Totech Super Dry ESDA Series User manual

INSTRUCTION MANUAL

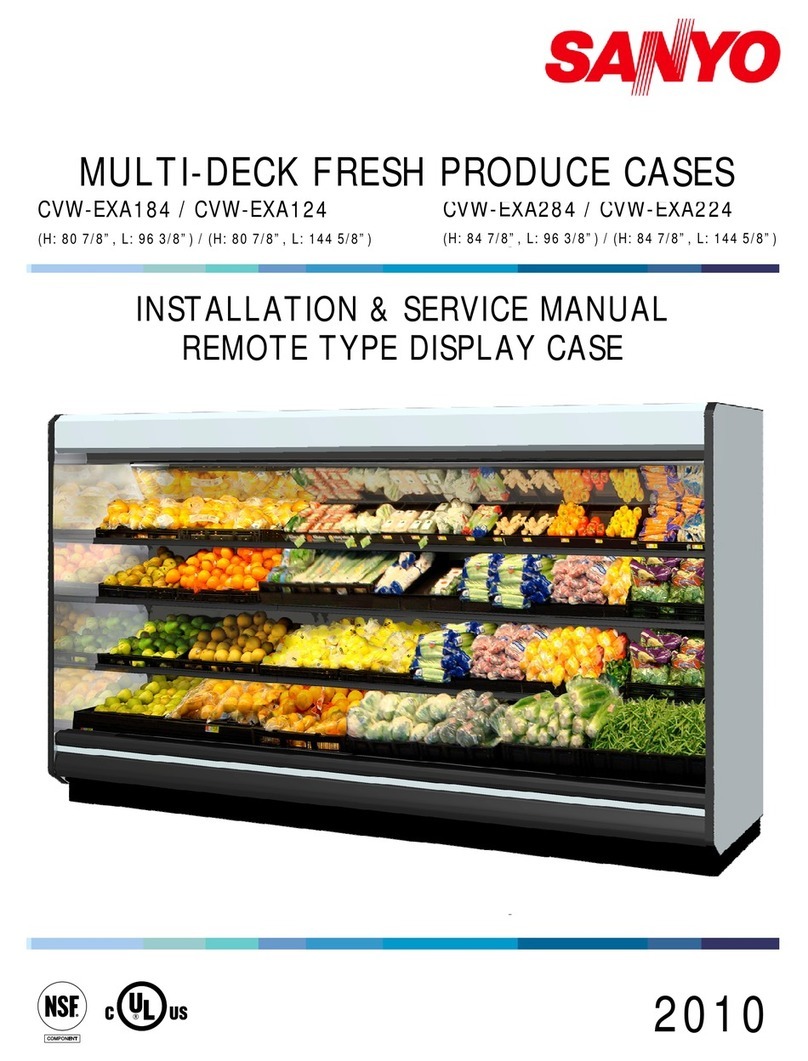

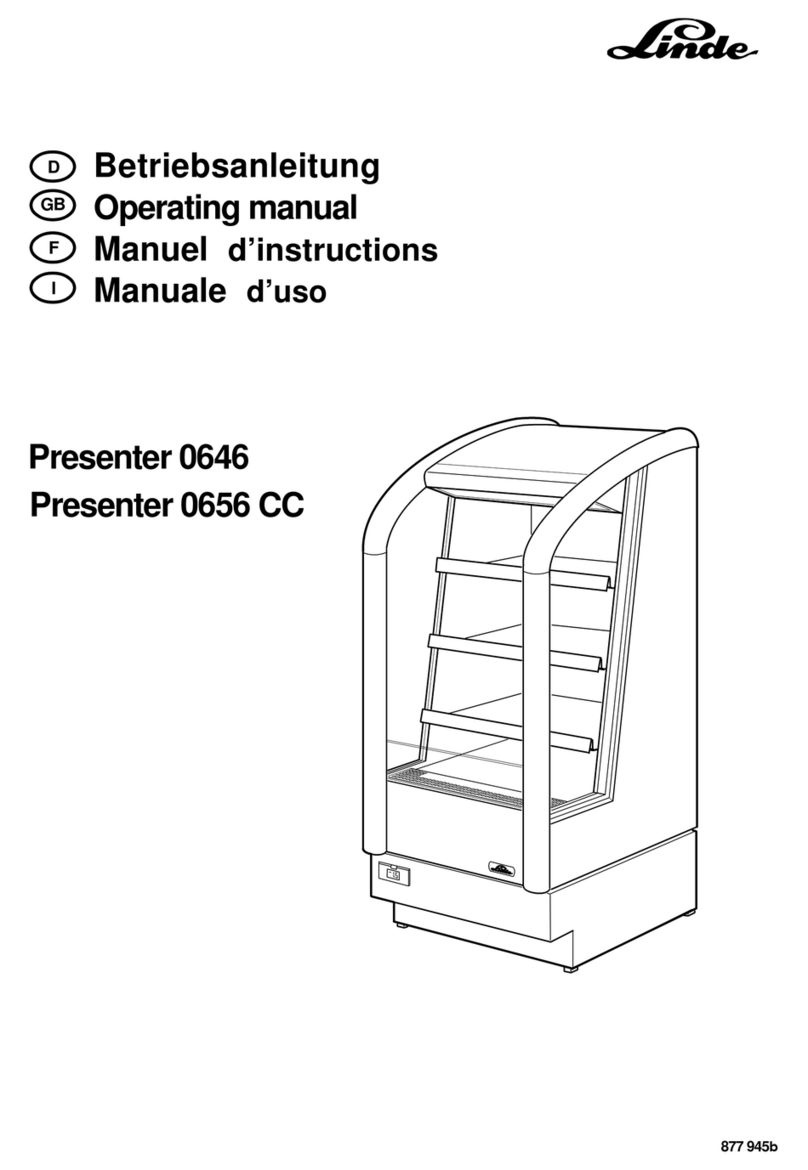

ESDA Cabinets with display

Thank you for purchasing our dry cabinet.

In order to use the drying cabinet properly and safer, please read this INSTRUCTION MANUAL care-

fully, and consult our representatives for any questions.

Please keep this INSTRUCTION MANUAL carefully for future reference.

CONTENT

1. SAFETY GUIDANCE

2. APPLICATIONS

3. SUPERIOR FEATURES OF DRYING

4. DEHUMIDIFICATION PROCESS

5. INSTALLATION

6. PARTS OF DRYING CABINET

7. ADJUSTMENTS

8. CALIBRATION

9. TROUBLE SHOOTING

10. OPTIONS

11. CE - DECLARATION

1. SAFETY GUIDANCE

Please read this SAFETY GUIDANCE carefully to avoid any possible danger of electric shock or damage

to the drying cabinet due to improper use.

Unplug the drying cabinet if there is any smoke or smell coming from it.

Do not try to repair the electric drying unit. To do so could void your warranty

Unplug the drying cabinet in case of spilled liquid inside it.

It may cause electric shock.

Do not disassemble or reconfigure the electric drying unit.

It may cause electric shock.

Do not put flammable or explosive materials inside the drying cabinet.

It may cause electric shock.

Do not operate the drying cabinet in a damp or wet environment.

It may cause electric shock.

Do not damage, twist, pull or place anything heavy on the power cord.

It may cause electric shock.

Do not block off the shutter. Always keep the electric drying unit upright. Do not

place the unit sideways or upside down. It may cause fire or damages.

Do not plug or unplug the drying cabinet with a wet hand. Make sure to plug it

properly.

It may cause electric shock.

Do not stand on or place anything heavy on the drying cabinet.

There is an extreme tipping danger.

Do not put any flammable or volatile liquids such as ether, benzene, LP gas or alcohol

etc inside the drying cabinet. It may cause explosion.

Do not place any hydrochloric acid, sulfuric acid or other corrosive chemicals in the

drying cabinet . It may cause corrosion.

The glass doors of the drying cabinet may shatter under impact.

2. APPLICATIONS

The drying cabinet maintains preset internal humidity levels from 1-50%RH, regardless of the ambient

relative humidity, and it is ideal for the storage of the following items:

1) Storage of all kinds of Integrated Circuits(IC)

e.g. Monolithic, LSI, VLSI, ULSI, Bipolar, MDS, CCD, MCM, DIP, SOP, SSOP, TSOP, VSOP, SDIP,

SIP, SOJ, SVP, QFJ, CSP, KGD, PGA, QFP, TCP, LCA and BGA etc.

2) Storage of Silicon Wafers

3) Storage of Aerospace related Instruments and Tools

4) Storage of Optical Equipments and Machine Tools

5) Storage of Watches

6) Storage of PDP Inspection Equipments, Liquid Crystal Cleaning Equipment’s, LCD’s and TAC’s etc.

7) Storage of LED’s & LD’s

8) Ideal for moisture-proof and anti-oxidation storage applications, offering protection from rust,

mold and deterioration.

3. SUPERIOR FEATURES OF DRYING

1) Speedy Dehumidification

After recycling the drying agent by heat, the interlocked fan inside the electric drying unit starts to

operate for about 2 hours to accelerate the moisture absorption.

2) Exception Recovery Times

The interlocked fan tops operating when the door is open to ensure minimal inflow of outside am-

bient air. Once the doors are closed, this fan starts operating again to accelerate the moisture ab-

sorption inside dry cabinet.

3) Flexible Humidity Setting

Ultra low humidity 1-5%RH or low humidity 1-50%RH can be adjusted flexibly for various applica-

tions.

4) Convenient Digital Control Panel

Precise humidity setting is easily controlled by a front digital control panel without opening the

doors.

5) ESD Safe Design

Equipped with conductive paint, conductive glass doors, chrome steel shelves. Our drying cabinet

is perfectly protected against ESD.

6) Dust Free Design

Urethane casters and chrome steel shelves make the drying cabinet especially suitable for use in

various kinds of clean rooms.

4. DEHUMIDIFICATION PROCESS

Our drying cabinet relies on a drying agent to control humidity lev-

els. This drying agent will be rejuvenated (recycled) for ½ hour in

every 6 hours. Its drying agent is completely recyclable and there is

no required maintenance. During the recycling period, absorbed

moisture will be discharged through the external shutter. After recy-

cling, the shutter will close and moisture inside dry cabinet will once

again be absorbed by the refreshed drying agent. This dehumidifica-

tion cycle will continue until the set humidity point is achieved. Once

the humidity level exceeds the setting level, this dehumidification

cycle will start again.

Every drying cabinet has contact switches installed on each of the doors to control a fan inside the

electric drying unit. The interlocked fan operates for about 2 hours after the drying agent is rejuve-

nated in order to accelerate moisture absorption. The interlock fan stops when the door is opened to

minimize inflow of ambient air into the unit. The interlock fan will operate for 20 minutes when the

doors are closed to speed up moisture absorption inside the drying cabinet.

5. INSTALLATION

Do not operate the drying cabinet near the shutter of air-conditioners, places with high temperature,

smoke and dust or a place with direct sunshine. Please use an extra metal plate, if necessary, to

place the drying cabinet in a stable place to avoid any instability for the glass doors.

6. PARTS of the DRYING CABINET

7. Adjustments

1) Plug in the drying cabinet and let it run one to two days before storing any items.

2) Power ON/OFF

•Press the “ON/OFF” button, internal humidity level will be shown on the LED DISPLAY.

•During the dehumidification process (for details, please refer to P.2“Dehumidification Process”),

only one “RECYCLE LIGHT” will be on. This light will switch off when the dehumidification process

finishes.

•To switch off the drying cabinet, press the “ON/OFF” button again.

3) Adjusting the humidity level

•Press the “SET” button.

•Adjust the humidity level by pressing either “UP” or “DOWN” button.

(Initial humidity setting is 1%RH).

•Press the “SET” button when finish setting. Current humidity level inside the drying cabinet will

be shown on the display.

4) Display of the temperature level

•Press the “H/T” button.

•The “TEMPERATURE DISPLAY LIGHT” will be on. Current internal temperature will be shown on

the LED DISPLAY.

•This “TEMPERATURE DISPLAY LIGHT” will switch off after 5 seconds automatically and the dis-

play will show the current internal humidity level.

5) Setting the humidity alarm

(The “HUMIDITY ALARM LIGHT” will be on if the internal RH level exceeds the setting point.)

•Press both “DOWN” and “SET” button at the same time to set the humidity alarm function.

•When the display is flashing, adjust the humidity setting point by pressing either “UP” or “DOWN”

button (There is no initial setting, the setting point descends from “99” to “98 by pressing the

“DOWN” button)

•Press the “SET” button again, the digital and the dot on the right hand side corner will flash.

This digit shows the time for the humidity alarm to activate.

•Adjust this activated time by pressing either “UP” or “DOWN” button.

•Press the “SET” button when finish setting, the internal humidity level will be shown on the dis-

play again.

E.g. this light will be on if the internal RH level exceeds 50% for 20 minutes, if the RH setting

point is 50%RH and the time setting value is 20 minutes.

6) Setting the Door Alarm Buzzer (provided as option, please refer to P.6)

(This “Door Alarm Buzzer” will sound when the door is left open for a certain period of time)

•Press both “UP” and “SET” button at the same time to set the door alarm buzzer function.

•When the display is flashing, adjust the activated time (in minutes) for the door alarm buzzer by

pressing either “UP” or “DOWN” button (The initial setting is 2 minutes).

•Press the “SET” button again when you finish setting, the internal humidity level will be shown on

the display again.

7) Setting the time of N2 Auto-Purge-System (provided as option)

•Press both “H/T” and “DOWN” button at the same time to set the rinsing time

•When the display is flashing, adjust the activated time (in minutes) for the N2 Auto-Purge-

System by pressing either “UP” or “DOWN” button (The initial setting is 10 minutes).

Press the “SET” button again when you finish setting, the internal humidity level will be shown on the

display again.

8) Setting the key lock function

•To lock the key, press both “H/T” and “SET” button for more than 3 seconds under the power on

condition.

•To unlock the key, press the “SET” button for more than 5 seconds.

8. Calibration

The calibration of a cabinet can be done in two different ways:

Exchanging the sensor. According to the effective ISO specifications it is recommended to

change the sensor every 12 to 24 Months by a new, calibrated sensor (incl. a calibration

report).

Calibrating / adjusting the offset value of the digital display.

Remark: Before calibrating, first a reference value must be determined with an additional calibrated

hygrometer (i.e. the cabinet atmosphere must be measured). Attention: do not measure the humidity

during the recycling mode of the drying unit!

Instruction

1. Unplug the main Power Plug.

2. Press both adjustment buttons (“UP” and “DOWN”), and keep pressed while plugging the

main power plug again. During this time the LED display is blank.

3. Press “ON / OFF”, the current offset value will be shown on the LED display.

4. Press the “SET” button to start the calibration, the current offset value on the LED display will

begin to flash.

(To end the calibration program and start the operation of SUPER DRY, press the “ON/OFF”

twice)

5. Adjust the humidity offset point with the “UP” or “DOWN” button:

“UP” increases, “DOWN” decreases the

offset value

. After finishing

adjustments press the “SET” button again. The new offset value will

be shown on the LED display.

E.g. the humidity display on the digital control panel is 3%RH, and the actual hu-

midity inside SUPER DRY is 1%RH, so set the offset value to 2 (3-1=2)

6. By pressing the “ON/OFF” button once, SUPER DRY will return to the standby condition.

To operate SUPER DRY, press the “ON/OFF” button a second time.

Press the “SET” button and follow the above instruction from point 3 to restart the calibration.

* The Temperature Display Light on the digital control panel will be on during the process from item

2 to item 3.

Maximum offset value

-9

Minimum offset value

9

Initial offset value

0

00.O

O0

02.0

9. TROUBLE SHOOTING

Check the following list before asking for repair services.

1) No Display

•Has the drying cabinet been switched on by pressing the “ON/OFF” button?

•Is the drying cabinet properly plugged in?

•Is the fuse or the breaker of the electric drying unit damaged?

•Is there any power?

2) Humidity level does not drop down to the set point

•Is the humidity point correctly set?

•Is the centre pillar of the drying cabinet properly installed?

•Are the doors of the drying cabinet tightly closed?

•Are the doors of the drying cabinet frequently opened?

Note: The humidity level inside the drying cabinet will be affected by the stored materials and the

outside ambient atmosphere. The humidity level will not drop down at once if the stored materials are

very damp. The humidity level will not rise above the ambient humidity level if the drying cabinet is

not equipped with humidification capability.

Please refer to the following instructions in case of any replacement of the electric drying unit or PCB.

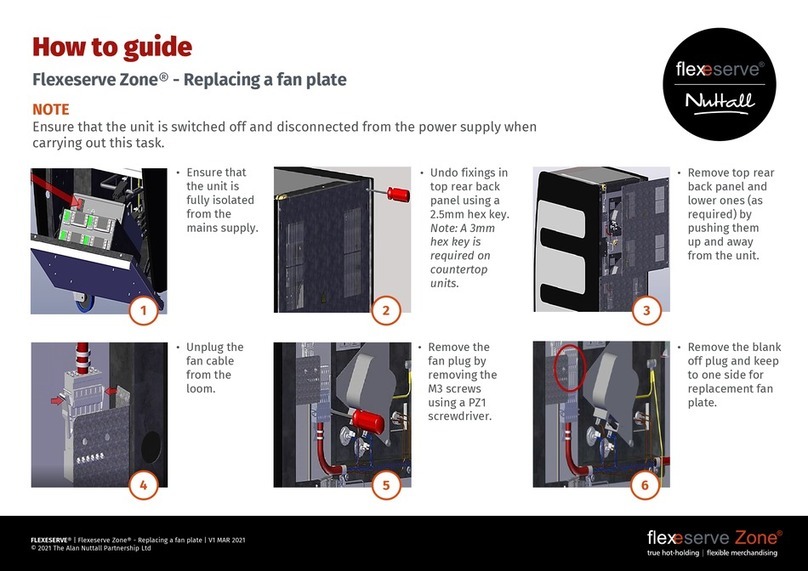

Replacement of the Electronic Drying Unit

1) Remove the power plug.

2) Remove the CONTROL BOX by loosening 4 screws.

3) Detach the connector JP6 & JP9 from the PRINTED

CIRCUIT BOARD and the ground wire form the terminal.

4) Take out the Electric Drying Unit by loosening 4 screws.

Replacement of the PRINTED CIRCUIT BOARD

1) Remove the power plug.

2) Take out the CONTROL BOX by loosening 4 screws

3) Detach the connector for Electric Dryer Unit (JP6 & JP9), connector for power supply(JP2), con-

nector for humidity sensor (JP7), connector for digital control panel (JP5), connector for door

Please contact our representatives or our service centre directly for any questions.

switch (JP3), connector for AC output (JP4) , connector for DC5V input (JP10).

ESDA-402-21

ESDA-804-21

humidity control

Microcomputer controller

sensor

Capacitance type

volume in liters

400

820

inside dimensions WxHxD

560 x 1480 x 480

1120 x 1480 x 480

overall dimensions WxHxD

574 x 1690 x 517

1152 x 1690 x 517

material

casing and door made from conductive acrylic glass (PMMA)

in aluminum profile frame

weight

48kg

92kg

dehumidifier

U-2000 for <1% RH

average energy consumption

31W

maximum energy consumption

290W

input supply voltage

230V~, 50Hz / 120V~ , 60 HZ

max. shelf bearing load

30kg

number of shelves

5

10

Environmental Conditions

-Temperature: 5°C bis 40°C

-Altitude: up to 2000m

-Relative humidity : 80% RH for temperature up to 31°C decreasing linearly to 50% RH at 40°C

10. OPTIONS

Extra shelves & Dividers are available for all models. It allows you to customize the

dry / storage cabinet more effectively.

Humidity Alarm Light flashes when the internal RH level exceeds its setting point.

Various optional N2 equipments provide more effective use of N2.

Humidity Alarm Buzzer sounds when the internal RH level exceeds its setting point.

Casters and Anchoring Legs are available for flexible movement of effective stabiliza-

tion.

Door Alarm Buzzer sounds when the door is left open for a certain period of time.

(standard SD, SDB not deliverable)

Wrist Strap Connection allows you to ground yourself prior to handling ESD sensitive

inventory.

Available for all SD-Series drying cabinet

Others options and custom orders are available, please contact our representatives direct for details.

11. CE-DECLARATION

With this writing we:,

Totech Europe BV,

Linge 28,

8252 PJ Dronten,

confirm that the drying cabinet described corresponds with the fundamental safety and health de-

mands of the following EC instructions:

EN55011: 1998+A1:1999+A2:2002

EN61000-6-2:2001

2006/95/EG

2004/108/EG

Totech Europe B.V.

Gerhard Kurpiela,

technical director

This manual suits for next models

2

Table of contents