tousek ST 40 Guide

Installation and connection manual

Bollard control unit ST 40

in a combination with trac light control STA 11

- 2 - tousek / EN_ST40A_02 / 27. 01. 2020

Index

General warning and safety notes.......................................................................................................................... 3

1. General features, function, technical data............................................................................................... 4

2. TraclightcontrolboardSTA11 ............................................................................................................. 5

2.1 Overview......................................................................................................................................... 6

2.2 ConnectionworksofthetraclightcontrolboardontheterminalblockX1 ................................. 7

Inductionloopinput(term.X1:inside:9/1+9/2,outside:9/3+9/4) ................................................. 7

Impulsebutton(term.X1:inside:30/32,outside:30/38)................................................................ 7

Traclightoutputs

(term.X1:inide:GREEN:6/96,RED:6/98,outside:GREEN:6/97,RED:6/99)

.............. 7

2.3 radioreceiver(optional).................................................................................................................. 8

2.4 indcutionloopdetectorISD6(optional) ........................................................................................ 9

3. BollardcontrolST40withtraclights,controlboardlayout............................................................. 10

3.1 terminalassignmentX1................................................................................................................11

3.2 Adjustments-overview .......................................................................................................................... 12

Programmingbuttons,Programmingmenu,basicsettings........................................................................ 12

Menustructure .......................................................................................................................................... 13

3.3 Connectionsandadjustments ............................................................................................................... 14

Safety .......................................................................................................................................... 14

G innerphotocell(contact:terminalsX1:45/46) .............................................................................. 15

G outerphotocell(contact:terminalsX1:45/48).............................................................................. 15

photocellfunctioninside ............................................................................................................... 15

photocellfunctionoutside............................................................................................................. 15

photocellpausetime(onlyconcernsouterphotocell) .................................................................. 15

photocellselftest........................................................................................................................... 15

photocells - connection examples ............................................................................................... 16

Bollard .......................................................................................................................................... 17

runtimeOPEN .............................................................................................................................. 17

runtimeCLOSE ............................................................................................................................ 17

Operatingmode........................................................................................................................................ 18

runtimecorrection......................................................................................................................... 18

positionmonitoring ....................................................................................................................... 18

Lights/lamps .......................................................................................................................................... 18

PrewarningOPEN ........................................................................................................................ 18

Greenphase ............................................................................................................................ 18

Leavetime ............................................................................................................................. 18

TraclightgateCLOSED ...................................................................................................... 18

Traclightlogic .................................................................................................................... 18

Peripheraldevices.................................................................................................................................... 19

serviceinterval.............................................................................................................................. 19

service reset ................................................................................................................................. 19

Diagnosis .......................................................................................................................................... 20

statusdisplay................................................................................................................................ 20

factorysetting ............................................................................................................................... 20

software version ........................................................................................................................... 20

serialnumber................................................................................................................................ 20

operatingtime............................................................................................................................... 20

protocol......................................................................................................................................... 20

4. Putting into operation ............................................................................................................................. 21

5. Error diagnosis......................................................................................................................................... 22

This manual is the sole property of the TOUSEK Ges.m.b.H. and may not be made available to competitors.All rights reserved. No part of it may be reproduced without our prior

written permission. We will not accept liability for any claims resulting from misprints or errors. This edition of the manual replaces all earlier publications of the same.

tousek / EN_ST40A_02 / 27. 01. 2020 - 3 -

Maintenance

• Maintenanceworksmayonlybecarriedoutbyqualiedpersonnel.

• Maintenance and servicing of the complete facility has to be carried out according to the barrier builder´s/

installer´sinstructions.

• Checkonamonthlybasiswhetherforceadjustmentworksproperly.

GENERALWARNINGANDSAFETYNOTES

•Theseinstallationandoperatinginstructionsformanintegralpartoftheproduct“control”.Theyhavebeenspecically

writtenforprofessionalinstallerstrainedandskilledinthetradeandshouldbecarefullyreadintheirfulllengthbefore

carryingouttheinstallation.Theydescribetheproperinstallationandoperationofthecontrolunitonly,notoftheoverall

device“automaticbarrier”.Aftertheinstallationthismanualhastobehandedovertotheuser.

•Installation,connection,adjustments,puttingintooperation,andservicingmayonlybecarriedoutbytrainedprofession-

alsinfullaccordancewiththeseinstallation-andoperatinginstructions.

•Beforecarryingoutworksatthebarrier-system,thepowersupplyhastobeturnedo.

•TheEUMachineDirective,lawsandrulesconcerningthepreventionofaccidents,andlawsandstandardswhicharein

forceintheEUandintheindividualcountrieshavetobestrictlyfollowed.

•TheTOUSEKGes.m.b.H.cannotbeheldliableforanyclaimsresultingfromdisregardsofthelawsandstandardsin

forceduringtheinstallationandoperation.

•Thepackagingmaterials(cardboard,plastic,EPSfoampartsandllingmaterialetc.)havetobeproperlydisposedof

inaccordancewiththeapplyingrecycling-andenvironmentalprocectionlaws.Theymaybehazardoustochildrenand

thereforehavetobestoredoutofchildren´sreach.

•Theproductisnotsuitableforinstallationinexplosion-hazardousareas.

•Theproductmayonlybeusedinaccordancewithitsoriginalpurpose,forwhichithasbeenexclusivelydesigned,and

whichisdescribedintheseinstallationandoperatinginstructions.TheTOUSEKGes.m.b.H.rejectsanyliabilityifthe

productisusedinanywaynotfullyconformingtoitsoriginalpurposeasstatedherein.

•Childrenhavetobeinstructed,thatthegatefacilityaswellasthebelongingpartsmaynotbeusedimproperly,e.g.for

playing.Furthermorehandheldtransmittershavetobekeptinsafeplacesandotherimpulseemittersasbuttonsand

switcheshavetobeinstalledoutofchildren‘sreach.

•Beforebeginningwiththeinstallationtheinstallerhastomakesurethatallmechanicalcomponentsofthegatefacil-

ity,likecarrierprole/rail,gateframeandpanels,guidingelementsetc.aresucientlysupportiveandresistantforthe

purposeofgateautomation.

•Allelectricalinstallationshavetobemadeinfullconformitywiththeapplyingrulesandlaws(e.g.usingafaultcurrent

circuitbreaker,propergroundingetc.).

•Anall-poledisconnectingmainswitchwithacontactopening-gapofminimum3mmhastobeforeseen.

•Theelectricmotorheatsupduringoperation.Thereforethedeviceshouldonlybetouchedafterithascooledo.

•Afterinstallationtheproperfunctionofthebarrierfacilityandthesafetydeviceshastobechecked!

•TheTOUSEKGes.m.b.H.rejectsanyliabilityforclaimsresultingfromusageoftheproductincombinationwithcompo-

nentsordeviceswhichdonotfullyconformtotheapplyingsafetylawsandrules.

•Onlyoriginalspare-andreplacementpartsmaybeusedforrepairoftheproduct.

•Theinstallerhastoinformtheuseraboutallaspectsoftheautomaticoperationofthecompletebarrierfacility,aswellas

aboutemergencyoperation.Theinstallerfurtherhastosupplytotheuserallinstructionsrelatingtothesafeoperation

ofthebarrierfacility.Theinstallationandoperatinginstructionsalsohavetobehandedovertotheuser.

Manufacturer´sDeclarationofconformity:

ThecompanyTOUSEKGes.m.b.H.,Zetschegasse1,1230Vienna/Austria,declaresthatthecontrolunitST40A,

complieswiththefollowingdirecives:

-LowVoltageDirective2006/95/EG,incl.changes

-ElectromagneticCompatibilityDirective2004/108/EG,incl.changes

Wien,Jänner2012

- 4 - tousek / EN_ST40A_02 / 27. 01. 2020

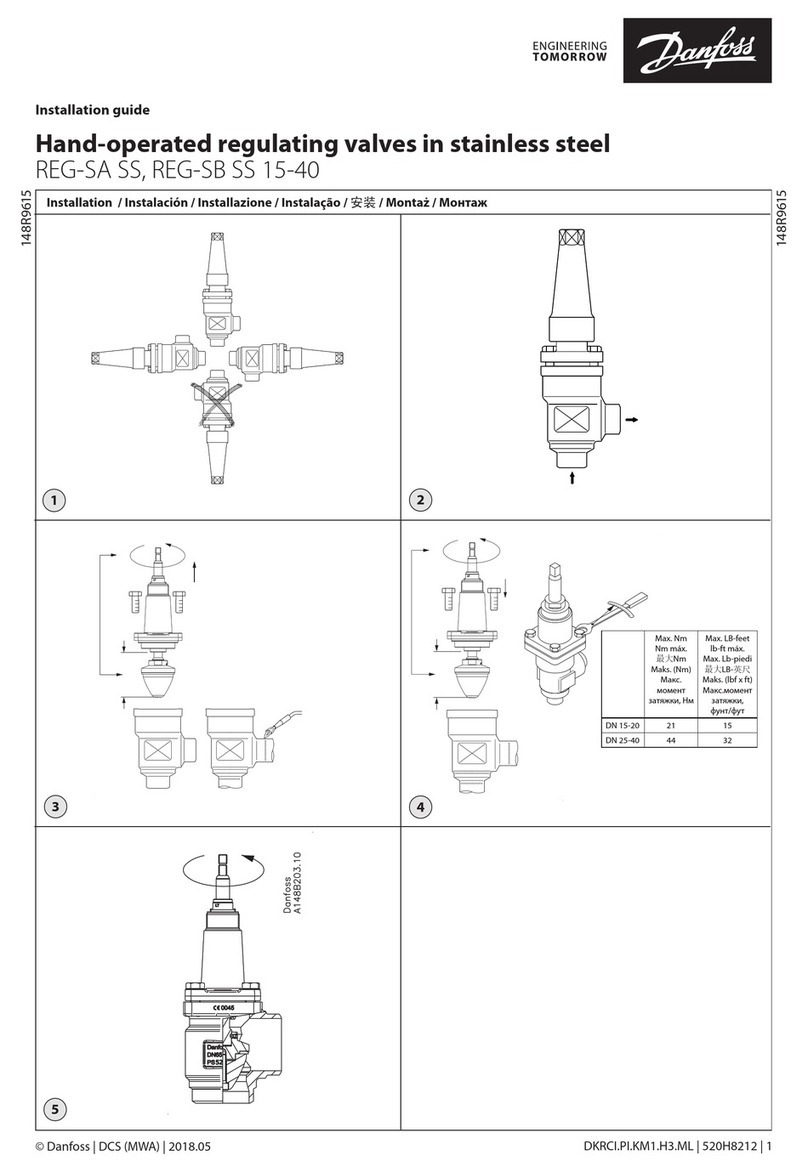

1. General BollardcontrolST40withtraclights

Controlboardcharacteristics

• Formax.4electro-hydraulicbollardVSZ4insynchronous

operation,230Va.c.

• Adjustableforone-wayortwo-waytracoperation

• Connectionfor2RED/GREENtraclights230V,60W

• ProgrammingwithilluminatedLCDisplayinenglishlanguage

(2x16characters)

• cleartextmenuprogrammablethrough4buttons

• separatespeedadjustmentforOPEN/CLOSE

•

SignaloutputforService(serviceintervaladjustable)

• continousREDfunctionadjustable

• Clearancetimeadjustable1-60s

• Greenphaseadjustable5-120s

• Storingofadrive-throughrequirement

• Statusdisplay

• Automaticmode

• Selfmonitoringfunctionofthephotocell

• Connectionpossibilityoftwoimpulseswitchesorinduction

loopsforgreenrequestandtwoRED/GREENtraclights

230V,60W(insideandoutside)

• STA 11: Connection slot for optional radio receiver and

inductionloopdetector

•

General

• TheST40controlboardforbollardcontainsthefollowingitems:operatorcontrolboard(ST),traclightcontrolboard

STA11,theconnectionterminalblockX1andotherelecticcomponents,whichareplacedtogetherinthecabinetIP66

(380x380x210)

• Fortheimplementationofthetraclightsystem,thetraclightcontrolboard(STA11)isconnectedviaabussystemwith

theoperatorcontrolboard(ST)(theyarealreadyprewiredinthecabinet)

ST40controlboardforbollardincabinetIP66

Powersupply 230Va.c.,+6/-10%,50Hz Ambienttemperature -20°Cto+70°C

4motoroutput 4x750W,230Va.c. protectionclass IP66

signallampoutput 230Va.c.,40W

photocelloutput 24Va.c.

servicesignaloutput 24Vd.c.(whenservicedue)

limitcontactswitchsupply 24Vd.c.

outputfor2RED/GREENtracligh 230Va.c.,max.60W articleno. 12120400

380mm

380mm

210mm

Measurementandtechnicalmodicationsarereserved.!

AlloftheconnectionworkshavetobemadeontheterminalblockX1. page 11: connection plan

ST STA11

X1

tousek / EN_ST40A_02 / 27. 01. 2020 - 5 -

2. TraclightcontrolboardSTA11 TraclightcontrolboardSTA11

Function

ThetraclightcontrolSTA11enablesinconjunctionwithasuitableoperatorcontrolboardtheautomationandcontrolofthe

entryandexitthroughatraclight.

Attheterminalsofthetraclightcontrollerseparateimpulsegeneratorscanbeconnectedfor„inside“and„outside“.

AlloftheconnectionworkshavetobemadeontheterminalblockX1!

The behavior of the traffic light control is determined by the settings of the connected operator control board.

Theserelatetothefunctionofthedurationofthegreenphaseandtheclearancetime,thetraclightattheposition„Bollard

closed“(whetherorcontinuousred)andthetraclightsystemlogic.

Dependingonhowthe„traclightlogic“wasadjusted,aftercompletionofcommandprocessingandgateopening,eitherthe

side,whichhasgiventheorder,orbothsidesreceivethegreenlight.Vehiclescanthereforeonlydriveinonedirectionorboth

directionsenteringthegatearea.Furthermore,thetraclightcontrollerhasthecapacitytostoreincomingtransitneedsand

toworkattheendofthecurrentcycle.

Functionalsequence

Traclight

(commandgiving

side)

Traclight

(counterside)

1

Bollard closed

Continuousredfunction

adjustableviaoperatorcontrolboard

selectable

no continuous

red OFF OFF

continuous red RED RED

2

openingcommand(INSIDEorOUTSIDE)

RED RED

PrewarningOPENisbeingstarted(=redtraclightwarningandpossibly

signallightwarningbeforeopeningthebollard),),durationadjustableviagate

automationcontrolboard

>Bollardopensaftertheprewarningtime.

3

Bollardopen(limitpositionreached)

traclightlogic,adjustableviaoperatorcontrolboard

selectable

bothsidesGreen GREEN GREEN

one side Green GREEN RED

4Green phase is started

Durationisadjustableviaoperatorcontrolboard

5

Clearancetimeisstarted(=timetoexitthetraclightintermediaryregion)

Durationofadjustabledrivecontrol

RED RED

>Closingthebollardafterclearancetime,

cyclestartsagain(→ 1)

• ifduringtheclosingprocedureanimpulseisgenerated,sothebollardopens

immediately,andthegreenphasebeginswhentheopeningiscompleted.

• Ifafurthercommandfromonesideisgivenwithtraclightlogic„bothsidesGreen“duringthegreenphase/

clearancetime,thenthegreenphaseisrestarted.

• Ifafurthercommandfromthesamesideisgivenwithtraclightlogic„onesideGreen“duringthegreenpha-

se/clearancetime,thenarestartofthegreenphaseforthissideiseected.

• Ifafurthercommandfromthecountersideisgivenwithtraclightlogic„onesideGreen“duringthegreenpha-

se/clearancetime,thenthebollardremainsafterthegreenphase/clearancetimeopenandtheGreendisplay

changestothecounterside.

Whenthestopbuttonistriggered,thebollardstopsmovingandonlyopensagainwithcommandby

either side.

-6- tousek / EN_ST40A_02 / 27. 01. 2020

B

K

TA

T2

ISD

FE

F2

L2 L1

prewired

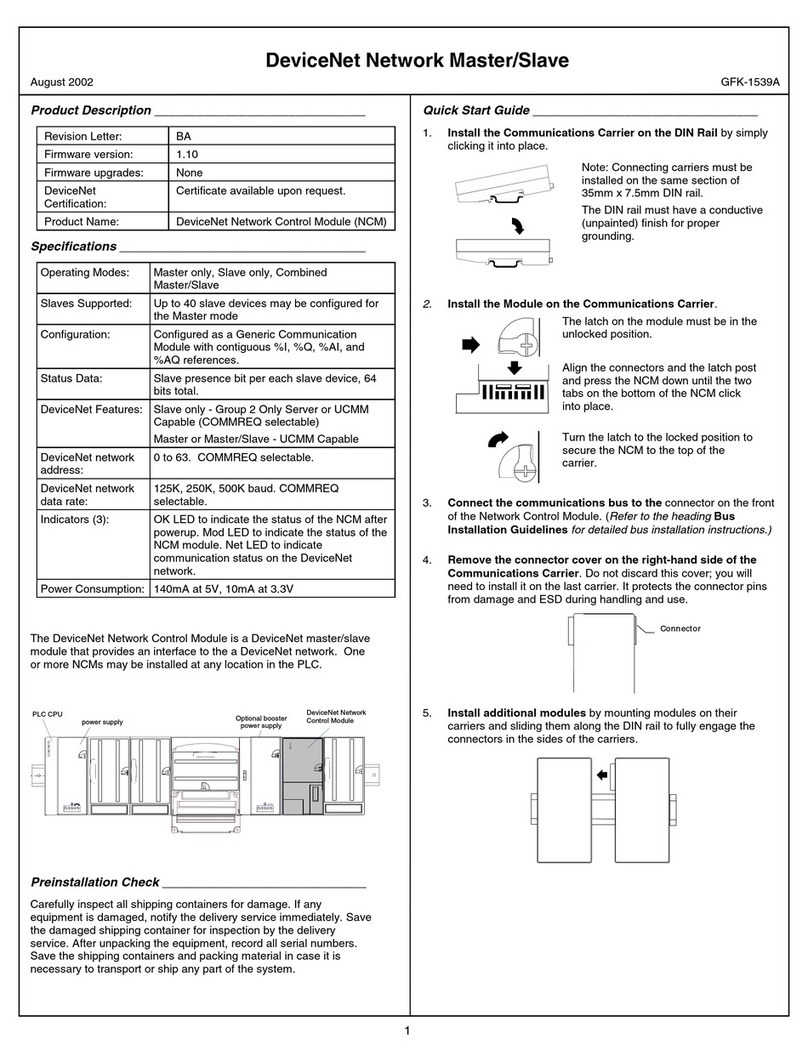

Connections

• Theclampsofthetraclightcontrolboardareal-

readyprewiredwiththeoperatorcontrolunitST40

orwiththeterminalblockX1.

• IMPORTANT:allconnectionworkhavetobedone

ontheterminalblockX1!(see page 11)

230Vmax.60W

LN

grounding

230Va.c. Phase

50Hz neutral

wire

0

1

2

9/1

9/2

9/3

9/4

38

30

32

30

97

6

99

6

96

6

98

6

nduction loop

outside

induction loop

inside

impulseswitch

outside

impulseswitch

inside

internal use

GREEN

outside

RED

outside

GREEN

inside

RED

inside

B

bussystem

high

bussystem

low

88

89

88

89

60

61

operatorcontrolboard

ST40

Pleaseconsidertheconnectioninstructions!

(see page 11).

terminalblockX1 terminalblockX1

prewired prewired

ComponentsoftraclightcontrolboardSTA11

(K) Terminals

(B) Systemplug(connectionwithoperatorcontrolboard)

(TA) Testbutton(switchesalltraclightson)

(L1) greenLED:StatusOK

(L2) redLED:error(messageonthedisplayofthedrive

control)

(T2) Transformerofthetraclightcontrolboard

(ISD)Slotforoptionalinductionloopdetector(p. 9)

(command)

(FE) Slotforoptionalradioreceiver(p. 8)

(F2) fuse3,15AT

2.1 Overview TraclightcontrolboardSTA11

tousek / EN_ST40A_02 / 27. 01. 2020 - 7 -

Important

Push button and key switch

with potential free closing

contact can be used as im-

pulsegeneratoronthetermi-

nalblockX1

page 8: Alternative a radio

system can be used as impulse

generator.

38

30

32

30

outside

inside

X1

Induction loops

• For the use of induction loops (for Green/Opening command) the I-loop slot (ISD) of the traffic

light board STA 11 has to be equipped with an optional avalaible I-loop detector ISD 6 (2-channels).

(see page 9)

2.2

ConnectionworksofthetraclightcontrolboardontheterminalblockX1

STA11

9/4

9/3

9/2

9/1

incution loop

outside

incution loop

inside

X1

Induction loop input (term.X1:inside:9/1+9/2,outside:9/3+9/4) Connections

• Fortheconnectionofinductionloopstogiveanimpulsetothegreenrequest.

• With the 2-channel I-loop detector ISD 6 both loops

(inside/outside)canbeevaluated.

Impulseswitch(term.X1:inside:30/32,outside:30/38) Connections

• For the connection of impulse switches on the inside

andoutsidetogiveanimpulseforthegreenrequest.

Theimpulseisalsopossibleviaanoptional,plug-in

radioreceiver.

• Thegreenswitchingforoneorbothsidesisdependent

ontheadjustmentofthetraclightlogicoftheoperator

controlboard(see operator control board).

Traclightoutputs

(term.X1: inside:RED:6/98,GREEN:6/96,

outside:RED:6/99,GREEN:6/97) Connections

• onthedescribedterminalsRed/Greentraclights(230Vmax.60W)canbe

connectedforinsideandoutsidelocation.

230Vmax.60W

lights outside

red

green

6

98

6

96

6

99

6

97

red

green

lights inside

X1

Adjustments

• Thefunctionsofthetraclightcontrolisdeterminedbythesettingsoftheconnectedoperatorcontrolboard.

Theserelatetothedurationofthegreenphaseandtheclearancetime,thetraclightattheclosedposition

(whetherorcontinuousred)andthetraclightsystem(bothsides/onesidegreen).

- 8 - tousek / EN_ST40A_02 / 27. 01. 2020

FE

STA11

FE

E

STA11

Important

• Theoptionalavailableradioreceivercardhastobepluggedontotheslot(FE)ofthetraclightcontrolboardSTA11.

• Theradioreceiverslotofoperatorcontrolunitiswithout functionwhenusedwithtraclightcontrolboard.

Important

• Withtheuseofthe2-channel-receivertherstchan-

neltakesoverthefunctionfortheimpulseswitch

outside and the second channel the function for the

impulseswitchinside.

• For programming the receiver please see the radio

receiver manual.

• Turnothepowersupply.

• Openthecontrolboardcover

• Plugthereceivercard(E)RS433/868-STN1(1-channel)or

RS433/868-STN2(2-channel)intotheconnectionslot(FE),

asshowninpicture.

• ForrangeextensionanexternalantennaFK433orFK868

canbeconnected.

2.3 Connectionoftheradioreceiever(optional) TraclightcontrolboardSTA11

tousek / EN_ST40A_02 / 27. 01. 2020 - 9 -

2.4 2channelinductionloopdetectorISD6(optional) STA11

Important

• Thedeviceisintendedformountingonacompactcontrolboard.Thecompactcontrolboardmust

beistalledinanenclosurewithadditionalIP54insulation.

• Aftereachdevicesettingareadjustmentiscarriedoutautomatically.Afterachangeoffrequency

(DIPswitch1:OFF/ON)theReset-button(RES)hastobepushed.

• specicinstructionsforloop:Thesafetyoperationonthedevicedependsmainlyonthetechni-

callycorrectinstallationandrelocationoftheloops,sincetheyarethesensorsofthedevice.The

loopmustnotbemechanicallystressedoragitated.Theloopcableistwistedabout20to50times

permeterandhastobelaidseparatelyfromthepowercables.

•

Withthe2-channel-inductionloopdetectorISD6bothloops(inside/outside)canbeevaluated.

•

TheinductionloophastobeconnectedtotheterminalsX1:9/1+9/2(=inside)and9/3+9/4(=outside).

• Specic informations are in the induction loop manual.

9/1

9/2

9/3

9/4

Induct. loop

inside

Induct. loop

outside

X1

• All detector settings can be made easily with the rotary

switches (D1)forchannel1and(D2)forchannel2aswell

astheDIP-switches(DIP). see corresponding manual.

Factorysettings(DIP1–DIP8=OFF,D1andD2=4).

DIP DIP-switch

RES Reset-button

M Molexstrip

D1 rotaryswitch

channel1

D2 rotaryswitch

channel2

LED´s for

channel display

G1 (green) 1detection

G2 (green) 2

R1 (red) 1defective

R2 (red) 2

PWR

(yellow)

blinkingwhen

adjusting/power

RES DIPG2D2D1 G1PWR

M

15 .1

9 .7

412

RotaryswitchesD1,D2andDIP

infactorysetting

RESDIP D2 D1G2 G1 PWR

R2 R1

TheResetbutton(RES)hastwofunctions,dependingonhowlongthebuttonispressed:

• Adjustment:shortkeystroke(<2s),Initializationofallactivatedloopchannels.

• Reset:averagedurationofthekeystroke(>2s),resetthedetector,subsequentinitializationofallchannels.

Installationandadjustments

Switchothepowersupply.openthecontrolboardcoverandplugtheI-loopdetectorontotheconnection

slotasshownonpicture.

ISD

STA11

Plug-intheprintoftheinductionloopdetectorinto

the socket (ISD)ofthetraclightcontrolboard

STA 11

ISD

-10- tousek / EN_ST40A_02 / 27. 01. 2020

Important

The optional tousek- ser-

vice-interfacemustbecon-

nectedtothesocket(SV)!

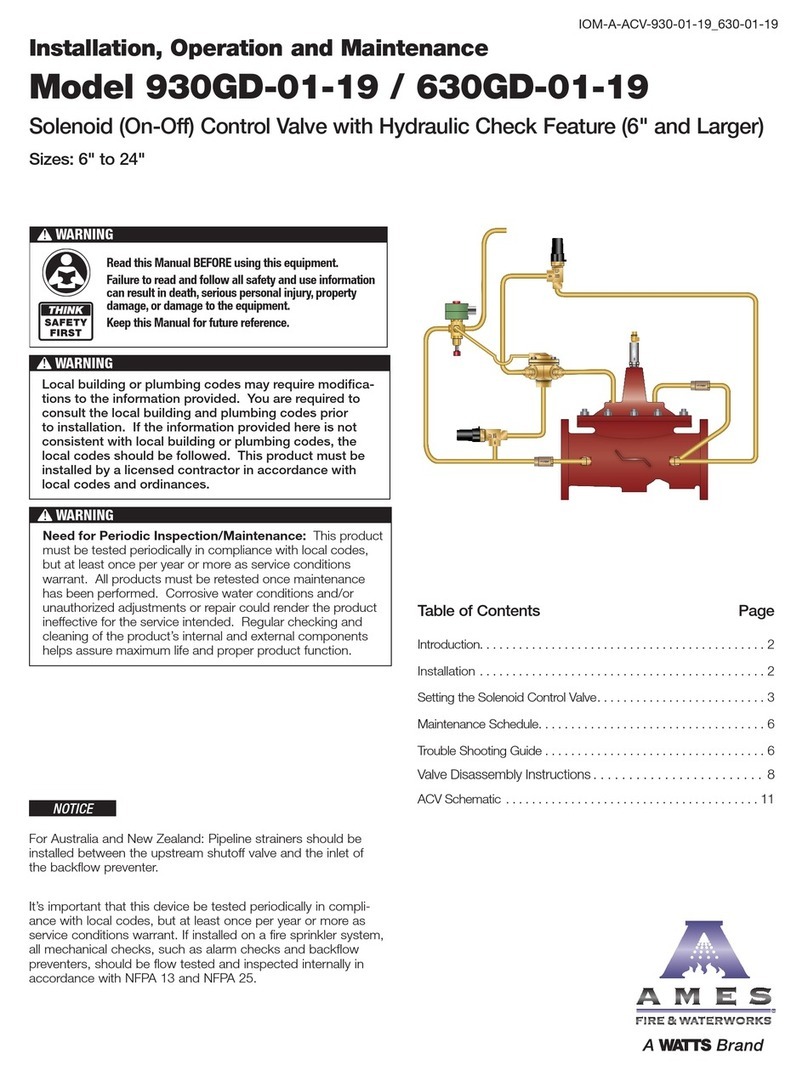

3. BollardcontrolboardST40withtraclights ST40withtraclights

Controlboardlayout

Attention

During connection, adjust-

ment and maintenance

works please take care,

that the electronic circuit

board won´t be damaged

bymoisture(rain).

Controlboardcomponentson

thecoverdoor

(SCH1)contactor 1

foropening

(SCH2) contactor 2

forclosing

(FP1–4)

fuses4x6,3AT

forbollardmotor

(FP5–6)

fuses2x2AT

forbollardvalveand

lighting

(REL)

limitcontactswitchrelays

(HS) mainswitch

Componentsinthecontrolunitbox

ST controlboardwithtextdisplayand4buttons

+,-,ENTERundESC

T1 transformeroftheoperatorcontrolboard

F1 fuse1AT

SV serviceplug(e.g.forsoftwareupdate)or

TSI-socket(optionaltousek-service-interface)

X1 terminalblock

STA11

traclightcontrolboard

T2 transformerofthetraclightcontrolboard

F2 fuse3,15AT

ISD socketforoptionalinductionloopdetector

FE socketforoptionalradioreceiver

B bussystemterminals

(connectionoperator-/traclightcontrolboard)

AllofconnectionworkshavetobedoneontheterminalblockX1.

X1

ST STA11

F1

SV

FE

B

B

Display

ESC ENTER

+

–

ISD

T1

T2

F2

SCH1

FP

1–4 5–6

REL

HS

SCH2

tousek / EN_ST40A_02 / 27. 01. 2020 - 11 -

Warnung

• Beforetakingothecontrolcover,

themainswitchmustbeturnedo!

• If the control is power supplied, its inner part is under

tension.

• Inordertoavoidelectricalstrokes,thesafetyregula-

tionshavetobekept.

• The device may only be connected by trained

professionals.

• Theproductisnotsuitableforinstallationinexplosion-

hazardousareas.

• Anall-poledisconnectingmainsswitchwithacontact

openinggapofmin.3mmhastobeforeseen.The

barrier facility has to be secured according to the

validsafetyregulations!

• IMPORTANT:Thecontrollines(buttons,radio,pho-

tocells,etc.)havetobelaidseparatelyfromthe230V

lines(supplyline,motors,signallamp).

Power supply 230V

blinking light

BOLLARD 4

BOLLARD 3

BOLLARD 2

BOLLARD 1

RED-light inside

GREEN-light inside

RED-light outside

GREEN-light outside

Bollard limit contact switch –

contact

Bollard limit contact switch +

signal output for bollard service

24V (if service needed) / max. 1W

Induction loop 2

Induction loop 1

Photocell (PHC) contact outside

Photocell (PHC) contact inside

Power supply PHC receiver

Power supply PHC transmitter

Impulse button outside

Impulse button inside

Stop button

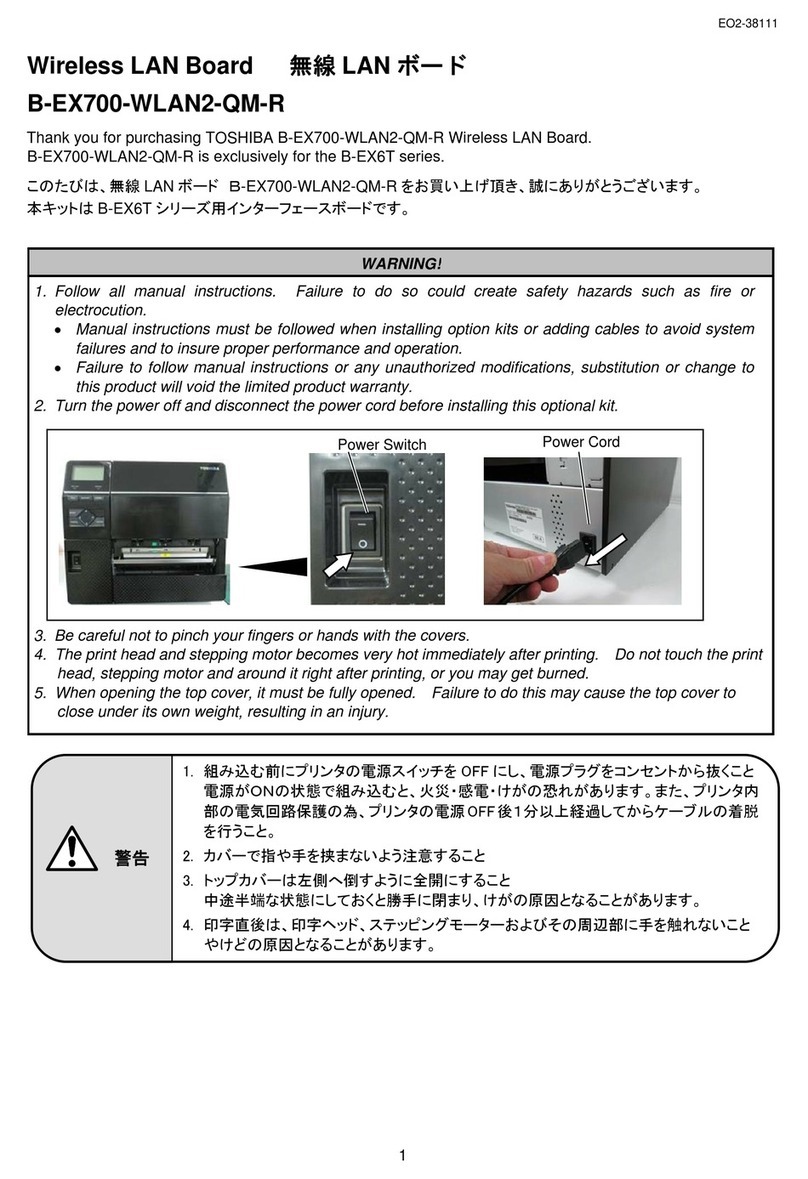

3.1 TerminalblockX1 ST40withtraclights

Ifnostopswitchisconnected,terminals

X1:30/31havetobewire-bridged!

Jumperisalreadyset.

onlyactiveif

induction loop de-

tector connected

Ifconnectingthebollards,pleasemindthenumbering1–5oftheconnec-

tionleads!

(1–3:opening/closingofthebollard,4–5:230Varerelevantforthe

bollard´sLED-lightsandfortheloweringvalve)Incaseofpowerfailurethe

loweringvalveensurestheautomaticopeningofthebollard.

Foreachbollardthe31,5µFcapacitorisconnectedbetweenterminals20/22.

page 17:

Connection of more

bollard limit contact

switches.

terminalblockX1

31,5µF

31,5µF

31,5µF

31,5µF

3

2

1

5

4

blue (–)

black

brown (+)

Buttons photocells I-loops

service limitswitch

OUSIDE INSIDE Bollard1 Bollard2 Bollard3 Bollard4 230Va.c.

30 31 30 32 30 38 41 42 43 44 45 46 45 48

9/1 9/2 9/3 9/4

65 66 68

97 699 6

96698 6L N 20 21 22 L N 20 21 22 L N 20 21 22 L N 20 21 22 10 11 L N

–

+

3

2

1

5

4

3

2

1

5

4

3

2

1

5

4

–

+

The stop input has no emergency stop

function!-Inordertoensuretheemergen-

cystopfunction,providethesupplyline

withanall-poledisconnectingemergency

stopswitch,thatlocksafteractuation!

- 12 - tousek / EN_ST40A_02 / 27. 01. 2020

• Theprogrammenuisdividedinto“BASICSETTINGS”and“MENUCONTROL”

–

ESC ENTER

+

text display

Programmingbuttons Adjustment-overview

• Thetextdisplay(T)informsyouaboutoperatingstatus,

chosenmenusandtheadjustmentofvariousparameters.

• Theprogrammingofthecontroliscarriedoutwiththehelp

offourbuttons(+,-,ENTERandESC).

• Scrolling through the available menu points (up/

down) or the adjustment of a parameter (value in-

crease/decrease) is carried out with buttons + and –.

AUTO-COUNT:whenholdingoneofthebuttonsthevalue

changesautomatically.

• When pressing the ENTER-button ea conrmation for

enteringtheshownmenupoint,resp.foracceptingthe

shownvalueofaparameterisgiven.

• WhenpressingtheESC-buttonyoureturntothesuperior

menupoint.Possiblychangedadjustmentsofaparameter

arerejectedwiththisbutton(theformervalueswillremain).

• AUTO-EXIT:ifnobuttonispressedduring1min.thenthemenuswitchesautomaticallytothe“ready”menu(wihtout

savingchangedparameters).

3.2 Adjustments-overview ST40withtraclights

Thedierentmenupointsareindicatedasfollows:

=selectablesettings=factorysettings=statusdisplay

Gshowsthemenupointswhichareinthe“BASICSETTINGS”

BASICSETTINGS

• WhenenteringtheprogrammingofthecontrolunitforthersttimeyouwillseetheBASICSETTINGS

• Herethenecessaryadjustmentswhicharenecessaryfortheuseoftheoperator/barriercanbesetquickly.

• Foradvancedsettings/programmingpleasechoosethemenupoint“menu(control)”.

MENUCONTROL

• ForfutherprogrammingyouwillreachimmediatlytheMENU(CONTROL) (Basicsettingsareskipped)

• Themenucontrolincludesallkindsofsettings.

Programmingmenu Adjustment-overview

• Programmingviafourprogrammingbuttonsandtextdisplay.

• Beforestartingtheprogramming,pleasechoosethelanguage.Usethebuttons+or -tochoosemenulangu-

ageandconrmwithENTER.

• Note:LanguageselectioncanalsobechosenbypressingtheESCbuttonfor5s,fromanypositioninmenu.

tousek / EN_ST40A_02 / 27. 01. 2020 - 13 -

Mainmenu sublayer Settings/adjustments

Safety

see page 14

Ginner photocell active

not active

Gouter photocell active

not active

photocell function inside duringclosereverse

stop-afterreleaseopen

duringopenstop,thenopen

photocell function outside duringclosereverse

stop-afterreleaseopen

photocellpausetime noinuenceofphotocell

immediateclosingafteropening

photocell selftest active

not active

Bollard

see page 17

runtimeOPEN 3...90s [increment1] =20s

runtimeCLOSE 3...90s [increment1] =20s

operatingmode

see page 18

runtimecorrection -10...0...+10s [increment1] =0s

positionmonitoring deactivated

6h...24h [increment6]

lights/lapms

see page 18

prewarning OPEN deactivated

1...30s [increment1]

Green phase

5...120s [increment1] =20s

Leavetime

1...60s [increment1] =5s

TraclightgateCLOSED

OFF

constantred

Traclightlogic

bothsidesgreen

onesidegreen

peripher.devices

see page 19

serviceinterval not active

1000...50000cycles[increment1000]

servicereset NO

YES

diagnosis

see page 20

status display statusdisplay

factory settings NO

YES

softwareversion displaysoftwareversion

serialnumber displayserialnumber

operatingtime displaythenumberofcycles

protocol displaytheprotocolmessage

BollardcontrolboardST40withtraclights

+

–

Menu structure Adjustment-overview

ESC ENTER

Note:someadjustmentsregardingfunctionoroperatinglogiccanonlybeexecutedifbarrierisclosedandifthedisplayshows„ready“.

- 14 - tousek / EN_ST40A_02 / 27. 01. 2020

Safety Connectionsandadjustments

Importantnotestophotocells

• Thecontrolunithasapowersupplyconnectionfora24Va.c.photocell(PHC):

teminalblockX1:supplyPHC-transmitter:41/42/supplyPHC-receiver:43/44

Hinweis:in„closed“positionterminalsX1:41/42arebeingswitchedintoenergysavingmode(nocurrent)

(onlyifthereisnoradiotransmissionsystemTX310connected)

• The contact has to be closed when using powered and positioned photocells. (opening contact).

ConnectionofthephotocellatterminalblockX1:inside:45/46,outside:45/48

• When using two pairs of photocells please do not

install both photocell transmitters/receivers on the

sameside(toeleminateinterferencebetweenboth)!

Exception:photocellswithSYNCfunctionallowthe

installation of both photocell transmitters/receivers

onthesameside.

• Photocellself-testfunction:

Thecontrolboardisequippedwithaself-testfunctionfortheconnectedphotocell.Withanopeningimpulse(switchor

button)thetransmitterofthephotocellisswitchedoforashorttimeinbarrierposition„closed“.Thusthephotocell

receiverinterruptsthecontact45/46(innerphotocell)bzw.thecontact45/48(outerphotocell)-sothecontrolboard

veriesthefunctionofthephotocellreceiver.Ifthisshortinterruptionatthephotocellinputisnotcarriedout,thecontrol

boardreportsanerror.

• Theexactfunctionofthephotocellsdependontheprogrammingofthecontrolunit.

Photocell function please see menu point SAFETY / photocell with pause time).

• Youwillnddetailedinformationinthecorrespondingphotocellmanual.

Standard:

transmitter1 receiver1

receiver2 transmitter2

mitSYNC-Funktion:

transmitter1 receiver1

transmitter2 receiver2

• AgeneralstatusdisplayofallinputscanbefoundinthemenuDIAGNOSIS/STATUSDISPLAY

3.3. Connectionsandadjustments ST40withtraclights

Warning

• Beforetakingothecontrolcover,the

mainsswitchmustbeturnedo!

• If the control is power supplied, its inner part is under

tension.

• Inordertoavoidelectricalstrokes,thesafetyregula-

tionshavetobekept.

• Thedevicemayonlybeconnectedbytrainedprofes-

sionals.

• Theproductisnotsuitableforinstallationinexplosion-

hazardousareas.

• Anall-poledisconnectingmainsswitchwithacontact

openinggapofmin.3mmhastobeforeseen.The

barrier facility has to be secured according to the

validsafetyregulations!

• IMPORTANT:Thecontrollines(buttons,radio,pho-

tocells,etc.)havetobelaidseparatelyfromthe230V

lines(supplyline,motors,signallamp).

Thedierentmenupointsareindicatedasfollows:

=selectablesetting=factorysettings=statusdisplay

Gshowsthemenupointswhichareinthe“BASICSETTINGS”

tousek / EN_ST40A_02 / 27. 01. 2020 - 15 -

Ginner photocell (contact:terminalsX1:45/46) Safety

active:tobeselected,ifinnerphotocellshouldbetriggered.

notactive:tobeselected,ifinnerphotocellshouldnotbetriggered.

Gouter photocell (contact:terminalsX1:45/48) Safety

active:tobeselected,ifouterphotocellshouldbetriggered.

notactive:tobeselected,ifouterphotocellshouldnotbetriggered.

Photocell function inside Safety

duringclosereverse:photocellinterruptionduringclosingcausesopening(movingdown)ofthebollard.Ifautomatic

operatingmodeisactivatedthebollardclosesafterthepausetimeisover.Ifimpulseoperatingmodeisactivatedyou

havetogiveaclosingimpulseagain.

stop - after release open:photocellinterruptionduringclosingoropeningcausesstopaslongasthephotocellstays

interrupted.Afterreleaseofthephotocellthebollardopens.Ifautomaticoperatingmodeisactivatedthebollardcloses

afterthepausetimeisover.Ifimpulseoperatingmodeisactivatedyouhavetogiveaclosingimpulseagain.

duringopenstop,thenopen:photocellinterruptionduringopeningcausesstopaslongasthephotocellstaysinter-

rupted.Afterreleaseofthephotocellthebollardopens(monitoringofthebackspace).Ifautomaticoperatingmode

isactivatedthebollardclosesafterthepausetimeisover.Ifimpulseoperatingmodeisactivatedyouhavetogivea

closingimpulseagain.

Photocell function outside Safety

duringclosereverse:photocellinterruptionduringclosingcausesopening(movingdown)ofthebollard.Ifautomatic

operatingmodeisactivatedthebollardclosesafterthepausetimeisover.Ifimpulseoperatingmodeisactivatedyou

havetogiveaclosingimpulseagain.

stop - after release open:photocellinterruptionduringclosingoropeningcausesstopaslongasthephotocellstays

interrupted.Afterreleaseofthephotocellthebollardopens.Ifautomaticoperatingmodeisactivatedthebollardcloses

afterthepausetimeisover.Ifimpulseoperatingmodeisactivatedyouhavetogiveaclosingimpulseagain.

Photocellpausetime(onlyouterphotocell) Safety

noinuenceofphotocell:thephotocellhasnoinuenceonthepausetime(greenphase)

immediateclosingafteropening:interruptionoftheouterphotocellduringopeningorinopenedpositioncauses

immediateclosingofthebollard.(=nogreenphase,nopausetime).Interruptionoftheinnerphotocellduringopening

causesstoppingorskippingofthegreenphase.

Photocell self-test Safety

active:Photocellself-testwillbetriggeredinclosedmodusifyougiveanopeningimpluse(buttororradioreceiver)

notactive:photocellself-testwillnotbetriggered

Attention

• Thephotocellself-testcanonlybedeactivatedbyselecting„notactive“.

• Thedeactivationoftheself-testfunctionisonlypermitted if the safety installations correspond to the

category3!

-16- tousek / EN_ST40A_02 / 27. 01. 2020

Important

• To activate the SYNC-function, the

plug-in bridges (J) in both photocell

transmitters have to be removed.

(see manual LS 41).

SYNC

J

Outer photocell

TousekLS41assafetydevice

Outer and inner photocell

TousekLS41assafetydevice

transmitter receiver

transmitter receiver

OUTSIDE:

INSIDE:

withactivatedSYNCfunction

Photocellconnectionexamples

Important

• TheJumperJhavetobeadjustedinthesameway

in the Photocell transmitter and in the photocell

receiver.

Outer photocell

TousekLS26assafetydevice

Outerreectionphotocell

TousekRLS610assafetydevice

N.O.

COM

N.C.

N.O.

COM

N.C.

X1

4142434445464548

transmitter receiver

N.O.

COM

N.C.

X1

4142434445464548

+

~

-

~

12/24V

J

+

~

-

~

12/24V

NC C NO J

transmitter receiver

X1

4142434445464548

24Va.c.

24–230V

a.c./d.c.

COM

NO

NC

COM

X1

4142434445464548

tousek / EN_ST40A_02 / 27. 01. 2020 - 17 -

RuntimeOPEN20s(factorysetting) Bollard

3–90sadjustable [increment1]:determinestheruntimeofthebollardopening

(fromendposition„closed“untilendpostion„open“).

RuntimeCLOSE20s(factorysetting) Bollard

3–90sadjustable [increment1]:determiniestheruntimeofthebollardclosing

(fromtheendposition“open”untiltheendposition“closed”).

Bollard Connectionsandadjustments

Connectingexample

inductivebollardlimitswitch24Vd.c.

X1

supply 230V

signal lamp

bollard 4

bollard 3

bollard 2

bollard 1

31,5µF

31,5µF

31,5µF

31,5µF

3

2

1

5

4

bollard1 bollard2 bollard3 bollard4 230Va.c.

L N 20 21 22 L N 20 21 22 L N 20 21 22 L N 20 21 22 10 11 L N

3

2

1

5

4

3

2

1

5

4

3

2

1

5

4

X1

with1bollard

blue (–)

black

brown (+)

limitswitch

65 66 68

–

+

blue (–)

black

brown (+)

blue (–)

black

brown (+)

blue (–)

black

brown (+)

blue (–)

black

brown (+)

with4bollards

limitswitch

65 66 68

–

+

X1

Warning

• Beforeconnectionworkspleaseturnothemainpowerswitch!

• Safetyrulespleaseseepage11!

Bollardconnection/Limitcontactswitch

• ATTENTION:Beforestarttheconnectionswitchthepowero!

• AlloftheconnectionshavetobeconnectedtotheterminalblockX1.

• TothecontrolunitST40canbeconnected4electro-hydraulikbollardsVSZ4(230Va.c.)incaseofsynchronouspro-

cessing.Pleasenotethenumbering1-5oftheconnectionleads!Theconnectionleads1-3arerelevantfortheopening/

closingofthebollard.Theconnectionsleads4-5arerelevantforthebollard´sLED-lights(bluelights)andforthelowering

valve.Incaseofpowerfailuretheloweringvalveensurestheautomaticopeningofthebollard(Bollard connection see

on the picture below).

• Foreachbollardthe31,5µFcapacitorisconnectedbetweenterminals20/22.

• ThebollardsVSZ4haveintegrated,inductivelimitcontactswitchesfortheopenposition.Ifthelimitcontactswitchis

activated,theinformation„bollardisinopenposition“willbetransmittedviatheinsidelimitcontactswitchrelaystothe

traclightcontrolboardSTA11(term.60/61).(Limit contact switch connection see on the picture below).

- 18 - tousek / EN_ST40A_02 / 27. 01. 2020

Signallamp(terminalsX1:10/11)

• ATTENTION:Beforeconnection

workspleaseturnothemain

powerswitch!

• A signal lamp 230V, max. 40W

can be connected at terminals

X1:10/11.

230Va.c.

10 11 L N

X1

Runtimecorrectionswitchedo(factorysetting) Operatingmode

+10sopen...switchedo...+10scloseadjustable [increment1]:

Theruntimecorrectionisusedinhydraulicalsystemsinthereversalofthemovementdirectiontobalancethereaction

inertia(thetimeisneededforpressurebuild-up).Ifthehydraulicalbollardwillbereversedduringclosing,theendposi-

tion“open”maynotbereachedwiththeadjustedtime“runtimeOPEN”.Thisfailureiscanbesolvedbysettingalonger

intervallfor“runtimecorrection”forexample+3s.

Positionmonitoring Operatingmode

deactivated

6–24hoursadjustable[increment6]:toavoidthesinkingofthecylinderwithhydraulicbollards,youcansetunder

themenupoint„Positionmonitoring“anintervall,inwhichthebollardswillbereadjusted.

Operatingmode Connectionsandadjustments

Lights/Lamps Connectionsandadjustments

Prewarning OPEN Light/Lamps

turnedo

1–30sadjustable: Beforeeachopeningmovementthe

signallamp/ashinglightisactivatedfortheadjusted

time..

Green phase 20s(factorysetting) Light/Lamps

5–120sadjustable[increment1]:durationofthegreenphase.

Leavetime5s(factorysetting) Light/Lamps

1–60sadjustable[increment1]:timetoleavethetraclightintermediatearea.

TraclightgateCLOSED Light/Lamps

OFF:redtraclightdoesnotilluminateinclosedposition.

Constantred:redtraclightilluminatesalsoinclosedposition.

Traclightlogic Light/Lamps

bothsidesgreen:bothtraclightsilluminateinopenpositionGREEN,regardlessofwhichsidehasbeengiventhe

greenrequest.

onesidegreen: onlythetraclightilluminatesinopenpositionGREEN,fromthesidefromwherethegreenrequest

hasbeenrequested.

Warning

• Beforeconnectionworkspleaseturnothemainpowerswitch!

• Safetyrulespleaseseepage11!

tousek / EN_ST40A_02 / 27. 01. 2020 - 19 -

Serviceinterval Peripherials

notactive

1000-50000cyclesadjustable[increment1000]:Thecountofthecyclesuntilthenextservice.Ifthecyclescounter

reachesthistarget,theserviceoutputisundervoltage(24Vd.c.)(terminalblockX1clapms:53(+)/54(-))

Servicereset Peripherials

NO

YES:Thenewcyclestatuswillbecalculated,sothecurrentcyclestatusandtheadaptedserviceintervallwillbeadded.

ThesignaloutputwillbezeropotentialuntilthecalculatedService-cycle-statusisreached.

Peripherials Connectionsandadjustments

Serviceoutput

• Incaseofpendingbollardservice,thereisontheservice

output(term.X1:+/–) a 24Vd.c.voltageforindicator

lightsorsimilar.

• Iftheserviceispendingornot,dependsontheservice-intervallsettingsandonthe„service-reset“date.Thecomple-

tedcycleswillberecordedbythecyclecounter.Thisstatusofthecyclecounterwillbethe„service-intervall“ifyoudo

the„service-reset“.Itdeterminiestheamountofthecyclesuntilthenextservicedate,Ifthecyclecounterreachesthis

targetstatus,theserviceoutputwillbeundervoltageuntilyoumakea„service-reset“oryousettheserviceintervallto

„NOTACTIVE“(=factorysettings).

Traclight(terminalsX1:inside:RED:6/98,GREEN:6/96,outside:RED:6/99,GREEN:6/97)

• ATTENTION:Beforeconnectionworkspleaseturnothemainpowerswitch!

• On the trac light (terminal block X1) output can be connected two RED/

GREENtraclights(230V,max.60W). see picture

230Vmax.60W

light outside

red

green

6

98

6

96

6

99

6

97

red

green

light inside

X1

service

+–

–

+

Service output

(24V / max. 1W)

-20- tousek / EN_ST40A_02 / 27. 01. 2020

Note:Thefactorysettingsofthesinglemenu

pointsaremarkedwith inthismanual

$$$$$$$$$$$$$$$$

$$$$$$$$$$$$$$$$

I P C S Pi Po 12

o o o oo

$$$$$$$$$$$$$$$$

$$$$$$$$$$$$$$$$

I P C S Pi Po 12

o o o - - oo

Diagnosis Connectionsandadjustments

Statusdisplay Diagnosis

Statusdisplayontextdisplayforinputslikephotocell,contactedge,stopswitch,impulseswitch....

I impulsebutton notinuse

P partialopening notinuse

C CLOSE-button notinuse

S STOP-button

Pi photocellinside

Po photocelloutside

1 inductionloop1

2 inductionloop2

Factorysetting Diagnosis

NO:noresetbacktofactorysettings

YES: resetbacktofactorysettingsanddeletethe

adjustedlimits.Theendposistions(limits)willbe

redeterminedafterimpulse.

Softwareversion Diagnosis

showsthesoftwareversionondisplay

Serialnumber Diagnosis

showstheserialnumberontextdisplay

operatingtime Diagnose

showsthecompletedcycles

Protocol Diagnosis

showstheprotocollistondisplay: alleventsthattakeplaceareprotocolledinthislist.

withthebuttons+and-thesingleeventscanbeseen:

STOPP-buttonandphotocellinside/outsidenottriggered

Allotherinputsarenotactive.

e.g.

$$$$$$$$$$$$$$$$

$$$$$$$$$$$$$$$$

T -00 00:00:00.0

Event

With* theprotocolbeginning

hencetheendisshown

eventtype

Timesincethelastevent:

DAYS HOURS:MINUTES:SECONDS

STOPP-buttonandInnerphotocellaretrigered.

Outerphotocellistnottriggered.

Allotherinputsarenotactive.

$ Status:nottriggered

$- Status:triggered

$x Status:contactstripnotconnectedordefect

$o Status:contactstriporphotocelldeactivatedinmenu

Table of contents

Other tousek Control Unit manuals