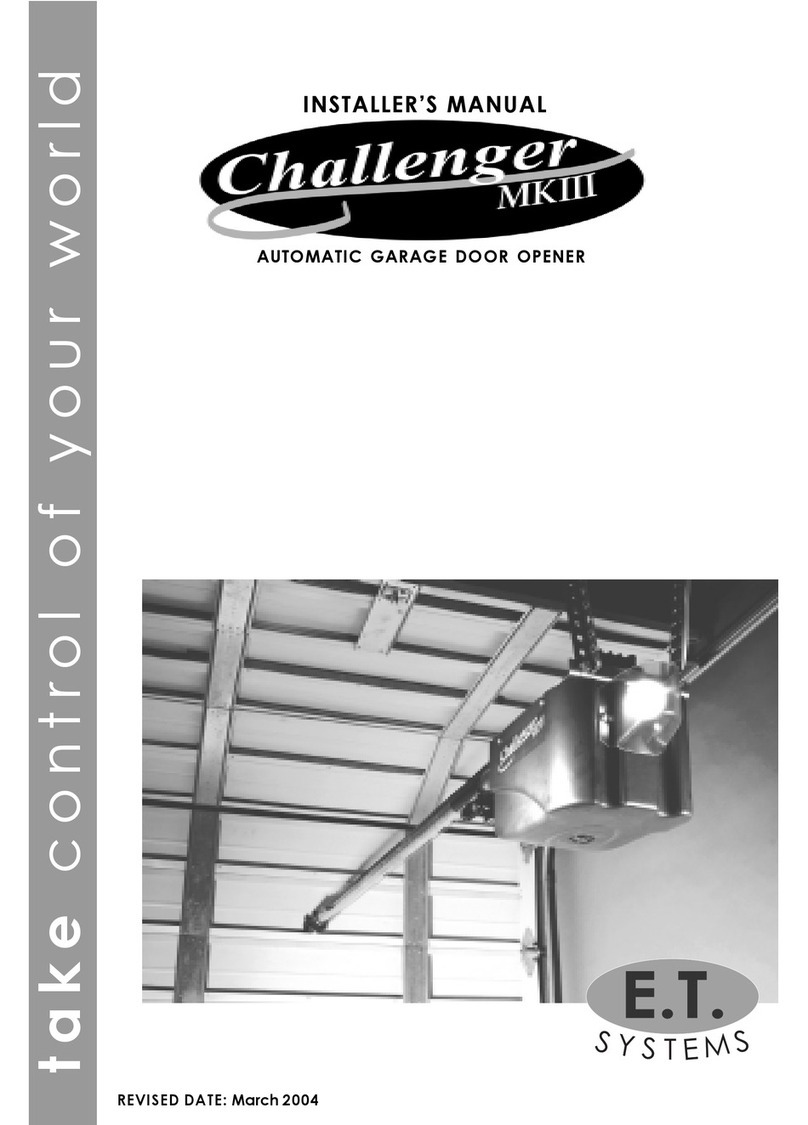

- 2 - tousek / EN_GTZ-Digital_07 / 10. 10. 2019

This manual is the sole property of the TOUSEK Ges.m.b.H. and may not be made available to competitors. All rights reserved. No part of it may be reproduced without our prior

written permission. We will not accept liability for any claims resulting from misprints or errors. This edition of the manual replaces all earlier publications of the same.

Index

About this document......................................................................................................................................... 4

Explanation of symbols .................................................................................................................................... 3

1. General safety information............................................................................................................................ 4

1.1 intended use............................................................................................................................................... 4

1.2 Target group .............................................................................................................................................. 4

1.3 Warranty .................................................................................................................................................... 4

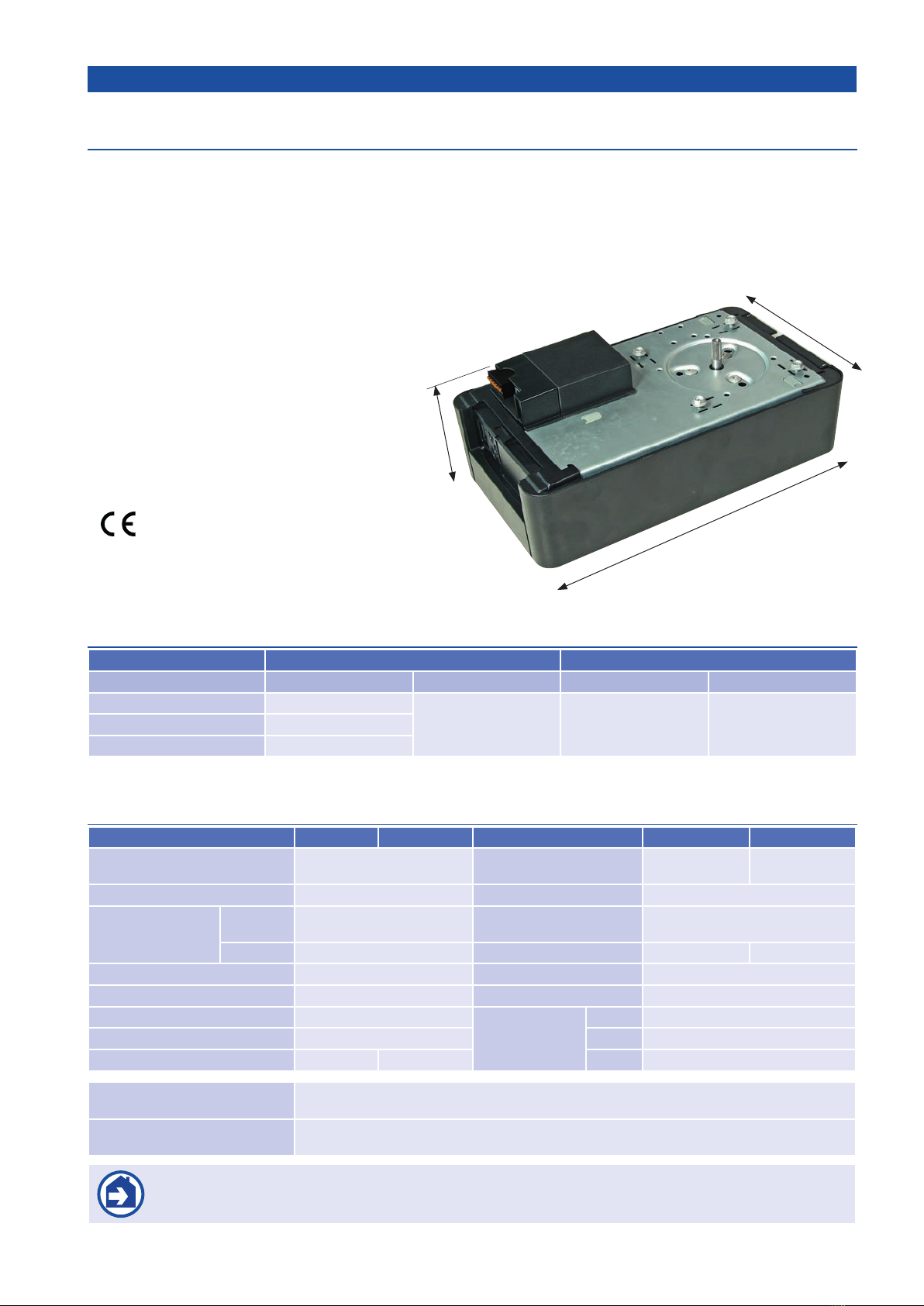

General features, application, technical Details.......................................................................................... 5

2. Scope of delivery............................................................................................................................................ 6

3. Door system.................................................................................................................................................... 7

4. Mounting ........................................................................................................................................................ 7

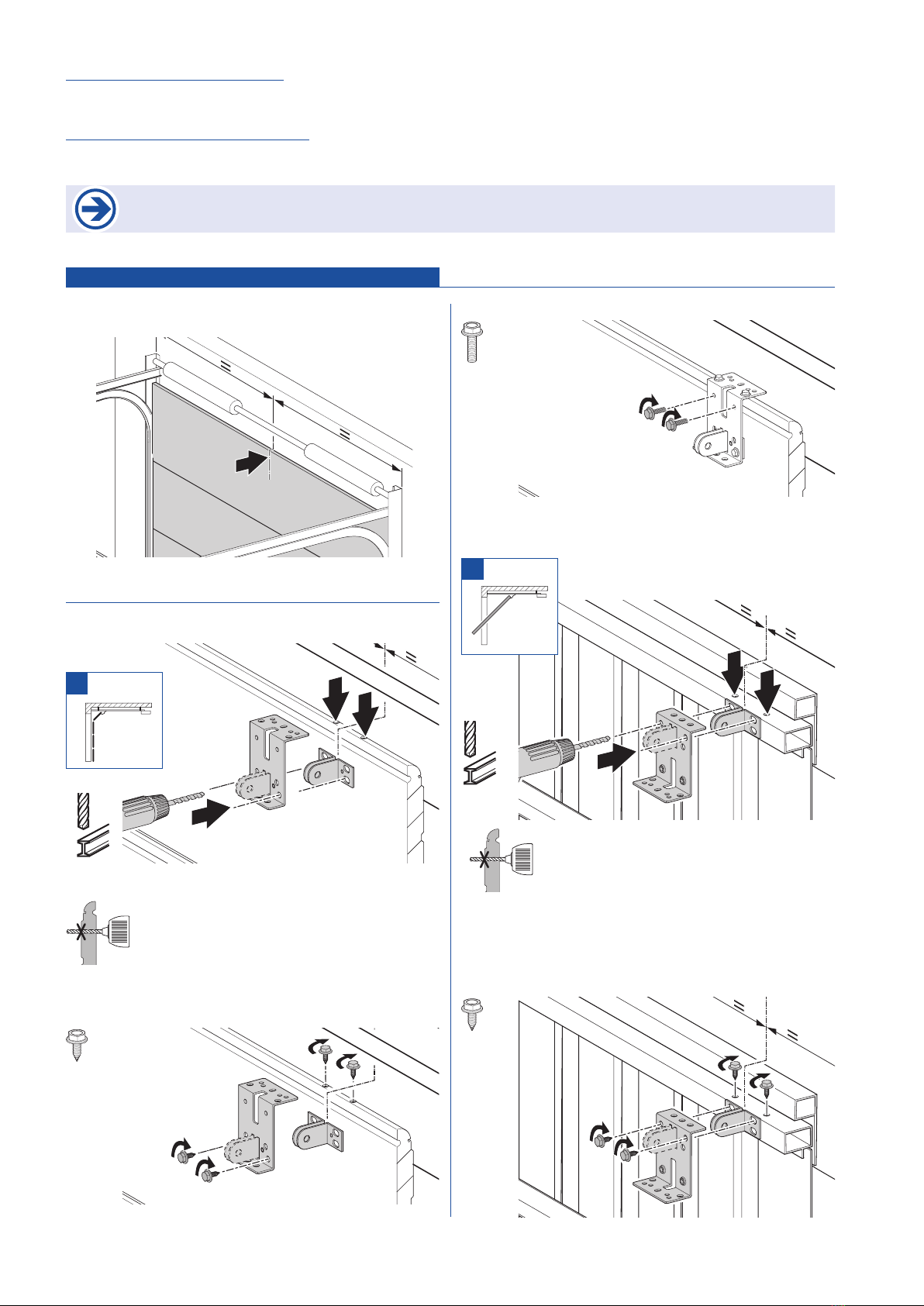

4.1 Installation preparation ............................................................................................................................... 7

4.2 Mounting..................................................................................................................................................... 8

4.3 Control connections.................................................................................................................................. 11

4.3.1 Overview of control connections......................................................................................................... 11

4.3.2 Connection at terminal strip K............................................................................................................. 12

4.3.3 Connection of the receiver (preinstalled) ............................................................................................ 12

4.4 Mounting completion ................................................................................................................................ 12

5. Putting into operation.................................................................................................................................. 13

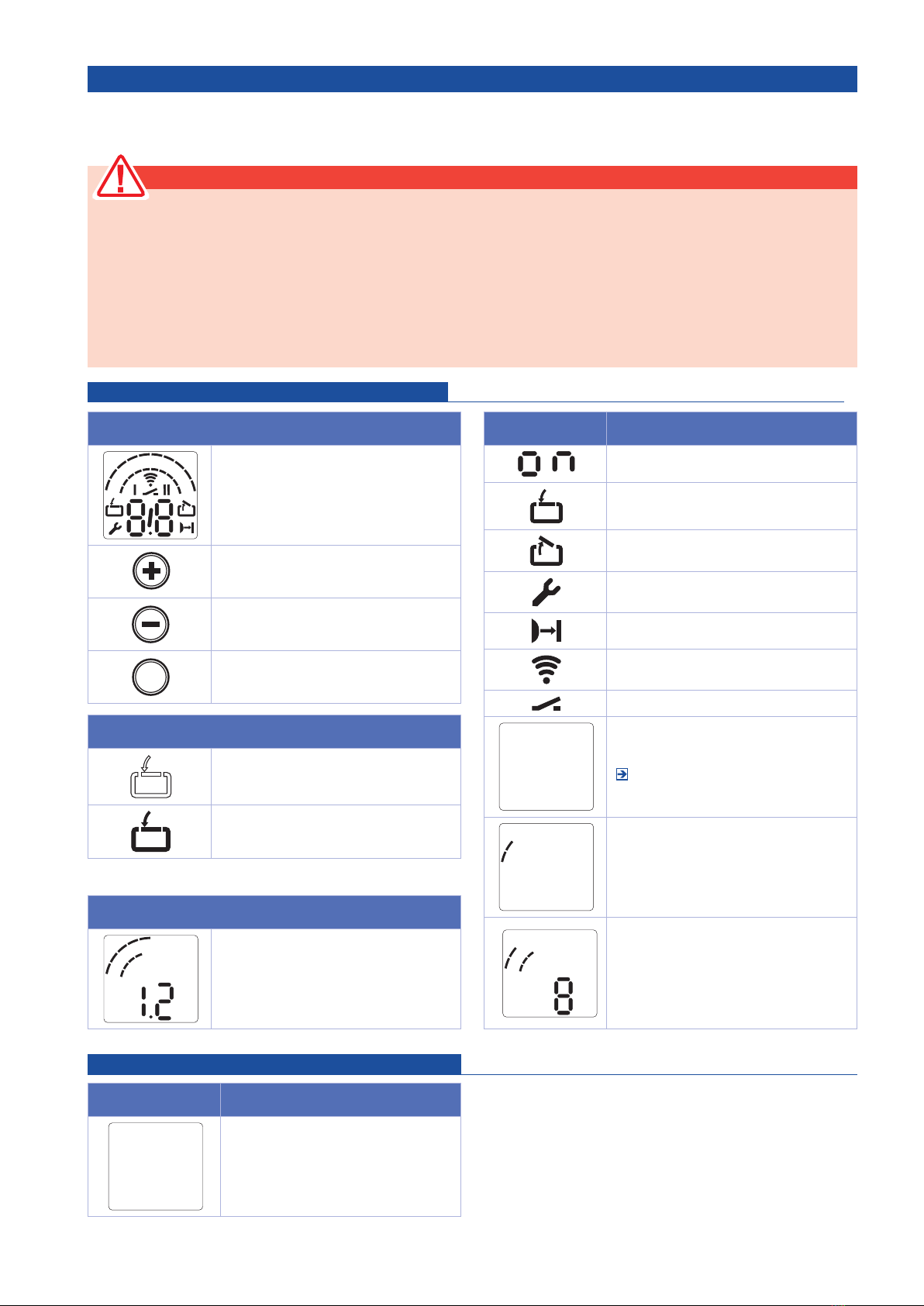

5.1 Overview central unit................................................................................................................................ 13

5.2 Status display ........................................................................................................................................... 13

5.3 Quick programming .................................................................................................................................. 14

5.4 Factory settings ........................................................................................................................................ 15

5.5 Function test............................................................................................................................................. 15

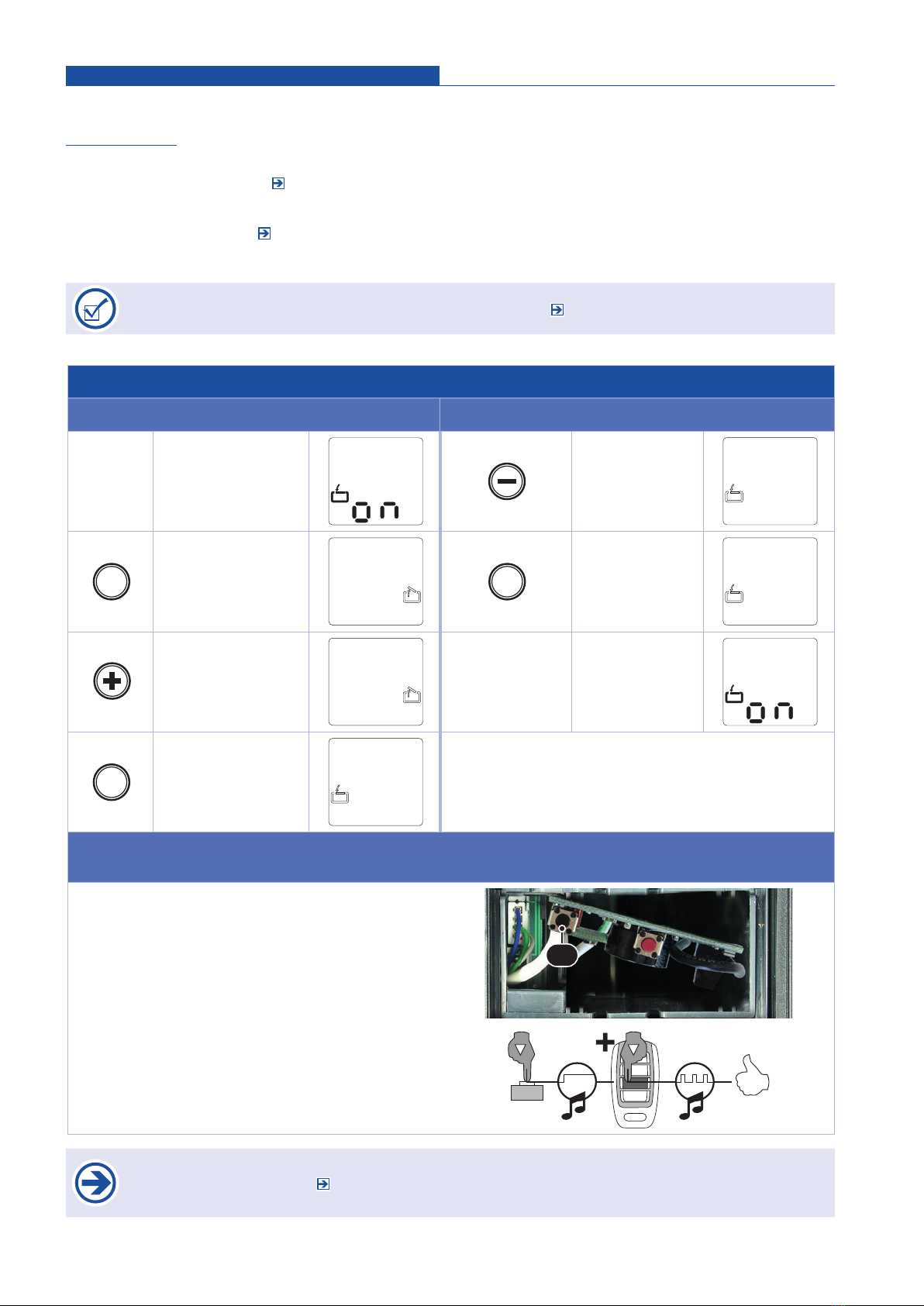

5.5.1 Learning cycle..................................................................................................................................... 15

5.5.2 Automaticswitch-ocontrol................................................................................................................ 15

5.5.3 Photocell test ...................................................................................................................................... 15

Special points regarding the door-frame photocell ............................................................................. 15

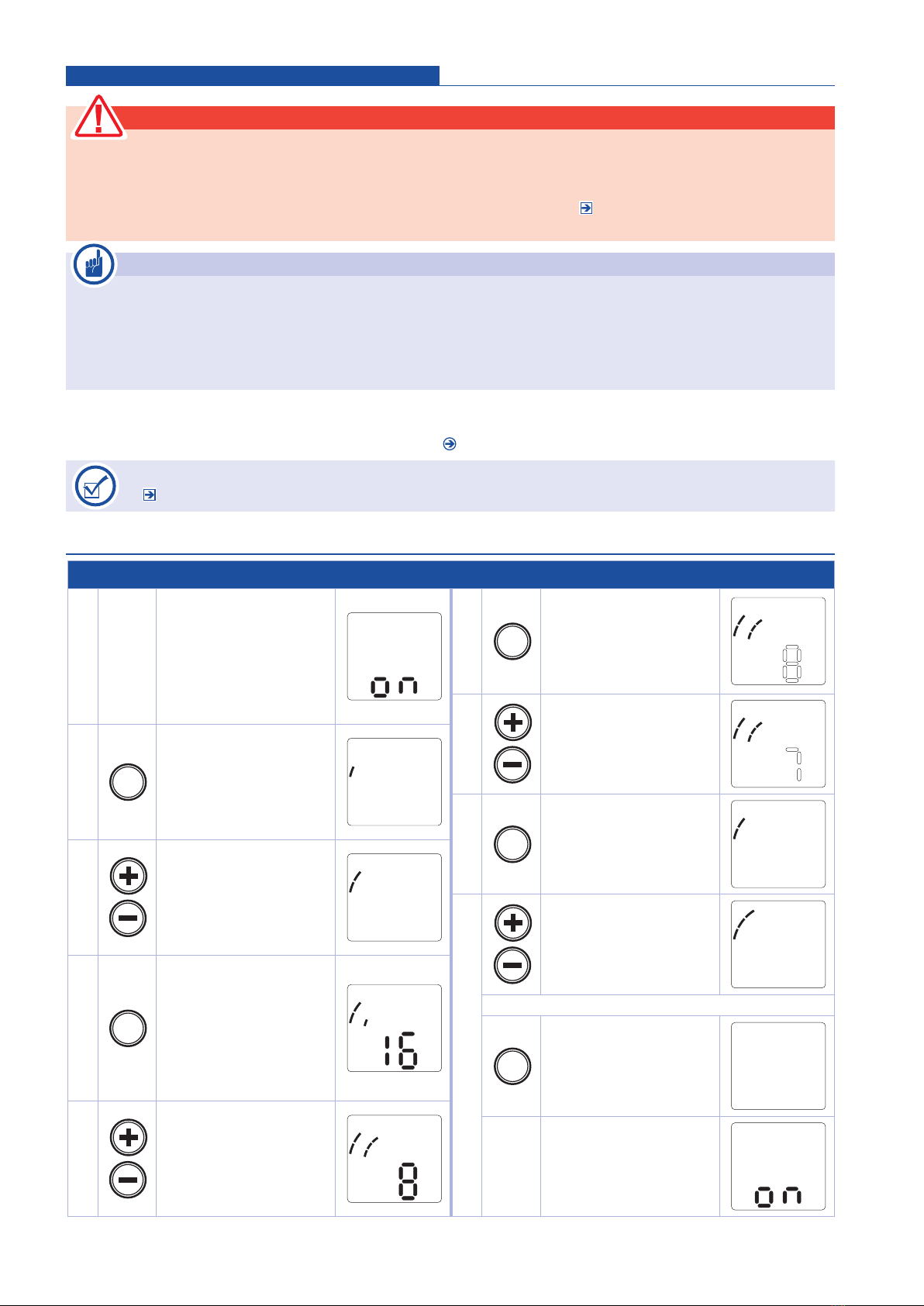

5.6 Special programming................................................................................................................................ 16

5.6.1 Programming the special functions..................................................................................................... 16

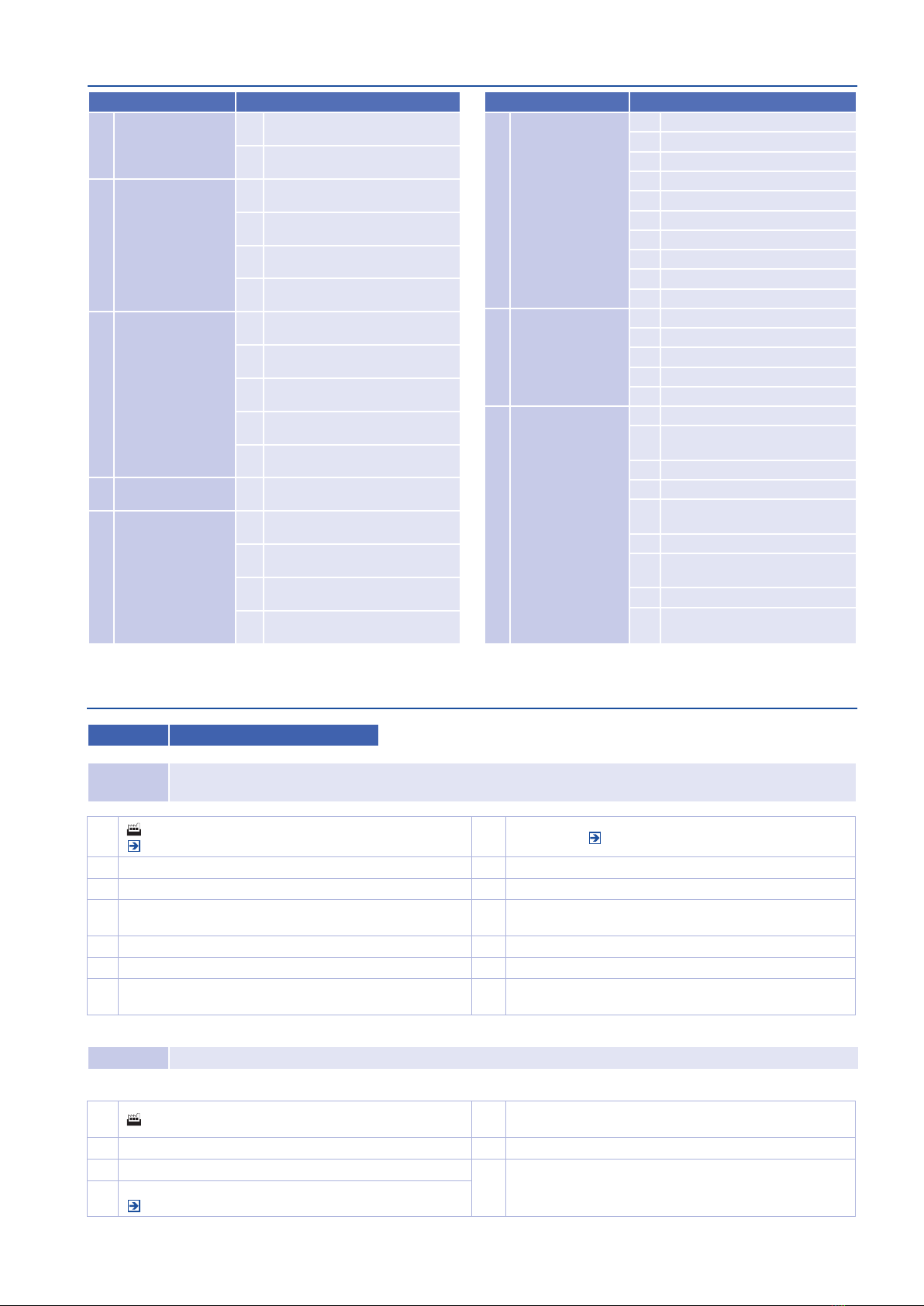

5.6.2 Overview on Special functions............................................................................................................ 17

5.6.3 Content of special functions................................................................................................................ 17

6. Operation ...................................................................................................................................................... 23

6.1 Transmitter ............................................................................................................................................... 23

6.2 Release .................................................................................................................................................... 24

7. Maintenance, care and cleaning ................................................................................................................. 25

8. Disassembly ................................................................................................................................................. 25

9. Disposal ...................................................................................................................................................... 25

10. Troubleshooting ........................................................................................................................................... 26

Faults with no fault messages .................................................................................................................. 26

Faults with fault messages ....................................................................................................................... 27

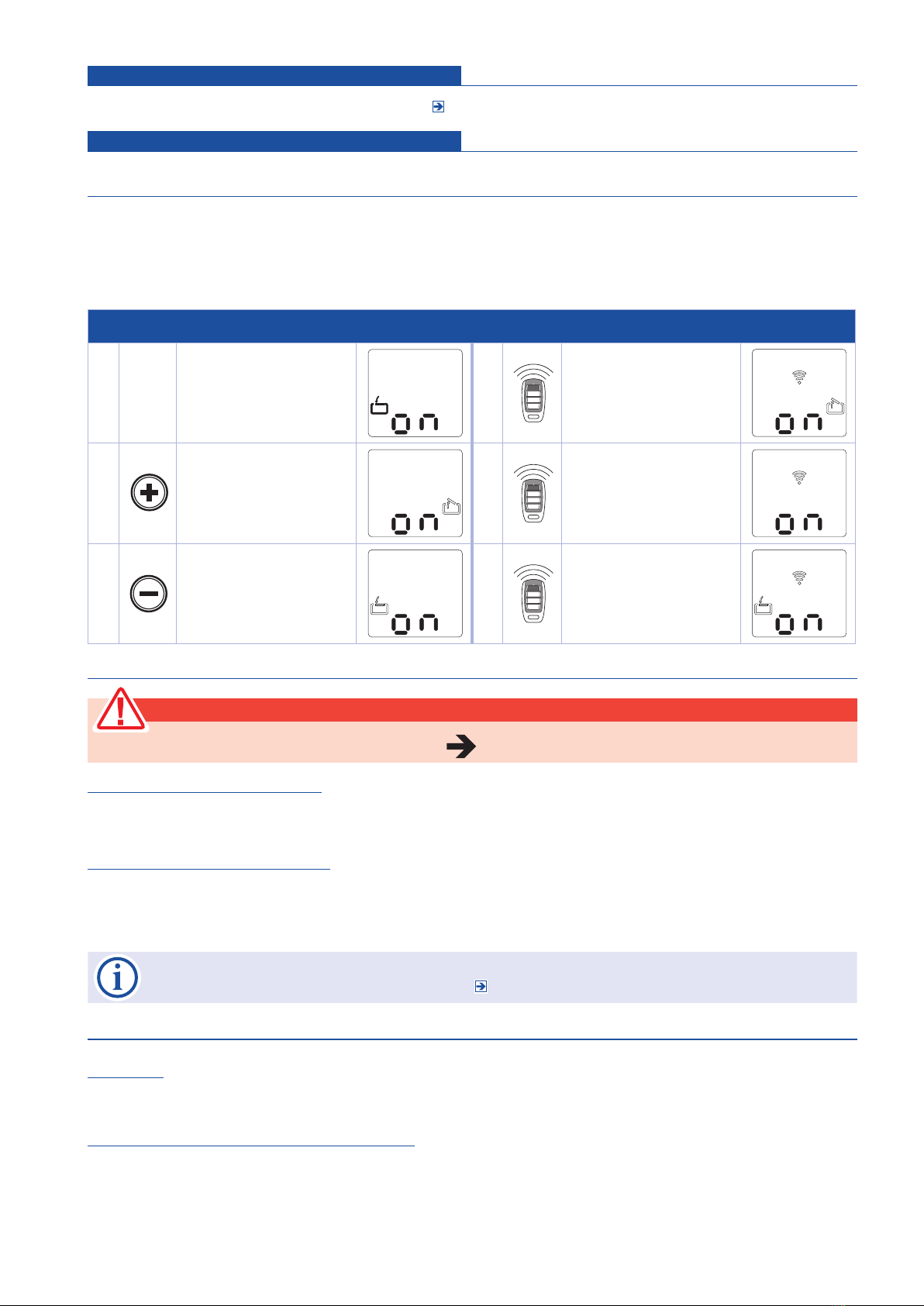

11. RADIO programming.................................................................................................................................... 28

Saving and deleting transmitters ............................................................................................................. 28

11.1 Saving a new transmitter.......................................................................................................................... 29

11.2 Deleting transmitters................................................................................................................................. 30

11.3 Troubleshooting and technical data radio RS 868................................................................................... 30

12. Photocell LS 55/3 (optional) ........................................................................................................................ 32

13. Flashlight module (optional) ....................................................................................................................... 34

14. Safety edge module (optional).................................................................................................................... 36

15. Dimensional drawing ................................................................................................................................... 38

Installation declaration ................................................................................................................................ 39