radonstraat 250

2718 TB Zoetermeer

The Netherlands

+31 79 2033133

www.tradinco.com

info@tradinco.com

User Manual

TRAQC-8

TRAQC-8 04/2017 EN Rev.4 page : 6

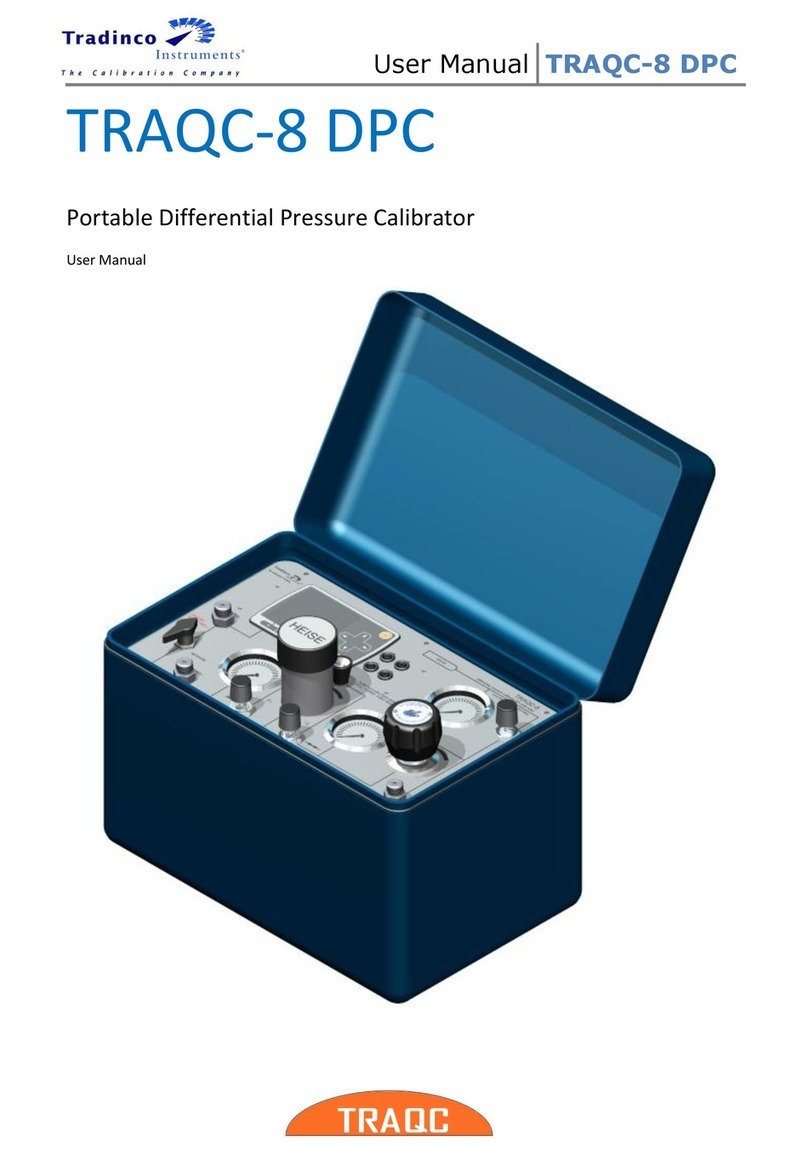

1.2 TRAQC-8 Description

The Tradinco Pneumatic Pressure Calibrator, TRAQC-8 is

a universal pressure calibrator, ranging from 0 to 250

bar.

The TRAQC-8 has been designed for the testing and

calibration of low and high pressure pneumatic

measurement equipment:

regulators, pressure gauges, pressure converters,

pressure switches, recorders, etc.

Because of the built-in rechargeable battery and high

pressure gas bottles it is possible to use this test unit at

location, independent of any external mains power

supply and/or pressure source.

The TRAQC-8 consists of 6 main parts.

•A high quality digital pressure display with curser and two function push buttons.

•One or more pressure sensors plus related pneumatic circuit.

•An electrical measuring circuit (standard mA + V DC)

•One high quality digital calibrator

•One pneumatic regulating system

•Two high pressure gas bottles

With the TRAQC-8 it is possible to measure test pressures generated by the built-in gas bottles

as well with test pressures which are generated by an external pressure source.

The aluminum case of the TRAQC-8 is provided with a lid which has a handle for carrying the

calibrator.

The test and filling hoses are stored in a case in the lid of the carrying case.

Dimensions are (LxWxH) 405x295x255 mm and the weight is approximately 17 kg.

1.2.1 CE Pressure Equipment Directive 2014/68/EU

The TRAQC-8 meets the safety regulations as mentioned in appendix 1 of the European

guideline 2014/68/EU.

The TRAQC-8 is a combination of different pressure component as mentioned in article 1

paragraph 2.1.5

The maximum volume of the biggest pressure bearing housing is 1 liter with a maximum

pressure of 200 bar.

TRAQC-8 classified to be used with gas group 2

Following table two the TRAQC-8 are manufactured in accordance with article 3 paragraph 3

"sound engineering practice" and CE marking based on the PED does not apply.

1.2.2 CE EMC Directive 2014/30/EU

The electrical part of the TRAQC-8 meets the regulations as mentioned standards

•EN-IEC 61000-4-2 : 2009

•EN-IEC 61000-4-3 : 2009

•EN-IEC 61000-4-4 : 2012

•EN-IEC 61000-4-5 : 2009

•EN-IEC 61000-3-2 : 2014

•EN-IEC 61000-3-3 : 2013

The unit is CE marked accordingly.

User Manual

TRAQC-8

TRAQC-8 04/2017 EN Rev.4 page : 7

1.2.3 CE Electrical Safety Directive 2014/35/EU

The electrical part of the TRAQC-8 (pressure calibrator of the Tradinco Traqc-7 series) meets

the regulations as mentioned standards

EN 61010-1 : 2010

•The unit is CE marked accordingly

1.3 Symbols Used

Warning for conditions or practices that could result in personal injury, loss of life and/or

in damage to the product or other property.

Attention signal or remark

1.4 Scope of this manual

This manual contains information for instruments built after Oktober 2015 with firmware revision

2.343 or higher.

This manual is a user manual on how to operate the instrument; it is not a calibration instruction

manual.

As Tradinco Instruments continuously strives to improve its products, specifications of

instruments may be altered without further notice.

User Manual

TRAQC-8

TRAQC-8 04/2017 EN Rev.4 page : 8

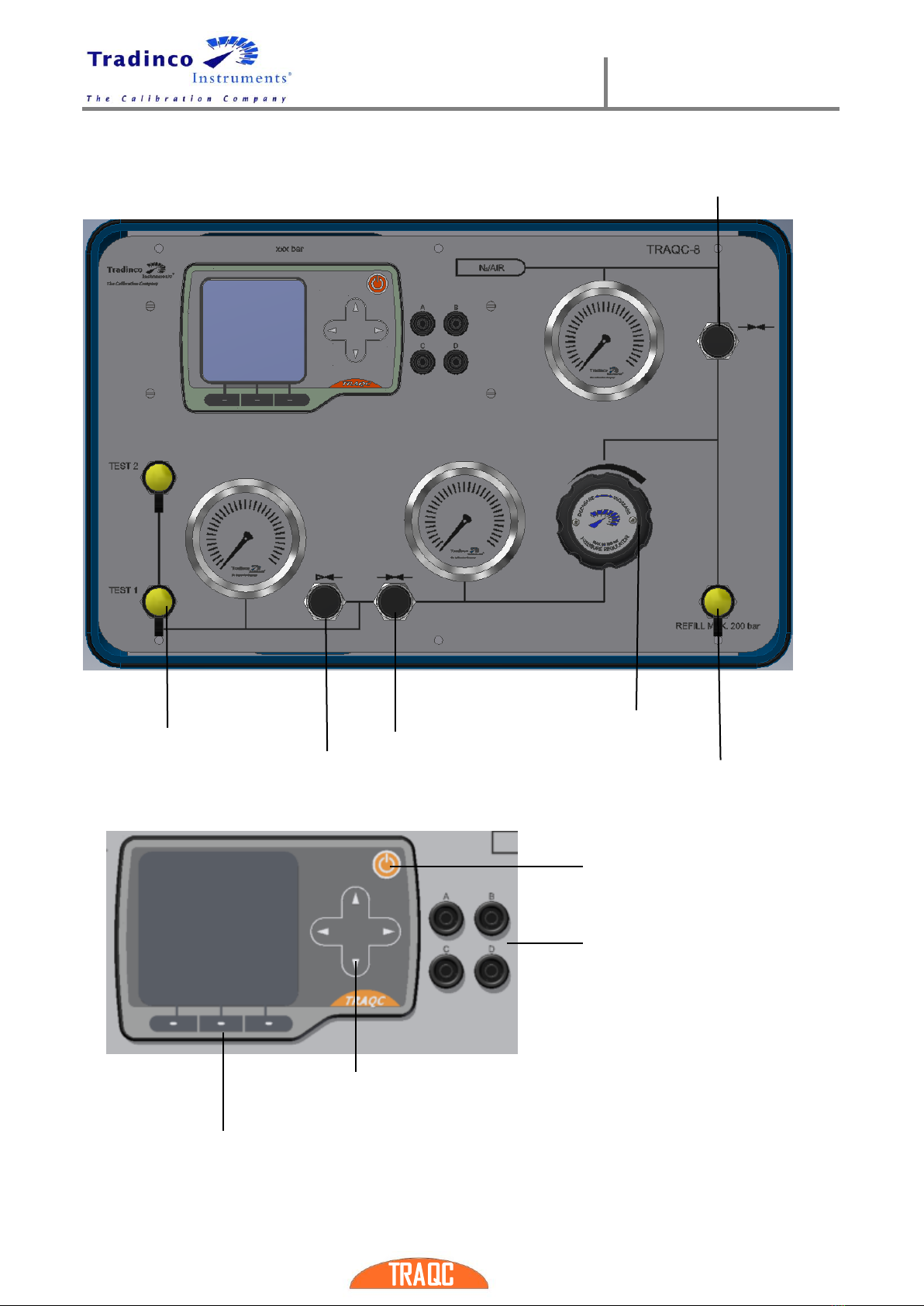

1.5 Calibrator Interface

Bottle shut off

valve

Test

connections

Relief (vent) valve

Supply valve

Pressure

control valve

(PCV)

Refill

connection

On / Off key

Electrical

connections

Navigation keys

Function keys (F1, F2, F3)

User Manual

TRAQC-8

TRAQC-8 04/2017 EN Rev.4 page : 9

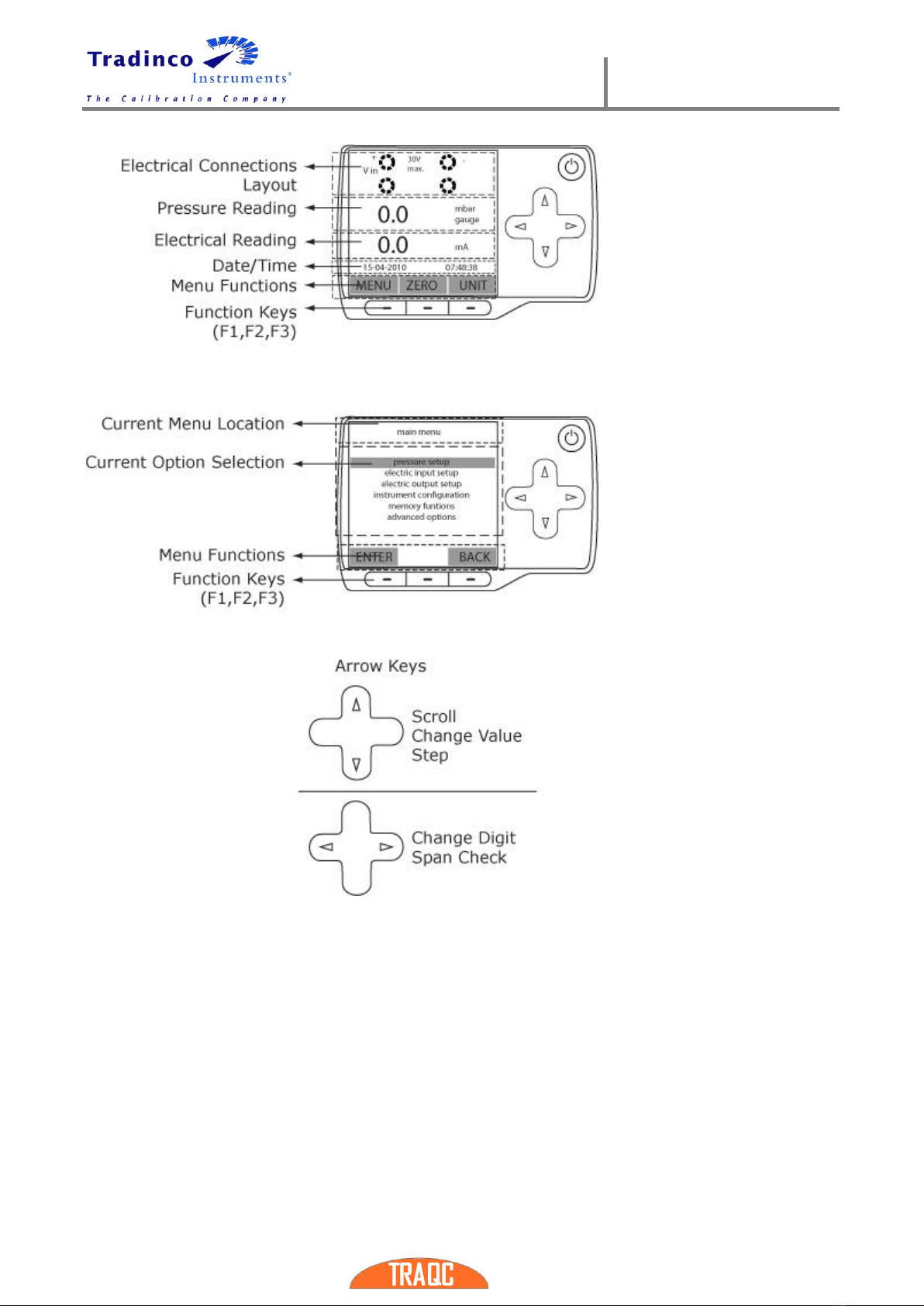

1.6 Navigation

The menus can be accessed when the calibrator is in measuring mode.

Navigating through the menus is possible by pressing the function keys (F1, F2 and F3) and the

‘ARROW’keys. Above the function keys in the display the meaning of the keys is displayed. By

pressing the function keys below the desired field in the display, the menu opens.

Pressing the key below the field ‘EXIT’(under F3) results in going one level back. By pressing the

key below the field ‘ENTER’ (under F1) results in going one level further.

The menus consist of multiple options to choose from. The option in the black bar is the one

selected. By using the navigation keys another option in the menu is selected.

User Manual

TRAQC-8

TRAQC-8 04/2017 EN Rev.4 page : 10

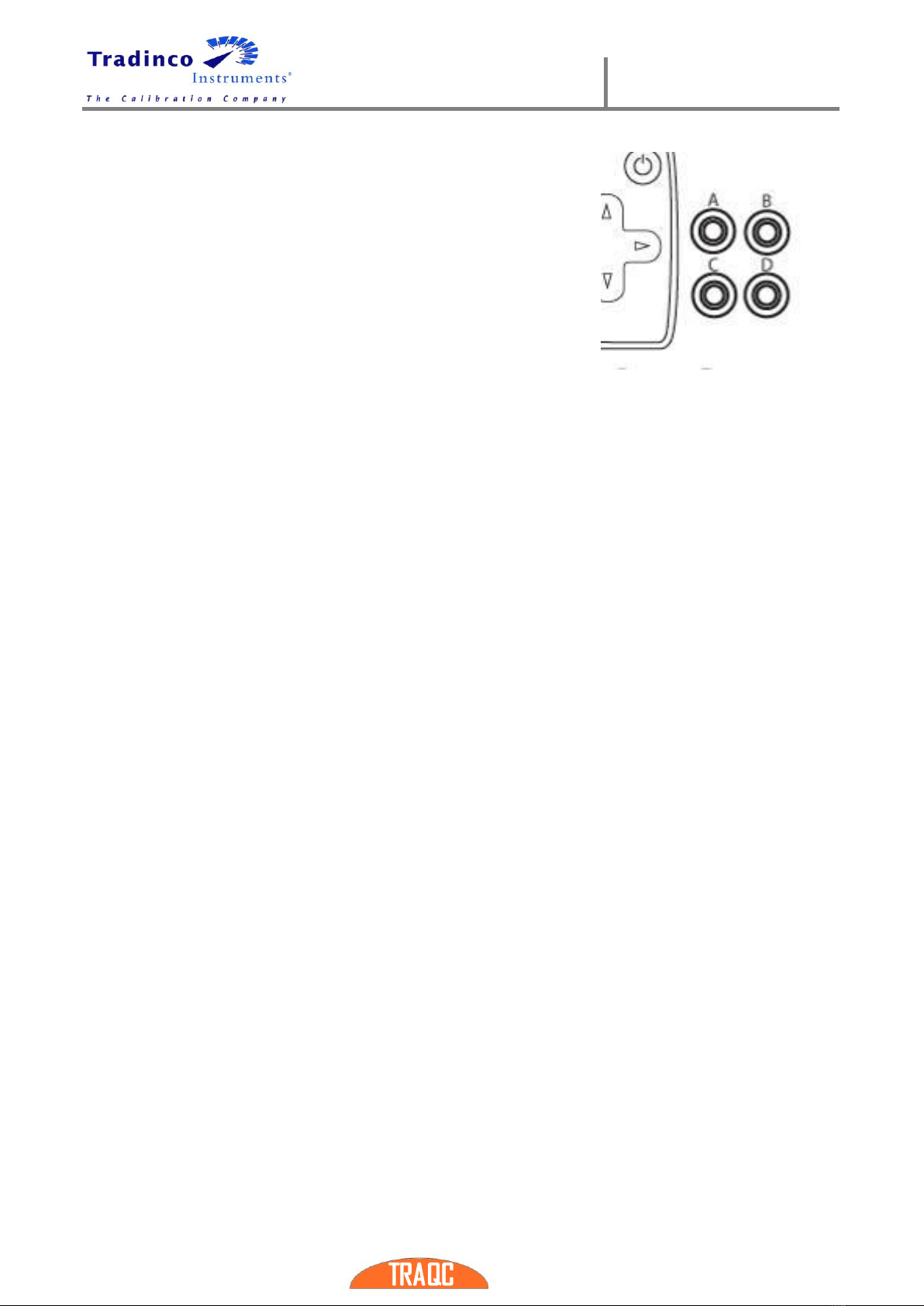

1.7 Electrical Connections

The “Electric Connections Layout” in the display references the

physical layout of these 4 banana socket. (Example see figure).

The letters A,B,C and D are for identification purposes and will

be of reference, in this manual only

User Manual

TRAQC-8

TRAQC-8 04/2017 EN Rev.4 page : 11

2.Operating Instructions

2.1 Set up

Place the unit on a stable table.

•Open the 4 (four) locks and take the lid of the case.

•Check the calibrator for damages.

•Plug the power supply cable in the right side of the unit.

•Control the power supply indication before plug in.

2.2 Operating Instructions

The TRAQC-8 is a pressure calibrator with a maximum of 200 bar and is design for a so-called

"dead end" system. The calibrator includes a high pressure reducer which has to be fed by an

external pressure source of maximal 200 bar or by the internal gas bottles. Depending on the

range of the pressure sensor which is mentioned on the front side of the TRAQC-8, the range of

the reducer is selected. On the pressure outlet of the reducer are a pressure shut off valve and

a bleed valve for fine adjustment of the test pressure.

•Close the “bottle shut off valve” by turning it fully clockwise.

•Decrease the “reducer” by turning it fully counterclockwise.

•Close the “pressure shut off valve” by turning it fully clockwise.

•Open the “bleed valve” by turning it fully counterclockwise.

•Connect the “test” coupling to the unit to be calibrated.

•Close the “bleed valve” and open both the “pressure shut off valve” and “bottle shut off

valve”.

•Slowly increase the pressure with the “reducer” until the maximum admissible pressure

for the unit under test is reached.

•Close the “pressure shut off valve”, close the “bottle shut off valve” and decrease the

“reducer” to minimum.

•Check with the TRAQC-8 if there is any leakage; this becomes apparent by an extreme

change of the test pressure.

•Remove the pressure from the system by opening the “bleed valve”(1).

•Eliminate any leaks and repeat the test as described above until all leaks are eliminated.

•Close the “bleed valve”.

•Open both the “bottle shut off valve” and “pressure shut off valve”.

•Increase the “reducer” to circa 110% of the desired test pressure. Than close the

“pressure shut off valve”.

•For regulating the test pressure:

-Slowly opening and closing the “pressure shut off valve” will result in a pressure

increase.

-Slowly opening and closing the “bleed valve” will result in a pressure decrease.

•A measurement can be performed when the “bottle shut of valve”, “pressure shut off

valve”, the “bleed valve” are all closed.

•Repeat the procedure as often as a new test pressure is desired. When all test pressures

have been generated repeat the following sequence for getting the system back to

atmospheric pressure:

-Close the “bottle shut off valve”

-Open the “bleed valve”

-Decrease the “reducer” to the minimum.

-Open the “pressure shut off valve”.

-Disconnect the test hoses

The valves have a soft seat and a tight shut-off. It is not necessary to close them with

excess force.

User Manual

TRAQC-8

TRAQC-8 04/2017 EN Rev.4 page : 12

2.2.1 Measurement of external test pressures

It is also possible to measure pressures generated by external systems. In this case the reducer

and the gas bottle will not be used. All control valves will have to be closed.

2.3 Instructions for the refilling of the gas bottles

The refilling of the gas bottles can be done by using either another bottle or a high pressure

compressor. The maximal refilling pressure is 200 and the capacity is 2 liters.

When the refilling is done from another bottle, the included RU 3 connector can be used.

The refilling by a high pressure compressor can be made by a direct connection.

•Close both the “bottle shut off valve” and the “pressure shut off valve”.

•Increase the “reducer” to a the maximum.

•Open the “bleed valve”.

•Connect the filling hose to the ‘refill connection’.

•Set the compressor or the external bottle to a maximum of 200 bar.

•Slowly open the “bottle shut off valve”. The gas bottle will be refilled and the

pressure of the bottle can be checked on the manometer.

•Slowly let the gas bottle be refilled. A quick refilling will increase the temperature.

An increase in temperature will affect the pressure by increasing it. This means no

optimal filling will be obtained.

•Close the gas ‘bottle shut off valve” and shut-off the compressor.

•To get the filling hose free of pressure, decrease the “reducer” to a minimum and

open the ‘Pressure shut off valve’

•Then disconnect the filling hose.

2.4 End of use

•Close the “bottle shut off valve”

•Open the “bleed valve”.

•Set the “reducer” to a minimum.

•Open the “pressure shut of valve”.

•Disconnect the unit under test from the unit.

•Disconnect the test hoses and put them in the carrying case in the lid of the 8185.

•Place the cover of the TRAQC-8 back on and close the four locks.

2.5 Storage

End the utilization of the TRAQC-8 as follows:

•Store it indoors, in a temperature between 0 and 60° Celsius.

•Decrease the “reducer” turning it fully anti clock wise

•Open both the “bleed valve” and the “pressure shut off valve”.

•Empty the internal gas bottles by slowly opening the “bottle shut off valve”.

•Place the cover of the 8185 back on and close the four locks.

•Place the case a horizontal position.

Equipment which has rechargeable batteries will need to be stored with fully charged batteries,

charging and discharging of batteries one every 3 months is advised.

When connected to the mains power a trickle charge will be maintained.

User Manual

TRAQC-8

TRAQC-8 04/2017 EN Rev.4 page : 13

2.6 Power Supply

The unit is equipped with an internal not removable Li-Ion battery. The charging of the batteries

is fully automated. The TRAQC-8 is charged when its connected to the mains power supply

charging will start as soon as the instrument is connected to the mains supply.

The instrument can be used while charging the battery, but the required charging time could be

increased depending upon the selected operating mode of the instrument.

2.6.1 Battery status display

The status of the battery is displayed with a battery symbol on the lcd display when the

instrument is switched on.

During charging the battery symbol will be filled with lines until it is completely filled and when

all lines are drawn the symbol will be cleared and starts filling again.

When charging is completed the symbol will be completely filled and remains filled as long as

the instrument is connected to the mains supply.

2.6.2 Operating time indication

The instrument has an internal ‘gas gauge’ to measure the battery capacity, this gas gauge is

automatically updated when the battery is charged or discharged and is used to indicate the

battery charging state and remaining operating time.

The charging state of the battery is indicated with lines in the battery symbol.

When the battery is full all lines in the battery are drawn and when the instrument is operating

on the battery less lines will be shown.

The number of lines shown in the battery is a rough indication of the remaining battery

capacity.

When the remaining operating time drops below 3 hours the remaining time will be shown next

to the battery symbol

The operating time of the instrument on the indicated charge state depends upon the

usage of the instrument, Operating modes where the electrical outputs are used draw

more current from the battery and therefore shorten the operating time more than other

modes.

2.6.3 Instrument charging before storage

The instrument should not be stored for longer periods with an empty battery, doing so will

reduce the capacity of the battery and shorten the battery life.

When the instrument must be stored the battery should be charged to at least 50% of its

indicated capacity.

2.6.4 Battery Replacement

The battery can only be replaced by Tradinco or a Tradinco approved repair facility.

User Manual

TRAQC-8

TRAQC-8 04/2017 EN Rev.4 page : 14

2.7 Power On/Off

The TRAQC-8 is switched on and off by pressing the on/off key. The TRAQC-8 will go through a

short startup self-check routine. During that routine the display shows the current firmware. After

completing the startup procedures the device switches into the measuring mode and displays the

measured value(s), and the measuring unit(s) from last time. When turning off the device, the

display shows ‘Shutting Down’.

If the calibrator needs to be recalibrated at short notice, a message with the date that the

instrument should be re-calibrated is displayed for several seconds before the startup

procedure continues. If the recalibration date has expired a message is displayed as a

warning. By pressing ‘ENTER’ key (F1) the start-up procedure is continued.

2.8 Menu

The main menu is accessed by pressing the ‘MENU’ key (F1). On

top in the display the current location in the menu structure is

shown.

Some of the functions in the menu structure are for

optional functionality of the instruments. Therefore it is

possible the TRAQC-8 included with this manual has less

functions than explained in this user manual.

Main Menu

pressure

setup

electric

input A

setup

electric

input B

setup

electric

output A

setup

electric

output B

setup

instrument

configuration

memory

functions

advanced

options

Pressure range

mA input

Under

development

pressure xmtr

mode

Under

development

backlight

setup

list by

tagnr.

Set rtc time

Pressure unit

mA + Xmtr

supply

xmtr mode

settings

select

language

list by

serialnr.

Set rtc date

Averaging

on/off

V input

mA source

output

date/time

display

view

definitions

Set recall

date

averaging setup

Resistance

input

mA simulator

output

show settings

Erase data

memory

resolution setup

RTD input

current output

settings

factory

defaults

Show

instrument

data

conversion table

Switch test

voltage output

Set IP address

Adjust

instrument

inputs

Set customer

unit

XMTR power

setup

voltage output

settings

Change PIN

code

Adjust

instrument

output

absolute mode

switch test

setup

auto span

check mode

Booster on

pressure

Show

calibration

factors

Hart resistor

Ramp mode

Booster on

differential

mA/V scaling

Set mA/V

scaling

User Manual

TRAQC-8

TRAQC-8 04/2017 EN Rev.4 page : 15

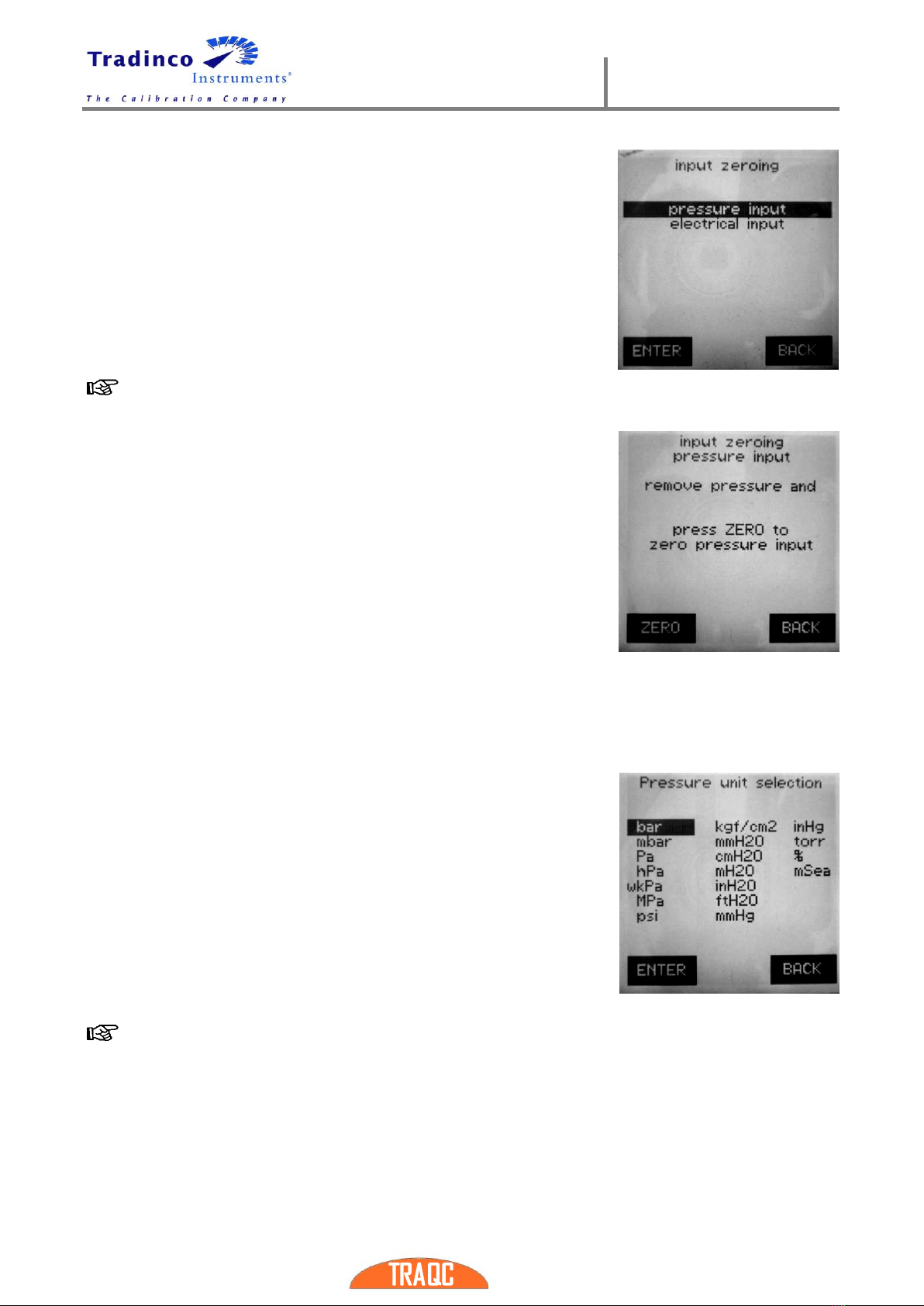

2.9 Zeroing

To zero an input signal press ‘ZERO’ key (F2) in the “measuring

mode” display. The menu shows the different inputs that can be

zeroed, consisting of pressure inputs and the electrical inputs.

Select the desired input using the ‘ARROW’ keys.

•By pressing the ‘BACK’ key (F3) the zeroing procedure is

stopped without making modifications.

•By pressing ‘ENTER’ key (F1) the zeroing procedure is

continued and there is asked to confirm the zeroing

procedure after which the calibrator returns to measuring

mode.

When zeroing the ‘Pressure Input’, ensure that the pressure ports are open to atmospheric

pressure.

The TRAQC-8 comes standard with a quick connect coupling with

integraded shut off valve. This can be opened by:

•Connect/insert the other half of the coupling to the pressure

coupling (-port) of the TRAQC-8

•Connect one side of a pressure hose to the pressure

coupling (-port) of the TRAQC-8 and leave the other side of

the hose unconnected.

With these procedures the pressure in the system of the TRAQC-8

can get equal with the atmospheric pressure.

To zero another test pressure and/or electrical signal, first generate

the required test signal (tare value) and carry out the above-

described zeroing procedure. The test value displayed is the difference between the actual test

value and the entered tare value.

2.10Selecting Pressure Units

When in “measuring mode” screen press the ‘UNIT’ key (F3) to change

the unit. Use the ‘ARROW’ keys to select the desired unit and press

‘ENTER’ key (F1) to confirm and go back to “measuring mode”.

The following units can be selected:

bar kgf/cm2inHg

mbar mmH2O torr

Pa cmH20 %

hPa mH2O mSeaw

kPa inH20

MPa ftH2O

psi mmHg

Not all operating modes that support pressure measurement have the ‘UNIT’ key due to lcd

and keyboard space limitations. The pressure unit can also be selected via the menu, press

the ‘F1’key and select the ‘pressure setup’ and then ‘pressure unit’ for these modes.

User Manual

TRAQC-8

TRAQC-8 04/2017 EN Rev.4 page : 16

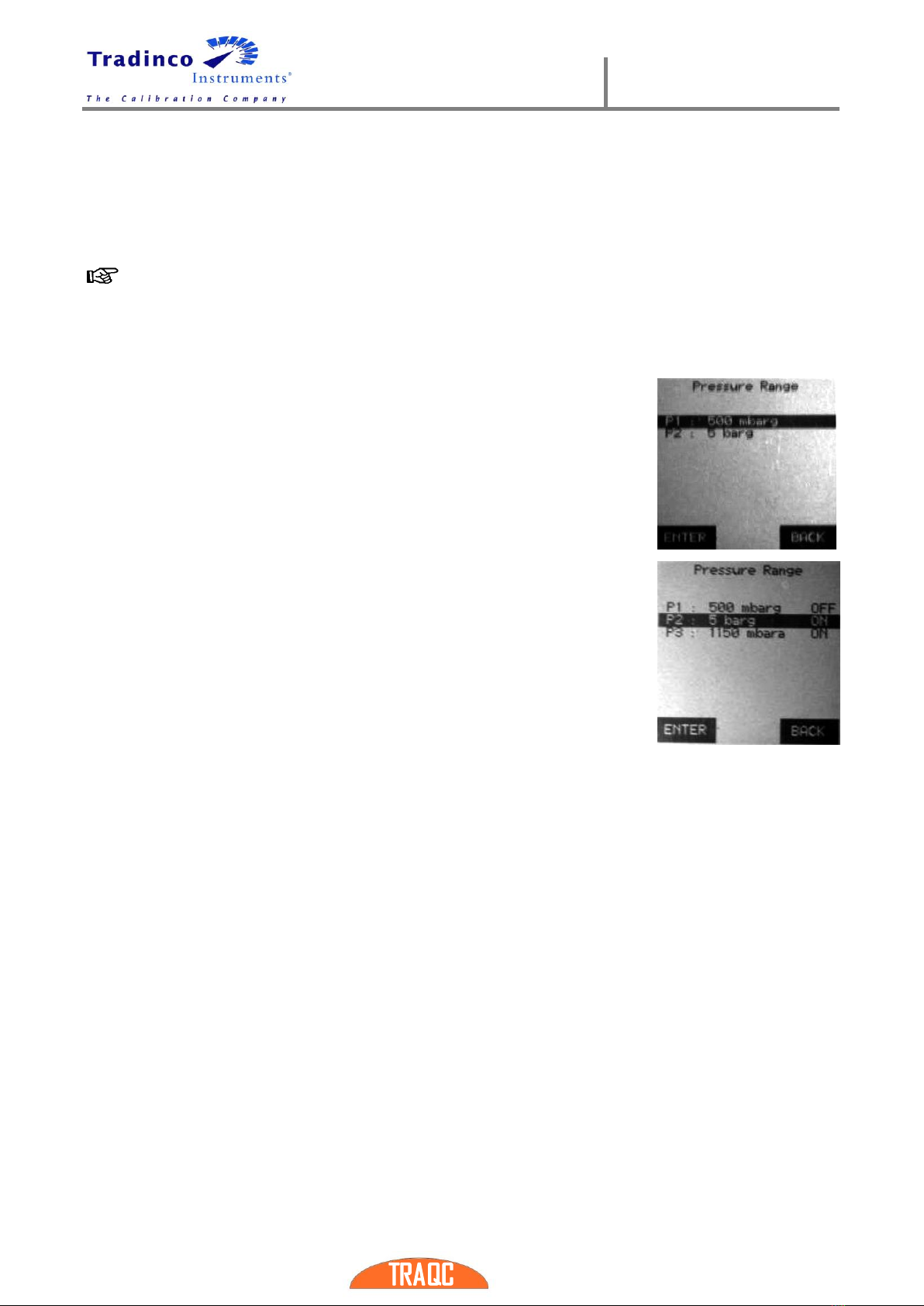

2.11Pressure Range

Depending upon the configuration of the instrument the TRAQC-8 can be equipped with one,

two or three pressure sensors.

In instruments with two or three sensors the user can select the pressure range by pressing the

‘UP’-or ‘DOWN’, ‘ARROW’ key in “measuring mode”

Not all operating modes support the ‘UP’ or ‘DOWN’ keys for selecting the pressure

range. To change the pressure range you can also select the option ‘pressure range’ in

the ‘pressure setup’ menu.

Depending upon the operating mode the range selection menu offers different possibilities.

2.11.1 Electric in- or output active

When the instrument is also measuring an electrical signal only one

pressure input can be used. By using the ‘ARROW’ keys, select the

desired pressure sensor and press ‘ENTER’ key (F1) to confirm, press

the ‘BACK’ key (F3) to cancel.

2.11.2 Electric in- or output not active

When the electrical input are not active an instrument with more than

one sensor can show the measured value of two pressure inputs.

In this situation the pressure range menu can be used to switch the

individual ranges on or off.

2.11.3 Selecting Pressure sensor Auto ranging

The TRAQC-8 can also be equipped with two pressure ranges and one pressure connection for

measuring test pressure. The TRAQC-8 is configured to automatically switch the measuring

range.

When the test pressure exceeds 101% of the low measuring range the TRAQC-8 will

automatically switch from the low pressure range to the high pressure range. If the test

pressure is lower than 99% of the low pressure range it will automatically switch back to the

low pressure range.

This auto ranging feature will be automatically be enabled when the TRAQC-8 is switched on.

Auto ranging instruments cannot display the measured value from both sensors at the same

time, only the pressure from the selected sensor will be displayed.

User Manual

TRAQC-8

TRAQC-8 04/2017 EN Rev.4 page : 17

To overwrite the automatic switching between the two pressure

sensors, one of the sensors can be selected as described in 2.11.

To enable the auto ranging again:

•Power the TRAQC-9 P off and start it up again.

•By entering the ‘Pressure range’ menu, and selecting the

‘Px auto ranging’ line with the ‘ARROW’ keys and press the

‘ENTER’ key (F1).

2.12Instrument Status

By pressing the ‘LEFT’-or “RIGHT’ ‘ARROW’ key in “measuring mode”

the instruments status is shown.

User Manual

TRAQC-8

TRAQC-8 04/2017 EN Rev.4 page : 18

3.User Configuration

3.1 Pressure Setup

The “Pressure Setup” menu shows the options for pressure inputs.

After pressing the ‘MENU’ key (F1), press the ‘ARROW’ keys until

the “pressure setup” is selected, then press ‘ENTER’ key (F1). The

available pressure options for the instrument are now displayed

(see figure) and it is now possible to select one of options with the

‘ARROW’ keys. The different options of the pressure setup are

described in the following paragraphs.

3.1.1 Pressure range

This menu option is available in instruments with 2 or more

pressure sensors installed.

When you select this option a menu with the available pressure

ranges is shown,

You can select a line with the arrow keys and then switch the

selected pressure range on or off depending upon its current status

when the electrical ranges are not active, otherwise you can select

only one range to be displayed. See also section 2.11.

3.1.2 Pressure unit

The menu to select the pressure unit can in most operating modes be accessed by pressing the

‘UNIT’ function key, There are however operating modes where this is not possible , for these

modes the pressure unit selection is also available in the pressure setup menu, see section 2.10.

3.1.3 Averaging on/off

A progressing averaging can be applied. The reading speed is standard three times per second.

The objective is to display the fluctuating measuring signals in a reliable manner. If averaging is

switched on, this is shown by ‘𝑥’ above the pressure unit reading in the ‘measuring mode’ menu.

To enable or disable the averaging function select the “averaging on/off” option in the “pressure

setup” menu.

The default state is the “averaging off”. To change the current state press ‘ENTER’ key (F1).

3.1.4 Averaging setup

The number of times that averaging must be performed can be set

as follows: Select the “averaging setup” in the pressure setup

menu with the ‘ARROW’ keys and press ‘ENTER’ key (F1) to

confirm. Now use the ‘ARROW’ keys to change the number of cycles

to the desired one, press ‘ENTER’ key (F1) to confirm.

The number of cycles default is 6. The cycles can be set from 3 to

9.

User Manual

TRAQC-8

TRAQC-8 04/2017 EN Rev.4 page : 19

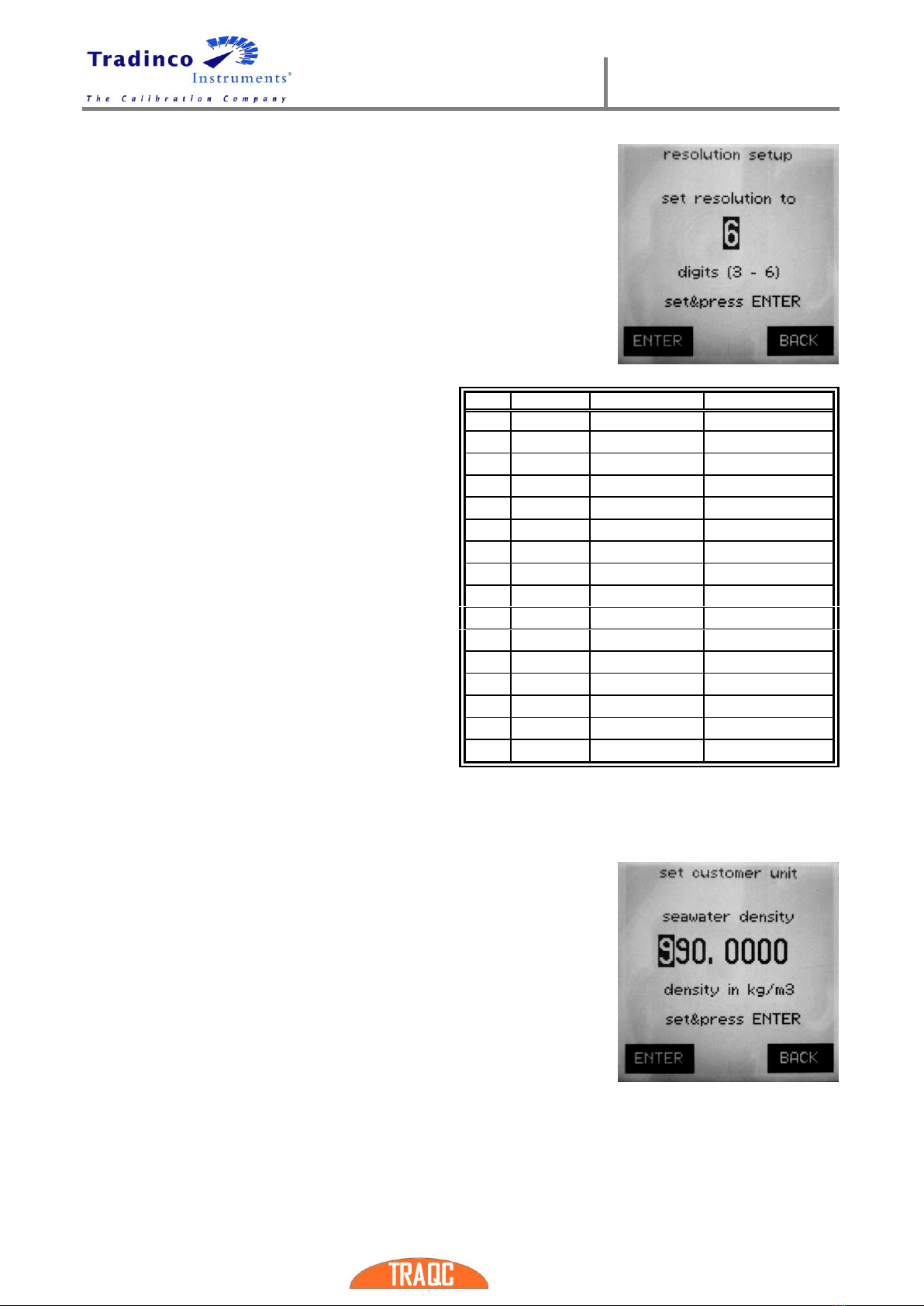

3.1.5 Resolution Setup

To change the number of digits (from 3 to 6) select “resolution

setup” in the “pressure setup” menu and use the ‘ARROW’ keys to

change the number of digits, confirm by pressing the ‘ENTER’ key

(F1)

3.1.6 Conversion Table

The pressure indicator is capable of displaying

pressure according to the SI or the ANSI

standards. Change between SI and ANSI using

the ‘ARROW’ keys and confirm by pressing

‘ENTER’ key (F1).

The ANSI standard has other conversion

factors than the SI standard; see the following

table for a number of units:

3.1.7 Set customer unit

The density of seawater for the region where the pressure

indicator is used can be set here.

When a test pressure is set, the TRAQC-8 can calculate the

pressure into meters under water. The density of the seawater

will differ in different parts of the world and the value has to be

adjusted for correcting for the pressure under water.

The seawater density is set in kg/m3and can be adjusted from

950 up to and 1100 kg/m3.

For adjusting the unit, use the left and right arrow keys to select

the digit which has to be altered and use the up and down arrow

keys for adjusting the selected digit. When the right value has

been set, press the enter key (F1).

Unit

SI

ANSI

01

bar

1

1

02

mbar

1000

1000

03

Pa

100000

100000

04

hPa

1000

1000

05

kPa

100

100

06

Mpa

0,1

0,1

07

psi

14,503768

14,503768

08

kgf/cm²

1,0197162

1,0197162

09

mmH²O

10197,162

10215,491

10

cmH²O

1019,7162

1021,5491

11

mH²O

10,197162

10,215491

12

inH²O

401,46293

402,1598

13

ftH²O

33,455222

33,513316

14

mmHg

750,063755

752,78742

15

inHg

29,52997

29,6373

16

torr

750,063755

750,063755

User Manual

TRAQC-8

TRAQC-8 04/2017 EN Rev.4 page : 20

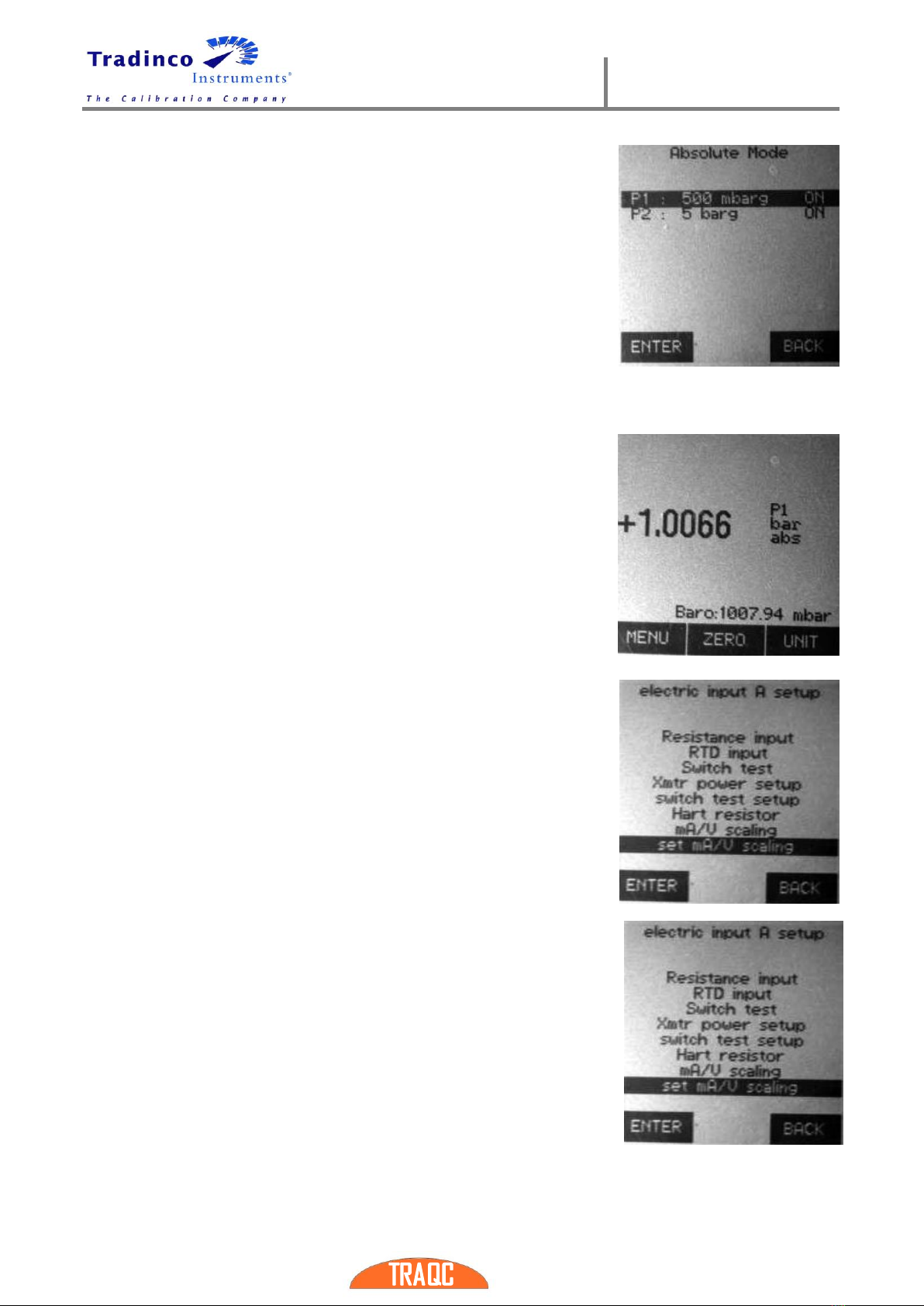

3.1.8 Absolute mode

This option is available when the instrument has two or more

pressure ranges and the last range is an absolute range or

barometric reference sensor.

In instruments with only one gauge range and an absolute range

you can switch the absolute mode on or off, in instruments with

two gauge sensors and a absolute sensor you can select the

range that should be displayed in absolute mode.

Note : In absolute mode the measured value of the absolute

range is added to the measured value of the gauge range. This

means that the uncertainty of the measurement is increased.

When the absolute mode is active the measured barometric

pressure will be displayed on the line just above the descriptions

of the function keys

This pressure is always displayed in mbar.

3.2 Electrical Input A Setup

The electrical connections can be used to measure currents

between 0 - 24 mA, DC voltages between 0 to 11V, resistance of 0

–4000 ohm, temperature with an RTD probe and for connection of

a switch.

To access the menu options for the electrical input first press the

‘MENU’ key, then select the ‘electric setup' line with the ’ARROW’

keys and press the ‘ENTER’ key, will be displayed. The options are

explained in the next paragraphs.

This menu has more than 8 entries, when you step through the

menu with the ‘UP’ and ‘DOWN’ arrow keys the menu scrolls to show

the additional items.

The options are explained in the next paragraphs.

3.2.1 mA Input

To switch the current input on or off select “current input on/off” with the ‘ARROW’ keys and press

Other manuals for TRAQC-8

1

This manual suits for next models

1

Table of contents

Other Tradinco Test Equipment manuals

Popular Test Equipment manuals by other brands

Sanyo

Sanyo MLR-350 instruction manual

Aeroflex

Aeroflex 3500 Operation manual

Hioki

Hioki 9262 user manual

Welch Allyn

Welch Allyn 9600 Plus manual

Chicago Electric

Chicago Electric 91129 Assembly and operating instructions

MAHA Maschinenbau Haldenwang

MAHA Maschinenbau Haldenwang MLT 1000 Original operating instructions