TOYOTA ADVANCED LOGISTICS Bastian SOLUTIONS Shoe Sorter Manual

Installation and Maintenance Manual

Model: Shoe Sorter

Effective February 2022

Rev. D

Installation and Maintenance Manual: Shoe Sorter

___________________________________________________________________________________

Install ati on a nd Maint ena nce Manual : Sh oe S o rter

Published February 2022

Rev. D

2

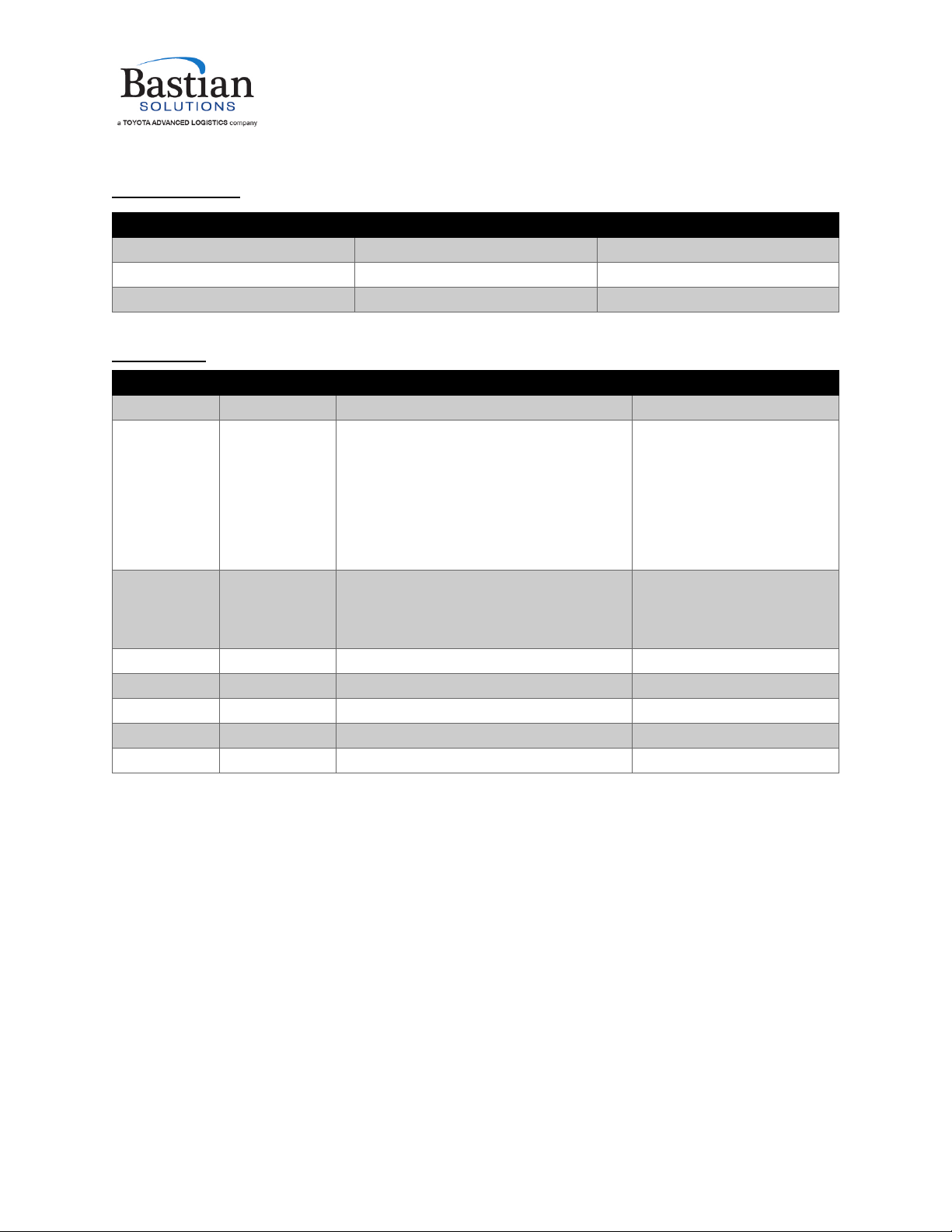

Contributions

ROLE

NAME

TITLE

Author Ben Baker Senior Design Engineer

Checker Evan Grimes Customer Service Engineer

Approver Sam Osterhout Design Team Lead

Revisions

DATE

REVISION

REVISION DESCRIPTION

AUTHOR

10/21/2019

A1

Initial document creation

Ben Baker

9/22/2020 B

Added info on sprocket alignment and

replacement; added info about decel

settings; crash gates added to

installation section; added tailshaft

encoder info to Controls section; added

several part numbers to GA drawings.

Changed all references to “ZiPline” to

“BSC” or “Bastian Solutions Conveyor”.

Ben Baker

5/3/2021 C

Updated GA drawing for divert switch;

revised distance recommendations

between knife edge and sorter infeed;

revised torque callouts on shoe bolts.

Ben Baker

10/12/2021

C1

Reformatting and Brand Update

Katie Smith

1/7/2022 Review D MKT final review Mark Fishback

2/18/2022

D

Document Formatting

Andrew W. Jones

Installation and Maintenance Manual: Shoe Sorter

___________________________________________________________________________________

Install ati on a nd Maint ena nce Manual : Sh oe S o rter

Published February 2022

Rev. D

3

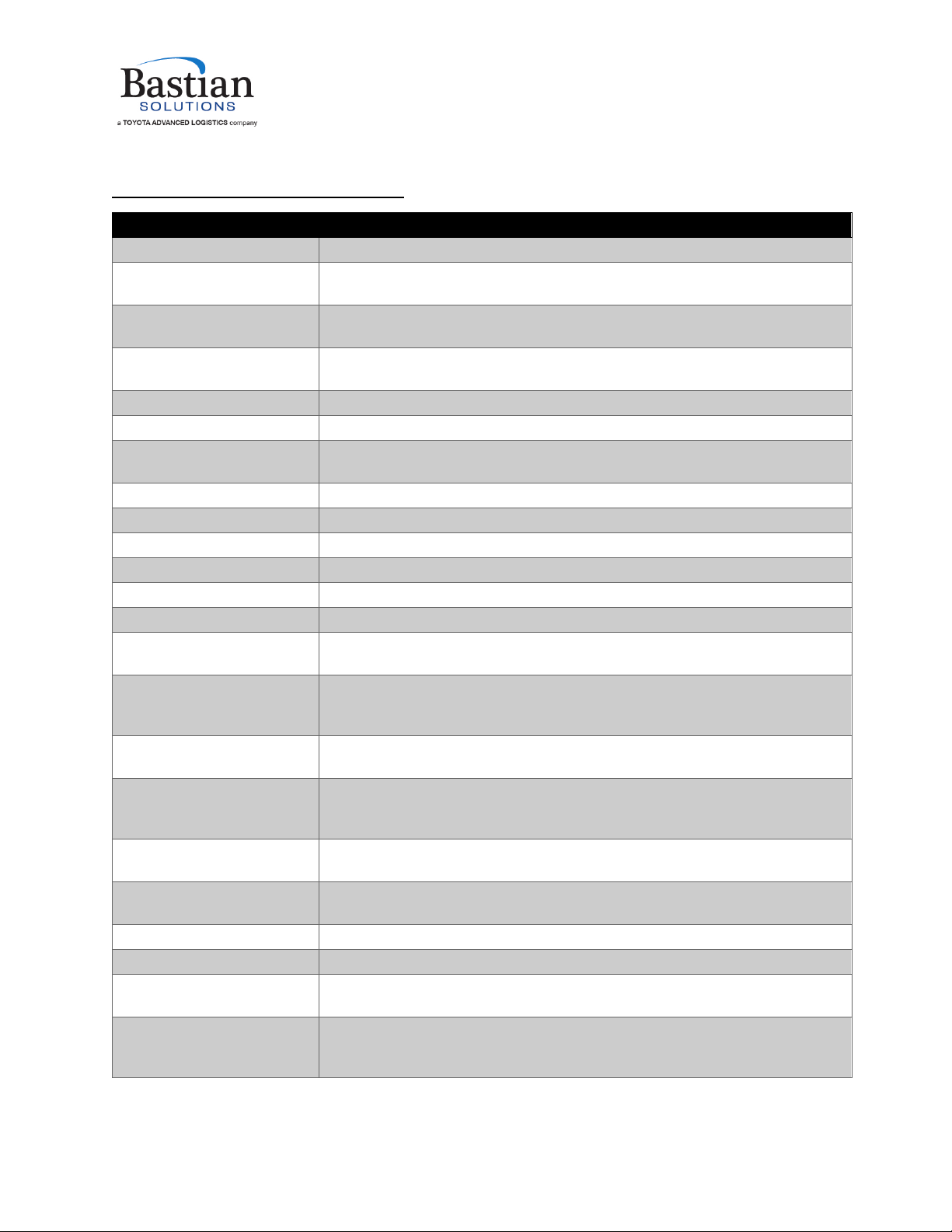

Term and Acronym Definitions

TERM/ACRONYM

DEFINITION

AC

Alternating current

Accumulation The collection or staging of multiple cartons, cases, or totes of product on

conveyor.

Back pressure Pressure against carton(s) in the direction of carton flow resulting from

weight of densely accumulated cartons.

BF Between frame; this refers to the distance between conveyor bed side

frames.

BHCS Button head cap screw

BOM

Bill of Materials

BRBDC Belted Roller Bed Direct Current; DC roller conveyor format driven by

brushless DC servo motors.

BSC

Bastian Solutions Conveyor

Carton or Case

Term for conveyable items generally contained in cardboard boxes.

CB

Carriage bolt

CCW

Counter-clockwise

CW

Clockwise

DC

Direct current

DC Card

A control card used to power and control the logic used when operating a

MDR in DC conveyor applications.

Diffuse

A photoeye format that houses both the emitter and receiver and senses

an object when the light beam is reflected back to the sensor. This type of

photoeye is a standalone unit and does not use reflectors.

Discharge The point where cartons, cases, or totes exit a conveyor or similar unit

used in a material handling system.

Divert

(noun) A conveyor unit used to change the direction of a carton, case, or

tote in a controlled manner. (verb) To change the direction of a carton,

case, or tote in a controlled manner.

Drive Pulley

A motor-driven pulley used to transmit rotational energy to linear motion in

AC belts.

E-stop A highly visible button or pull cable designed to shut down equipment in

the case of an emergency.

ETO

Engineered to Order; Orders requiring custom Engineering

FAT

Factory Acceptance Testing

Flange A feature in sheet metal consisting of a face and bend connected to an

existing face along a straight edge.

Gapping

The separation of cartons, cases, or totes which are initially in contact with

one another. Generally done by progressively increasing the speed of

consecutive zones, forcing cartons, cases, or totes to "pull a gap."

Installation and Maintenance Manual: Shoe Sorter

___________________________________________________________________________________

Install ati on a nd Maint ena nce Manual : Sh oe S o rter

Published February 2022

Rev. D

4

TERM/ACRONYM

DEFINITION

Guide Rail Mechanism used to maintain the desired position of conveyable cartons,

cases, or totes on their respective conveying surface.

HHCS

Hex head cap screw

HMI

Human-Machine Interface; an operating console or control panel of a

conveyor system.

HTL High Threshold Logic. In the context of an encoder, a differential push-pull

output intended to operate on 24VDC.

ID

Inner diameter of a circular, cylindrical or arced body.

Idler Roller Cylindrically-shaped material handling component that is unpowered and

used to support a belt.

Infeed The point where cartons, cases, or totes enter a conveyor or similar unit

used in a material handling system.

LOTO

Lockout Tagout

Mark Number

A numeric or alphanumeric term used to uniquely identify a conveyor bed

or collection of beds (of similar model type) within a material handling

system.

Match

A mark made on mating conveyor assemblies to assist in identifying

orientation and placement within a system.

MDR

Motorized drive roller; DC powered conveyor roller with an internally

mounted motor which may be controlled via internal or external

commutation.

MSD Master specification document; a document used to describe a product's

intended capabilities, appearance, and interaction with users.

NO

Normally Open

OAW

Overall width of any given conveyor bed.

OD

Outer diameter of a circular, cylindrical, or arced body.

O-Ring A plastic ring with a circular cross section used for power transmission in

DC conveyor applications.

OSHA Occupational Safety and Health Administration

OTD

On-Time Delivery

Photoeye

Device used to detect the presence of an object-such as a carton, case, or

tote-by use of an emitter and receiver (not necessarily in the same unit as

one another).

PM

Project Management (or Project Manager)

PO

Purchase Order

PPE Personal protective equipment

Proximity Sensor

(“Prox”)

A sensor able to detect the presence of nearby objects without any

physical contact. Typically an inductive sensor that detects nearby

electrically conductive (metal) objects.

Pulley Mechanical device used to change the direction of the belt in a conveyor

system, to drive and/or tension the belt.

Installation and Maintenance Manual: Shoe Sorter

___________________________________________________________________________________

Install ati on a nd Maint ena nce Manual : Sh oe S o rter

Published February 2022

Rev. D

5

TERM/ACRONYM

DEFINITION

Reflector A reflective component needed for retroreflective photoeyes to receive

transmitted light or radiation when no object is in front of the photoeye.

Retroreflective Of or relating to a surface or device that reflects light or other radiation

back to its source.

Return Idlers

Belt-routing rollers on the underside of any given AC conveyor.

RLSDC Roller Live Spur Direct Current; DC roller conveyor powered by live MDRs

and configured as a spur.

Roller

Powered or unpowered cylindrically-shaped material handling component

used for mechanical power transmission, a conveying surface, and/or

support for a belted conveying surface.

Shingling

Event in which surfaces of adjacent cartons, cases, or totes are forced to

lift off the conveyor due to elevated uneven carton, case, or tote back

pressure.

Shoe

A sliding element that engages with cartons, cases, or totes to divert from

a shoe sorter onto a spur.

Side Cover A PVC cover used to conceal and protect electrical components and wiring

from foreign debris and moving obstacles.

Side Frame

Structural member used to support rotating components needed for

conveyor beds.

Singulation

The active separation of cartons, cases, or totes.

Skatewheel Small unpowered wheels used to replicate nearly frictionless guidance or

support of conveyable cartons, cases, or totes.

Skew

A format of DC conveyor where one end of all rollers are shifted one roller

position to provide an angled conveying surface for left or right justification

of cartons, cases, or totes.

SKU Stock Keeping Unit; Product and service identification code for a product

(i.e. bar code).

Slug Collection of two or more cartons, cases, or totes that are in contact with

one another.

Snub Roller

A roller or pulley mounted to increase the arc of contact between a belt

and drive pulley. Additionally, this can be used to change the direction of

the return belt travel.

Sorter

Any piece of conveyance equipment used to divert a series of cartons,

cases, or totes simultaneously.

Splice Assembly

A five-component assembly-consisting of a plate (or formed plate), two

bolts, and two nuts-that is used to secure a piece of guide rail to an

adjacent piece of guide rail, or a side frame to an adjacent side frame. This

is used to provide additional structural rigidity and ensure relative position

of components is maintained.

SPST

Single Pole Single Throw; a type of electrical switch.

Spur

A format of DC conveyor used to create linear transitions into intersecting

lines of conveyor positioned at a non-perpendicular angle. Typically

includes 30deg and 22deg configurations.

Table of contents

Other TOYOTA ADVANCED LOGISTICS Industrial Equipment manuals