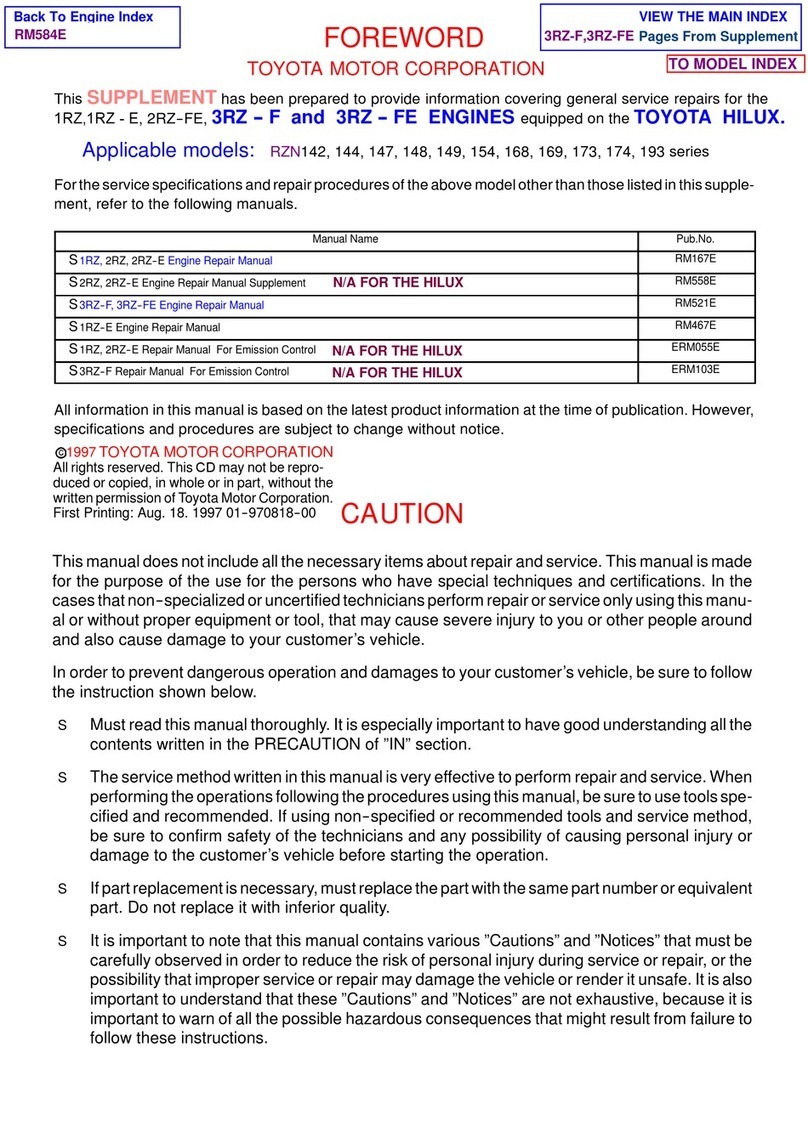

INTRODUCTION - General Repair lnstructions tN-5

Seal Lock Adhesive

CORRECT

Precoated Parts

Precoated parts are bolts and nuts, etc. Which are coated

with ? seal lock adhesive at the factory.

(a) lf a precoated part is tightened, loosened or caused to

move in any way, it must be recoated with the

specified adhesive.

(b) Recoating of Precoated Parts

(1) Clean off the old adhesive from the bolt, nut or

installation part threads.

(21 Dry with compressed air.

(3) Apply the specified seal lock adhesive to the bolt

or nut threads.

(c) Precoated parts are indicated in the component illus-

trations by the "*" symbol.

When necessary, use a sealer on gaskets to prevent leaks.

Carefully observe all specifications for bolt tightening

torques. Always use a torque wrench.

Use of special service tools (SST) and special service

materials (SSM) may be required depending on the nature

of the repair. Be sure to use SST and SSM where specified

and follow the proper work procedure. A list of SST and

SSM can be found at the back of this manual.

When replacing fuses, be sure the new fuse is the correct

amperage rating. Do NoT exceed the fuse amp rating or

use one of a lower rating.

Care must be taken when jacking up and supporting the

vehicle. Be sure to lift and support the vehicle at the proper

locations.

(a) lf the vehicle is to be jacked up only at the front or

rear end, be sure to block the wheels in order to

ensure safety.

(b) After the vehicle is jacked up, be sure to support it on

stands. lt is extremely dangerous to do any work on

the vehicle raised on a jack alone, even for a smalljob

that can be finished quickly.

12. Observe the following precautions to avoid damage the

parts:

(a) To disconnect vacuum hoses, pull on the end, not the

middle of the hose.

(b) To pull apart electrical connectors, pull on the con-

nector itself, not the wires.

(c) Be careful not to drop electrical components, such as

sensors or relays. lf they are dropped on a hard floor,

they should be replaced and not reused.

6.

the

s

ean

7.

8.

the

EC-

the

icle

0st,

ght

9.

10.

11.

nal

rOf

the

Do

is

lls,

;-

Dnt