Trademaster WA-BM21 User manual

OPERATOR’S MANUAL

BM-21

BEVELLING MACHINE

2

Operator’s Manual – BM-21 Bevelling Machine

WARRANTY TERMS

In addition to any warranties or conditions implied by applicable Statute or Regulations,

Industrial Tool & Machinery Sales warrants all of it’s products against defective workmanship

and faulty materials for a period of twelve (12) months from the date of purchase, unless oth-

erwise stated. At our option we will repair or replace, free of charge, any item on the condi-

tion that:

- The complete machine or tool is returned, freight prepaid to ITM or one of it’s authorised

service agents as directed by ITM, and is found to have a material or constructional defect.

- The machine or tool has not been subject to misuse, neglect or damage by accident.

- The fault is not a result of normal “wear and tear”.

- Written permission has been received from ITM prior to commencement of repair.

- Repairs, tampering or modification carried out by unauthorised personnel will void all war-

ranty.

- Consumable items such as cutting tools, pilot pins, saw blades, grinding wheels etc. are

NOT covered by warranty.

Our goods come with guarantees which cannot be excluded under the Australian Consumer

Law. You are entitled to replacement or refund for a major failure and to compensation

for other reasonably foreseeable loss or damage. You are also entitled to have the goods

repaired or replaced if the goods fail to be of acceptable quality and the failure does not

amount to a major failure.

IMPORTED & DISTRIBUTED BY

INDUSTRIAL TOOL & MACHINERY SALES

18 BUSINESS ST

YATALA QLD 4207 AUSTRALIA

T

F

E

W

07 3287 1114

07 3287 1115

www.industrialtool.com.au

Read Operator’s Manual

before you start to work with the machine

INDUSTRIAL TOOL

CONTENTS

3

Operator’s Manual – BM-21 Bevelling Machine

1. GENERAL INFORMATION.................................................................4

1.1. Application....................................................................................4

1.2. Technical data..............................................................................4

1.3. Equipment included ....................................................................5

2. SAFETY

PRECAUTIONS....................................................................6

3. STARTUP AND OPERATION.............................................................8

3.1. Preparing to operation..................................................................8

3.2. Adjusting bevel width and angle...................................................9

3.3. Bevelling metal plates.................................................................10

3.4.Bevelling pipes............................................................................10

3.5.Bevelling larger pipes (only for optional equipment)...................13

3.6.Replacing cutting inserts.............................................................14

3.7.Replacing milling head................................................................15

4. WIRING DIAGRAM...........................................................................16

1.1. Application

The BM-21 Bevelling Machine is designed for milling edges of plates and pipes

made of carbon steel. The machine enables the bevelling of sheet steel edges and

pipe edges with diameters from 150 mm (6’’) to 300 mm (12’’) in 0–60° angular range

with maximum bevel width of 21 mm (13/16’’). When equipped with the optional

guide available on request, it can also work on pipes with diameters above 300 mm

(12’’). The machine contains dampers that enable more comfortable operation, re-

ducing unwanted vibrations.

1.2. Technical data

1. GENERAL INFORMATION

1.

GENERAL

IN

F

OR

M

ATION

4

Operator’s Manual – BM-21 Bevelling Machine

5

Operator’s Manual – BM-21 Bevelling Machine

Voltage ~ 220–240 V, 50–60 Hz

Electric motor Single-phase induction motor with run

capacitor; 1100 W

Power 1600–1800 W

Rotational speed 2780–3340 rpm

Protection level IP 20

Milling speed 550–650 m/min (1800–2200 ft/min)

Maximum bevel width b 21 mm (13/16’’, Figure 1)

Bevel angle range 0° ß 60° (Figure 1)

Weight Approx. 23 kg (51 lbs)

Milling tool is equipped with 10 removable multi-edge cutting inserts made of carbide.

Figure 1. Bevel dimensions

1.3. Equipment included

BM-21 Bevelling Machine is supplied in metal box with complete standard equipment.

The included equipment consists of:

• bevelling machine with a set of cutting inserts – 1 unit

• metal box – 1 unit

• size 8 Allen key – 1 unit

• size 6 Allen key – 1 unit

• size 4 Allen key – 1 unit

• size 12 flat key – 1 unit

• torx T15 screwdriver – 1 unit

• Operator’s Manual – 1 unit

2. SAFETY PRECAUTIONS

6

Operator’s Manual – BM-21 Bevelling Machine

Using the machine is not allowed if:

1. Operator has not read Operator’s Manual or has not completed proper occupational safety and

health training.

2. Machine is to be used in applications not stated in Operator’s Manual.

3. Machine is not complete or parts used for repair are not genuine.

4. Power supply specifications do not conform to those stated on rating plate.

5. Operator has not checked condition of machine, including power cord, control panel components

and milling tools.

6. Power supply socket is not equipped with earthing pin.

7. Bystanders are present in immediate vicinity of machine.

Detailed safety rules:

1) Before you start to work with machine, check condition of electrical installation, including power

cord and plug.

2) Connect machine only to power sockets equipped with a safety circuit (earthing) protected with

16A fuse for 230 V supply. When used on building sites, supply power to machine through

a separation transformer with a class 2 power supply.

3) Never carry machine by cord or pull it to disconnect plug from socket. It may cause power cord

to break and result in electric shock.

4) Keep machine dry. Exposing it to rain or snow is prohibited.

5) Ensure proper lighting on your worksite.

6) Never use machine in vicinity of combustible fluids or gases or in explosive environments.

7) Always use safety goggles, hearing protection, gloves and protective clothing during operation.

Do not wear loose clothing!

8) Never use blunt or damaged tools.

9) Never remove hot and sharp metal chips with bare hands.

10) Securely fasten cutting inserts in milling head using fastening screws.

WARNING! Do not hold rotating parts

of the machine or metal chips formed during milling!

7

Operator’s Manual – BM-21 Bevelling Machine

11) If cutting edge of insert is worn out, rotate insert in socket by 90° or, if all edges are worn out,

replace with new insert specified in Operator’s Manual.

12) Before every use, inspect machine to ensure it is not damaged. Check whether any part is

cracked and whether all parts are properly fitted. Make sure to maintain proper conditions that

may affect machine operation.

13) Maintain machine and tools with care. Cover steel parts with thin grease layer to protect them

against rust when not in use for a long period.

14) After every use, remove metal chips from machine, particularly from milling head, ensuring that

power cord is unplugged from power socket.

15) Use only parts recommended by manufacturer and specified in Operator’s Manual.

16) Perform all maintenance work and repairs only with power cord disconnected from power socket.

17) Replace damaged parts of machine only with genuine parts.

18) Perform all mechanical and electrical repairs only in service centre appointed by seller.

19) If machine falls on a hard surface, from a height, is wet or has other damage that could affect

technical state of machine, stop operation and immediately send machine to service centre for

inspection.

WARNING! Do not hold rotating parts.

Safety rules must be closely observed.

START UP AND OPERATION

START

U

P

AND

O

P

ERATION

8

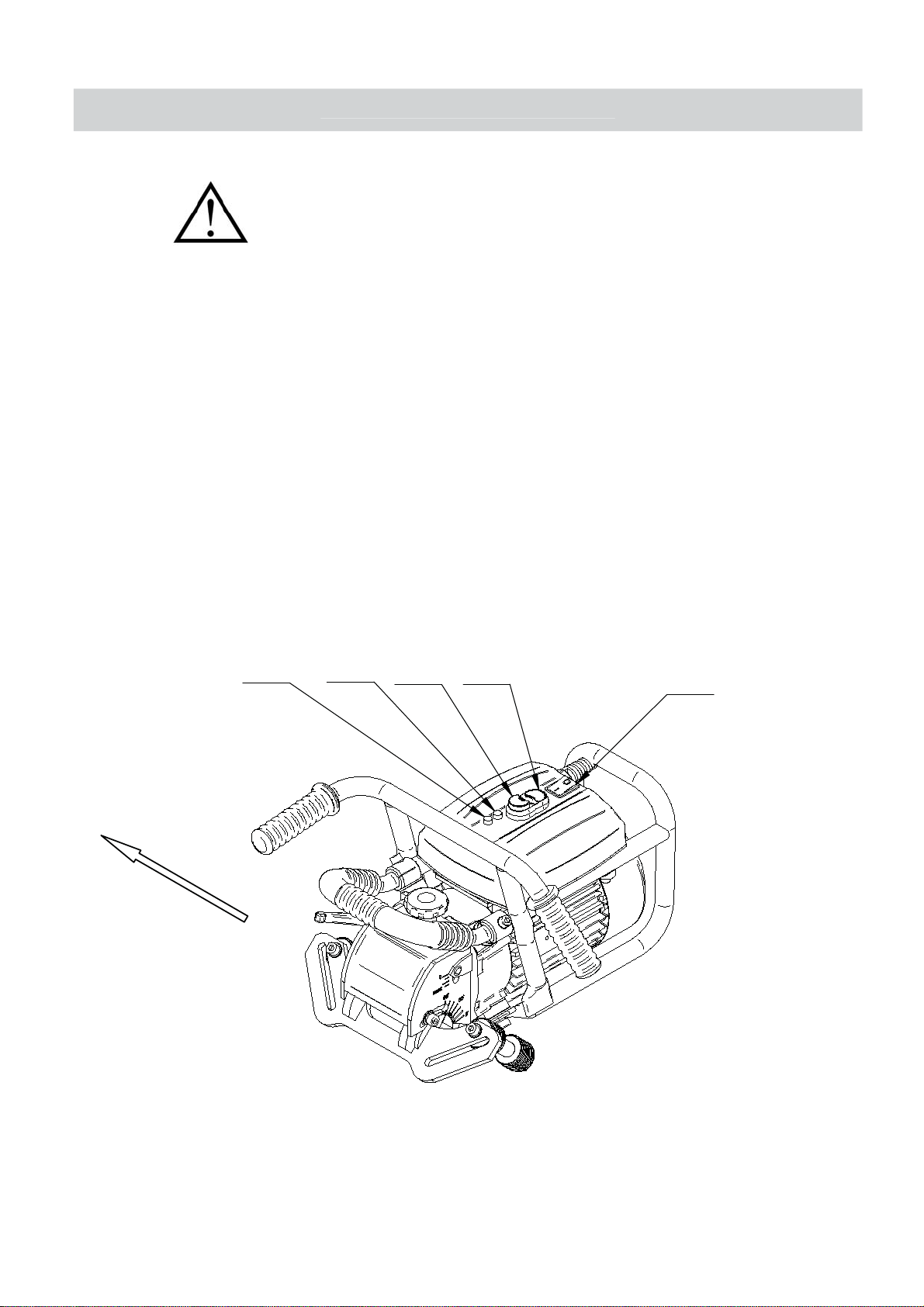

3.1. Preparing for operation

Before performing any work, set required bevel width and angle (see “Adjusting bevel width and angle”

pg 9).

After setting proper values, plug the machine into an earthed power socket. Place machine

vertically on the right edge of workpiece in a way that milling head does not touch working edge. Then,

turn on the power by pressing main switch located on the motor housing (Figure 2, Item 1) to “I” position,

what will be indicated by amber light. The green button marked “I” (Figure 2, Item 2) is used to start the

machine, pressing red button marked “0” (Figure 2, Item 3) stops the machine. To turn off the power,

press main switch back to “0” position. The yellow lamp (Figure 2, Item 4) indicates operation of the tool.

Pressing vertical guide to the working edge, slowly slide machine until the tool starts to cut steel.

Bevelling is performed according to counter-rotation. The proper feed direction is shown in Figure 2;

direction of milling head rotation is indicated on the motor disc under milling head cover.

WARNING! Read safety precautions

before you start to work with the machine.

1

2

3

4

5

Figure 2. Control panel design and proper machine feed direction

Operator’s Manual – BM-21 Bevelling Machine

9

Operator’s Manual – BM-21 Bevelling Machine

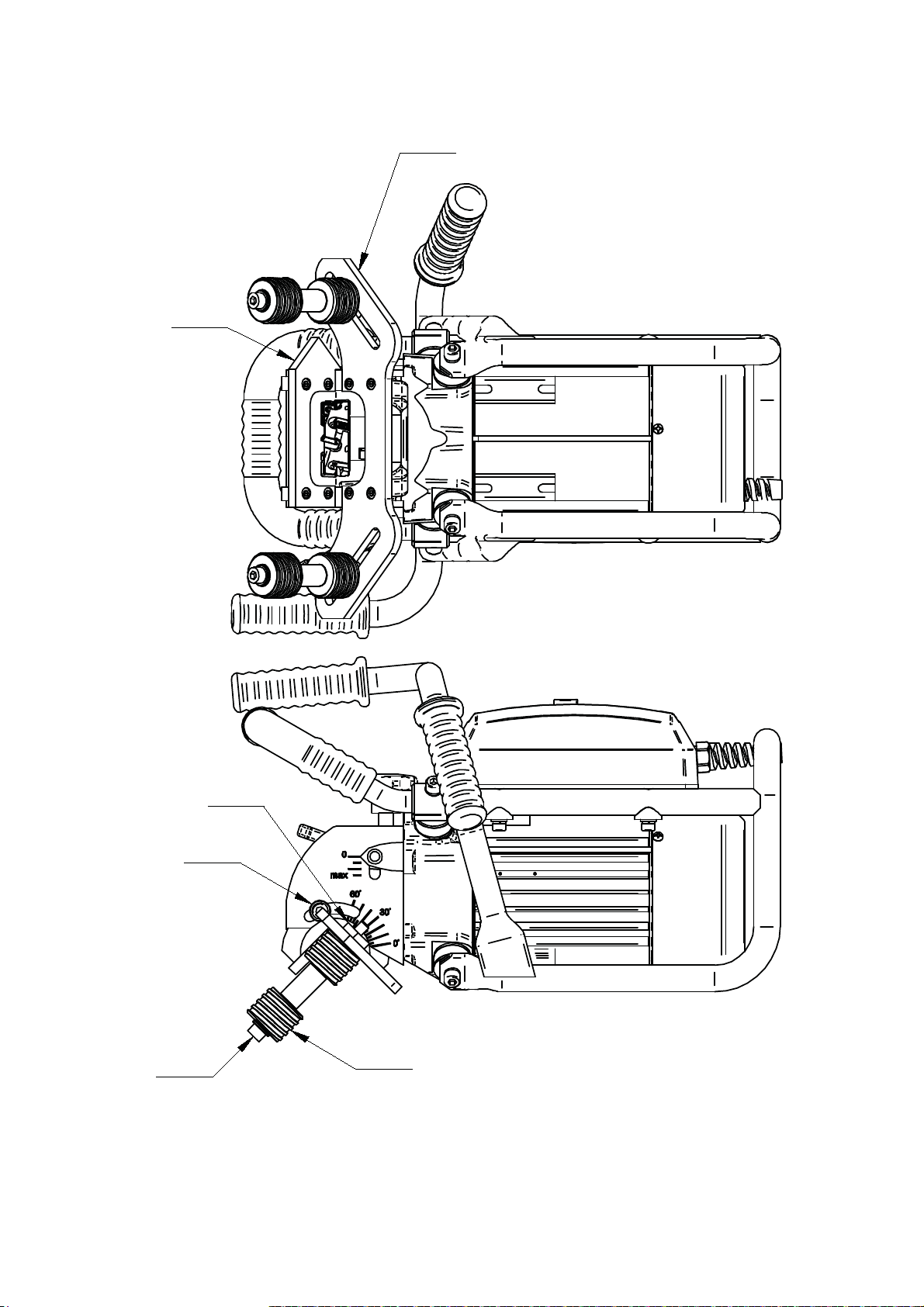

3.2. Adjusting bevel width and angle

The machine enables easy and quick adjustment of bevel parameters. Before performing adjust-

ments, ensure that the power cord is unplugged from power socket. Adjustment of the bevel angle starts

with milling head penetration set to zero (indication “0” on the milling head cover side wall).

To change bevel angle, use size 6 Allen key and loosen two M8 bolts (Figure 3, Item 1) that lock ma-

chine guide. Then, turn the guide, setting required angle on the scale located on milling head cover side

wall (Figure 3, Item 3) and secure the bolts afterwards.

To adjust bevel width, change penetration of the milling head: loosen M8 lever (Figure 3, Item 2) and

turn adjusting knob (Figure 3, Item 5) to obtain required width.

The pitch that indicates milling head penetration (Figure 3, Item 4) is only an estimate, because

bevel width varies with angle. For example, for the angle of 10° the maximum width “b” (Figure 1) is

approximately equal 18 mm (11/16’’), while the scale indicates 9 mm (6/16’’). Increasing penetration at

this angle will distort the bevel. You can obtain maximum bevel width (b 21 mm, 13/16’’) for the angle

of 45°. Experimentally determine the required bevel width for individual angles, by gradually increasing

milling head penetration into the working piece.

112

3

45

5

Figure 3. Adjusting bevel width and angle

10

Operator’s Manual – BM-21 Bevelling Machine

3.3. Bevelling metal plates

Slide the bevelling machine to the left. Note that the feed rate depends on the profile and

composition of the working material. You can bevel the majority of weldable steels in just one pass.

It is recommended to perform bevels wider than 12 mm (1/2’’) in at least two or three passes.

To obtain maximum bevel width (21 mm, 13/16’’) in two passes, first pass should be 14 mm wide

(9/16’’), whereas for three passes the first one should be 12 mm wide (1/2’’) and the second one

should be 16 mm wide (5/8’’).

If the feed is too fast, a red signal lamp illuminates, indicating motor overload (Figure 2, Item 5).

Further load increasing triggers safety circuit and shuts down the motor. In this case, move the tool away

from bevelled edge, press main switch to “0” position and after red signal lamp turns off press main

switch back to “I” position. Operation with the maximum permitted load (with flashing red signal lamp) is

technically possible, but motor temperature should not exceed 85°C (185°F). The motor can work under

high temperatures, but long overheating may permanently damage the windings. Therefore, after every

hour of working under full load, stop the motor to cool it down for 10–15 minutes. Do not cool the motor

down by leaving it in the idle state, because it will become heated even faster than when working with

load.

3.4. Bevelling pipes

The guide with rollers supplied as a part of standard equipment enables to bevel pipes with

diameters 150–300 mm (6–12’’).

To prepare the machine for work on pipes, unscrew two M8 bolts (Figure 4a, Item 2) using size 6

Allen key. Then, take out the guide set (Figure 4a, Item 1, 5), rotate it by 180º around the axis indicated

in Figure 4a, mount as shown in Figure 4b and secure again with M8 bolts. Using size 8 Allen key and

size 12 flat key, unscrew bolts (Figure 4a, Item 4) that secure the rollers. Then, move rollers (Figure 4a,

4b, Item 3) from opening (Figure 4a) to slot (Figure 4b), placing T-nut (Figure 4a, 4b, Item 6) into the

slot.

Using adjusting knob (Figure 3, Item 5), set “0” position on the pitch (Figure 3, Item 4).

Move rollers away from each other and place the machine as shown in Figure 5, with horizontal guide

(Figure 4b, Item 5) touching the pipe. Then, move rollers (Figure 4a, 4b, Item 3) symmetrically to touch

the pipe and secure with bolts (Figure 4b, Item 4) in this position. Adjust required bevel width and angle

(see “Adjusting bevel width and angle”) and start to work with bevelling machine.

11

Operator’s Manual – BM-21 Bevelling Machine

1

4

2

5

3

6

Figure 4a. Machine prepared for work on metal plates

12

Operator’s Manual – BM-21 Bevelling Machine

1

2

43

5

6

Figure 4b. Machine prepared for work on pipes

13

Operator’s Manual – BM-21 Bevelling Machine

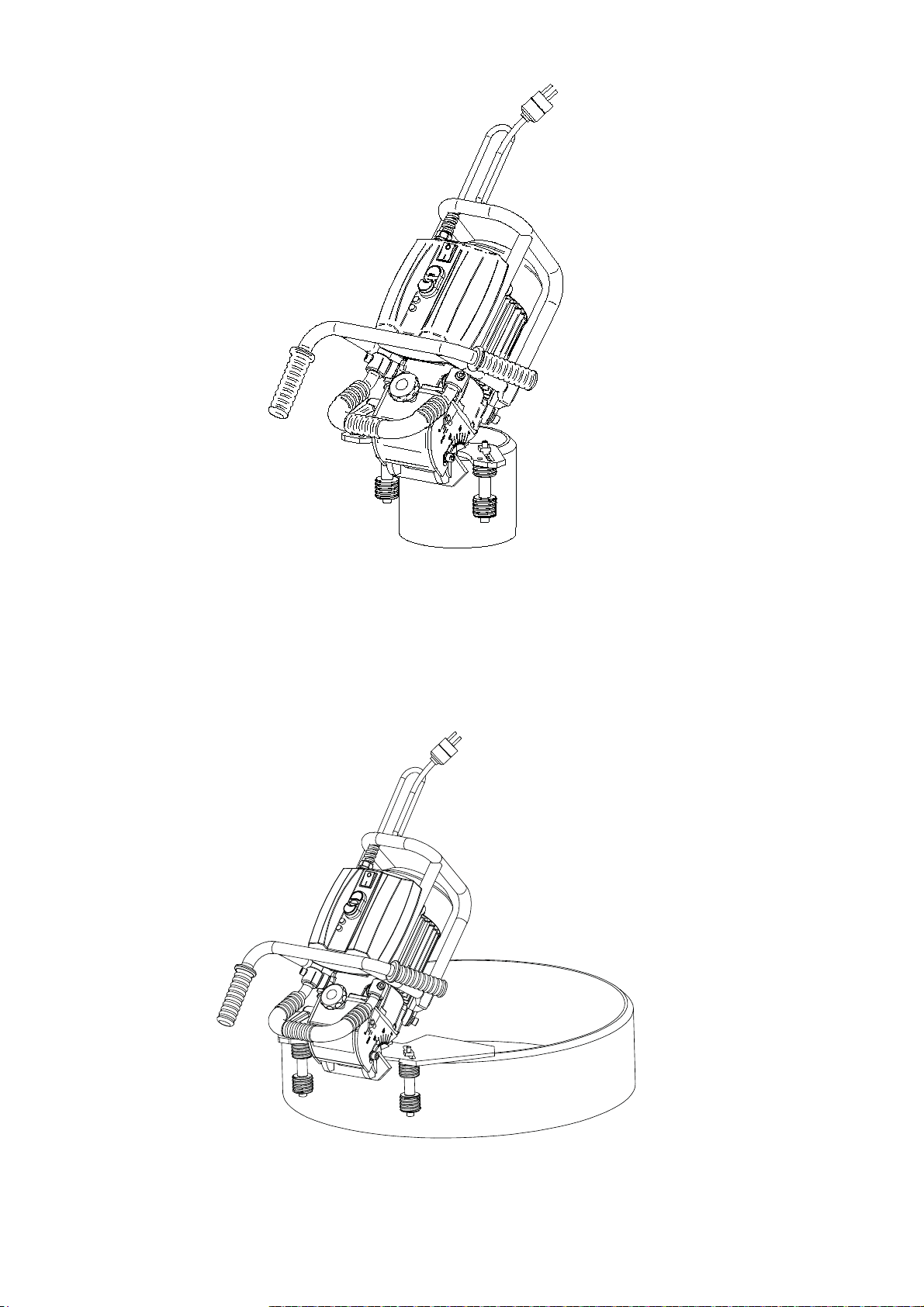

3.5. Bevelling larger pipes (only for optional equipment)

You can optionally order the guide for bevelling larger pipes with diameters 260–600 mm (

10–24’’, Figure 6). To prepare the machine for work on larger pipes, proceed as described in previ-

ous section.

Figure 5. Machine prepared for work on smaller pipes ( 150–300 mm, 6–12’’)

Figure 6. Machine prepared for work on larges pipes ( 260–600 mm, 10–24’’)

14

Operator’s Manual – BM-21 Bevelling Machine

3.6. Replacing cutting inserts

BM-21 Bevelling Machine is equipped with uniform milling head (Figure 8, Item 1), containing

two insert rings, each holding five cutting inserts, for a total of 10 inserts. The inserts can be replaced

or rotated. Perform this work only with power cord unplugged from power socket. To replace or

rotate the insert, unscrew lever (Figure 7, Item 1), remove pitch (Figure 7, Item 2) and remove milling

head cover (Figure 7, Item 3).

12

3

Figure 7. Dismantling milling head cover Using torx T15 screwdriver, unscrew bolt (Figure 8,

Item 3), remove external insert (Figure 8, Item 2) and clean the socket. Then, place rotated

insert again or replace with new one if all four edges are worn out. To replace insert from

internal ring, remove external insert first.

AA

1:2

1

1

2 3

Figure 8. Milling Tool

15

Operator’s Manual – BM-21 Bevelling Machine

When performing small width bevels, cutting inserts wear only on one, internal corner.

Rotate inserts between rings (Figure 9), to extend the life of inserts.

Worn out corners Worn out corners

Figure 9. Changing cutting inserts between rings

3.7. Replacing milling head

To replace milling head, unscrew lever (Figure 7, Item 1), remove pitch (Figure 7, Item 2) and

remove milling head cover (Figure 7, Item 3). Place size 32 flat key on driving ring (Figure 10, Item 1)

to lock spindle rotation. Then, use size 8 Allen key to unscrew bolt (Figure 10, Item 2) and remove

milling head. Size 32 flat key is not included in standard equipment.

AA

1

2

Figure 10. Replacing milling head

4. WIRING DIAGRAM

16

Operator’s Manual – BM-21 Bevelling Machine

Parts list BM-21 v.1.05

This document is protected by copyrights.

Copying, using, or distributing without permission of ITMS is prohibited. 1

46

59

36

58

51

47

32

35

49

53

13

38

40

38 52

43

43

1

46

28

38

16

29

57

45

15

44

49

56

14

3

38

17

19

23

18

21

22

60

48

5

4

30

31

37

41

39

20

34

54

12

50

11

8

50

12

24

7

9

38 33

10

34

55

6

Parts list BM-21 v.1.05

This document is protected by copyrights.

Copying, using, or distributing without permission of ITMS is prohibited. 2

ITEM

PART NUMBER

DESCRIPTION

QTY

1

WAP-B21/3101

POWER CORD - 230V (AU)

1

3

WAP-B21/3103

MOTOR ASSY - 230V

1

4

WAP-B21/3104

DRIVING RING

1

5

WAP-B21/3105

KNOB

1

6

WAP-B21/3106

MILLING HEAD COVER

1

7

WAP-B21/3107

VERTICAL GUIDE

1

8

WAP-B21/3108

HORIZONTAL GUIDE

1

9

WAP-B21/3109

GUIDE HOLDER I

1

10

WAP-B21/3110

GUIDE HOLDER II

1

11

WAP-B21/3111

PIVOT

2

12

WAP-B21/3112

ROLLER

4

13

WAP-B21/3113

FRAME

1

14

WAP-B21/3114

FRONT HANDLE

1

15

WAP-B21/3115

ELECTRONIC MODULE COMPLETE - 230V

1

16

WAP-B21/3116

BOTTOM PLATE

1

17

WAP-B21/3117

CONTROLLER HOUSING COVER

1

18

WAP-B21/3118

RED LAMP

1

19

WAP-B21/3119

YELLOW LAMP

1

20

WAP-B21/3120

PENETRATION INDICATOR COMPLETE

1

21

WAP-B21/3121

LINK

1

22

WAP-B21/3122

RUBBER SEAL

1

23

WAP-B21/3123

DAMPER

4

24

WAP-B21/3124

MILLING HEAD WITH BOLTS

1

28

WAP-B21/3128

HEX. NUT M4

2

29

WAP-B21/3129

NUT SHORT M4

2

30

WAP-B21/3130

T-NUT

2

31

WAP-B21/3131

ROUND HEAD RIVET 2x6

2

32

WAP-B21/3132

ROUND WASHER 6,4

4

33

WAP-B21/3133

ROUND WASHER 8,4

3

34

WAP-B21/3134

ROUND WASHER 10,5

4

35

WAP-B21/3135

SADDLE WASHER

4

36

WAP-B21/3136

EXTERNAL TOOTH SPRING WASHER 4,3

6

37

WAP-B21/3137

SPRING WASHER 10,2

2

38

WAP-B21/3138

SPRING WASHER 8,2

8

39

WAP-B21/3139

CUTTING INSERT

10

40

WAP-B21/3140

HANDLEVER

1

41

WAP-B21/3141

MOUNTING BOLT

10

43

WAP-B21/3143

SCREW M4x10 PHCRMS

4

44

WAP-B21/3144

CAPACITOR 30uF - 240V

1

45

WAP-B21/3145

STRAIN RELIEF NUT

1

46

WAP-B21/3146

SPRING WASHER 4,1

6

47

WAP-B21/3147

SPRING WASHER 6,1

4

48

WAP-B21/3148

POWER SWITCH

1

49

WAP-B21/3149

MOTOR ON/OFF SWITCH

1

50

WAP-B21/3150

HEX. SOCKET BOLT M5x10

8

Parts list BM-21 v.1.05

This document is protected by copyrights.

Copying, using, or distributing without permission of ITMS is prohibited. 3

ITEM

PART NUMBER

DESCRIPTION

QTY

51

WAP-B21/3151

HEX. SOCKET BOLT M6x40

4

52

WAP-B21/3152

HEX. SOCKET BOLT M8x14

2

53

WAP-B21/3153

HEX. SOCKET BOLT M8x35

2

54

WAP-B21/3154

HEX. SOCKET BOLT M10x25

1

55

WAP-B21/3155

HEX. SOCKET BOLT M10x120

2

56

WAP-B21/3156

HEX. SOCKET BOLT M8x20

2

57

WAP-B21/3157

STOP BUTTON WIRE SET

1

58

WAP-B21/3158

CONTROLLER PLATE GROUNDING WIRE

1

59

WAP-B21/3159

MOTOR GROUNDING WIRE

1

60

WAP-B21/3160

CROSS RECESSED SCREW M4x20

2

Parts list BM-21 v.1.05

This document is protected by copyrights.

Copying, using, or distributing without permission of ITMS is prohibited. 4

WAP-B21/3290

MOTOR ASSY 230V

ITEM

DESCRIPTION

PART NUMBER

QTY

1

WAP-B21/3201

BEARING DISK N

1

2

WAP-B21/3202

BEARING DISK P

1

3

WAP-B21/3203

STATOR BODY 230V

1

4

WAP-B21/3204

ROTOR

1

5

WAP-B21/3205

CLEARANCE REMOVAL SPRING WASHER

1

6

WAP-B21/3206

FAN COVER

1

7

WAP-B21/3207

FAN

1

8

WAP-B21/3208

4-TERMINAL PLATE

1

9

WAP-B21/3209

SEAL no.4

1

10

WAP-B21/3210

SELF-TAPPING SCREW M4x8

3

11

WAP-B21/3211

PIN A6x6x32

1

12

WAP-B21/3212

BALL BEARING 6204 2Z C3

1

13

WAP-B21/3213

BALL BEARING 6206 2Z CM

1

14

WAP-B21/3214

DRAWBOLT E/M5x168

3

15

WAP-B21/3215

SELF-TAPPING SCREW M4x12

1

This manual suits for next models

1

Table of contents

Other Trademaster Power Tools manuals

Popular Power Tools manuals by other brands

Bosch

Bosch GHG 660 LCD Professional Original instructions

EINHELL

EINHELL TE-JS 18 Li Original operating instructions

Parkside

Parkside 290752 Translation of the original instructions

WELDY

WELDY Energy HT1600 operating manual

Hilti

Hilti HIT-HY 100 Technical supplement

Max

Max Rebartier RB398S Instruction manual and safety instructions