Contents

Introduction

2

EMC according to guideline 2004/108/EEC

Introduction........................................................................................................................2

Handling instructions..........................................................................................................3

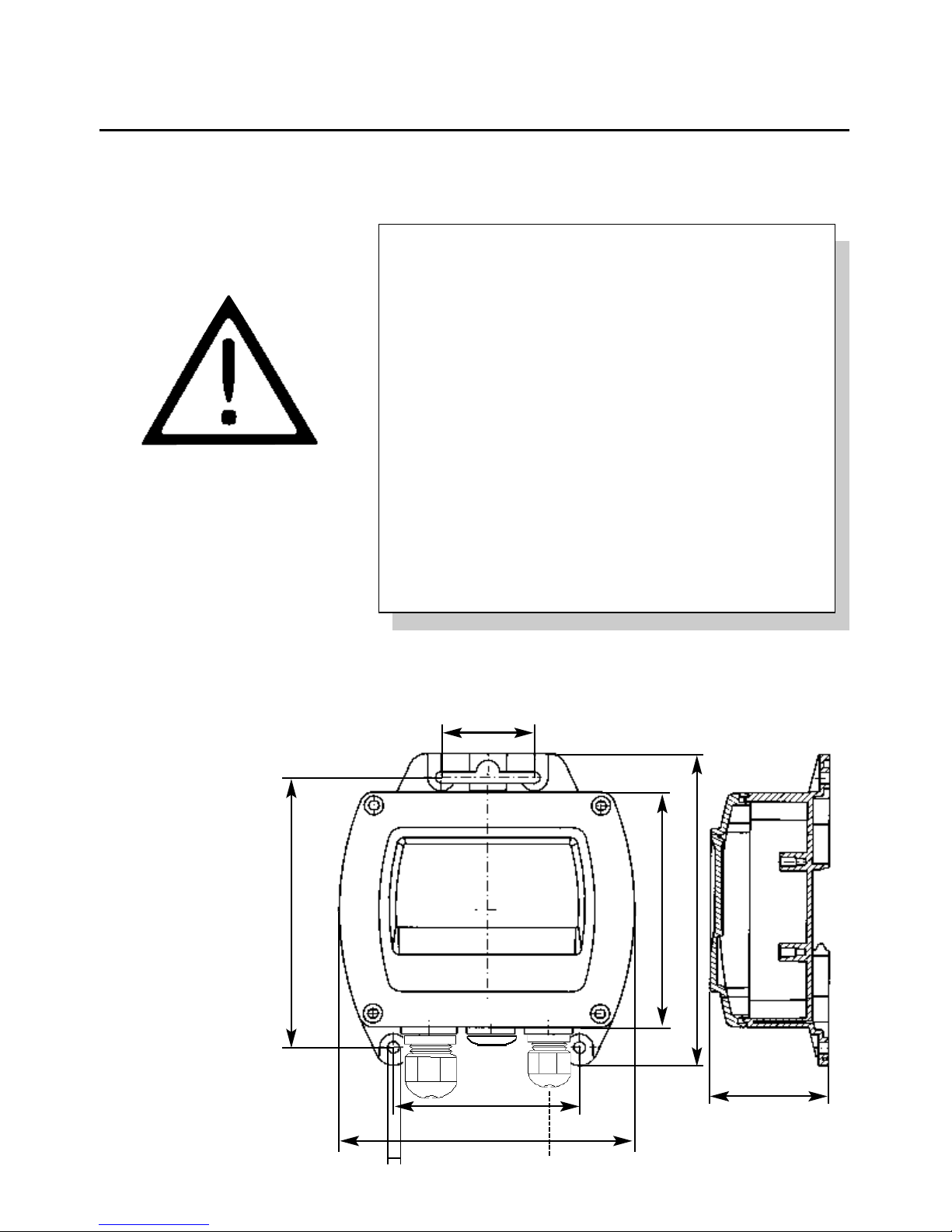

Dimensions of measuring instrument ................................................................................3

Description of functions ....................................................................................................4

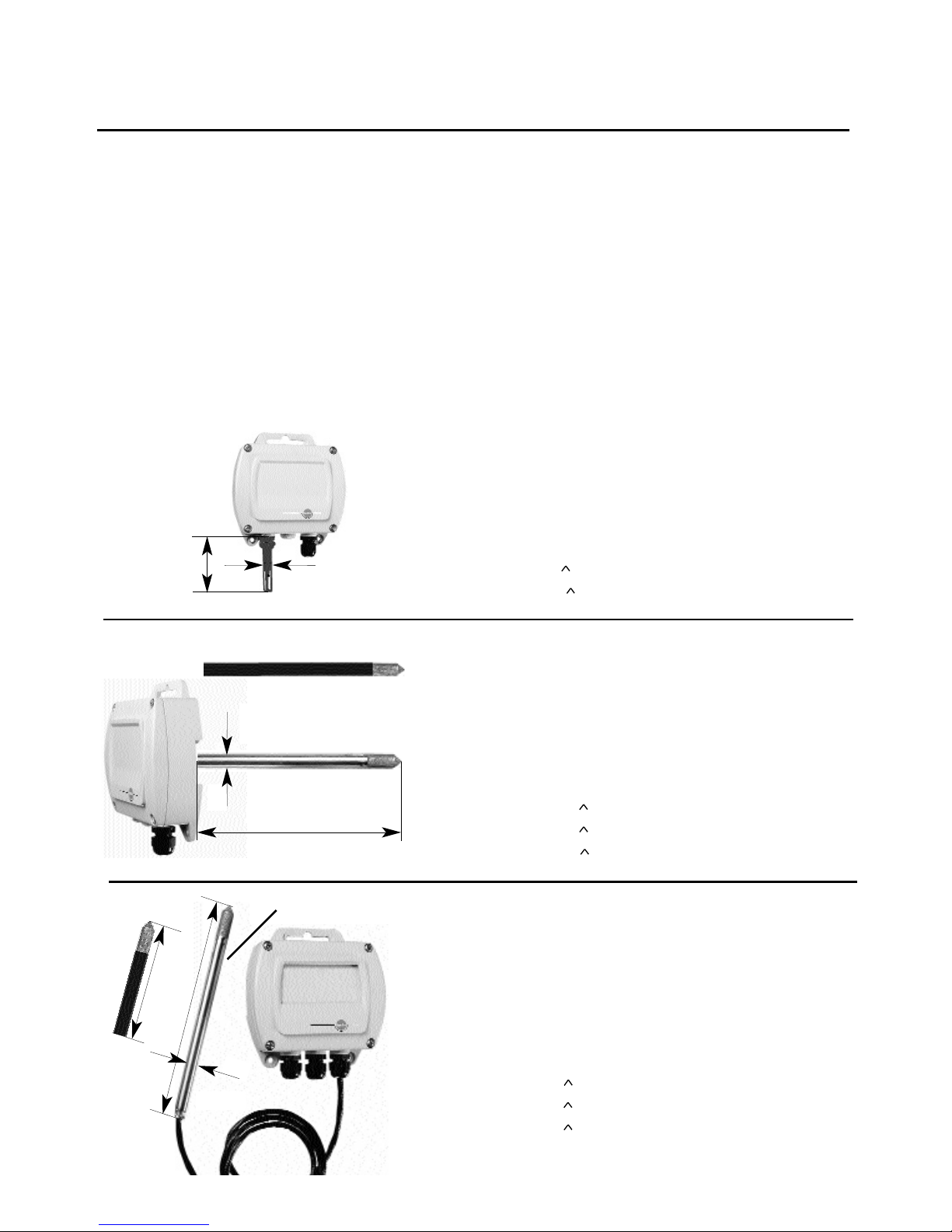

Standard versions ..............................................................................................................5

Version options ..................................................................................................................6

Connection assignment ....................................................................................................8

Description of 2 wire technology ........................................................................................8

Connection suggestions for 2 wire technology ..................................................................9

Current measurement ..................................................................................................9

Voltage measurement ................................................................................................10

Attaching ferrite sleeve ....................................................................................................11

Installing a digital display..................................................................................................11

Advice on use ..................................................................................................................12

Adjustment ......................................................................................................................13

Adjustment with testo 650/400..................................................................................13

Adjustment with control and adjustment set ..............................................................14

Maintenance ....................................................................................................................15

Cleaning the humidity sensor ....................................................................................15

Technical data..................................................................................................................16

Ordering data ..................................................................................................................17

Dear Customer

Thank you for purchasing a Testo product. We hope you will enjoy the benefits of this product for a long

time to come and that it will aid you with your work.

Please read this instruction manual carefully and familiarise yourself with the operation of the instrument

before putting it to use.

If problems should occur which you cannot rectify yourself, please consult our Customer Service

Department or your nearest distributor. We will do our best to help you quickly and competently to

avoid downtimes.