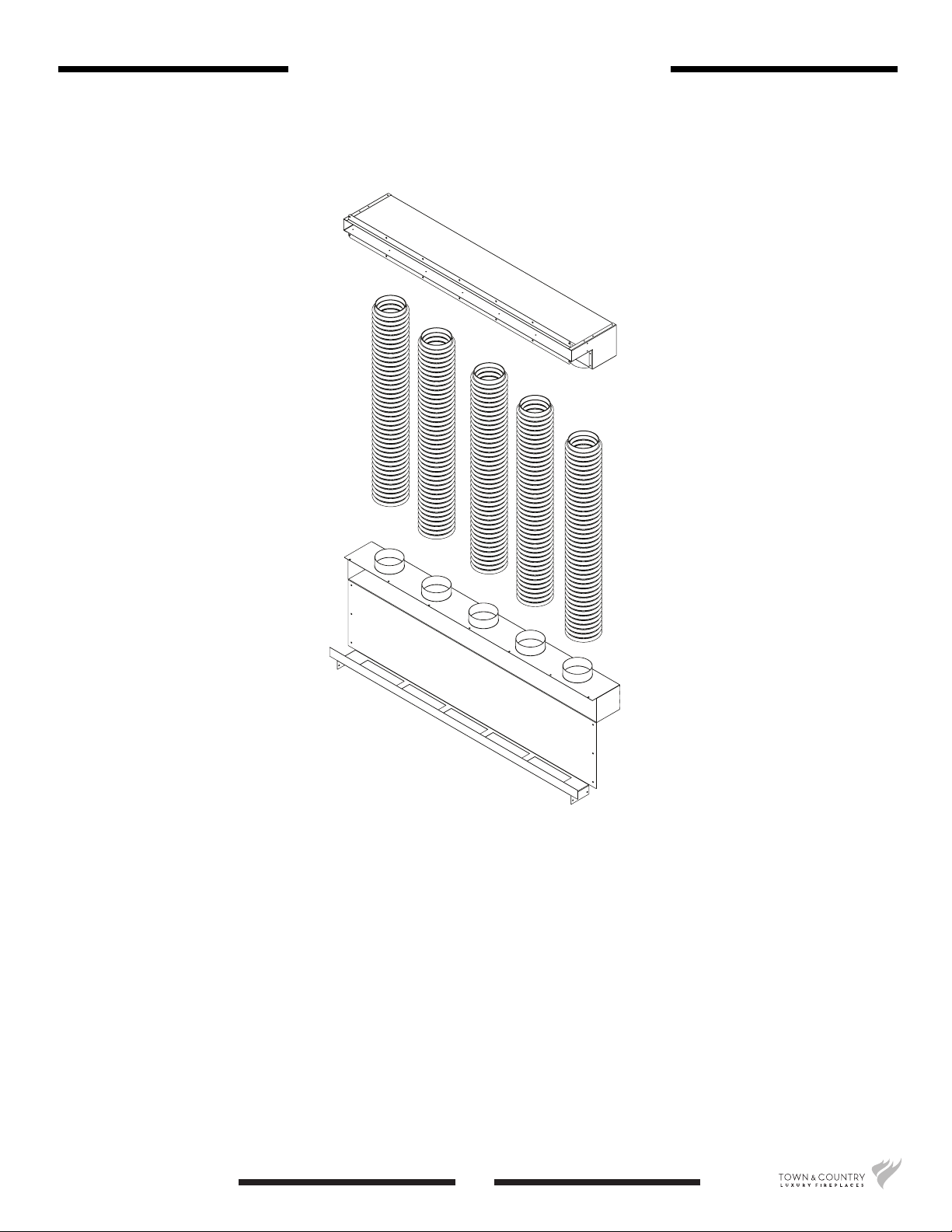

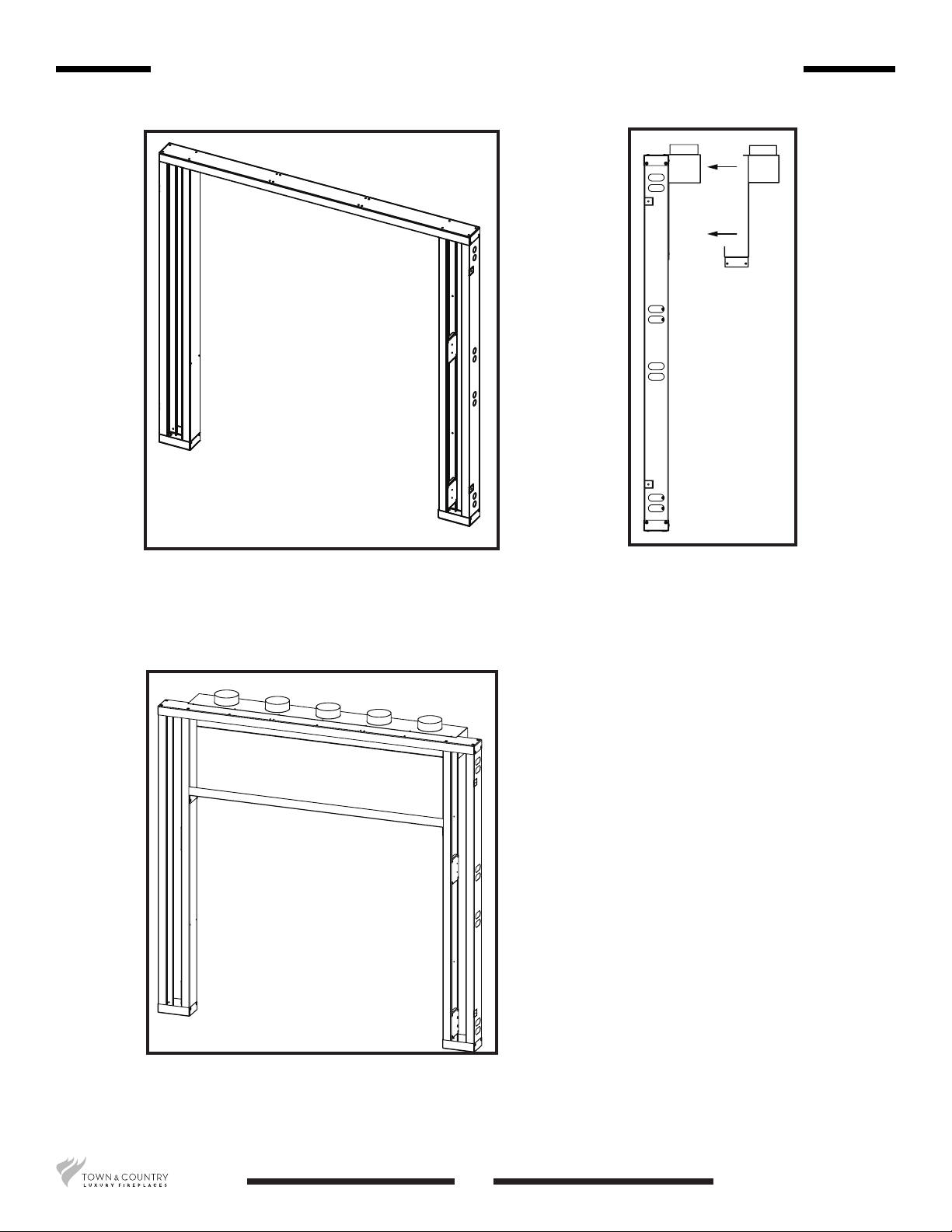

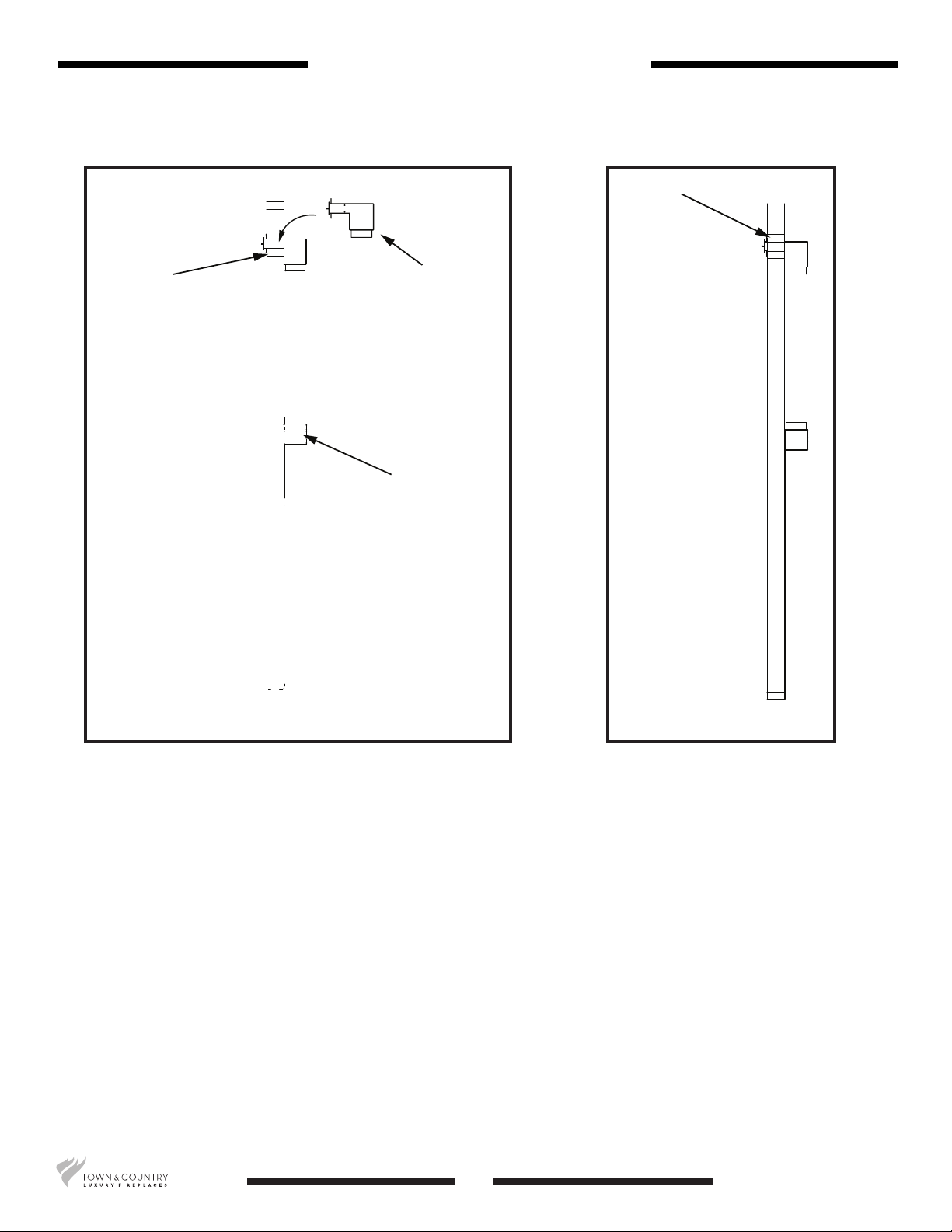

1. Top Frame Assembly

Lay out the horizontal header stud (Item #5 in Figure 1) on a large at surface. (Position all pieces on

their narrow edges as shown in Figure 1.

2. Attach Side Studs (Legs)

Lay the inner vertical side studs (Item #2 in Figure 1) so that it’s top end aligns with the 2nd set of

screw holes of the header stud (Item #5 in Figure 1). Fasten with screws provided.

Fasten the vertical outer side studs (Item # 3 in Figure 1) to the ends of the horizontal header stud

(Item #5 in Figure 1).

Position the base plates (Item #7 in Figure 1) at the bottom of the inner and outer side stud legs and

fasten with the screws provided.

Turn the assembled frame over and install screws to the remaining fastening points.

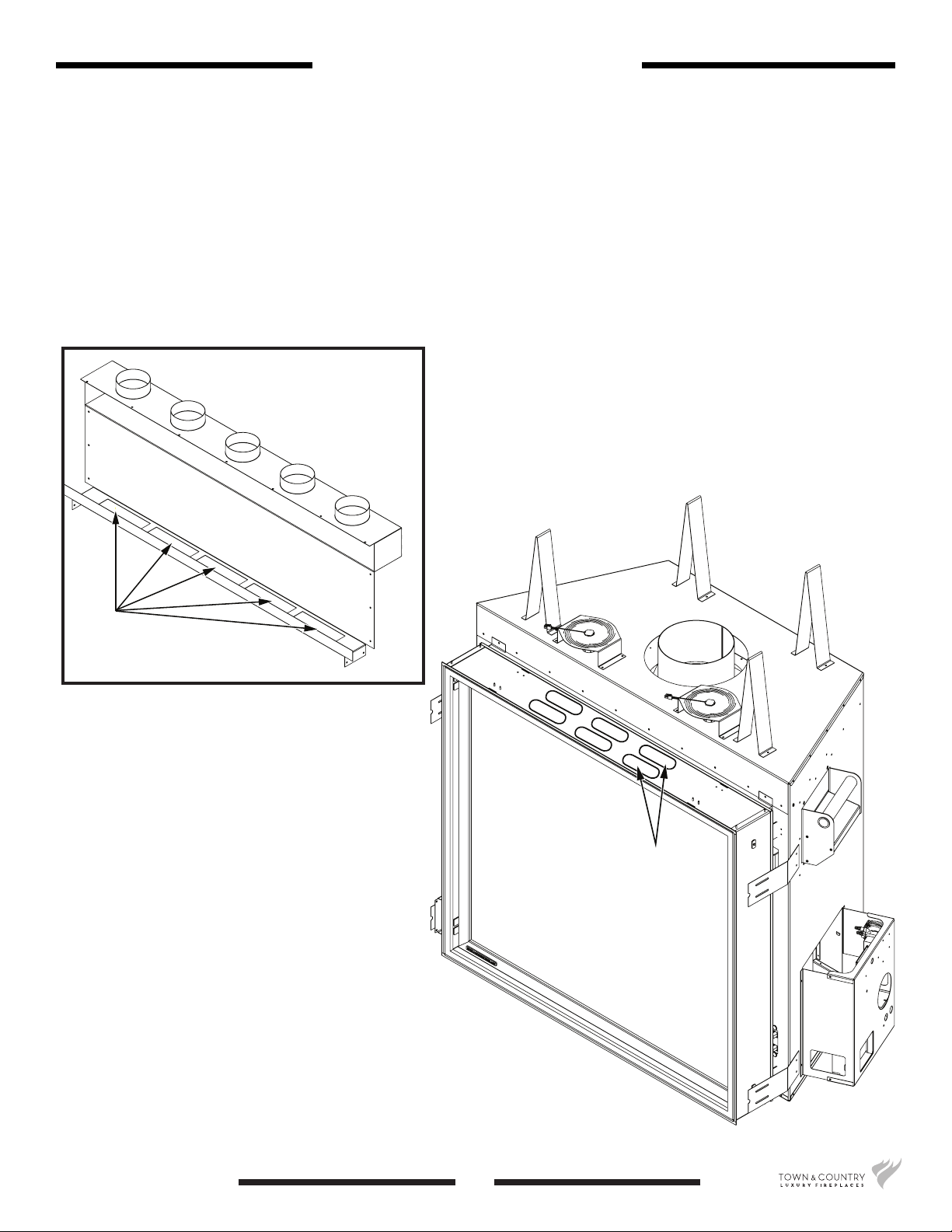

3. Attach Lower Venting Box to steel frame

Align and secure the Lower Venting Box to the steel frame with provided hardware prior to mount-

ing the steel frame and Lower Venting Box onto the TC42. See “Mounting the Lower Venting Box to

Steel Frame” on page 6.

4. Attach the Assembled Frame with the Lower Venting Box to the Unit

Align the assembled frame and Lower Venting Box to the TC42 and attach to the framing brackets

(Items #8 in Figure 1). Align the framing brackets to the fastening points through the access holes in

the outer side studs (Item # 3 in Figure 1).

5. Secure to Lumber Framing using four framing tabs

Bend the (four) framing tabs out and use to secure the steel frame assembly and the TC42 to the

lumber framing through the horizontal top header and the base plates (Items #5 & 7 in Figure 1).

6. Install Facing Material.

Install Facing Material according to the requirements described in “Distribution of Facing Material”

on page 14.

Steel Frame assembly instructions

5100001060

Cool Wall TC42 070918-16