3.3.2. PLATING

This is a process used to form a very thin plate on the surface of the Working Electrode

and only takes a few minutes to complete. The plating step is necessary prior to the

analysis of each element, however it is possible to analyse elements consecutively if they

share a common plating solution (e.g. Cd, Pb and Zn all use HG500 Hg Plating Solution).

Before carrying out the plating step, the Working Electrode surface must be polished to

remove any scratches and imperfections (see page X).

There are two preliminary steps required for any analysis with the Metalyser®. The

plating step uses the HG500 Hg Plating Solution, HG1000 Thick Hg Plating Solution or

AU500 Au Plating Solution, added to the SAB, to form a plate on the Working

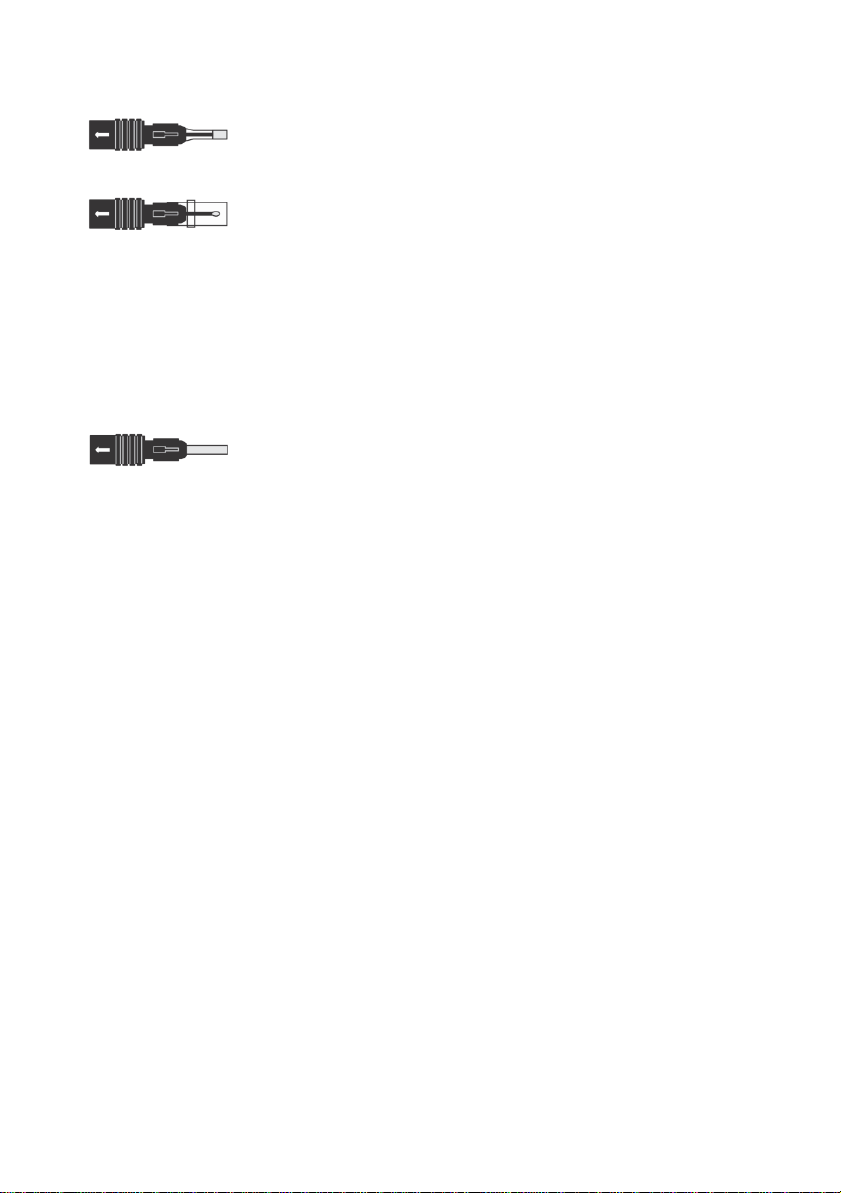

Electrode. After plating, the mirror-finish black tip is covered with a plate that is either

grey (Hg Plating Solutions) or yellow/ gold (Au Plating Solution) in colour.

The element being tested determines the plating solution required:

HG500 Hg Plating Solution –Cd, Pb, Cu, Zn

AU500 Au Plating Solution –Hg and As

HG1000 Thick Hg Plating Solution –Mn

AU1000 Thick Au Plating Solution –Cr(VI)

WE1 is used for Cd, Pb, Cu, Zn and Mn analysis

WE2 is used for Hg and As analysis

WE3 is used for Ni analysis

Chromium Electrode is used for Cr(VI) analysis only

It is necessary to perform the plating and conditioning before an analysis session or if

the sensitivity of the analysis decreases. This is because, over time, the plate will

reduce in thickness and eventually come off. Typically this will be after 20+ consecutive

samples or a period of 2-3 hours. It is therefore suggested to regularly re-plate the

electrode; if analysing a lot of samples, it is recommended to plate in the morning and

again at the beginning of the afternoon session.

If in doubt, remove the old plate by wiping the surface, polishing the tip of the Working

Electrode to a mirror-finish (with the polishing kit provided), then rinse with the wash

bottle and perform a new plating.

When analysing for elements requiring a plate different to the one currently being used,

the electrode not in use will need to be removed from the sonde to prevent

interference. It is advised to group together analyses using the same plate to save

switching between them.

The conditioning of the electrode occurs when the element of interest is selected in the

Test Methods menu and then choosing condition electrode, which is at the top of the

list for the selected electrode. The conditioning step should be carried out in sample

water, and undertakes a run which sensitises the Working Electrode.